Documente Academic

Documente Profesional

Documente Cultură

Ese 00523 en

Încărcat de

Hoàng Minh ÁiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ese 00523 en

Încărcat de

Hoàng Minh ÁiDrepturi de autor:

Formate disponibile

Return to menu

Instruction Manual

Unique Single Seat Valve - Manually Operated

TD 461-584

TD 461-583

ESE00523EN1

2008-11

Return to menu

Return to menu

Declaration of Conformity

The designating company

Alfa Laval

Company Name

Albuen 31, DK-6000 Kolding, Denmark

Address

+45 79 32 22 00

Phone No.

hereby declare that

Single Seat Valve

Manually Operated

2008

Denomination

Type

Year

is in conformity with the following directive:

- Machinery Directive 98/37/EEC

- Pressure Equipment Directive 97/23/EC category 1 and subjected to assessment procedure

Module A.

Manager, Product Centres,

Compact Heat Exchangers & Fluid Handling

Bjarne Sndergaard

Title

Name

Alfa Laval Kolding

Company

Signature

Designation

Return to menu

Return to menu

Table of contents

The information contained herein is correct at the time of issue but may be subject to change without prior notice.

1. Safety...................................................................................................... 6

1.1 Important information......................................................................... 6

1.2 Warning signs.................................................................................... 6

1.3 Safety precautions............................................................................. 7

2. Installation.............................................................................................. 8

2.1. Unpacking/Delivery........................................................................... 8

2.2. General installation............................................................................ 9

2.3. Welding.......................................................................................... 10

3. Operation.............................................................................................. 11

3.1 Operation......................................................................................... 11

3.2 Trouble shooting.............................................................................. 13

3.3 Recommended cleaning.................................................................. 14

4. Maintenance......................................................................................... 16

4.1 General maintenance....................................................................... 16

4.2 Dismantling of valve......................................................................... 18

4.3 Plug seal replacement...................................................................... 18

4.4 Assembly of valve............................................................................ 18

5. Technical data....................................................................................... 19

5.1 Technical data.................................................................................. 19

6. Parts List and Service Kits.................................................................. 20

6.1 Unique Single Seat Valve................................................................. 20

Return to menu

1.1 Important information

1.2 Warning signs

Unsafe practices and other important information are emphasized in this manual.

Warnings are emphasized by means of special signs.

Always read the manual before using the valve!

WARNING!

Indicates that special procedures must be followed to avoid severe personal injury.

CAUTION!

Indicates that special procedures must be followed to avoid damage to the valve.

NOTE!

Indicates important information to simplify or clarify practices.

General warning:

Caustic agents:

1. Safety

Return to menu

1. Safety

1.3 Safety precautions

All warnings in the manual are summarized on this page.

Pay special attention to the instructions below so that severe personal injury and/or damage to the valve are avoided.

Installation

- Always read the technical data thoroughly (see chapter 5).

- Never touch the valve or the pipelines when processing hot liquids or when sterilizing.

- Never dismantle the valve with valve and pipelines under pressure.

- Never dismantle the valve when it is hot.

Operation

- Never dismantle the valve with valve and pipelines under pressure.

- Never dismantle the valve when it is hot.

- Always read the technical data thoroughly (see chapter 5).

- Never touch the valve or the pipelines when processing hot liquids or when sterilizing.

- Always rinse well with clean water after the cleaning.

Always handle lye and acid with great care.

Maintenance

- Always read the technical data thoroughly (see chapter 5).

- Never service the valve when it is hot.

- Never service the valve with valve and pipelines under pressure.

Return to menu

2.1 Unpacking/Delivery

2. Installation

The instruction manual is part of the delivery. Study the instructions carefully.

The items refer to parts list and service kits section.

The valve is supplied as separate parts as standard (for welding).

The valve is assembled before delivery, if it is supplied with fittings.

Step 1

CAUTION!

Alfa Laval cannot be held responsible for incorrect unpacking.

Check the delivery for:

1. Complete valve, shut off valve or change-over valve.

2. Delivery note.

3. Instruction Manual.

TD 461-585

Step 2a

Shut-off valve:

Complete handle.

Bonnet (20)

Clamp (19).

Valve plug (23).

Valve body (22).

Step 2b

Change-over valve:

Complete handle.

Bonnet (20)

2 x clamp (19).

Valve plug (27).

Lower valve body (22).

Valve seat (28).

Upper valve body (26).

