Documente Academic

Documente Profesional

Documente Cultură

My 2

Încărcat de

Shubham BaloniTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

My 2

Încărcat de

Shubham BaloniDrepturi de autor:

Formate disponibile

Project By :- Divyansh

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHL

A

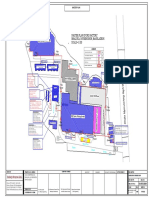

G O V I N D P U R I M E T R O S TAT I O N

NEW DELHI-20

NAME

DIVYANSH

BRANCH

CIVIL ENGG. (IV SEM)

: 1403041017

B.T.E. ROLL NO.

CLASS ROLL NO.: 17GBC14

DATE

GUIDED BY

APRIL 13, 2016

PRASHANT RAMTEKE

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

Submitted To:- PRASHANT RAMTEKE

Submitted By:-

DIVYANSH

PROJECT ON BUILDING

COMPONENTS

BASIC COMPONENTS OF A BUILDING

There are two basic components of a building.

1. Sub Structure: The part of building that is constructed

below ground level.

2. Super Structure: The part of building that is above ground

level

SUB-STRUCTURE

Footing and plinth of a building are a part of a sub-structure.

This part of building safely transfers the load of building to

the underlying soil. Therefore, footing should be of such

strength that it can easily carry the building load. Failure of

footing leads to failure of building. Width and depth of

footing should be designed according to the load of a

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

building coming on it plus the bearing capacity of soil.

Bottom part of footing is generally constructed of Plain

Cement Concrete (P.C.C) or Reinforced Cement Concrete

(R.C.C). Steps are made above (P.C.C) by using bricks,

stones or concrete to reach the plinth level. Generally,

Damp Proof Course (D.P.C) is laid on plinth level. This layer

stops the penetration of moisture to the super structure part

of a building.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

SUPER STRUCTURE

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

Super-structure is a part of structure that is above plinth

level (P.L). Generally columns and walls are constructed in

super structure. Following are the important parts of superstructure.

WALLS

Walls are the vertical elements on which the roof finally rests. They can be

made of different materials like bricks, stones, mud, concrete blocks,

lateritic blocks etc. If the walls are very long, columns can be provided to

carry the roof.

Walls provide privacy and enclosure. Walls also provide security and

protection against natural elements such as wind, rain and sunshine.

Openings are to be provided in wall for access and ventilation

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

DAMP PROOF COURSE (DPC)

Damp proof course is a layer of water proofing material such as asphalt or

waterproof cement. Walls are constructed above the damp proof course.

Damp proof course prevents surface water from rising into the walls.

Dampness reduces the strength of the walls and creates unhealthy living

conditions. Also it affects the paint and plaster and increasing the cost of

maintenance.

Damp proofing layer is not required where a plinth beam is constructed,

because the plinth beam already performs like a DPC .

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

ROOF

The roof provides protection for the building and the people living in it. The

roof rests on the walls and requires proper anchoring so that wind and

other mechanical impact cannot destroy it. A roof can have different shapes

but it is always either flat or sloping.Roof is typically made of RCC, stone

slab, tiles etc.

PLINTH BEAM

A plinth beam is constructed depending upon the type of the structure of

the building and nature of the soil. It provides additional stability in regard

to settlements of the building and earthquake damages.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

FLOOR

This is the surface on which we do most of our activities. Floorings is laid

over the filling of the plinth and on subsequent floors.

Flooring can be done with different materials, but care must be given that

the ground below the floor is well compacted. Flooring is done to prevent

dampness from rising to the top and to have a firm platform that can be

kept hygienic and clean.

STAIRS

A stair is a sequence of steps and it is provided to afford the means of

ascent and descent between the floors and landings.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

The apartment or room of a building in which stair is located is called

staircase. The space or opening occupied by the stair is called a stairway.

There are different kind of stairs are used in buildings, like RCC stair,

wooden stair, metal stair, brick stair etc.

.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

OPENINGS

Openings are normally provided in the walls as door, windows and

ventilators.

Doors provide access; windows and ventilators provide light and

ventilation.

Lintels are constructed just above the openings. It is normally a stone slab

or a concrete slab.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

Sill is the part of the wall that is just below the window.

Lintels are constructed to hold up the walls above the openings. In

earthquake prone areas a continuous lintel beam is provided all over the

walls.

