Documente Academic

Documente Profesional

Documente Cultură

(AMW0001) Biasing LDMOS FETs For Linear Operation

Încărcat de

Thanhha NguyenTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

(AMW0001) Biasing LDMOS FETs For Linear Operation

Încărcat de

Thanhha NguyenDrepturi de autor:

Formate disponibile

Biasing LDMOS FETs for Linear

Operation

Bias choices determine linearity, gain and efficiency, but also require

attention to thermal effects

By Cindy Blair

Ericsson RF Power Products

he new CDMA and WCDMA

wireless standards have dramatically impacted the optimization criteria that a wireless base

station designer might choose in

designing or selecting RF ower amplifiers. Now, more than ever before, linearity is of paramount importance.

Lateral DMOS devices have provided

superior performance at a reasonable

price per watt. RF power amplifier

designers must choose the bias point

that will give them the best trade-offs

between linearity, gain and efficiency. Figure 1. A standard typical temperature plot given by most

In order to provide these high degrees

manufacturers of commercial LDMOS devices.

of linearity under all reasonable conditions, this bias point must be reasonably maintained over time and temperature. Basic considerations

A FET device has three parameters that

In all FET bias circuits, it is of critical imporchange with increasing temperature: the gate tance that the gate bias voltage be derived from

threshold shifts; gm drops; and RDS (on) goes a very well regulated source. It is also assumed

down. The combined result of this is shown in that whatever sense element is used should be

Figure 1, displaying a standard typical tempera- thermally linked to the device for which it is

ture plot given by most manufacturers of com- providing the correction reference. With the low

mercial LDMOS devices. The gate bias values currents present in the gate circuitry, this can

shown are normalized to 1 volt at 25 C and be accomplished simply and very inexpensively.

depict the bias values needed to maintain the Furthermore, in linear operation, any correcgraphed current point over temperature.

tive bias circuit will reduce the bias voltage

At low drain currents, the LDMOS device has with temperature to retain the same operating

a positive temperature coefficient. As the drain point. While at the same time gm is dropping,

current increases, the positive coefficient this will appear as less amplifier gain at high

becomes progressively less positive, until at very temperatures. For most applications the gain

high currents it goes negative. This is wonderful change is slight, and most system designers proprotection against thermal runaway, but it makes vide a system ALC loop, which should mask this

the designers job a little more difficult. These effect in the end product.

plots serve as a good basic guideline, but the

designer should be aware that normal process The diode compensation network

variations might affect these curves slightly.

Diode compensation networks (as shown in

90 APPLIED MICROWAVE & WIRELESS

Figure 2) are perhaps the simplest and most

widely used bias circuit. They have been used

for years in bipolar circuits to prevent thermal

runaway. There are excellent application articles available for their use in FET products as

well. Operation is very straightforward. As D1

becomes hotter, its enhanced conduction will

increase the current through R2, thus altering

the divide ratio of R1/R2/D1. Single diode networks are, however, somewhat limited, in that

it is more difficult to tailor the compensation

curve to a specific device curve without additional circuitry. One may also series two or

more diodes to increase the amount of compensation available.

Figure 2. Diode compensation network.

The thermal sensor

If the designer desires a bit more sophistication, a thermal sensor (as shown in Figure 3)

may be used. This eliminates the guesswork and

extra characterization associated with the diode

compensator. The designer simply looks up the

thermal coefficient of the device at the specific

desired operating current, then compares that

to the 10 mV/K slope of the temperature sensor

(in this case, LM335). A simple op-amp circuit

takes care of providing the desired slope conversion. In the sensor shown in Figure 3, R1 can be

replaced by automated methods of main bias

control for the device (e.g., IDQ set from the system controller). R4 will adjust the amount of

temperature slope at the output of IC1. R2, R3,

and R5 may be tailored to the bias controls of

individual systems. This is a well behaved configuration that is easily modeled in Spice.

Figure 3. Thermal sensor.