TD 461-586

Step 3

Remove possible packing materials from the valve/valve parts.

Inspect the valve/valve parts for visible transport damages.

Avoid damaging the valve/valve parts.

Return to menu

2. Installation

2.2 General installation

Study the instructions carefully and pay special attention to the warnings!

The valve has welding ends as standard but can also be supplied with fittings.

Step1

- Always read the technical data thoroughly (see chapter 5).

CAUTION!

Alfa Laval cannot be held responsible for incorrect installation.

Step 2

Never touch the moving parts during operation

Moving parts!

TD 461-589

Step 3

It is recommended to install the valve so that the flow is

against the closing direction to avoid water hammer.

Avoid water

hammer!

Inlet

TD 461-590

Inlet

Step 4

Avoid stressing the valve.

Pay special attention to:

- Vibrations.

- Thermal expansion of the pipelines.

- Excessive welding.

- Overloading of the pipelines.

Risk of damage!

TD 461-591

Return to menu

2. Installation

2.3 Welding

Study the instructions carefully.

The valve is supplied as separate parts to facilitate the welding.

The items refer to the parts list and service kits section.

Check the valve for smooth operation after welding.

Step 1

Always install valves with more than one valve body so

that the seals between the valve bodies can be replaced.

Do not weld more than one valve body into the system.

Measurement A is depending on body combination and

piping solution.

TD 461-592

Please see actual PD-sheet for further information

Step 2

Assemble the valve in accordance with the steps in section 4.4.

Pay special attention to the warnings!

TD 461-593

TD 461-614

Step 3

Pre-use check:

1. Open and close the valve several times to ensure that it

operates smoothly.

Pay special attention to the warnings!

TD 461-594

10

Return to menu

3. Operation

3.1 Operation

Study the instructions carefully and pay special attention to the warnings!

Ensure that the valve operates smoothly.

The items refer to the parts list and service kits section.

Step 1

- Always read the technical data thoroughly (see chapter 5).

CAUTION!

Alfa Laval cannot be held responsible for incorrect operation.

Step 2

Never touch the valve or the pipelines when processing hot

liquids or when sterilizing.

Burning danger!

TD 461-595

Step 3

Never touch the moving parts during operation.

Moving parts!

TD 461-589

Step 4

Lubrication of valves:

1. Ensure smooth movement between lip seal (25)

and plug stem (23, 27).

2. Lubricate with Klber Paraliq GTE 703 if necessary.

(see section 4.1)

Shut-off valve

Change-over valve

TD 461-597

TD 461-615

11

Return to menu

3. Operation

3.1 Operation

Step 5

Lubrication of crank mechanism

1. Ensure smooth movement of the crank mechanism

(the crank is lubricated before delivery).

2. Lubricate with Molykote Longterm 2 plus if necessary.

TD 461-598

12

Return to menu

3. Operation

3.2 Trouble shooting

Pay attention to possible faults. Study the instructions carefully.

The items refer to the parts list and service kits section

NOTE!

Study the maintenance instructions carefully before

replacing worn parts. - See section 4.1!

Problem

Cause/result

Repair

External product leakage

Worn or product affected lip

- Replace the seals

seal and/or O-ring

- Replace with seals of a

different rubber grade

Internal product leakage

- Worn or product affected

- Replace the seal

plug seal

- Replace with a seal of a

different rubber grade

- Product deposits on

- Frequent cleaning

the seat and/or plug

- Product pressure exceeds

- Replace with a high pressure actuator

actuator specification

- Use auxiliary air on the spring side

- Reduce product pressure

Water hammer

The flow direction is the

same as the closing direction

The valve does not

Product pressure exceeds

open/close

specification

The flow direction should be

against the closing direction

Reduce pressure

13

Return to menu

3. Operation

3.3 Recommended cleaning

The valve is designed for cleaning in place (CIP). CIP = Cleaning In Place.

Study the instructions carefully and pay special attention to the warnings!

NaOH = Caustic Soda.

HNO3 = Nitric acid.

Step 1

Caustic danger!

Always handle lye and acid with great care.

Always use

rubber gloves!

Always use

protective goggles!

Step 2

Never touch the valve or the pipelines when sterilizing.

Burning danger!

TD 461-595

Step 3

Clean the plug and the seats correctly.

Pay special attention to the warnings!

Lift and lower valve plug momentarily!

