Documente Academic

Documente Profesional

Documente Cultură

Uhlted States Patent (19) (11) Patent Number: 4,579,373: Neal Et Al. (45) Date of Patent: Apr. 1, 1986

Încărcat de

daniel_iosif_glTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Uhlted States Patent (19) (11) Patent Number: 4,579,373: Neal Et Al. (45) Date of Patent: Apr. 1, 1986

Încărcat de

daniel_iosif_glDrepturi de autor:

Formate disponibile

UHlted States Patent [19]

[11] Patent Number:

Neal et al.

[45]

[54]

INSULATED CONCENTRIC TUBING JOINT

ASSEMBLY

[76]

Inventors:

[56]

Date of Patent:

Apr. 1, 1986

References Cited

U.S. PATENT DOCUMENTS

861,828

7/1907

Grindrod et al. ............. .. 285/392 X

William J. Neal, 1700 Rivercrest Dr.,

#1412, Sugarlandy Tex, 77478;

2,805,871 9/1957 Hammon ................... .. 285/393 X

3,928,903 12/1975 Richardson et a1. .

285/47 X

Robert V_ Verity, 1456 Domingo Rd.

4,332,401

6/1982 Stephenson et a1. .

4,340,245

7/1982

Fullerton Cam 92633

_

Appl No" 785011

[22]

Flled:

Stalder

..1... .. .... .. ...

4,341,392 7/1982 van Dongeren

4,396,211 8/1983

4,415,184 11/1983

[21]

4,423,778

285/47

. . . ..

285/53

285/138 x

McStravick et al. ............... .. 285/47

Stephenson et a1. ............... ,. 285/47

1/1984 Goldsmith .................... .. 285/138 x

Primaijv Examiner-Thomas F. Callaghan

Oct 7 1985

Attorney, Agent, or FirmArno1d S. Cohn

[57]

Related U5, Application Data

[63]

4,579,373

An insulated pipe assembly and joint apparatus and

continuation of Ser No 395129 Jul 6 1982 abam

domed

'

'

'

ABSTRACT

'

method for assembly thereof utilized in hydrocarbon

recovery steam processes whereby a pre-tensile stressed

tubing and pre-compressive stress casing are assembled

with a sealably threaded combination coupling, this said

[51]

[52]

Int. Cl.4 .................................. .. F16L 59/14

U.S. Cl. ...................................... .. 285/47; 29/446;

[58]

Field of Search ................. .. 285/47, 53, 393, 392,

29/455 R; 138/149; 285/138

285/138; 138/149; 29/446, 455 R

assembly being a pre-assembled unit which ultimately in

application is strung with additional units and held to

gether with a plurality of standard pipe couplings.

4 Claims, 4 Drawing Figures

4,579,373

INSULATED CONCENTRIC TUBING JOINT

ASSEMBLY

mechanical and self sustaining combination coupling

connecting the inner tubing and outer casing.

A further object of the invention is to provide a joint

which is leak resistant and positively sealed.

A further object of the invention is to provide a joint

CONTINUATION APPLICATION

This application is a continuation application based

on the applicants pending application Ser. No. 395,127,

?led July 6, 1982 and now abandoned.

A further object of the invention is to provide a pipe

length assembly which can be connected to other such

CROSS REFERENCES TO RELATED

APPLICATIONS

utilizing standard threaded couplings.

The foregoing and similar objects, advantages and

There are no cross-references in this Application for

Letters Patent.

features may be achieved by the INSULATED CON

CENTRIC TUBULAR JOINT ASSEMBLY for con

veying heated ?uids such as steam and the like from the

FEDERALLY SPONSORED RIGHTS

ground source to the down hole formation as described

There are no rights to any inventions made under or

in conjunction with any Federally Sponsored Research

and Development Programs.

having no welds which are critical to its structural in

tegrity.

in the following description read in conjunction with

the drawings and claims.

DESCRIPTION OF THE PRIOR ART

In Trucano, US. Pat. No. 1,140,633, an insulating

BACKGROUND OF THE INVENTION

system is disclosed. This system utilizes a threaded cou

The ?eld of this invention is in connection with the

pling which connects the inner tubing. A flanged cou

end threaded and intermediate annularly insulated tubu

pling is welded to the outer casing. The difference be

lar conduits utilized in the steam injection of oil wells.

tween the subject invention and that in Trucano is that

In the recovery of high viscosity hydrocarbons it is

Trucano requires welding and the instant invention

common practice to supply high temperature steam to

does not. The joining of pipe sections in Trucano is

the producing formation. The steam is directed to the

accomplished through a ?anged joint.