The Like material reference

When the designer wants the mirroring

effect in a compensation circuit as close to perfect as possible, there is no substitute for a like

material reference (as shown in Figure 4). Q2

contains an RF transistor die that is similar in

semiconductor processing characteristics to the

die contained in Q1, but is much smaller (for Figure 4. Like material reference.

this discussion, 1/56 size). Q2 is kept small to

maximize system efficiency. The reference

device may be any scalable size. R5 and R6 set the gate compensation for hot electron effects. High frequency

bias on Q2, typically set so that the drain current is (short gate length) lateral DMOS devices exhibit over

scaled down to the same ratio as the difference in die time a gate oxide charging phenomenon. This oxide

size. For example, if the normal operating current in Q1 charging leads to an upward shift in threshold voltage in

is 2.6 amperes, Q2 would be set to run at 1/56 of that the enhancement mode device. For example, assume

value (assuming a 56:1 Q1/Q2 size ratio). As Q2 changes that the gate bias of an FET is set so that the quiescent

temperature, the change in current causes the drain drain current is 1 A. If the FET is operated for 20 years

voltage of Q2 to change. This voltage feeds the correc- and the quiescent current is re-measured as 0.95 A, the

FET has drifted 5 percent, due to this oxide charging

tion input of the op-amp Summing circuit above.

A second, less obvious advantage to this topology is effect. One ampere was the value of quiescent current

92 APPLIED MICROWAVE & WIRELESS

that provided optimal linearity performance; consequently the linearity

performance (and small signal gain)

of our device has degraded over

time. These effects are minimized if

the gate bias is increased over time

to compensate for the charging

effect. In the ideal case, VDD* will be

above VDD so that with the current

drawn the actual VDD of Q2 will

approximate VDD on Q1.

One very important assumption

for this is that both transistors are

new when installed. (On a mass

production base station line, this

will not be an issue.) When properly

implemented, the like material

reference compensates for many

drift and thermal effects. This is certainly not a perfect solution, but it

allows offsetting negative characteristics to subtract; even if material

types are not perfectly matched, you

are still subtracting errors.

Although device manufacturers

are continually reducing this drift

effect, it will be a factor for some

time to come. The like material

reference eliminates the need for

burn in, but requires the amplifying

and compensating devices be of

identical age. This may add substantial cost to any field replacement of devices.

The correction circuits presented

here are generic in nature, and may

be modified to individual system

requirements. This paper is intended as a general reference only.

Equations for the sum/difference circuits are available in the references.

Most of these correction circuits are

easily modeled. If a higher degree of

manufacturing ease is needed a custom integrated circuit could be produced for method 1 or 2.

References

1. R. Pierret, Semiconductor

Device Fundamentals, AddisonWesley, 1996.

2. N. Dye, H. Granberg, Radio

Frequency Transistors Principles

and Practical Applications, Butterworth-Heinemann, 1993.

3. J. Duclercq, O. Lembeye; RF

LDMOS Power Modules for GSM

Base Station Application: Optimum

Biasing Circuit. Motorola application note AN1643.

4. D. Bell, Operational Amplifiers,

Prentice Hall, 1990.

5. E. Oxner, FET Technology and

Application Marcel Dekker, Inc.,

1989.

6. S. Porro, FETs Address

Linearity Challenge. Ericsson

Application Note.

Author information

Cindy Blair is a member of the

Research and Development staff at

Ericsson Inc. RF Power Products,

Morgan Hill, CA. She may be

reached by telephone at 408-7760600 or by fax at 408-779-3108.

