Documente Academic

Documente Profesional

Documente Cultură

M PL 033

Încărcat de

Ali ClubistDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

M PL 033

Încărcat de

Ali ClubistDrepturi de autor:

Formate disponibile

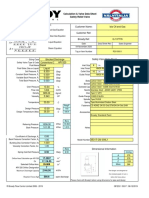

IGS-M-PL-033(0)

Dec. 2014

Approved

IGS

Technical Purchasing Specification

Hot Tapping Split Tee

Fax:(9821)-8131-5679

**+, -./0+1 23*40562780 9:284* ;5<+=7>1 -?@6 A:+BC -D EFG 23*40562780H0 ;*2I780 J0+D

http://igs.nigc.ir

igs@nigc.ir

`N.I.G.C.

IGS-M-PL-

FOREWORD

This standard is intended to be mainly used by NIGC and

contractors, and has been prepared based on interpretation of recognized

standards, technical documents, knowledge, backgrounds and experience

in natural gas industry at national and international levels.

Iranian Gas Standards (IGS) are prepared, reviewed and amended by

technical standard committees within NIGC Standardization division and

submitted to the NIGC's "STANDARDS COUNCIL" for approval.

IGS Standards are subject to revision, amendment or withdrawal, if

required. Thus the latest edition of IGS shall be checked/inquired by NIGC

employees and contractors.

This standard must not be modified or altered by NIGC employees or its

contractors. Any deviation from normative references and/or well-known

manufacturers specifications must be reported to Standardization division.

The technical standard committee welcomes comments and feedbacks

about this standard, and may revise this document accordingly based on

the received feedbacks.

GENERAL DEFINITIONS:

Throughout this standard the following definitions, where applicable,

should be followed:

1- "STANDARDIZATION DIV." is organized to deal with all aspects of

industry standards in NIGC. Therefore, all enquiries for clarification or

amendments are requested to be directed to mentioned division.

2- "COMPANY": refers to National Iranian Gas Company (NIGC).

3- "SUPPLIER": refers to a firm who will supply the service, equipment or

material to IGS specification whether as the prime producer or

manufacturer or a trading firm.

4- "SHALL ": is used where a provision is mandatory.

5- "SHOULD": is used where a provision is advised only.

6- "MAY": is used where a provision is completely discretionary.

------------------------------------Website: http://igs.nigc.ir

E-mail: igs@nigc.ir

`N.I.G.C.

IGS-M-PL-

CONTENT

1. SCOPE

2. REFERENCES

3. TERMS AND DEFINITIONS

4. DESIGN

5. MATERIAL

6. FABRICATION

7 TOLERANCES

10

8. INSPECTION AND TESTING

11

9. SURFACE PREPARATION AND COATING

12

10. MARKING

13

11.DOCUMENTATION

13

12. PACKAGING

13

13. DATA SHEET

14

`N.I.G.C.

IGS-M-PL-

1. SCOPE

This standard specification defines NIGCs mandatory requirements for design, material

selection, fabrication, testing and marking of flanged split tees for hot tapping branch

connection and stopple fittings furnished with Lock-O-Ring Flanges, for sizes of 4 inches

through 56 inches, concerning pressure class rating of 150, 300 and 600 to be used In sweet

natural gas services.

2. REFERENCES

The selection of material and equipment, and the design, construction, maintenance, and repair

of equipment and facilities covered by this standard shall comply with the latest edition of the

references listed below, unless otherwise noted.

2.1 Normative References

Iranian Gas Standards (IGS)

IGS-M-PL-022-1:2000 Butt Welding Ends Carbon Steel Fitting

American Petroleum Institute

API SPEC 5L: 2013 Specification for Line Pipe

API 1104:2005 Welding of Pipelines and Related Facilities

American Society of Mechanical Engineers

ASME B16.5: 2013Steel Pipe Flanges and Flanged Fittings

ASME B16.47 :2006Large Diameter Flanges

ASME B31.4 :2009Liquid Petroleum Transportation Piping Systems

ASME B31.8:2010 Gas Transmission and Distribution Piping Systems

ASME B36.10:2004 " Welded and Seamless Wrought Steel Pipe"

ASME Sec II :2010Materials

ASME Sec V : 2013Nondestructive Examination

ASME Sec VIII 2013Rules for Construction of Pressure Vessels

ASME Sec IX :2013Welding and Brazing Qualification

`N.I.G.C.