formation through a tubing string which is hung from

In Ricker, US. Pat. No. 1,909,075, a coupling for

the surface. The tubing string is made up of multiple

double pipe sections is disclosed. Concentric spacers are

lengths with threaded end connections to facilitate in

welded to the inner pipe and then welded to the outer

stallation into and removal from the well. It is common

pipe after ?rst cutting into the outer pipe at the outer

practice to insulate the outer surface of the tubing to

weld locations. The subject matter of this invention

prevent heat loss and maintain the enthalpy of the

does not require welding. A sealing collar communi

steam. The well environment usually requires that this

cates with the inner tubing and is mechanically self

insulation be protected from abrasion and contact with

sealing in reliance on the compressive contact between

liquids by an outer jacket, or casing. The tubing, insula

the end of the outer casing and the mating surface of the

tion, and outer casing are preassembled in individual

collar.

lengths to facilitate installation into and removal from

In Alexandru, US. Pat. No. 3,574,357, a typical insu

the well.

lated tubing assembly for a deep well string is disclosed.

Since the tubing and casing are therefore exposed to 40 The inner tube has an enlarged upper end and a lower

different temperatures, the linear expansion rate of the

end that is self-centralizing. This slip joint allows the

tubing and of the outer casing are different. Due to this

longitudinal expansion thereof. The difference between

fact, there are typically three (3) types of joints pres

the invention in hand and Alexandru uses the slip joint

ently used which so connect the outer casing to the

concept and the subject invention is a hard type joint.

tubing. The joints are either hard, ?exible, or slip-type. 45

DESCRIPTION OF THE DRAWINGS

In a hard joint the tubing and easing are welded to

gether on the body of the tubing a short distance from

In FIG. 1 the outward vertical appearance of the

each end. The exposed tubing end connections are used

outer casing 25 is illustrated.

to join adjacent lengths, and therefore the tubing be

comes the principal tensile load carrying member. The

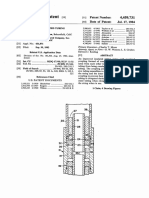

In FIG. 2 a section view of the INSULATED CON- .

CENTRIC TUBULAR JOINING ASSEMBLY is

high strength steel tubing, normally used in this applica

illustrated.

In FIG. 3, a section view of the inner coupling 30 is

tion, has poor weldability. Leakage or tensile failure

often occurs in this type of joint due to stress cracks that

illustrated.

In FIG. 4, the end preparation of outer casing 25 is

develop in the weld or in the heat affected zones of the

55 illustrated.

tubing.

Referring to FIG. 1, an outer casing 25 vertically

Flexible joints are often used which utilize bellows

oriented is illustrated. In actual use, a plurality of said

type devices to seal the annular insulation space be

outer casing 25 would be utilized, each one being con

tween the tubing and outer jacket while allowing rela

nected to the adjacent one by utilizing the outer cou

tively free expansion of the tubing with respect to the

outer casing. A potential weakness of this design is the 60 pling 50. Each outer coupling 50 connects and seals the

outer diameter of each adjacent said outer casing 25.

susceptability of the relatively thin metal bellows to

Referring to FIG. 2, an assembly view of the INSU

corrosion failure.

LATED CONCENTRIC TUBULAR JOINT AS

Slip joints have been utilized which usually consist of

SEMBLY is illustrated. The innermost member is tub~

a piston ring or packing material arrangement. The

disadvantage of this joint is the leakage potential inher 65 ing 20. The inside diameter of said tubing 20 is in

contact with steam and other pressurized media which

ent in slip joints.

is transmitted to the down hole formation. For the most

An object of this invention is to provide a prestressed

part said tubing 20 is constant thickness until at the

insulated concentric tubing and outer casing unit, and a

4,579,373

proximity of each end a transition zone 23 is provided.

The inside diameter of said tubing 20 remains constant

throughout the length of said tubing 20. At each end of

device, the tubing and outer casing return to thermal

equilibrium, establishing a tensile prestress in the tubing

and a corresponding compressive prestress in the outer

the tubing 10 a tapered male thread 22 is cut which

communicates with a combination coupling 30 at the

casing.

combination coupling female tapered thread 32. The

combination coupling 30 is axially positioned on the

steam injection service, the tubing and outer casing

approach minimum acceptable within design limit stress

tubing male thread 22 at the time when the tubing 20 is

levels.

hot and the outer casing 25 is cold. The seating of the

A standard casing coupling 50 permits the assembly

of a plurality of INSULATED CONCENTRIC TU

BULAR JOINT ASSEMBLY during ?eld installation.