94 APPLIED MICROWAVE & WIRELESS

S-ar putea să vă placă și

- Ecuaciones para Curva de Conductores y MotoresDocument6 paginiEcuaciones para Curva de Conductores y MotoresCarlos Lovera Rodriguez100% (1)

- Service Manual RAINBOW 180E EnglishDocument54 paginiService Manual RAINBOW 180E EnglishJaroslaw BrzozowskiÎncă nu există evaluări

- Using The ADC0808/ADC0809 8-Bit P Compatible A/D Converters With 8-Channel Analog MultiplexerDocument23 paginiUsing The ADC0808/ADC0809 8-Bit P Compatible A/D Converters With 8-Channel Analog MultiplexerRiskyÎncă nu există evaluări

- Applied Physics TYBscDocument95 paginiApplied Physics TYBscAtharv PatadeÎncă nu există evaluări

- Multisim Thermal ModelingDocument23 paginiMultisim Thermal ModelingAzxctybv VpolmÎncă nu există evaluări

- A Modified SEPIC Converter For High Power Factor Rectifier and Universal Input Voltage ApplicationsDocument12 paginiA Modified SEPIC Converter For High Power Factor Rectifier and Universal Input Voltage ApplicationsBritto TigerÎncă nu există evaluări

- Ena Lab Manual - SolvedDocument69 paginiEna Lab Manual - SolvedUmair Ejaz Butt100% (1)

- Alone, FCG-Driven High Power Microwave SystemDocument5 paginiAlone, FCG-Driven High Power Microwave SystempauljansonÎncă nu există evaluări

- Synchronous CondenserDocument2 paginiSynchronous CondenserblaagicaÎncă nu există evaluări

- Pvsyst 5Document219 paginiPvsyst 5nexarsolarÎncă nu există evaluări

- Multiple Transformers Oil Temperature Monitoring With Automatic CircuitDocument25 paginiMultiple Transformers Oil Temperature Monitoring With Automatic CircuitPrem Narayan Singh100% (1)

- Power Rectifier ASIC ControllerDocument5 paginiPower Rectifier ASIC ControllerQuang TaÎncă nu există evaluări

- Bearing Pad - Regular Test 1 PDFDocument1 paginăBearing Pad - Regular Test 1 PDFShoyeeb AhmedÎncă nu există evaluări

- A Study On Heat Transfer in MicroDocument2 paginiA Study On Heat Transfer in MicroPabitraBadhukÎncă nu există evaluări

- Construction of An Automatic Night LampDocument10 paginiConstruction of An Automatic Night Lampmekm09Încă nu există evaluări

- Test de RadiadorDocument10 paginiTest de RadiadorOmar Reinoso TigreÎncă nu există evaluări

- 4Document5 pagini4Alsmany ArdabÎncă nu există evaluări

- RL RC CircuitDocument13 paginiRL RC CircuitMadhav Sameer100% (1)

- Itron DTM System SolutionDocument11 paginiItron DTM System SolutionDist TxÎncă nu există evaluări

- 00092929Document14 pagini00092929Sunandan KumarÎncă nu există evaluări

- Effect of BLDC Motor Commutation Schemes On Inverter Capacitor Size SelectionDocument5 paginiEffect of BLDC Motor Commutation Schemes On Inverter Capacitor Size SelectionXristos LianÎncă nu există evaluări

- Automatic Load SharingDocument41 paginiAutomatic Load SharingSaravanan ViswakarmaÎncă nu există evaluări

- Report of Project 18pulseDocument6 paginiReport of Project 18pulsedhaval2430100% (1)

- Transmission Line EditorDocument4 paginiTransmission Line EditorHassen LazharÎncă nu există evaluări

- ABSTRACT Solar Peltier Air Cooler and HeaterDocument7 paginiABSTRACT Solar Peltier Air Cooler and HeaterMectrosoft Creative technologyÎncă nu există evaluări

- Adaptive Protection Scheme For Smart GridsDocument6 paginiAdaptive Protection Scheme For Smart GridsMiguel QuispeÎncă nu există evaluări

- Comparison TableDocument3 paginiComparison TableRodriguez Villalobos NelsonÎncă nu există evaluări

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 paginiManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanÎncă nu există evaluări

- HarmonicsDocument3 paginiHarmonicsMiko QuijanoÎncă nu există evaluări

- Wireless Power Transfer SynopsisDocument3 paginiWireless Power Transfer Synopsisa d100% (1)