.SURFACES / FINISHES

External finishes are the outer

most layer of protection,

which protect the structure

from weathering. Internal

finishes are the layers given

on internal faces. They give

durability and pleasing

appearance to the inside

.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

FIELD VISIT - II

AT

Govindpuri Metro Station,

Okhla Ph-3

Location Of Site : This site is located at Govindpuri metro station Okhla

Phase-III,

Anandmayi Marg, New Delhi 110020.

What is Metro Rail ?

Metro Rail is a Mass Rapid Transport System (MRTS).

It is a convenient, fast, efficient, reliable, modern, user friendly,

comfortable and affordable mode of urban transport.

It is safe and eco-friendly.

It is electric and requires only 1/5th energy per passenger km

compared to road based transport systems.

Brings about a more equitable allocation of road space by

encouraging greater use of public transport.

Provides point to point connectivity.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

Pillar

In architecture and structural engineering is a structural element that

transmits, through compression, the weight of the structure above to other

structural elements below. In other words, a column is a compression

member. The term column applies especially to a large round support

(the shaft of the column) with a capital and a base or pedestal and made of

stone, or appearing to be so. A small wooden or metal support is typically

called a post, and supports with a rectangular or other non-round section

are usually called piers. For the purpose of wind or earthquake engineering,

columns may be designed to resist lateral forces. Other compression

members are often termed "columns" because of the similar stress

conditions. Columns are frequently used to support beams or arches on

which the upper parts of walls or ceilings rest. In architecture, "column"

refers to such a structural element that also has certain proportional and

decorative features. A column might also be a decorative element not

needed for structural purposes; many columns are "engaged", that is to say

form part of a wall.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

BEARING

A bearing is a machine element that constrains relative motion to

only the desired

motion, and reduces friction between moving parts. The design of the beari

ng may

vary.For example, provide for free linear movement of the moving part or fo

r free rotate

around a fix axis, or it may prevent a motion by controlling the vectors of n

ormal forces

that bearing on the moving parts. Many bearings also facilitate the desired

motion as

much as possible , such as by minimizing friction ,bearing are classified bro

adly

according to the type of operation , the motions allowed ,or to the direction

s of the loads

(forces) applied to the parts .

TYPES OF BEARING

Animation of ball bearing: - The inner ring rotates and the outer rin

g is

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

stationary.

Plain bearing :- Also known by the specific styles ; bushing , journa

l bearing ,

sleeve bearing , rifle bearing

Rolling element

:- Bearing such as ball bearings and roller bearings

s.

Jewel bearings: - Bearing in which the load is carried by rolling the

axle slightly

off centre.

Fluid bearing: - Bearing in which the load is carried by a gas or liqu

id.

Fllexure bearring: - Bearring in which the motiion is suppoorted by a lload ele

mennt

BRIDGE BEARINg

A bridge bearing iss a component of a bridge which typically provides a

resting surface

between bridge piers and the bridge deck. The purpose of a bearing is to

allow

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

controlleed movemeent and thereby reduce the stresses involved.

Movement could be

thermal expansion or contraction, or movement from other sources such

as seismic

activity. There are several different types of bridges bearing which are

used depending

on a number of different factors including the bridges span. The oldest

form of bridge

bearing is simply two plates resting on top of each other. A common

form of moder bridge is the elastommeric bridg bearing. Another type of

bridge bearing is the mechanical bridge bearing. Thhere are sevveral

types of mechannical bridge bearing, suuch

as the piinned beariing, which is turn incllude specifiic types succh as the

rocker bearinng,

and the roller bearing. Anothe type of mechanical bearing is the fixed

beearing, whiich

allows rotation, but not other forms of movement

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

EPOXY LIQUID

coll

oqui

Epoxy is a term used to denote both the basic

al

components

na

and the

me

cured end

for

products

the

of epo

xy

epo

resins,

as

xide

well as

func

tion

al

gro

up.

Epo

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

xy resins, also known as polyepoxides, are a class

of reactiveprepolymers and polymers which contain

epoxide groups. Epoxy resins may be reacted (crosslinked) either with themselves through catalytic

homopolymerisation, or with a wide range of coreactants including polyfunctional amines, acids (and

acid anhydrides), phenols, alcohols and thiols. These

co-reactants are often referred to as hardeners or

curatives, and the cross-linking reaction is commonly

referred to as curing. Reaction of polyepoxides with

themselves or with polyfunctional hardeners forms

a thermosetting polymer, often with high mechanical

properties, temperature and chemical resistance.