said combination coupling 30 with the said outer casing

25 occurs at each chamfered end of said outer casing 25

and combination coupling mating surface 35. Prior to

the assembly of the said outer casing 25, tubing 20 and

two (2) each of said combination coupling 30, a plural

ity of centralizing rings 61 and insulation 60 is provided

within the annular space between said outer casing 25

and said inner tubing 20. Combination couplings 30 are

externally taper threaded after ?nal assembly with outer

casing male tapered thread 29 and combination cou

pling outer thread 33 (see FIG. 3). The said outer casing

male tapered thread 29 and combination coupling male

tapered thread 33 is a common thread continuously cut

at the same time after ?nal assembly of tubing 20, the

The magnetic or prestress is such that in the intended

DESCRIPTION OF THE PREFERRED

EMBODIMENTS

During the steam injection process for production of

high viscosity hydrocarbons from the producing forma

tion, it is necessary to supply high pressure and high

temperature steam to the producing formation as an aid

to encourage the flow of high viscosity oil. The INSU

LATED CONCENTRIC TUBULAR JOINT AS

SEMBLY permits the injection of said steam with a

minimum heat loss. The said INSULATED CONCEN

TRIC TUBULAR JOINT ASSEMBLY relies on taper

combination coupling 30, and outer casing 25. Each said

threaded connections instead of welded connections for

assembly is serially connected utilizing a standard cas 25

ing coupling 50 and maintaining the gap 70 vis-a-vis the

outer coupling inner thread 51, outer casing male thread

29 and combination coupling outer thread 33.

Referring to FIG. 3, a section view of the combina

tion coupling 30 is illustrated. Its inner diameter is fully

threaded with combination coupling inner thread 32.

The centralizing diameter 34 slideably communicates

with the inner diameter of outer casing 25 so centraliz

ing the sub-assembly. The combination coupling mating

surface 35 is cut at an angle 36 which so seats with

chamfer 26 (see FIG. 4). The combination coupling

~'- outer thread 33 is continuously cut at the same time as

" the outer casing male thread 29 after ?nal assembly.

Referring to FIG. 4, the end of the outer casing 25 is

its structural integrity.

High temperature steam is exposed to the inner tub

ing 20 which is insulated from the outer casing; there

fore, marked temperature gradients exist. The inner

tubing temperature is substantially greater than the

temperature of the outer casing. In hard type joints

which rely on welding to join the tubing and outer

casing, these thermal gradients cause severe stress levels

at the juncture point of the inner tubing and outer cas

ing. The calculation of stress is dif?cult to predict due

to the in?uence of stress concentration factors which

are dependent on the joint types. It is ideal not to have

high levels of stress at the heat effected zone of welded

joints.

An embodiment of this invention is the assembly

procedure of an inner tubing and outer casing which

results in a low and predictable stress level during steam

'mating surface 35 (see FIG. 3).

injection service. This embodiment permits the stress

SUMMARY OF THE INVENTION

levels to be minimized in the following manner. The

An inner tubing member is externally taper threaded 45 assembly of the INSULATED CONCENTRIC TU

- illustrated. Each said end is chamfered to an angle 36 to

* so seat and communicate with combination coupling

at each end to facilitate the communication of a combi

BULAR JOINT ASSEMBLY occurs when the inner

nation coupling. Each inner tubing end is of increased

thickness of strength reinforcement.

The combination coupling is internally threaded to

tubing 20 with one (1) combination coupling 30 thread

ably connected to one end, and a plurality of centraliz

ing rings 61 and insulation 60, is then centrally located

communicate with each end of an inner tubing. The two

(2) outside diameters are stepped, the smaller diameter

being utilized to centralize itself within the inside diam

eter of an outer casing. The juncture of the diameters is

prepared in an angulated shape to provide a seating

surface. The outside diameter is of sufficient diameter to

allow itself to be trued and simultaneously threaded

with each end of the outer casing. The outer casing is

cut to a ?nished length, based on the length of its re

spective inner tube, and the magnitude of prestress re

within an outer casing 25 which is at room or ambient

temperature. The inner tubing 20 is then heated to ex

pand it suf?ciently in the axial direction to allow the

second combination coupling 30 to be threadably con

nected to the remaining end of the inner tubing 20, upon

cooling, without interference with the outer casing 25.

The outer casing 25 and combination coupling mating

surface 35 seat on each other placing the outer casing 25

at a predictable compressive stress level and the inner

tubing 20 at a predictable tensile stress level. In the

operational mode, the tubing and outer casing operate

quired in the assembled unit. Each end of the outer

at near zero stress, an ideal condtion.

casing is then chamfered before assembly.