Shut-off valve

TD 461-599

Change-over valve

Lift/lower

valve plug

TD 461-600

4

Step 4

Examples of cleaning agents:

Use clean water, free from clorides.

1. 1% by weight NaOH at 70o C

1 kg

+

NaOH

100 l

water

= Cleaning agent

2.2 l

+

33% NaOH

100 l

water

= Cleaning agent

2. 0.5% by weight HNO3 at 70o C

14

0.7 l

+

53% HNO3

100 l

water

= Cleaning agent

Return to menu

3. Operation

3.3 Recommended cleaning

Step 5

Always rinse!

1. Avoid excessive concentration of the cleaning agent

2. Adjust the cleaning flow to the process

3. Always rinse well with clean water after the cleaning.

Clean water

Cleaning agents

Step 6

NOTE!

The cleaning agents must be stored/disposed of in accordance

with current rules/directives.

15

Return to menu

4. Maintenance

4.1 General maintenance

Maintain the valve regularly.

Study the instructions carefully and pay special attention to the warnings!

Always keep spare rubber seals and lip seals in stock.

Step 1

-

Always read the technical data thoroughly (see chapter 5).

CAUTION!

All scrap must be stored/disposed of in accordance with

current rules/directives.

Step 2

Atmospheric

pressure

required!

- Never service the valve when it is hot.

- Never service the valve with valve and pipelines

under pressure.

Burning danger!

TD 461-602

Step 3

Never stick your fingers through the valve ports.

Cutting danger!

TD 461-589

Step 4

Never touch the moving parts during operation.

Moving parts!

TD 461-589

16

Return to menu

4. Maintenance

4.1 General maintenance

Maintain the valve regularly.

Study the instructions carefully.

Always keep spare rubber seals and lip seals stock.

Check the valve for smooth operation after service.

Below are some guidelines for maintenance and lubrication intervals. Please note that the guidelines are for normal

working conditions in one shift.

Product wetted

seals

Preventive

Replace after

maintenance

12 months depending

on working conditions

Maintenance after

Replace at the

leakage (leakage

end of the day

normally starts slowly)

Planned

- Regular inspection

maintenance for leakage and

smooth operation

- Keep a record of

the valve

- Use the statistics for

planning of inspections

Replace after leakage

Lubrication

Before fitting

Klber Paraliq GTE 703

or similar USDA H1

approved oil/grease

Pre-use check:

1. Open and close the valve several times to

ensure that it operates smoothly.

Pay special attention to the warnings!

TD 461-589

Recommended spare parts

Service kits (see chapter 6)

17

Return to menu

4. Maintenance

4.2 Dismantling of valve

4.3 Plug seal replacement

4.4 Assembly of valve

Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly.

Step 1a

Shut-off valve:

1. Remove cap, loosen screw and remove the washer by

sliding it sideways.

2. Loosen and remove clamp.

3. Lift away the crank.

4. Remove valve plug.

5. Remove O-ring, lip seal and bushing in bonnet.

(Use bushing tool and rubber mallet).

Pay special attention to the warnings!

TD 461-959

Note! For plug seal replacement please see section 4.3.

TD 461-601

Step 1b

Change-over valve:

1. Loosen and remove lower clamp.

2. Lift away the crank and upper valve body.

3. Remove cap, loosen screw and remove the washer by

sliding it sideways.

4. Loosen and remove upper clamp.

5. Lift away the crank.

6. Remove valve plug.

7. Remove seat and O-rings.

8. Remove O-ring, lip seal and bushing in bonnet.

(Use bushing tool and rubber mallet. See drawing, step 1a).

Pay special attention to the warnings!

Note! For plug seal replacement please see section 4.3.

4.3 Plug seal replacement

1. Remove old seal ring using a knife, screwdriver or similar.

Be careful not to damage metal parts.

2. Pre-mount plug seal without pressing it into the groove.

3. Squeeze plug seal into the groove using opposite pressure points.

4. Release compressed air behind plug seal.

Note! For plug seal replacement please read instruction in service kit.

4.4 Assembly of valve

Reverse order of 4.2, Dismantling of valve.

Lubricate O-ring (21) and lip seal (25) with Klber Paraliq GTE 703.

Note!

Do not forget to screw in lower set screw 7 when assembling the valve.

It acts as a stroke stop. Without this screw the valve can be opened so

far that the crank comes off. In some valve sizes the flats on the plug

stem may enter into the lip seal, which will then leak.