IGS-M-PL-

American Society for Testing and Materials

ASTM A 105:2012 Specification for Forgings Carbon Steel for Piping Components

ASTM A 106:1999 Standard Specification for Seamless Carbon Steel Pipe for HighTemperature Service

ASTM A 193: 2012 Standard Specification for Alloy-Steel and Stainless Steel Bolting for High

Temperature or High Pressure Service or both

ASTM A 194 : 2012Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High

Pressure or High Temperature or both

ASTM A 216: 2012 Specification for Steel Castings

ASTM A 234 :2011Standard Specification for Piping Fittings of Wrought Carbon Steel and

Alloy Steel for Moderate and High Temperature Service

ASTM A 350:2012 Standard Specification for Carbon and Low Alloy Steel Forging

ASTM A 370:2007 Standard Test Methods and Definitions for Mechanical Testing of Steel

Products

ASTM A 516:1990 Specification for Pressure Vessel Plates, Carbon Steel

ASTM A 537 :2006Specification for Pressure Vessel Plates, Heat-Treated CarbonManganese-Silicon Steel

ASTM A 578 :2007Standard Specification for Straight-Beam Ultrasonic Examination of Plain

and Clad Steel Plates for Special Applications

ASTM A 694:2003 Specification for Forgings, Carbon Steel and Alloy Steel

ASTM A 860:2000 Standard Specification for Wrought High-Strength Low-Alloy Steel ButtWelding Fittings

ASTM E 92:2000 Standard Test Method for Vickers Hardness

ASTM E 165 :2002Standard Test Method for Liquid Penetrant Examination

Manufacturers Standardization Society

MSS SP-44:1996 Steel Pipeline Flanges

MSS SP-75:2008 Specification for High Test Wrought Butt-Welding Fittings

American Welding Society

AWS A5.1:1991 Specifications for Carbon Steel Electrodes for Shielded Metal Arc Welding"

`N.I.G.C.

IGS-M-PL-

AWS A5.5:2006 Specifications for Low-Alloy Steel Electrodes for Shielded Metal Arc

Welding"

3. TERMS AND DEFINITIONS

DFT (Dry Film Thickness)

The thickness of a coating remaining on the surface when the coating has hardened

NPS

Nominal Pipe Size (in)

PSL

Product Specification Level

SAWL

Tubular product having one longitudinal / straight seam produced by double submerged-arc

welding

SMLS

Pipe without any weld seam, produced by a hot-forming process, which can be followed by cold

sizing or cold finishing to produce the

NIGC

National Iranian Gas Company

4. DESIGN

4.1 General

Split tee in general shall appropriately comply with requirements of ASTM A234 or MSS-SP 75

(regarding it' s size) for any specification not specified in this IGS.

4.1.1 Mechanical calculation of split tee shall be done according to ASME B31.8 (Gas Services)

Appendix F or ASME B31.4 (Liquid services) Chapter II with design factor 0.5.

4.1.2 The top half and bottom half of the split tee shall have a longitudinal bevel as figure2.

4.1.3 Backing strips for the field longitudinal welds shall be supplied. They shall be weld able

carbon steel strips 1.5 mm thick and approximately 25 mm wide. The length shall be the same

as the length of the run of the split tee. A matching recess shall be machined into each half of

the split tee. The backing strips shall be tack or skip welded to the top half of the split tee.

4.1.4 Flanges used for branch connection or stopple fittings shall be standard welding neck

meeting the requirements of the bolting and seating area ( raised faced ,serrated finished) of

ASME B16.5 for up to 24"or ASME B16.47 (Series A) / MSS SP44 for greater sizes or standard

drawings specified in the purchase order.

4.1.5 Lifting lugs shall be provided on both sides of the bottom half of all fittings size 10 in and

larger. The top and bottom half of each fitting shall be identified with an individual number.

4.1.6 Split tee shall be welded to pipeline according to ASME B31.8 Figure I-3.1 (figure 3)

`N.I.G.C.

IGS-M-PL-

Figure1-- Fit-up of Full Circumferential Fitting

4.1.7 The top half and bottom half of the split tee shall have a bevel as below figure

figure:

Figure 2- Longitudinal

tudinal seam ((Dimensions are in mm)

`N.I.G.C.

IGS-M-PL-

Figure 3- Circular fillet weld (A-A)

4.1.8 Guide bar and Lock-o-Ring flange should be devised for pipeline requiring pigging when

branch size is larger or equal to one half of run pipe diameter.

4.1.8 Extruded Split Tees

Branch size 32inch and smaller shall be hot drawn, extruded type. The wall thickness of

extruded type split tees shall be determined in accordance with the requirements of ASME

B31.4 Paragraph 404.3.1(b)or ASME B31.8, Paragraph 831.4.

4.3 Welded type Split Tees

Split tee with branch size 36 inches and larger fabricated by welding (instead of extruded) is

acceptable. This type of split tee shall fully comply with requirements of ASME B31.4 Paragraph

404.3.1(b) or ASME B31.8 Paragraph 831.4,It shall have all required reinforcements integrated

in branch and run pipe (only two pieces).

5. MATERIAL

5.1 General

5.1.1 The material shall be one of the below list as specified in the purchase order. Split tee

materials of lower yield strength may be used with the same material group (clause 5.4.2.2 of

API 1104) but nominal wall thickness shall not exceed 1.5 times the run pipe thickness or 38

mm whichever is less.

5.2 Grade B or X 42 Pipelines

5.2.1 Materials shall conform to the requirements of ASTM A234/ASTM A234M Grade WPB.

`N.I.G.C.

IGS-M-PL-

5.2.2 Supplementary requirements S3 shall be included but the carbon equivalent (CE) shall

not exceed 0.42% when calculated according to the formula:

5.2.3, Hardness of finished fitting shall not exceed 180 HB .