Each end of the tubing 20 is of heavier thickness to

The ?nal assembly of the foregoing is accomplished

accommodate the tubing male thread 22. A combination

by heating the inner tubing to expand its length and

coupling 30 is threadably connected to each end of the

allow installation of the second combination coupling

without interference with the outer casing. The tubing 65 inner tubing 20. The said combination coupling 30 has a

is heated by insertion of an electrical resistance heater

centralizing diameter 34 which communicates centrally

or like heating machanism or device into the tubing

bore. After assembly and withdrawal of the heating

with the inside diameter of the outer casing 25 and inner

tubing 20 and is sealed at each end of this sub-assembly

4,579,373

6

tension and said outer tubing member is under

compression for coupling to an internally threaded

by means of the tapered thread 32 in the combination

coupling 30.

casing coupling member.

At the conclusion of the assembly of the tubing 20,

2. The apparatus as set forth and de?ned in claim 1,

outer casing 25 and combination coupling 30, the outer

diameter of the ends of the outer casing 25 which coin 5 wherein said composit tubing joint has a plurality of

cide with the outer diameter of the combination cou

centralizing rings disposed between said inner and outer

pling 30 are trued, turned and simultaneously taper

concentrically disposed tubing members along the

threaded. The stringing of said assemblies are then so

length of said tubing members between the tubular

connected utilizing a plurality of industrially standard

coupling members, and insulation material disposed

casing couplings 50.

between said centralizing rings.

It is intended and desired that the embodiments

shown and described in detail herein shall be deemed

3. A method of constructing a composite tubing joint

for use in an oil well including the steps of:

disposing an inner tubing member within an outer

illustrative in nature and not restrictive in order that

various modi?cations thereof will be apparent to those

skilled in the art and be applied thereto without depart

ing from the scope of the present invention.

Having just described the invention what we claim

being new is:

1. A composite insulated tubing joint for use in a

tubular string in an oil well including;

inner and outer concentrically disposed tubing mem

bers, each having outer threaded ends:

tubular coupling members at each end of said tubing

tubing member where the inner tubing member has

externally threaded ends;

disposing insulating material between the inner and

outer tubing members along their length;

threadedly attaching tubular coupling members to

the externally threaded ends of the inner tubing

joint until a shoulder on a coupling member en

gages the end surface of the outer tubing member

and where each of the coupling members has an

outer surface which has the same diameter as the

members, said coupling members respectfully hav

ing an outer wall surface with stepped ?rst and

25

second diametrical portions de?ning an abutment

perature to an elevated temperature to elongate the

shoulder;

inner tubing member and tightening the coupling

each of said tubular coupling members having inter

members while the inner tubing member is at an

nal threads for threaded coupling to the outer

threads on an end of said inner tubing member,

elevated temperature to bring the coupling mem

bers into engagement with the end surfaces of the

each of said ?rst diametrical portions being dis

posed within the inner wall of said outer tubing

outer tubing member;

returning the temperature of the inner tubing member

member and each of said second diametrical por

tions extending to the outer surface of said outer

tubing member;

outer surface of the outer tubing member;

heating the inner tubing member from ambient tem

to ambient temperature thereby placing the outer

35

said tubing coupling members being threadedly ad

tubing member under compression and the inner

tubing member under tension; and

forming a continous externally threaded surface on

the outer surface of the coupling member and on

the ends of the outer tubing member for threaded

justable on said inner tubing member when said

inner tubing member is heated to engage the abut

ment shoulders of the coupling members with an

end of an outer tubing member so that upon cool

coupling to standard casing couplings.

4. The method as set forth in claim 3 wherein the

ing of said inner tubing member said outer tubing

member is under compression and said inner tubing

member is under tension;

each of said tubular coupling members and said outer

heating of the inner tubing member is such that the

elongation of the inner tubing member is suf?cient to

equalize the compression of the outer tubing member to

tubing member having a common continuous ex 45 the tension of the inner tubing member for operational

conditions in a well bore.

ternal threaded at each end of said outer tubing

member when said inner tubing member is under

55

65

=k

S-ar putea să vă placă și

- Method of Increasing Strength of Welded Slat Assembly for Inflatable PackersDocument6 paginiMethod of Increasing Strength of Welded Slat Assembly for Inflatable Packersmohammadreza91Încă nu există evaluări

- Scientific American Supplement, No. 470, January 3, 1885De la EverandScientific American Supplement, No. 470, January 3, 1885Încă nu există evaluări

- United States Patent (19) : Patent Number: (45) Date of PatentDocument10 paginiUnited States Patent (19) : Patent Number: (45) Date of PatentMichael JordanÎncă nu există evaluări