- Low Power Boost Converter For Portable Applications by Eddy Wells and Mark JordanDocument9 paginiLow Power Boost Converter For Portable Applications by Eddy Wells and Mark JordanberbouÎncă nu există evaluări

- High-Speed Low-Power Viterbi Decoder Design For TCM DecodersDocument16 paginiHigh-Speed Low-Power Viterbi Decoder Design For TCM DecodersShruti Tajne100% (1)

- BLR-CA Banco CapacitoresDocument4 paginiBLR-CA Banco Capacitoresalex0% (1)

- Application Thermistor NTC 10kDocument2 paginiApplication Thermistor NTC 10kAlexanderNugrohoÎncă nu există evaluări

- Trends in Ac Drive ApplicationsDocument9 paginiTrends in Ac Drive Applicationsbark77100% (3)

- Design DC-DC Converter Topology Full-Bridge 24/400 V 300 W 100Khz With Zero Voltage Switching Phase Shift PWM MethodDocument6 paginiDesign DC-DC Converter Topology Full-Bridge 24/400 V 300 W 100Khz With Zero Voltage Switching Phase Shift PWM MethodtriwahonoÎncă nu există evaluări

- Smart GridDocument44 paginiSmart GriddaminhvienÎncă nu există evaluări

- Frequency Modulation Analysis: Experiment # 6Document5 paginiFrequency Modulation Analysis: Experiment # 6Ghaznooq AhmadÎncă nu există evaluări

- Pnspo!: Modbus Solution Cp1H / Cp1L / Cj1 / Cj2 / Cs1Document17 paginiPnspo!: Modbus Solution Cp1H / Cp1L / Cj1 / Cj2 / Cs1jmauricio19100% (1)

- Battery DC Generator Electric Power Voltage: NextDocument13 paginiBattery DC Generator Electric Power Voltage: NextHussam GujjarÎncă nu există evaluări

- Formula SAE Electric Division: Safety Failure Modes Effects AnalysisDocument19 paginiFormula SAE Electric Division: Safety Failure Modes Effects AnalysisNelsonÎncă nu există evaluări

- Parts HVRZ5UDocument17 paginiParts HVRZ5UacharlessÎncă nu există evaluări

- One Wire ProtocolDocument22 paginiOne Wire ProtocolPiPo Tui100% (1)

- Design Considerations For System-Level ESD Circuit ProtectionDocument6 paginiDesign Considerations For System-Level ESD Circuit Protectionmincingthought6612Încă nu există evaluări

- Representation of Power Systems: 1.1 One Line DiagramDocument17 paginiRepresentation of Power Systems: 1.1 One Line DiagramDr. Gollapalli Naresh100% (1)

- Baliga Figure of MeritDocument3 paginiBaliga Figure of MeritKyle BotheÎncă nu există evaluări

- 50Hz Submersible Pumps CRI PDFDocument120 pagini50Hz Submersible Pumps CRI PDFAlijimal JimalÎncă nu există evaluări

- MIM Cap ModelDocument4 paginiMIM Cap ModelDuc DucÎncă nu există evaluări

- Novel Switching Sequences For A Space Vector Modulated Three Level Inverter-LibreDocument11 paginiNovel Switching Sequences For A Space Vector Modulated Three Level Inverter-LibreHollie RosaÎncă nu există evaluări

- Multi LVL DC DC BoostDocument9 paginiMulti LVL DC DC BoostDurga PrathibhaÎncă nu există evaluări

- Mosfet DataDocument8 paginiMosfet Dataibnu malkanÎncă nu există evaluări

- Protection Techniques With Renewable Resources and Smart Grids-A Survey 2015 PDFDocument23 paginiProtection Techniques With Renewable Resources and Smart Grids-A Survey 2015 PDFbdsrlÎncă nu există evaluări