Epoxy has a wide range of applications, including

metal coatings, use in electronics / electrical

components, high tension electrical insulators, fiberreinforced plastic materials and structural adhesives.

TENDOn wires

.

Prestressed concrete is a method for overcoming concretes natural weakne

ss in tension

it can be used to produce beams , floors or bridges with a longer span than

is practical

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

with ordinary reinforced concrete . It is often used in commercial and resid

ential

construction as a foundation slab . Prestressing tendon ( generally of high t

ensile

strength steel cable or rods ) are used to provide a clamping load which pro

duces a

compressive stress that balances the tensile stress than that the concrete c

ompression

member would otherwise experience due to a bending load . Traditional rei

nforced

concrete is based on the use of steel reinforcement bars , rebars , inside po

ured

concrete . Prestressing can be accomplished in three ways : pre- tensioned

concrete,

and bonded or unbounded post-tensioned concrete.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

HINGE BEAM (PIN BEAM)

Beam is one of the most common structure member used in structure f

or supporting

vertical loads which are perpendicular to the axis of the beam. Usually

the axial force

If internal forces along the axis of the beam can be ignored as there is either no

horizontal load acting on the beam or thhe horizontaal loads can be neglected. The

refore,

the internal forces in beam are shear and bending moment

commonly. However, when the

applied force to the beam is not perpendicular to thhe axis of thhe beam,

the internal axial

forces should also be considered.

An internal hinge is a hinge linkage located betweeen ends of two separate beams

at

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

which here may be discontinuous slope from one side of the hinge linkage to the o

ther,

and the allowed dissplacement on both sides of the hinge linkage separating the t

wo

beams continuous.

Loads are applied along the pan of a beam. In general, the loads considered in stat

ic are

the concentrated load P and distributed load W. Concentrated load is the one which

can

be considered as acting at a point although the load is distributed over a small leng

th of

the beam in practicce. Distributed load is the one which cannot be considered as a

cting

at a point because the load is spread over a considerable length of the b

eam. The

distributed load is usually expressed as load W per unit length. The distributed loa

d is

An internal hinge is a hinge linkage located betweeen ends of two separate beams

at

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

which here may be discontinuous slope from one side of the hinge linkage to the o

ther,

and the allowed dissplacement on both sides of the hinge linkage separating the t

wo

beams continuous.

Loads are applied along the pan of a beam. In general, the loads conside

red in static are

the concentrated load P and distributed load W. Concentrated load is the

one which can

be considered as acting at a point although the load is distributed over a

small length of

the beam in practicce. Distributed load is the one which cannot be consi

dered as acting

at a point because the load is spread over a considerable length of the b

eam. The

Distributed load is usually expressed as load W per unit length. The distributed loa

d is

called uniformly distributed looad when the load W per unit length is a constant or

uniform from point to point over the length of load distributed are grouped as vary

ing

distributed load, e.g. linear varying distributed load order to determine the reaction

for

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

statically in determine beams, additional equations can be taken from the relations

hips

based on the properties of thee beam and the resistance to bending under the appl

ied

loads. If there are totally only two unknown reaction involved in all suppp

orts, the beam

is not stable for any applied loads and thhe beam is partially constrained only. Ther

efore

beam supported by two rollers is partiallly constrainned. The beam is sta

ble when the

applied loads is vertical and he beam will move when the horizontal components o

f the

applied loads is not equal to zero. Therefore in practice, a horizontal rest

raints used in

one suppport to restrain the beam from rotating or moving horizontal.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

HOLLOW

pillar

A hollow str

uctural sect

ion (HSS) is

a typeof me

tal profile wi

th a hollow t

ubular crosssection.HSS, esspecially rectangular sections, are commonly used

in welded steel fres wheere

member experienc loading in multiple directions.efficient shapes

for this multiple axis loading as hey have unniform geommetry along

two or more cross-sectional axis, and thus uniform strength characteristics. Th

is make

them good choice for columns. They also have excellent resistance t

o torssion

HSS can also be used as beams, although wide flange or I-beam shapes are

in many

cases a more efficient structural shape for this application. However, the HS

S has

superior resistance to lateral torsion buckling.