18

TD 461-607

Return to menu

5. Technical data

5.1 Technical data

It is important to observe the technical data during installation, operation and maintenance.

Inform the personnel about the technical data.

Data - valve

Max. product pressure........................................................ 1000 kPa (10 bar)

Min. product pressure......................................................... Full vacuum (depending on product specifications)

Temperature range............................................................. -10o C to + 140o C (standard EPDM seal)

Materials - valve/crank mechanism

Product wetted steel parts.................................................. 1.4404 (316L) (internal Ra < 0.8 m)

Other steel parts................................................................. 1.4301 (304)

Plug seal............................................................................. EPDM / PTFE (TR2)

Other product wetted seals................................................ EPDM (standard)

Optional product wetted seals............................................ HNBR and FPM

19

Return to menu

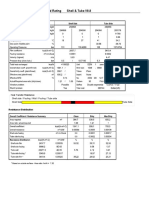

6. Parts List and Service Kits

6.1 Unique Single Seat Valve - Shut-off

The parts list includes all items.

Parts List

Pos.

1

2

3

4

8

6

7

19

20

21

22

23

23.1

23.2

24

25

Service Kits

Qty.

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

Denomination

Denomination

Crank

Handle (included in pos. 1)

Cap

Washer

Stem holder

Guide

Set screw

Clamp

Bonnet

O-ring, EPDM (standard)

Valve body, lower

Plug, shut off, complete

Plug, shut off

Plug seal, EPDM (standard)

Bushing

Lip seal, EPDM (standard)

Product wetted parts (Shut-off)

D: Service kits - EPDM

D: Service kits - HNBR

D: Service kits - FPM

Item number

25 mm / DN 25

Service kit, EPDM...........................................9611-92-6501

Service kit, HNBR.......................................... 9611-92-6507

Service kit, FPM.............................................9611-92-6513

38 mm / DN 40

Service kit, EPDM...........................................9611-92-6502

Service kit, HNBR...........................................9611-92-6508

Service kit, FPM.............................................9611-92-6514

51 mm / DN 50

Service kit, EPDM...........................................9611-92-6503

Service kit, HNBR...........................................9611-92-6509

Service kit, FPM.............................................9611-92-6515

63.5 mm / DN65

Service kit, EPDM...........................................9611-92-6504

Service kit, HNBR...........................................9611-92-6510

Service kit, FPM.............................................9611-92-6516

76.1 mm / DN 80

Service kit, EPDM...........................................9611-92-6505

Service kit, HNBR...........................................9611-92-6511

Service kit, FPM.............................................9611-92-6517

101.6 mm / DN 100

Service kit, EPDM...........................................9611-92-6506

Service kit, HNBR...........................................9611-92-6512

Service kit, FPM.............................................9611-92-6518

TD 461-666

20

Return to menu

6. Parts List and Service Kits

6.1 Unique Single Seat Valve - Shut-off

This page shows an exploded drawing of Unique Single Seat

Valve, shut-off.

21

Return to menu

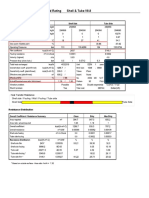

6. Parts list and Service Kits

6.1 Unique Single Seat Valve - Change-over

Parts List

Pos.

1

2

3

4

8

6

7

19

20

21

22

24

25

26

27

27.1

27.2

28

Service Kits

Qty.

1

1

1

1

1

1

2

2

1

3

1

1

1

1

1

1

2

1

Denomination

Denomination

Crank

Handle (included in pos. 1 )

Cap

Washer

Stem holder

Guide

Set screw

Clamp

Bonnet

O-ring, EPDM (standard)

Valve body, lower

Bushing

Lip seal, EPDM (standard)

Valve body, upper

Plug, change over, complete

Plug, change over

Plug seal, EPDM (standard)

Seat

Product wetted parts (Change-over)