- Bidirectional DC-DC Converter With Full-Bridge / Push-Pull Circuit For Automobile Electric Power SystemsDocument5 paginiBidirectional DC-DC Converter With Full-Bridge / Push-Pull Circuit For Automobile Electric Power SystemsPaulo UchihaÎncă nu există evaluări

- TP 1800 DC-DC Converter For Hybrid Electric Vehicle and EV ArrowTimesDocument7 paginiTP 1800 DC-DC Converter For Hybrid Electric Vehicle and EV ArrowTimespapipapii100% (1)

- Cpe08 Midterm Exam Part 1and 2Document4 paginiCpe08 Midterm Exam Part 1and 2Elle ElleÎncă nu există evaluări

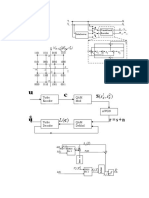

- Power Electronics: THYRISTOR ProtectionDocument12 paginiPower Electronics: THYRISTOR ProtectionK Lokesh LingaiahÎncă nu există evaluări

- ReadMe12 PDFDocument6 paginiReadMe12 PDFLuis RodriguezÎncă nu există evaluări

- A Simple Guide To Selecting Power MOSFETsDocument7 paginiA Simple Guide To Selecting Power MOSFETsJUANnn100Încă nu există evaluări

- Microwaves101 - Spectrum AnalyzerDocument9 paginiMicrowaves101 - Spectrum AnalyzerThanhha NguyenÎncă nu există evaluări

- 1i308a 1i308b 1i308v 1i308g 1i308d 1i308e 1i308zh 1i308i 1i308kDocument1 pagină1i308a 1i308b 1i308v 1i308g 1i308d 1i308e 1i308zh 1i308i 1i308kThanhha NguyenÎncă nu există evaluări

- Схема Блока Питания ТрансивераDocument17 paginiСхема Блока Питания ТрансивераThanhha NguyenÎncă nu există evaluări

- Analog Filters Using MATLABDocument14 paginiAnalog Filters Using MATLABThanhha NguyenÎncă nu există evaluări

- Gain Characterization of The RF Measurement Path: J. Wayde AllenDocument20 paginiGain Characterization of The RF Measurement Path: J. Wayde AllenThanhha NguyenÎncă nu există evaluări

- 13 Commsys Rev5 Lab5Document22 pagini13 Commsys Rev5 Lab5Thanhha NguyenÎncă nu există evaluări

- Scanner: Monitor. Protect. Control. Visualize. CommunicateDocument2 paginiScanner: Monitor. Protect. Control. Visualize. CommunicateThanhha NguyenÎncă nu există evaluări

- 307RF Rudra38Document6 pagini307RF Rudra38Thanhha NguyenÎncă nu există evaluări

- Programming A Cypress PSoC Using PSoC DesignerDocument12 paginiProgramming A Cypress PSoC Using PSoC DesignerThanhha NguyenÎncă nu există evaluări

- 0632 Hf/uhf Field Radio EquipmentDocument166 pagini0632 Hf/uhf Field Radio EquipmentRamon C. Pastores100% (2)

- V An Innovative Magnetic Field Sweep Unit: of of of ofDocument20 paginiV An Innovative Magnetic Field Sweep Unit: of of of ofBerthaFloresÎncă nu există evaluări

- Wireless Data Transmission Between Two PIC Microcontrollers Using Low-Cost RF Modules - Embedded LabDocument12 paginiWireless Data Transmission Between Two PIC Microcontrollers Using Low-Cost RF Modules - Embedded Labmoonaliawan100% (3)

- Sga 6589Document4 paginiSga 6589Thanhha NguyenÎncă nu există evaluări

- H 11 Aa 1Document7 paginiH 11 Aa 1Josetheking CrackedsoftwaresÎncă nu există evaluări

- 7 PLL Synthesizer 4 55Document55 pagini7 PLL Synthesizer 4 55Thanhha NguyenÎncă nu există evaluări

- Us 7088830Document9 paginiUs 7088830Thanhha NguyenÎncă nu există evaluări

- My C NotesDocument30 paginiMy C NotesBrijendra Mohan GuptaÎncă nu există evaluări