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- Tube Saport PDFDocument4 paginiTube Saport PDFjr110livecomÎncă nu există evaluări

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDe la EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerEvaluare: 5 din 5 stele5/5 (1)

- Tài liệu5Document12 paginiTài liệu5Hoàng ĐứcÎncă nu există evaluări

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Inflatable Packer Reinforcement MethodDocument5 paginiInflatable Packer Reinforcement Methodmohammadreza91Încă nu există evaluări

- Scientific American Supplement, No. 392, July 7, 1883De la EverandScientific American Supplement, No. 392, July 7, 1883Încă nu există evaluări

- Wellhead Connector H4 TypeDocument9 paginiWellhead Connector H4 Typeste7ieÎncă nu există evaluări

- Us3266821 PDFDocument5 paginiUs3266821 PDFDiogo CorreaÎncă nu există evaluări

- Us4506432 PDFDocument5 paginiUs4506432 PDFchemsÎncă nu există evaluări

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 paginiTEPZZ - 4 885B - T: European Patent SpecificationshamsÎncă nu există evaluări

- United States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008Document7 paginiUnited States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008aqil_shamsiÎncă nu există evaluări

- Dresser Industries, Inc. v. The United States, R. H. Baker & Company, Inc., Graver Tank and Manufacturing Co., and Western-Knapp Engineering Company, Third-Party, 432 F.2d 787, 3rd Cir. (1970)Document21 paginiDresser Industries, Inc. v. The United States, R. H. Baker & Company, Inc., Graver Tank and Manufacturing Co., and Western-Knapp Engineering Company, Third-Party, 432 F.2d 787, 3rd Cir. (1970)Scribd Government DocsÎncă nu există evaluări

- United States PatentDocument6 paginiUnited States Patentaless2056Încă nu există evaluări

- Cement BasketDocument4 paginiCement Basketराजकुमार यादवÎncă nu există evaluări

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Document5 paginiUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91Încă nu există evaluări

- Us 5360355Document6 paginiUs 5360355kimscribd66Încă nu există evaluări

- Pipe Sealing PATENTDocument23 paginiPipe Sealing PATENTDaniel InemughaÎncă nu există evaluări

- United States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977Document16 paginiUnited States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977liÎncă nu există evaluări

- Ion Cluster Acceleration for Subnuclear Particle ProductionDocument9 paginiIon Cluster Acceleration for Subnuclear Particle ProductionVictor Von DoomÎncă nu există evaluări

- Fabrication of Steel PipeworkDocument10 paginiFabrication of Steel PipeworkjoseritoÎncă nu există evaluări

- US4893426Document7 paginiUS4893426Jean DelaronciereÎncă nu există evaluări

- US460Document5 paginiUS460bbÎncă nu există evaluări

- Patent for ambient air vaporizer with dissimilar materials couplingDocument12 paginiPatent for ambient air vaporizer with dissimilar materials couplingJaime Ocampo SalgadoÎncă nu există evaluări

- Fluid Power Fluid Power Equipment Tutorial - Pipe Work: Outcome 2Document12 paginiFluid Power Fluid Power Equipment Tutorial - Pipe Work: Outcome 2cataiceÎncă nu există evaluări

- Bonded Slab Post-Tension SystemDocument7 paginiBonded Slab Post-Tension SystemMaris BauersÎncă nu există evaluări

- J. W. Mayo Etal Electrical-Connector: Filed June 1965Document3 paginiJ. W. Mayo Etal Electrical-Connector: Filed June 1965Kevin CooperÎncă nu există evaluări

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pagini11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91Încă nu există evaluări

- (1956), June 14) US2970812 Drum Type Heat ExchangerDocument4 pagini(1956), June 14) US2970812 Drum Type Heat ExchangeraegosmithÎncă nu există evaluări

- LLLLLLLLLLL: United States Patent (191Document9 paginiLLLLLLLLLLL: United States Patent (191Mark EdowaiÎncă nu există evaluări

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Document25 paginiPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleÎncă nu există evaluări

- Us2996100 PDFDocument8 paginiUs2996100 PDFerzrzretgertfertgeÎncă nu există evaluări

- Dual split tubing hanger seal for oil and gas wellsDocument10 paginiDual split tubing hanger seal for oil and gas wellsabodolkuhaaÎncă nu există evaluări

- Inbound 969313096968477811Document7 paginiInbound 969313096968477811REANNÎncă nu există evaluări

- Composite Bridge Plug System (US Patent 6796376)Document16 paginiComposite Bridge Plug System (US Patent 6796376)PriorSmartÎncă nu există evaluări