5.3 Grade X42 through X80 Pipelines

5.3.1 With the exception of the chemical composition requirements in Paragraph 5.3.2 and

impact testing requirements in Paragraph.5.3.3 below, the material shall conform to the

requirements of MSS SP-75, with supplementary requirements SR-4( for hardness only) and

SR-5.(Actual Yield Strength Limitation).

5.3.2 Chemical composition, including carbon equivalent, shall be in accordance with the

following table:

Table 1- Chemical Composition Requirement of Grade X42 through X70 Fittings

Chemical Requirements

Composition Weight %

Product Analysis

Manganese

0.20

1.00-1.45

Phosphorus

Sulfur

Silicon

Nickel

Chromium

0.030

0.010

0.15-0.40 c

050 d

0.30 d

Carbon

0.25 d

0.35 d

0.05

0.10

0.04

0.12

0.06

Molybdenum

Copper

Titanium

Vanadium

Columbium

Vanadium plus Columbium

Aluminum

NOTES:

a) All values are maximum unless a range is stated.

b) The carbon equivalent, as calculated by the formula .5.2.2, shall not exceed

0.42 %.

c) If vacuum carbon de-oxidation is used, silicon shall not exceed 0.10 % by

heat analysis and 0.12 % by product analysis.

d) The sum of Ni + Cr + Mo + Cu shall not exceed 1.0%.

`N.I.G.C.

IGS-M-PL-

5.3.3 Charpy V- Notch Impact Test

a) Impact testing is required for all sizes and grades.

b) The impact tests method shall be conducted -10 C in accordance with ASTM A 370.

c) Welding procedure qualifications shall include impacts tests of the base metal, weld metal,

and heat-affected zone (HAZ).

d) The average of three specimens shall not be less than 50J. Single value shall not be less

than 45J.

5.4 The vendor shall provide a certified material test report listing the actual results of the

chemical analysis, mechanical properties, notch toughness properties, heat treatment, nondestructive examination, and any special tests required by the Purchased Order.

5.5 Materials used for fittings shall be as follow:

a) Plates: ASTM A 516N (all grades)

b) Pipe: ASTM A 106 or API SPEC 5L, PSL2 (seamless only).

c) Forge: ASTM A 105N or ASTM A 694 (F42 through F 70)

5.6 All other non-pressure containing components shall be as per vendor's standard material.

5.7 All O-rings supplied for use on LOR plugs shall be the molded type. O-rings with joints

(including those made by joining O-ring cord) are not acceptable. The materials shall be

specified by manufacturer and approved by NIGC.

6. FABRICATION

6.1 Welding

6.1.1 All Welding Procedure Specifications and Procedure Qualification Records shall be

written in English and conform to ASME Sec IX.

6.1.2 All welders shall be qualified in accordance with ASME Sec IX, including tack

welders.

6.1.3 Processes

The following processes are approved for use:

6.1.3.1 Shielded Metal Arc Welding (SMAW)

6.1.3.2 Gas Tungsten Arc Welding (GTAW)

6.1.3.3 Submerged Arc Welding (SAW)

6.1.3.4 Gas Metal Arc Welding (GMAW) - Short circuiting transfer shall not be used.

6.1.3.5 Flux Cored Arc Welding (FCAW) - Shall not be used for the root pass on single sided

welds

`N.I.G.C.

IGS-M-PL-

6.1.4 Welding without the addition of filler material is not permitted.

6.1.5 Welding Consumables.

Electrodes, filler wires, and fluxes shall conform to the requirements of the ASME Sec II, part C

(identical to the AWS A5.XX specification series). Other consumables may be used only with

the specific approval by NIGC.

Active submerged arc welding fluxes shall not be used.

6.1.6 Hardness testing conducted in accordance with ASTM E92. Hardness of base metal, weld

metal and HAZ shall not exceed 250 HV10 (or 22 HRC).

6.2 Extruded split tees and full encirclement saddles shall have the outlet hot extruded.

6.3 Split tees with branch welded

Split tees with branch welded to run shall have full penetration welds as indicated in ASME

B31.8, Appendix I Figure I-1 and I-2.

6.4 Heat Treatment

6.4.1 All fittings shall be heat treated after all forming and welding processes are completed.

Flanges may be welded to the heat treated tee without reheat treating provided that the heat

treatment of the flange to tee weld is not required by the governing code.

6.4.2 All fittings supplied in accordance with this specification shall be heat treated as follows:

Table 2 Heat Treatment of Extruded Tee and Branch Welds

Heat Treatment

Extruded Tee

or

Branch Weld

Extruded Tee

Normalize, Normalize and temper, or quench and temper

Welded Tee

Post-weld Heat Treatment (PWHT)

Flange to Tee

PWHT if required by governing code or service requirement

6.4.3 Stress relieved, or normalized, or normalized and tempered, or quenched and tempered

shall be as defined in ASTM A 234, MSS SP-75 or ASME SEC. VIII Div.1. (Heat treatment

report and Graph shall be issued by vendor/manufacturer)

6.4.4 Hot formed high strength fittings shall be cooled below the lower critical temperature prior

to heat treatment.