The flat square surfaces of rectangular HSS can ease construction, and they

are

something preferred for architectural aesthetics in exposed structures, alth

ough

elliptical HSS are becoming more popular in exposed structures for the sam

e aestheticreasons.

In the recent past, HSS was commonly available in mild steel, such as A500

grade B.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

Today, HSS is commonly available in mild steel, A500 grade C. other steel g

rades

available for HSS are A847(weathering steel), A1065(large section up to 50

inch sq)

(made with SAW process), and recently approved A1085

(higher strength, tightertolerances than A500).

USE

OF CIRCU

UMN OVER RECTANGULAR COLUMN

LAR COL

The resistance to bending or deflection of a circular cross section is

higher than a

rectangular cross section with the same area. In addition, the load

required to buckle a

column with a circular cross section is the same around its perimet

er. But a beam with

a rectangular cross section may bend first in either of two axes.

Rectangular c/s or Shear walls > square c/s > Round c/s.

There are some logical reasons to it.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

1. It is way much easier to construct and cast rectangular or sq

uare columns than

circular ones. This is primarily for the ease of working with the

shuttering (the

cast prepared to pour concrete) and to support it from it collap

sing due to

pressure while the concrete is still in flow-able form. The squar

e and rectangular

ones eventually are easier and less costly to cast.

2. Due to architectural appearance. All (mostly) the buildings ha

ve flat walls and

other vertical surfaces, which are at right angles to each other

. To successfully

camouflage the skeleton of beams and columns, square or rec

tangular (more

better) is preferred. The rectangular columns can be easily lev

eled by the walls

and other partitions. People in present times do not want colu

mns stranding in

their way.

3. You would find circular columns as pillars of Bridges because

there you dont

need to flush them to anything. Also circular looks a aesthetic

there. They are

also present in buildings but only in large areas like common p

laces, auditoriums

or fire assembly zones, where you have enough space for the

m not to hinder any

movement of people or look bad with flat surfaces

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

EXPANSION JOINT

Bridge expansion joints are designed to allow for continuous traffic

between structures while accommodating movement, shrinkage, and

temperature variations on reinforced and prestressed concrete,

composite, and steel structures. They stop the bridge from bending out

of place in extreme conditions, and also allow enough vertical

movement to permit bearing replacement without the need to

dismantle the bridge expansion joint. There are various types, which

can accommodate movement from 30 to 500 millimetres (1.2 to

19.7 in). They include joints for small movement (EMSEAL BEJS, XJS,

JEP, WR, WOSd, and AC-AR), medium movement (Etic EJ, Wd), and

large movement (WP, Etic EJF/SFEJ).

Modular expansion joints are used when the movements of a bridge

exceed the capacity of a single gap joint or a finger type joint. A

watertight system, invented by the Swiss company Mageba, is

designed on a modular basis and can be tailored to satisfy the specific

requirements of almost any structure. Modular multiple-gap expansion

joints can accommodate movements in every direction and rotations

about every axis. They can be used for longitudinal movements of as

little as 160 mm, or for very large movements of well over 3000 mm.

The total movement of the bridge deck is divided among a number of

individual gaps which are created by horizontal surface beams. The

individual gaps are sealed by watertight elastomeric profiles, and

surface beam movements are regulated by an elastic control system.

The drainage of the joint is via the drainage system of the bridge deck.

Certain joints feature so-called sinus plates on their surface, which

reduce noise from over-passing traffic by up to 80%.

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

Project By :- Divyansh

G.B.PANT INSTITUTE OF TECHNOLOGY, OKHLA

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CE231 Course SyllabusDocument4 paginiCE231 Course SyllabusAlyfer del Rosario100% (1)

- Analysis of Concrete Beams Prestressed and Posttensioned With Externally Unbonded Carbon Fiber Reinforced Polymer TendonsDocument14 paginiAnalysis of Concrete Beams Prestressed and Posttensioned With Externally Unbonded Carbon Fiber Reinforced Polymer TendonsTan Duy LeÎncă nu există evaluări

- Chapter Fluid MachineryDocument50 paginiChapter Fluid MachineryWan AimanÎncă nu există evaluări