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Document7 paginiUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348Încă nu există evaluări

- C 1541 - 04 Qze1ndeDocument5 paginiC 1541 - 04 Qze1ndecarlosÎncă nu există evaluări

- Dec. 29, 1970 Jean-Claude Asscher 3,550,228: Filed Aug. 6, 1968 4 Sheets-Sheet LDocument6 paginiDec. 29, 1970 Jean-Claude Asscher 3,550,228: Filed Aug. 6, 1968 4 Sheets-Sheet LVansala GanesanÎncă nu există evaluări

- Separable Attachment Plug Patent from 1904Document3 paginiSeparable Attachment Plug Patent from 1904Jose Leonardo CabrejoÎncă nu există evaluări

- Login Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationDocument8 paginiLogin Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationFilipÎncă nu există evaluări

- Siled Sept. 8, 1966: T, N. NccomeDocument5 paginiSiled Sept. 8, 1966: T, N. NccomeliÎncă nu există evaluări

- Us 5988287Document14 paginiUs 5988287mohammadreza91Încă nu există evaluări

- ASWP Manual - Section 3 - Joints (10!6!12)Document12 paginiASWP Manual - Section 3 - Joints (10!6!12)shah1980Încă nu există evaluări

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Document7 paginiUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91Încă nu există evaluări

- Cumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2Document3 paginiCumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2monem2014Încă nu există evaluări

- Babani-Crystal Set ConstructionDocument16 paginiBabani-Crystal Set ConstructionRonLayton100% (2)

- 11.6 Longitudinal Finned Double-Pipe ExchangersDocument14 pagini11.6 Longitudinal Finned Double-Pipe Exchangersvatsal07Încă nu există evaluări

- Welding Brazing Pipe TubeDocument4 paginiWelding Brazing Pipe TubeJohn Campbell UÎncă nu există evaluări

- Segmented Sealing Lips Reduce Cracking in Turbine Disk SealsDocument4 paginiSegmented Sealing Lips Reduce Cracking in Turbine Disk SealsshamsÎncă nu există evaluări

- United States Patent: Price (45) Date of Patent: Apr. 22, 2008Document11 paginiUnited States Patent: Price (45) Date of Patent: Apr. 22, 2008Aslam KhanÎncă nu există evaluări

- Connecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsDocument12 paginiConnecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsOkta Pariantoro Budi SetiawanÎncă nu există evaluări

- FGR Eadips Ebook 04.2011 10 ChapterDocument10 paginiFGR Eadips Ebook 04.2011 10 ChapterIvor VlahovićÎncă nu există evaluări

- Coupling InformationDocument4 paginiCoupling Informationamanpreet_ahujaÎncă nu există evaluări

- Pipe Drafting Q and ADocument7 paginiPipe Drafting Q and AHamed FaragÎncă nu există evaluări

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDocument15 pagini915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelÎncă nu există evaluări

- Literature On Boiler Tube Fitup by ExpandingDocument17 paginiLiterature On Boiler Tube Fitup by Expandingakv030011Încă nu există evaluări

- Essential Gas Pipe Network Data Management in Arcgis: April 2019Document22 paginiEssential Gas Pipe Network Data Management in Arcgis: April 2019daniel_iosif_glÎncă nu există evaluări

- Ac DTC CheckDocument8 paginiAc DTC Checkdaniel_iosif_glÎncă nu există evaluări

- Ac DTC CheckDocument8 paginiAc DTC Checkdaniel_iosif_glÎncă nu există evaluări

- Divi Snippets BookDocument51 paginiDivi Snippets Bookdaniel_iosif_glÎncă nu există evaluări

- ServiceOperationsGuide 062608 PDFDocument62 paginiServiceOperationsGuide 062608 PDFdaniel_iosif_glÎncă nu există evaluări

- Optimization of Biodiesel Production From Sunflower OilDocument5 paginiOptimization of Biodiesel Production From Sunflower Oildaniel_iosif_glÎncă nu există evaluări

- D815 Metric Section2 Belt and Chain Drives PDFDocument245 paginiD815 Metric Section2 Belt and Chain Drives PDFdaniel_iosif_glÎncă nu există evaluări

- Ac DTC CheckDocument8 paginiAc DTC Checkdaniel_iosif_glÎncă nu există evaluări

- BGT Cloud Computing ExtractDocument34 paginiBGT Cloud Computing ExtractAnuj SharmaÎncă nu există evaluări

- ReadmeDocument1 paginăReadmedaniel_iosif_glÎncă nu există evaluări

- Emerging-Risks Medical MalpracticeDocument1 paginăEmerging-Risks Medical Malpracticedaniel_iosif_glÎncă nu există evaluări