7. DIMENSIONS

Dimensions of the fitting shall be specified by manufacturer/suppler and drawings shall be

approved by end user.

`N.I.G.C.

IGS-M-PL-

7.1 For branch connection, the minimum inside diameter of flange shall be in accordance with

the minimum full-operating bore as per table 1 of API 6D.

8. TOLERANCES

8.1 Fittings shall have tolerances such that they provide the following gap between inside radius

of fitting (sleeve) and nominal outside radius of run pipe:

NPS 24 and smaller: maximum 3.2 mm

NPS 30 and Larger: maximum 6.4 mm

8.2 The fittings dimensions shall provide a root gap on the longitudinal joint of 3.2 to 8.0 mm

when fit onto the specified nominal size pipe.

8.3 inside diameter of branch bore shall have tolerances - 0, +1.6 mm of specified nominal ID.

8.4 Wall thickness shall have tolerances 12.5% of specified thickness (if considered tolerances

in thickness design) or - 0, +12.5% of specified thickness (if do not considered in thickness

design).

8.5 Length of fitting shall have tolerances 10 mm of specified length.

8.6 Center run to top outlet: 6.0 mm of specified distance.

8.7Intersection of centerline of branch with centerline of run: 1.6 mm max. Offset.

8.8 The flange face shall be perpendicular to branch bore with angular tolerance of 0.50.

9. INSPECTIONS AND TESTING

9.1 General

The manufacturer shall perform all inspection and tests as per requirement of this standard

specification and the relevant codes prior to shipment.

9.2 Visual Examination and Dimensional Check

General appearance shall show good workmanship and fit-up. Weld surfaces shall show a

smooth contour. Welds shall be visually inspected in accordance with ASME Sec. V article 9.

Dimensions of the fitting shall be checked against approved vendor's drawings and specified

dimensions and tolerances in paragraphs 7 & 8 of this standard.

Repairs by welding on parent metal are not permitted. Repairs of weld shall be carried out only

after specific approval by purchaser's representative for each repair. The repair welding shall be

carried out by the welders and welding procedures only qualified as per ASME Section-IX and

records for each repair shall be maintained

9.3 Non-Destructive Examination

9.3.1 The plate to be used for the fabrication of high yield strength fittings which have a

specified minimum yield strength of 359 MPa (52 000 psi) and higher shall be ultrasonically

tested for laminations in accordance with ASTM A 578. The edges of the fitting shall be free of

laminations for a width of 50 mm.

`N.I.G.C.

IGS-M-PL-

9.3.2 The fitting shall be 100% UT examined for laminations at extruded area (extruded type)

and branch to run weld (welded type). Acceptance criteria shall be as per ASME Sec. VIII Div. I

Appendix 12.

9.3.3 All butt welds in fabricated fittings, regardless of strength level, shall be 100% radio

graphed in accordance with ASME Sec VIII Div. 1, UW-51.

9.3.4 All other full penetration groove welds cannot be inspected by radiographic methods shall

be checked by ultrasonic or magnetic particle methods. Acceptance criteria shall be as per

ASME Section VIII Appendix-12 and Appendix-6 respectively.

9.3.5 The bevels prepared for field welding shall be 100% ultrasonically or magnetic particle

method tested for lamination in accordance with ASTM A 578 for a distance of 50mm from the

end.

9.4.6 All forgings shall be wet magnetic particle examined on 100% of the forged surfaces.

Method and acceptance shall comply with MSS-SP-53.

9.4 Hydrostatic Tests

9.4.1 All fittings shall be hydrostatic tested after fabrication and heat treatment by 1.5 times of

its design pressure with design factor of 0.5 for one hour.

9.4.2 The Lock-O-Ring plug shall be hydrostatic tested to 1.5 times the design pressure from

the underside (header side) of the plug. No leakage of the O-ring seals is allowed.

9.5 Production Hardness Tests

The hardness tests shall be conducted on all fittings and:

9.5.1 Hardness testing shall be conducted in accordance with ASTM E 92.

9.5.2 A minimum of three hardness indentations shall be made on the parent metal of each

fitting, with the test locations spaced evenly across the piece being tested. For extruded fittings

one of the hardness shall be in the outlet section. For fabricated fittings, an additional three

hardness indentations shall be made, evenly spaced, along the weld. Where accessible, the

weld metal hardness should be measured on the I.D. surface of the fittings. in all case, the

hardness shall not exceed 250 HV10 .If any single indentation exceeds the allowable hardness

limit, two additional hardness indentations shall be taken within 25 mm of the first reading, and

the three hardness values shall be averaged. If the average exceeds the allowable limit, The

fitting shall be rejected, and all the other fittings from the same heat shall be 100% hardness

tested.

9.5.4 At the manufacturer's option, all fittings that have failed the hardness test requirements in

paragraphs 9.5.2 may be re-heat treated and hardness tested again. The second heat

treatment shall be equivalent to the original heat treatment unless additional production test

coupons are made to verify all the required mechanical properties are met. Any second heat

treatment must still comply with the original welding procedure essential and supplementary

essential variables. Fittings that pass the hardness test requirements and the strength

requirements after re-heat treatment may be accepted. Fittings that fail a second time shall be

permanently rejected.