- FM Digital Tuner FM 数字调谐器Document4 paginiFM Digital Tuner FM 数字调谐器Thanhha NguyenÎncă nu există evaluări

- Wireless Data Transmission Between Two PIC Microcontrollers Using Low-Cost RF Modules - Embedded LabDocument12 paginiWireless Data Transmission Between Two PIC Microcontrollers Using Low-Cost RF Modules - Embedded Labmoonaliawan100% (3)

- Koch 2016Document331 paginiKoch 2016Thanhha NguyenÎncă nu există evaluări

- ME1010 RF Circuit Design (Agilent Genesys) Lab 7 RF Oscillator DesignDocument14 paginiME1010 RF Circuit Design (Agilent Genesys) Lab 7 RF Oscillator DesignThanhha NguyenÎncă nu există evaluări

- Schottky Barrier Diodes: Lead (PB) - FreeDocument2 paginiSchottky Barrier Diodes: Lead (PB) - FreeDario G. MartinezÎncă nu există evaluări

- Serial DDS Controller: Dave Ek, NK0E George Heron, N2APBDocument1 paginăSerial DDS Controller: Dave Ek, NK0E George Heron, N2APBThanhha Nguyen100% (1)

- Osciladores Simplificados Con Proyectos by EnigmaelectronicaDocument261 paginiOsciladores Simplificados Con Proyectos by EnigmaelectronicaCarlos RamirezÎncă nu există evaluări

- Pira - CZ AM Transmitter 25 W PLL Class D/E: VIN VoutDocument1 paginăPira - CZ AM Transmitter 25 W PLL Class D/E: VIN VoutThanhha NguyenÎncă nu există evaluări

- 93071ADocument10 pagini93071AThanhha NguyenÎncă nu există evaluări

- FM Digital Tuner FM 数字调谐器Document4 paginiFM Digital Tuner FM 数字调谐器Thanhha NguyenÎncă nu există evaluări

- Bai BaoDocument1 paginăBai BaoThanhha NguyenÎncă nu există evaluări

- 7 PLL Synthesizer 4 55Document55 pagini7 PLL Synthesizer 4 55Thanhha NguyenÎncă nu există evaluări

- ME1010 RF Circuit Design (Agilent Genesys) Lab 7 RF Oscillator DesignDocument14 paginiME1010 RF Circuit Design (Agilent Genesys) Lab 7 RF Oscillator DesignThanhha NguyenÎncă nu există evaluări

- Wien's Bridge Oscillator Using Op-AmpDocument19 paginiWien's Bridge Oscillator Using Op-Ampgcn57567% (3)

- ET1006 Chapter 23 Part 1Document29 paginiET1006 Chapter 23 Part 1fastÎncă nu există evaluări

- Am/Fm Tuner For Car Radio and Hi-Fi Applications: General DescriptionDocument38 paginiAm/Fm Tuner For Car Radio and Hi-Fi Applications: General DescriptionMartin MartinÎncă nu există evaluări

- Automotive Catalog Ver.2.1 (En)Document88 paginiAutomotive Catalog Ver.2.1 (En)AnugrahÎncă nu există evaluări

- Configuring Instrumentation and Control DevicesDocument30 paginiConfiguring Instrumentation and Control DevicesAbela DrrsÎncă nu există evaluări

- Mobile Phone DetectorDocument10 paginiMobile Phone DetectorNikhil MundraÎncă nu există evaluări

- Manual FOR Electrical Engineering Laboratory IiDocument41 paginiManual FOR Electrical Engineering Laboratory IiWilliams A.Subanth Assistant ProfessorÎncă nu există evaluări

- Edc Lab Manuals Third SemesterDocument56 paginiEdc Lab Manuals Third SemesterSprout GigsÎncă nu există evaluări

- Oscillators & Applications LongstreetDocument4 paginiOscillators & Applications Longstreetnapoleon_velasc3617Încă nu există evaluări