- Structural Analysis & Design of MSBDocument29 paginiStructural Analysis & Design of MSBthak49100% (1)

- Live Load Distribution Factor CalculationsDocument5 paginiLive Load Distribution Factor CalculationsBunkun15Încă nu există evaluări

- HVAC System Vendor and Subcontactor List: Technical Finance Product Manufactures Country Subcontractor Offer RemarkDocument1 paginăHVAC System Vendor and Subcontactor List: Technical Finance Product Manufactures Country Subcontractor Offer RemarkMuhammad ElbarbaryÎncă nu există evaluări

- Civil Engineering: Year ofDocument4 paginiCivil Engineering: Year ofdipinnediyaparambathÎncă nu există evaluări

- Ceo QuizDocument1 paginăCeo QuizJohn Lesther PabiloniaÎncă nu există evaluări

- Repair of Concrete in Highway Bridges - A Practical GuideDocument100 paginiRepair of Concrete in Highway Bridges - A Practical GuideAmer Gonzales100% (1)

- Types of DrawingsDocument25 paginiTypes of DrawingsRajesh Prabtani100% (1)

- Astm-53-A-53m-07Document22 paginiAstm-53-A-53m-07Allen EspeletaÎncă nu există evaluări

- Master Plan of Ors Factory Bhaluka, Mymensingh, Bangladesh SCALE 1:100Document1 paginăMaster Plan of Ors Factory Bhaluka, Mymensingh, Bangladesh SCALE 1:100Safe circle bdÎncă nu există evaluări

- Macropoxy 646 SEDocument4 paginiMacropoxy 646 SESleyda MunozÎncă nu există evaluări

- April Monthly Progress ReportDocument78 paginiApril Monthly Progress ReportDaniel EvansÎncă nu există evaluări

- Advanced Geotechnical Engineering PDFDocument4 paginiAdvanced Geotechnical Engineering PDFAnil MarsaniÎncă nu există evaluări

- Manual de Usuario de Calentador EléctricoDocument12 paginiManual de Usuario de Calentador Eléctricohxzg7d7w8dÎncă nu există evaluări

- Chapter 2 B 1 Arch ButressDocument19 paginiChapter 2 B 1 Arch ButressYasin Mohamed BulqaazÎncă nu există evaluări

- 291 en Concrete Shear Wall v01Document11 pagini291 en Concrete Shear Wall v01ismal sirajÎncă nu există evaluări

- Design of Machine Elements - Design Under Variable LoadingDocument76 paginiDesign of Machine Elements - Design Under Variable LoadingPraveenÎncă nu există evaluări

- Hvac Watt Per Square Meter CalculationsDocument2 paginiHvac Watt Per Square Meter Calculationsmohammed_hatem96% (24)

- Classification of Soils and Soil-Aggregate Mixtures For Highway Construction PurposesDocument9 paginiClassification of Soils and Soil-Aggregate Mixtures For Highway Construction PurposesEng. Al Motasem DarawishÎncă nu există evaluări

- N2 Underbalance Calculations 4TH EditionDocument8 paginiN2 Underbalance Calculations 4TH Editionislam atifÎncă nu există evaluări

- 콘크리트 사장교의 장기거동 해석을 위한 예측 모델의 비교Document108 pagini콘크리트 사장교의 장기거동 해석을 위한 예측 모델의 비교Jin-hwan KimÎncă nu există evaluări

- Twist Faults GuideDocument26 paginiTwist Faults GuideJakJhonÎncă nu există evaluări

- 113AQ032017 MSM PDFDocument2 pagini113AQ032017 MSM PDFPeeka Prabhakara RaoÎncă nu există evaluări

- Pelat (TT)Document444 paginiPelat (TT)Dummy EmailÎncă nu există evaluări

- Crude Oil Tank ConstructionDocument3 paginiCrude Oil Tank ConstructionEpiphany ChijiokeÎncă nu există evaluări

- Bills of Quantity For Road WorksDocument5 paginiBills of Quantity For Road WorksFaizal Hakimi100% (1)

- Thin Shell Buckling Pit-Falls - NASADocument88 paginiThin Shell Buckling Pit-Falls - NASAPrasad PbnÎncă nu există evaluări

- Concrete TechnologyDocument16 paginiConcrete Technologysefatwrdk21Încă nu există evaluări