`N.I.G.C.

IGS-M-PL-

9.6 Production Tensile Test

A tensile test shall be performed on one specimen per lot (10 pcs) of extruded fitting production

and shall meet the requirements of the basic specification.

9.7. Impact Test

Charpy impact test should be conducted as per 5.3.3 of this standard specification.

9.8 Test Certificates

9.8.1. Manufacturer shall submit following certificates to purchaserDs representative:

9.8.1.1. Test certificates relevant to the chemical analysis and mechanical properties of the

materials used for the construction as per this standard specification and relevant standards.

9.8.1.2 Test reports on radiographic and ultrasonic inspection and magnetic particle

examination.

9.8.1.3 Hydrostatic tests certificate

9.7.1.4 Test reports on heat treatment carried out.

10. SURFACE PREPARATION AND COATING

The fittings shall be sandblasted internally and externally according to standard SA 2 and

coated with two layer red lead epoxy or equivalent with min DFT25micron internally and

externally.

11. MARKING

11.1 The fittings shall be marked with a 50 mm wide painted band around top and bottom half

at one end in order to facilitate matching during field installation.

11.2 Top and bottom halves shall be marked with following data:

Manufacturers Name

Design Pressure in psig

Nominal Diameter in inch, D X d

Run and Branch Thickness in inch or mm, T X t

Run/Branch and Flange Material Designation

11.3 The top and bottom halves shall also be die-stamped, using low stress stamps, with the

serial no. and manufacturer name. The stamping shall be adjacent to the stencil-marks.

`N.I.G.C.

IGS-M-PL-

12. DOCUMENTATION

12.1 Below document shall be submitted for purchaser/NIGC approval before fabrication:

MPS (Manufacturing Process Specification)

Inspection and Test Plan

Mechanical Calculation

Fabrication Drawing

WPS, PQR

12.2 Below document shall be submitted after fabrication:

Material Test Certificate

Visual and Dimensional Check Report

WQT (Welder Qualification Test)

RT , UT, MT and PT Reports

Heat Treatment Report and Graph

Hardness Test Report

Hydrostatic Test Report

Surface Preparation and Coating Report

Release Note

12.3 All above documents (before and after fabrication) shall be in English Language and to be

issued to purchaser in 3 final books.

13. PACKAGING

Each fitting shall be suitably protected to avoid damage during transport. Packing procedure

shall be specified by manufacturer and approved by end user. Metallic or high impact plastic

bevel protectors shall be provided for weld ends.

`N.I.G.C.

IGS-M-PL-

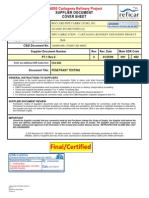

14. DATA SHEET

The following data sheet shall be filled by end user and attached to inquire.

Hot tapping tee Data Sheet

Element

NIGC.S requirement as per

this standard specification

DESIGN DATA

Size(Run Branch) a

Quantity a

Design Code b

Medium

Natural Gas

Extruded

Split Tee Manufacturing method

Welded

Design pressure a

Design temperature(C)

-29 to 60

Design factor(F)

0.5

Flange Standard

ASME B16.5

ASME B 16.47/series A

MSS SP 44

Flange Size & Rating a

Flange Facing

Raised Face

Flange Finish

Serrated finished

Lock O-Ring flange

Yes

No

Guide bar

Yes

No

Guide bar holder type a

Hydro Test Pressure(kg/cm2 ) c

Manufactures' comment

`N.I.G.C.

Pipeline Details(on which hot

taping is to be conducted)a

IGS-M-PL-

Outside Diameter(inch):

Thickness(mm):

Material:

Connecting Branch Pipeline

Detailsa

Outside Diameter(inch):

Thickness(mm):

Material

Inside diameter of run. (mm) c

thickness of run (mm) c

Overall length of run (mm) c

Minimum branch inside

diameter. (mm)

Minimum branch thickness(mm) c

Fitting Height (Center line of run

to the top face of flange)-(mm) c

Weight (kg) c

Tapping Machine Specification a

MATERIAL REQUIREMENT

Part Description

Top half Portion c

Bottom half Portion c

`N.I.G.C.

IGS-M-PL-

Branch c

Flange/Lock O-Ring flange c

Guide bar Assembly c

Lock O-Ring Retaining Device c

O-Ring c

Notes:

a) shall be specified by end user

b) as per this standard

c) shall be specified by manufacturer

1- This data sheet shall be filled for each item.

2- Clause wise deviation shall be specified by manufacturer/supplier.

3- This data sheet shall be signed and sealed by manufacturer's authorized person.