- Errata For The 5th EditionDocument3 paginiErrata For The 5th EditionLeonardo Bellincanta de SouzaÎncă nu există evaluări

- Lecture - 11:: Applications of Operational AmplifiersDocument47 paginiLecture - 11:: Applications of Operational AmplifiersMani Kandan KÎncă nu există evaluări

- Circuits Laboratory Experiment 9 Operational AmplifiersDocument22 paginiCircuits Laboratory Experiment 9 Operational AmplifiersSridhar JayaramanÎncă nu există evaluări

- 6AntiAndLogAmplifiers (4p) PDFDocument24 pagini6AntiAndLogAmplifiers (4p) PDFCostel CojocaruÎncă nu există evaluări

- Operational AmplifierDocument44 paginiOperational AmplifierPoornima GnÎncă nu există evaluări

- Analog Lab 8: Jadavpur UniversityDocument11 paginiAnalog Lab 8: Jadavpur UniversityIron PatriotÎncă nu există evaluări

- Basic Op-Amp CircuitsDocument12 paginiBasic Op-Amp CircuitsRoxana100% (1)

- Chap4c - OpAmp - Stability (v1.0)Document43 paginiChap4c - OpAmp - Stability (v1.0)Al AidenÎncă nu există evaluări

- Infineon Coreless Transformer Bodo ART v1.0 enDocument3 paginiInfineon Coreless Transformer Bodo ART v1.0 enLullaby summerÎncă nu există evaluări

- OPA2134Document9 paginiOPA2134King NordiÎncă nu există evaluări

- LM358 Diodes PDFDocument14 paginiLM358 Diodes PDFgonzalo benitezÎncă nu există evaluări

- BEE (R-20) : Parameters Half-Wave Rectifiers Full-Wave RectifiersDocument4 paginiBEE (R-20) : Parameters Half-Wave Rectifiers Full-Wave Rectifierssurya pratapÎncă nu există evaluări

- 3 TcHxW6S6 k3B8VuouvuA Mod2 Devices QC Whiteoutsremoved Mar 2021Document173 pagini3 TcHxW6S6 k3B8VuouvuA Mod2 Devices QC Whiteoutsremoved Mar 2021Umair Ejaz ButtÎncă nu există evaluări

- AN218 Vehicle Detection Using AMR SensorsDocument10 paginiAN218 Vehicle Detection Using AMR SensorsIndra Panggalo100% (1)

- LM118/LM218/LM318 Operational Amplifiers: General DescriptionDocument15 paginiLM118/LM218/LM318 Operational Amplifiers: General DescriptionHo PhuÎncă nu există evaluări

- Op-Amp Circuits, and Circuit Analysis. How To Measure: 2-Stage OpampDocument2 paginiOp-Amp Circuits, and Circuit Analysis. How To Measure: 2-Stage OpampShachi P GowdaÎncă nu există evaluări

- Power Electronics Text BookDocument264 paginiPower Electronics Text BookZakaria MourtadiÎncă nu există evaluări

- F. Y. B. Sc. (Computer Science) Examination - 2010: Total No. of Questions: 5) (Total No. of Printed Pages: 4Document76 paginiF. Y. B. Sc. (Computer Science) Examination - 2010: Total No. of Questions: 5) (Total No. of Printed Pages: 4Amarjeet DasÎncă nu există evaluări

- Chapter 4 Op-AmpDocument25 paginiChapter 4 Op-Ampfirst lastÎncă nu există evaluări

- BTech Textile Tech Syllabus PDFDocument48 paginiBTech Textile Tech Syllabus PDFDurjoy RoyÎncă nu există evaluări

- Design and Development of A Portable Recording System For Simultaneous Acquisition of SCG and ECG SignalsDocument6 paginiDesign and Development of A Portable Recording System For Simultaneous Acquisition of SCG and ECG SignalsSyed Shouvik Islam (sSi)Încă nu există evaluări