Item number

25 mm / DN 25

Service kit, EPDM...........................................9611-92-6579

Service kit, HNBR...........................................9611-92-6585

Service kit, FPM.............................................9611-92-6591

38 mm / DN 40

Service kit, EPDM...........................................9611-92-6580

Service kit, HNBR...........................................9611-92-6586

Service kit, FPM.............................................9611-92-6592

51 mm / DN 50

Service kit, EPDM...........................................9611-92-6581

Service kit, HNBR...........................................9611-92-6587

Service kit, FPM.............................................9611-92-6593

63.5 mm / DN65

Service kit, EPDM...........................................9611-92-6582

Service kit, HNBR...........................................9611-92-6588

Service kit, FPM.............................................9611-92-6594

D: Service kits - EPDM

D: Service kits - HNBR

D: Service kits - FPM

76.1 mm / DN 80

Service kit, EPDM...........................................9611-92-6583

Service kit, HNBR...........................................9611-92-6589

Service kit, FPM.............................................9611-92-6595

101.6 mm / DN 100

Service kit, EPDM...........................................9611-92-6584

Service kit, HNBR...........................................9611-92-6590

Service kit, FPM.............................................9611-92-6596

TD 461-667

22

Return to menu

6. Parts list and Service Kits

6.1 Unique Single Seat Valve - Change-over

This page shows an exploded drawing of Unique Single Seat

Valve, change-over.

23

Return to menu

How to contact Alfa Laval

Contact details for all countries are

continually updated on our website.

Please visit www.alfalaval.com to

access the information direct.

S-ar putea să vă placă și

- Aspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceDocument1 paginăAspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceHoàng Minh ÁiÎncă nu există evaluări

- Aspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceDocument1 paginăAspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceHoàng Minh ÁiÎncă nu există evaluări

- 20/01/2018 17:43 MATLAB Command Window 1 of 1Document1 pagină20/01/2018 17:43 MATLAB Command Window 1 of 1Hoàng Minh ÁiÎncă nu există evaluări

- E5006 ModelDocument1 paginăE5006 ModelHoàng Minh ÁiÎncă nu există evaluări

- CLCDocument3 paginiCLCHoàng Minh ÁiÎncă nu există evaluări

- HFHFDocument37 paginiHFHFHoàng Minh ÁiÎncă nu există evaluări

- FLooding FactorDocument20 paginiFLooding FactorHoàng Minh ÁiÎncă nu există evaluări

- 4.1 16163070-BOM - 01 CommentedDocument3 pagini4.1 16163070-BOM - 01 CommentedHoàng Minh ÁiÎncă nu există evaluări

- Script File To Calculate The Fugacity of A Mixture Based On TheDocument5 paginiScript File To Calculate The Fugacity of A Mixture Based On TheHoàng Minh ÁiÎncă nu există evaluări

- FLoodingDocument17 paginiFLoodingHoàng Minh ÁiÎncă nu există evaluări

- FLoodingDocument4 paginiFLoodingHoàng Minh ÁiÎncă nu există evaluări

- Info RASCHIG Super Ring 250Document24 paginiInfo RASCHIG Super Ring 250Hoàng Minh ÁiÎncă nu există evaluări

- NCNCDocument2 paginiNCNCHoàng Minh ÁiÎncă nu există evaluări

- BVBVDocument67 paginiBVBVHoàng Minh ÁiÎncă nu există evaluări

- GDGDFDocument8 paginiGDGDFHoàng Minh ÁiÎncă nu există evaluări

- Dresser Italia S.R.L.: MasoneilanDocument1 paginăDresser Italia S.R.L.: MasoneilanHoàng Minh ÁiÎncă nu există evaluări

- EML PumpDocument6 paginiEML PumpJordan Alejandro CoronaÎncă nu există evaluări

- Dresser Italia S.R.L.: MasoneilanDocument1 paginăDresser Italia S.R.L.: MasoneilanHoàng Minh ÁiÎncă nu există evaluări

- READMEDocument4 paginiREADMEHoàng Minh ÁiÎncă nu există evaluări

- GPSADocument13 paginiGPSAMuhammadÎncă nu există evaluări

- 03RMPCODocument58 pagini03RMPCOHoàng Minh ÁiÎncă nu există evaluări

- Optimized Gas Treating, Inc PDFDocument1 paginăOptimized Gas Treating, Inc PDFHoàng Minh ÁiÎncă nu există evaluări

- Find The Best Licensing Option For Your Business - WangDocument36 paginiFind The Best Licensing Option For Your Business - WangHoàng Minh ÁiÎncă nu există evaluări

- Optimized Gas Treating, IncDocument1 paginăOptimized Gas Treating, IncHoàng Minh ÁiÎncă nu există evaluări

- 02APCOVDocument48 pagini02APCOVHoàng Minh ÁiÎncă nu există evaluări

- Seal 1Document6 paginiSeal 1Hoàng Minh ÁiÎncă nu există evaluări

- Profit Controller Design Considerations: Process SolutionsDocument41 paginiProfit Controller Design Considerations: Process SolutionsHoàng Minh ÁiÎncă nu există evaluări