S-ar putea să vă placă și

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDe la EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionÎncă nu există evaluări

- 02 Samss 006Document17 pagini02 Samss 006inatt101Încă nu există evaluări

- Mechanical Specifications For Fiberbond ProductDocument8 paginiMechanical Specifications For Fiberbond ProducthasnizaÎncă nu există evaluări

- Agip-15801 Pip Mec SDSDocument64 paginiAgip-15801 Pip Mec SDSFAUSTO SAMPIETROÎncă nu există evaluări

- ANSI-ASME B16.5 Blind Flange 300lb PDFDocument1 paginăANSI-ASME B16.5 Blind Flange 300lb PDFVishal MistryÎncă nu există evaluări

- Material Selection GuideDocument1 paginăMaterial Selection Guidesuresh_vikiÎncă nu există evaluări

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 paginiASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaÎncă nu există evaluări

- What Is An ASME Appendix 2 Flange Design PDFDocument1 paginăWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleÎncă nu există evaluări

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 paginăTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1Încă nu există evaluări

- Calculo Brida Ejemplo PV - EliteDocument8 paginiCalculo Brida Ejemplo PV - ElitePedro Montes MarinÎncă nu există evaluări

- Rps Pipe Support 2014Document91 paginiRps Pipe Support 2014Vishal SoniÎncă nu există evaluări

- SPE 76-002 (2006) Flange MaterialsDocument6 paginiSPE 76-002 (2006) Flange Materials김창배Încă nu există evaluări

- Calc Hoop StressDocument11 paginiCalc Hoop StressApril Trevino100% (1)

- Cast - Basket Strainers - 2nd EditionDocument27 paginiCast - Basket Strainers - 2nd EditionmartinnovelÎncă nu există evaluări

- New Storage Tanks Design GuidelinesDocument6 paginiNew Storage Tanks Design GuidelinespaaryÎncă nu există evaluări

- WRC 107 WRC 297 Co MP PDFDocument11 paginiWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Piping Engineering - Tank Nozzle Loads 1Document1 paginăPiping Engineering - Tank Nozzle Loads 1Nasrul AdliÎncă nu există evaluări

- Calculation of PipeReinforcement ASMEB31 1Document4 paginiCalculation of PipeReinforcement ASMEB31 1threedlabsÎncă nu există evaluări

- Ansi B16.9-16.28-MSS SP-43Document3 paginiAnsi B16.9-16.28-MSS SP-43vangie3339515Încă nu există evaluări

- Mitered BendsDocument1 paginăMitered BendsTsouki TsoukiÎncă nu există evaluări

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 paginiHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadÎncă nu există evaluări

- Sizing CalcDocument1 paginăSizing CalcHilary AbaratuÎncă nu există evaluări

- Ansi b31.3 Allowable StressDocument2 paginiAnsi b31.3 Allowable StressTsouki Tsouki100% (2)

- Flange Pipe SupportDocument1 paginăFlange Pipe SupportindeskeyÎncă nu există evaluări

- Car Washer CatalogueDocument24 paginiCar Washer Cataloguesra electricalsÎncă nu există evaluări

- Data Sheet 26 - Fig FT702 150 T StrainerDocument1 paginăData Sheet 26 - Fig FT702 150 T StrainerSteve NewmanÎncă nu există evaluări

- Igat6 D PL Me SPC 0007 01 Spec For Barred TeeDocument9 paginiIgat6 D PL Me SPC 0007 01 Spec For Barred Teeamini_mohi100% (1)

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 paginiTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoÎncă nu există evaluări

- Snamprogetti: CustomerDocument3 paginiSnamprogetti: CustomeradesloopÎncă nu există evaluări

- Burst PR Calculation PDFDocument1 paginăBurst PR Calculation PDFAranga KeerthiÎncă nu există evaluări

- PIP - Piping Material Specifications Collection - IHSDocument3 paginiPIP - Piping Material Specifications Collection - IHSmontanovillarroelfabiolalourdeÎncă nu există evaluări

- Pn16 - FlangeDocument2 paginiPn16 - FlangeJebranÎncă nu există evaluări

- Weldolet CalculationDocument20 paginiWeldolet Calculationanhdung_proÎncă nu există evaluări

- Ligament Efficiency and Thickness of The Support PlateDocument10 paginiLigament Efficiency and Thickness of The Support PlatePankajDhobleÎncă nu există evaluări

- Virgo Trunnion Ball ValveDocument16 paginiVirgo Trunnion Ball ValveKamalÎncă nu există evaluări

- A 1 KDocument5 paginiA 1 KSumantrra ChattopadhyayÎncă nu există evaluări

- Max Allowable Nozzle LoadDocument1 paginăMax Allowable Nozzle Loaddskr fkshÎncă nu există evaluări

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 paginiPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeÎncă nu există evaluări

- 4 2500 (F347H)Document2 pagini4 2500 (F347H)siddhesh_guessÎncă nu există evaluări

- Realistic Fasteners in AutoCAD Plant 3DDocument5 paginiRealistic Fasteners in AutoCAD Plant 3DEvaldo BritoÎncă nu există evaluări

- Trun CalcDocument215 paginiTrun CalcmohamedeliasÎncă nu există evaluări

- Datasheet For Pig Signaler: DSH Serial 05 Project Pro. Part Scope Dis. 0002 Igat6 D PL IN Doc. RevDocument22 paginiDatasheet For Pig Signaler: DSH Serial 05 Project Pro. Part Scope Dis. 0002 Igat6 D PL IN Doc. Revamini_mohiÎncă nu există evaluări