- Specification For Safe Working in The Vicinity of CadentDocument15 paginiSpecification For Safe Working in The Vicinity of Cadentdaniel_iosif_glÎncă nu există evaluări

- 151 D00004 PDFDocument4 pagini151 D00004 PDFdaniel_iosif_glÎncă nu există evaluări

- Jurnal Biodiesel SunflowerDocument6 paginiJurnal Biodiesel SunflowerTaufik HidayatÎncă nu există evaluări

- Make Your Own BiofuelDocument6 paginiMake Your Own Biofueldaniel_iosif_glÎncă nu există evaluări

- Clean Cities Fact Sheet Straight Vegetable Oil As A Diesel Fuel PDFDocument2 paginiClean Cities Fact Sheet Straight Vegetable Oil As A Diesel Fuel PDFdaniel_iosif_glÎncă nu există evaluări

- BiodieselDocument36 paginiBiodieselda8d8ash8Încă nu există evaluări

- Rhesus Type and Abo Incompatibility in Jaundiced NeonatesDocument7 paginiRhesus Type and Abo Incompatibility in Jaundiced Neonatesdaniel_iosif_glÎncă nu există evaluări

- Forbes Saudi ArabiaDocument14 paginiForbes Saudi Arabiadaniel_iosif_glÎncă nu există evaluări

- MuseScore enDocument227 paginiMuseScore endaniel_iosif_glÎncă nu există evaluări

- GrantPrideco Drill Pipe Data TablesDocument24 paginiGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezÎncă nu există evaluări

- Concentric Tubing Completion System for Communicating Fluids Between a Surface Structure and Subsea WellboreDocument21 paginiConcentric Tubing Completion System for Communicating Fluids Between a Surface Structure and Subsea Wellboredaniel_iosif_glÎncă nu există evaluări

- Pedia Nr-4 2008 Art-6 PDFDocument11 paginiPedia Nr-4 2008 Art-6 PDFdaniel_iosif_glÎncă nu există evaluări

- Recommended Practice For Occupational Safety For Onshore Oil and Gas Production OperationsDocument36 paginiRecommended Practice For Occupational Safety For Onshore Oil and Gas Production Operationsdaniel_iosif_glÎncă nu există evaluări

- Drilling ProblemsDocument59 paginiDrilling ProblemsRaghav Kiran100% (3)

- Oilfield Acronym Update Aug 2015Document37 paginiOilfield Acronym Update Aug 2015Eswar PrasadÎncă nu există evaluări

- Us 4459731Document7 paginiUs 4459731daniel_iosif_glÎncă nu există evaluări

- How To Unprotect An Excel Sheet Without PasswordDocument3 paginiHow To Unprotect An Excel Sheet Without Passworddaniel_iosif_glÎncă nu există evaluări

- Microcontroller Lab Manual With Arduino Programe PDFDocument63 paginiMicrocontroller Lab Manual With Arduino Programe PDFTejasaiÎncă nu există evaluări

- How To Build Clam Antivirus RPM Package For Fedora Core 1Document3 paginiHow To Build Clam Antivirus RPM Package For Fedora Core 1Mahir EfendiyevÎncă nu există evaluări

- GFRC AppliccationDocument79 paginiGFRC AppliccationKristiantoÎncă nu există evaluări

- Telit WE866C3 Datasheet-1Document2 paginiTelit WE866C3 Datasheet-1SailajaUngatiÎncă nu există evaluări

- Shop Drawing: Type - B1 Type - B2 Type - B3Document1 paginăShop Drawing: Type - B1 Type - B2 Type - B3Kroos BabaÎncă nu există evaluări

- DetailDocument4 paginiDetailAzmat ArifÎncă nu există evaluări

- Strength Requirement: (1) - Pile Shear CapacityDocument4 paginiStrength Requirement: (1) - Pile Shear CapacityAlma M. LaraÎncă nu există evaluări

- User Manual: Rovus Arctic Air UltraDocument76 paginiUser Manual: Rovus Arctic Air Ultrad_ghitacÎncă nu există evaluări

- Exam Management System NotesDocument24 paginiExam Management System NotesRanganathan NagendranÎncă nu există evaluări

- USB Flash Drive 101 - Flash-Media - StorageDocument7 paginiUSB Flash Drive 101 - Flash-Media - Storageshowtelay33Încă nu există evaluări

- Polymer CentralizerDocument7 paginiPolymer CentralizerwijiestÎncă nu există evaluări

- Manual A ArgonautDocument14 paginiManual A ArgonautalexmancillaÎncă nu există evaluări