- Profit Controller - Implementation Course 4516: Process SolutionsDocument5 paginiProfit Controller - Implementation Course 4516: Process SolutionsHoàng Minh ÁiÎncă nu există evaluări

- Ese 00528 enDocument36 paginiEse 00528 enHoàng Minh ÁiÎncă nu există evaluări

- Api ListDocument2 paginiApi ListHoàng Minh Ái50% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Overview On Image Captioning TechniquesDocument6 paginiOverview On Image Captioning TechniquesWARSE JournalsÎncă nu există evaluări

- Evolution of Computers: A Brief HistoryDocument15 paginiEvolution of Computers: A Brief HistoryshinÎncă nu există evaluări

- PLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalDocument5 paginiPLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalTriston DurbinÎncă nu există evaluări

- CA Ashish Dewani - Resume-1Document2 paginiCA Ashish Dewani - Resume-1Payal JainÎncă nu există evaluări

- CBL Training ReportDocument12 paginiCBL Training ReportSwapnil Modak100% (1)

- Active-Passive VoiceDocument18 paginiActive-Passive VoiceDivya JainÎncă nu există evaluări

- Aw MD700 Manual G10 150706Document73 paginiAw MD700 Manual G10 150706Heraldo Ulguim Luis OliveiraÎncă nu există evaluări

- Chem 361 Separation Methods IntroDocument8 paginiChem 361 Separation Methods IntroTwum SomoahÎncă nu există evaluări

- Druckabschaltventil enDocument4 paginiDruckabschaltventil enSakthi Sekar CbiÎncă nu există evaluări

- Listening Script 11Document11 paginiListening Script 11harshkumarbhallaÎncă nu există evaluări

- Clinical TeachingDocument29 paginiClinical TeachingJeonoh Florida100% (2)

- Topic 3Document28 paginiTopic 3Ashraf YusofÎncă nu există evaluări

- A. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềDocument5 paginiA. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềPham Thuy HuyenÎncă nu există evaluări

- Capacitor BanksDocument49 paginiCapacitor BanksAmal P RaviÎncă nu există evaluări

- Presentation SkillsDocument22 paginiPresentation SkillsUmang WarudkarÎncă nu există evaluări

- Mitigating arc ash hazards design constraintsDocument6 paginiMitigating arc ash hazards design constraintswaqas_a_shaikh4348Încă nu există evaluări

- DUPLICATE BILL TITLEDocument8 paginiDUPLICATE BILL TITLEMohammed AhmedÎncă nu există evaluări

- Tiger AnddragonDocument61 paginiTiger AnddragonAdil SiddiquiÎncă nu există evaluări

- Bicycle Repair ManualDocument162 paginiBicycle Repair Manualrazvancc89% (9)

- 182 - GE8076, GE6075 Professional Ethics in Engineering - 2 MarksDocument17 pagini182 - GE8076, GE6075 Professional Ethics in Engineering - 2 Markssharon sylvia .sÎncă nu există evaluări

- Adiabatic Production of Acetic AnhydrideDocument7 paginiAdiabatic Production of Acetic AnhydrideSunilParjapatiÎncă nu există evaluări

- Electronics Today 1977 10Document84 paginiElectronics Today 1977 10cornel_24100% (3)

- BOQ Sample of Electrical DesignDocument2 paginiBOQ Sample of Electrical DesignAshik Rahman RifatÎncă nu există evaluări

- Halo Outdoor slmt1000 - slmt1000wDocument1 paginăHalo Outdoor slmt1000 - slmt1000wFrank MoyaÎncă nu există evaluări

- FMBXXX Quick Manual v3.5Document18 paginiFMBXXX Quick Manual v3.5AMÎncă nu există evaluări

- Shadow The Hedgehog (Sonic Boom)Document11 paginiShadow The Hedgehog (Sonic Boom)Tamajong Tamajong PhilipÎncă nu există evaluări

- LADY BroshureDocument2 paginiLADY BroshureMcGabi GabrielÎncă nu există evaluări

- Jupiter - The Giant Planet That Destroys CometsDocument2 paginiJupiter - The Giant Planet That Destroys Cometsmaiche amarÎncă nu există evaluări

- Mid SemDocument1 paginăMid SemvidulaÎncă nu există evaluări