- Kpeter PDFDocument3 paginiKpeter PDFlive4sankarÎncă nu există evaluări

- Grating Weight - CalculationDocument1 paginăGrating Weight - CalculationMuthuram NÎncă nu există evaluări

- En 13121-3:2008+a1:2010 (E)Document1 paginăEn 13121-3:2008+a1:2010 (E)TIME STAR COMPOSITEÎncă nu există evaluări

- Stainless Steel Pressure Filters - BrochureDocument20 paginiStainless Steel Pressure Filters - Brochureviktor_gligorovÎncă nu există evaluări

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 paginiBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloÎncă nu există evaluări

- Commercial Gas Pipe Sizing PART 2 - Using The Pressure Drop Calculator (PDC)Document12 paginiCommercial Gas Pipe Sizing PART 2 - Using The Pressure Drop Calculator (PDC)Catalin StrugariuÎncă nu există evaluări

- HDPE Flange AdaptorDocument1 paginăHDPE Flange Adaptorcld72Încă nu există evaluări

- SBC (Safety Break-Away Couplings) v140630Document16 paginiSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- SP Item DatasheetsDocument21 paginiSP Item DatasheetsSELVAMANIÎncă nu există evaluări

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LDocument7 paginiSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukÎncă nu există evaluări

- PSV Reaction Force - Closed SystemDocument5 paginiPSV Reaction Force - Closed SystemWayne MonneryÎncă nu există evaluări

- Low-Pressure Hoselines SN 544: Double Nipple Welding NippleDocument2 paginiLow-Pressure Hoselines SN 544: Double Nipple Welding NippleNaveen Kumar Chauhan100% (1)

- TEMA Shell Bundle Entrance and Exit AreasDocument3 paginiTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaÎncă nu există evaluări

- PED 2014-68-EU Guidelines EN v4Document235 paginiPED 2014-68-EU Guidelines EN v4Nav TalukdarÎncă nu există evaluări

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocument1 paginăTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNEÎncă nu există evaluări

- Oil and Gas Pipeline Design and MaintenanceDocument27 paginiOil and Gas Pipeline Design and MaintenanceernmrajaÎncă nu există evaluări

- 1113 DWSDWSDDocument53 pagini1113 DWSDWSDenjoygurujiÎncă nu există evaluări

- Penetrant TestingDocument8 paginiPenetrant TestingAli ClubistÎncă nu există evaluări

- AWS D1.1-D1.1M-2015 (WeldingWorld) 250Document1 paginăAWS D1.1-D1.1M-2015 (WeldingWorld) 250Ali Clubist100% (1)

- UTP2Document47 paginiUTP2Ali ClubistÎncă nu există evaluări

- UTP3Document17 paginiUTP3Ali ClubistÎncă nu există evaluări

- M ChoiceDocument37 paginiM Choicevasunookesh100% (1)

- Iprm S10-Safety d5Document72 paginiIprm S10-Safety d5Ali ClubistÎncă nu există evaluări

- Wall Chart For Hardness TestingDocument1 paginăWall Chart For Hardness TestingAli ClubistÎncă nu există evaluări

- TWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Document68 paginiTWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Ali ClubistÎncă nu există evaluări

- TWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Document68 paginiTWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Ali ClubistÎncă nu există evaluări

- Aws Classificati v991NDocument1 paginăAws Classificati v991NMax RosasÎncă nu există evaluări

- Instruction API 650 RadioDocument3 paginiInstruction API 650 RadioAli Clubist100% (1)

- Chapter 9 - Welding DefectsDocument18 paginiChapter 9 - Welding Defectsbibin2010100% (1)

- Residual StressDocument5 paginiResidual StressAli ClubistÎncă nu există evaluări

- 1 Guide For WPS PQR WPQR PDFDocument6 pagini1 Guide For WPS PQR WPQR PDFmuhammadazhar100% (1)

- WIS5 Paper 2 Rev 3Document4 paginiWIS5 Paper 2 Rev 3Ali ClubistÎncă nu există evaluări

- Wowlibrary Gmaw Fcaw Mcaw WeldingDocument6 paginiWowlibrary Gmaw Fcaw Mcaw WeldingPhuong HuynhÎncă nu există evaluări

- H W T W T F: Dimensions Are in Millimeters Unless Otherwise IndicatedDocument1 paginăH W T W T F: Dimensions Are in Millimeters Unless Otherwise IndicatedAli ClubistÎncă nu există evaluări

- Wis 5 Eoca AnswersDocument34 paginiWis 5 Eoca AnswersAli ClubistÎncă nu există evaluări

- WIS 5 EOCA QuestionsDocument31 paginiWIS 5 EOCA QuestionsAli ClubistÎncă nu există evaluări

- A Comparison of ISO 15614 Part 1 and ASME IXDocument3 paginiA Comparison of ISO 15614 Part 1 and ASME IXsusanwebÎncă nu există evaluări