- Mman TechDocument17 paginiMman TechPeter DokpesiÎncă nu există evaluări

- Jkt3 MTR El 060a Lighting Fixtures (Office) APDocument55 paginiJkt3 MTR El 060a Lighting Fixtures (Office) APIvan Rudolf De FretesÎncă nu există evaluări

- Arched Top: Make Arched Raised-Panel DoorsDocument5 paginiArched Top: Make Arched Raised-Panel DoorsAnonymous QJ5j94luLmÎncă nu există evaluări

- Pre Insulated Piping Sytem HDPEDocument15 paginiPre Insulated Piping Sytem HDPEVincent SablanÎncă nu există evaluări

- E1 TesterDocument12 paginiE1 TesterNarendra PattanayakÎncă nu există evaluări

- Hmad Mar Ammad: Linkedin: Skype:Ahmadhammad229Document4 paginiHmad Mar Ammad: Linkedin: Skype:Ahmadhammad229Ahmad HammadÎncă nu există evaluări

- BS 8204-4-1993-In-Situ Floorings-Code of Practice For TerrazDocument22 paginiBS 8204-4-1993-In-Situ Floorings-Code of Practice For Terrazgops1963100% (1)

- Hyd Calc of in Rack Sprinklers HandoutDocument9 paginiHyd Calc of in Rack Sprinklers HandoutYoesof HilabyÎncă nu există evaluări

- Computer Graphics Second Module SecondDocument19 paginiComputer Graphics Second Module Seconddgk84_idÎncă nu există evaluări

- Ek 4100a SV A01Document292 paginiEk 4100a SV A01dbo61Încă nu există evaluări

- Manual Funciones Alternantes stm32f7Document227 paginiManual Funciones Alternantes stm32f7erika salinasÎncă nu există evaluări

- ASME B31 1 ASME B31 3 Hugo JulienDocument3 paginiASME B31 1 ASME B31 3 Hugo JulienRami Elloumi0% (1)

- Introduction To Xamarin FormDocument37 paginiIntroduction To Xamarin FormKurniaÎncă nu există evaluări

- JK Cement ISIN Numbers ListDocument621 paginiJK Cement ISIN Numbers ListkenindiÎncă nu există evaluări

- Finite Element Analysis of Fastening and Joining: A Bibliography (1990 - 2002)Document19 paginiFinite Element Analysis of Fastening and Joining: A Bibliography (1990 - 2002)Alexandru AsmarandeiÎncă nu există evaluări

- Cutting PropagationDocument31 paginiCutting PropagationDrRuby Ranjan SharmaÎncă nu există evaluări

- Articulo 2 - 2021Document13 paginiArticulo 2 - 2021Alberto Vásquez DiazÎncă nu există evaluări

- SWITCH Mar 2019 PDFDocument253 paginiSWITCH Mar 2019 PDFdejendranÎncă nu există evaluări

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- Modeling and Dimensioning of Structures: An IntroductionDe la EverandModeling and Dimensioning of Structures: An IntroductionÎncă nu există evaluări

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareDe la EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareEvaluare: 4.5 din 5 stele4.5/5 (15)

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualDe la EverandTransmission Pipeline Calculations and Simulations ManualEvaluare: 4.5 din 5 stele4.5/5 (10)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Built: The Hidden Stories Behind Our StructuresDe la EverandBuilt: The Hidden Stories Behind Our StructuresEvaluare: 4 din 5 stele4/5 (27)

- Design and Construction of Soil Anchor PlatesDe la EverandDesign and Construction of Soil Anchor PlatesEvaluare: 5 din 5 stele5/5 (1)

- Pile Design and Construction Rules of ThumbDe la EverandPile Design and Construction Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDe la EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingÎncă nu există evaluări

- Advanced Design Examples of Seismic Retrofit of StructuresDe la EverandAdvanced Design Examples of Seismic Retrofit of StructuresEvaluare: 1 din 5 stele1/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- Natural Ventilation of Buildings: Theory, Measurement and DesignDe la EverandNatural Ventilation of Buildings: Theory, Measurement and DesignÎncă nu există evaluări

- Matrix Methods for Advanced Structural AnalysisDe la EverandMatrix Methods for Advanced Structural AnalysisEvaluare: 5 din 5 stele5/5 (1)

- Pipeline Planning and Construction Field ManualDe la EverandPipeline Planning and Construction Field ManualEvaluare: 5 din 5 stele5/5 (3)

- Concrete Structures: Repair, Rehabilitation and StrengtheningDe la EverandConcrete Structures: Repair, Rehabilitation and StrengtheningÎncă nu există evaluări