- MetalLurgie ExerciceDocument44 paginiMetalLurgie ExerciceAli Clubist0% (1)

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 paginiWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- WIS5 Paper 1 Rev 3Document4 paginiWIS5 Paper 1 Rev 3Ali ClubistÎncă nu există evaluări

- Check Liste de Verification WpsDocument1 paginăCheck Liste de Verification WpsAli ClubistÎncă nu există evaluări

- Chapter 9: Mechanical Failure: Issues To Address..Document16 paginiChapter 9: Mechanical Failure: Issues To Address..Sharat ChandraÎncă nu există evaluări

- Iprm S03-Indgas d6Document36 paginiIprm S03-Indgas d6Ali ClubistÎncă nu există evaluări

- MetalLurgie ExerciceDocument44 paginiMetalLurgie ExerciceAli Clubist0% (1)

- IPRM S01-ServiceOffer D4Document6 paginiIPRM S01-ServiceOffer D4Ali ClubistÎncă nu există evaluări

- Pressure Vessel Design Safety: Suryakant RanderiDocument46 paginiPressure Vessel Design Safety: Suryakant Randericonny julandaÎncă nu există evaluări

- The Design of Vertical Pressure Vessels Subjected To Applied ForcesDocument5 paginiThe Design of Vertical Pressure Vessels Subjected To Applied Forcestranhonghakd5533Încă nu există evaluări

- 11 ASME Secc VIII Part UCL Requirements For Welded Pressure Ves PDFDocument7 pagini11 ASME Secc VIII Part UCL Requirements For Welded Pressure Ves PDFAnthony Bare Huané SalcedoÎncă nu există evaluări

- Compress CalculationDocument106 paginiCompress CalculationKrupal Patel100% (1)

- Astm A312 PDFDocument12 paginiAstm A312 PDFStephen TilleyÎncă nu există evaluări

- Coca-Cola Femsa Philippines, Inc.: Report On The Result of Inspection of Pressure VesselDocument30 paginiCoca-Cola Femsa Philippines, Inc.: Report On The Result of Inspection of Pressure VesselEphraim John Tangelon AquinoÎncă nu există evaluări

- ReferencesDocument4 paginiReferencesAKSHAY BHATKARÎncă nu există evaluări

- Mtech 2013 DPVP Model QuestionDocument2 paginiMtech 2013 DPVP Model QuestionMathew JohnÎncă nu există evaluări

- FMDocument65 paginiFMtedÎncă nu există evaluări

- SunsilDocument4 paginiSunsilsam3461Încă nu există evaluări

- GratingsDocument371 paginiGratingskris_kcpÎncă nu există evaluări

- 1 การตรวจสอบการสร้างหม้อน้ำตามมาตรฐานASME2013Document24 pagini1 การตรวจสอบการสร้างหม้อน้ำตามมาตรฐานASME2013Surasan ThepsiriÎncă nu există evaluări

- Material Selection and Name PDFDocument6 paginiMaterial Selection and Name PDFDaško MedenjaškoÎncă nu există evaluări

- Astm A530 PDFDocument9 paginiAstm A530 PDFTam Huynh Thanh100% (1)

- Horizontal Pressure VesselDocument37 paginiHorizontal Pressure VesselOld Oromo music museum100% (1)

- Astm A105-A105mDocument5 paginiAstm A105-A105mAries MarteÎncă nu există evaluări

- Api 510Document24 paginiApi 510maani7zeroÎncă nu există evaluări

- X-Cor Boiler Plates and Pressure Vessel Steels en PDFDocument8 paginiX-Cor Boiler Plates and Pressure Vessel Steels en PDFIgor GrujićÎncă nu există evaluări

- ASTMA240Document5 paginiASTMA240Mani MaÎncă nu există evaluări

- Plant Integrity Management Services4224Document32 paginiPlant Integrity Management Services4224sajeed76740100% (2)

- Astm B283-20Document16 paginiAstm B283-20Gregory Alan Francisco IIÎncă nu există evaluări

- Mechanical Integrity UpdateDocument36 paginiMechanical Integrity UpdateRASHEED YUSUF100% (1)

- Paper - Finite Element Analysis of Pressure Vessels (Jones)Document15 paginiPaper - Finite Element Analysis of Pressure Vessels (Jones)Zarra FaktÎncă nu există evaluări

- Unit IiDocument60 paginiUnit IiAmit YadavÎncă nu există evaluări

- Gokulnath GDocument4 paginiGokulnath GgokulnathÎncă nu există evaluări

- As 2337.1-2004 Gas Cylinder Test Stations General Requirements Inspection and Tests - Gas CylindersDocument9 paginiAs 2337.1-2004 Gas Cylinder Test Stations General Requirements Inspection and Tests - Gas CylindersSAI Global - APACÎncă nu există evaluări

- Reli-Sleeve CatalogueDocument5 paginiReli-Sleeve CatalogueUtpal SarmahÎncă nu există evaluări

- FinalDocument72 paginiFinalRyan FisherÎncă nu există evaluări

- OSH Standards Amended 1989 LatestDocument338 paginiOSH Standards Amended 1989 Latestverkie100% (1)