Documente Academic

Documente Profesional

Documente Cultură

Carbo Cya Nation

Încărcat de

Gia ObligadoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Carbo Cya Nation

Încărcat de

Gia ObligadoDrepturi de autor:

Formate disponibile

2012 The Chemical Society of Japan

Bull. Chem. Soc. Jpn. Vol. 85, No. 7, 731745 (2012)

731

Award Accounts

The Chemical Society of Japan Award for Young Chemists for 2010

Nickel/Lewis Acid-Catalyzed Carbocyanation

of Unsaturated Compounds

Yoshiaki Nakao

Department of Material Chemistry, Graduate School of Engineering, Kyoto University,

Katsura, Nishikyo-ku, Kyoto 615-8510

Received March 7, 2012; E-mail: yoshiakinakao@npc05.mbox.media.kyoto-u.ac.jp

Addition reactions of the organic and cyano groups of nitriles through cleavage of the CCN bonds, namely

carbocyanation, have been developed using nickel/Lewis acid (LA) cooperative catalysis. Originally, the reaction was

performed with a nickel catalyst alone and was limited to the use of aryl and allyl cyanides as the nitrile substrates.

By employing LA cocatalysts, the rate of the arylcyanation was accelerated signicantly and the scope of nitriles used in

the reaction across alkynes was expanded to include alkenyl, alkynyl, and alkyl cyanides. The high chemo-, regio-, and

stereoselectivities of the alkynecarbocyanation reactions were highlighted by the syntheses of biologically active

compounds including the synthetic precursor of P-3622 and plaunotol, which possess dened tri- or tetrasubstituted

ethene structures. Intramolecular arylcyanation of alkenes was also achieved by cooperative catalysis. Mechanistic studies

on this particular transformation allowed us to identify several reaction intermediates, which revealed the modes of the

cooperative catalysis derived from nickel- and aluminum-based LA. Intramolecular arylcyanation was achieved in an

enantioselective manner using optically active bidentate phosphorus ligands, aording a protocol to introduce both a

quaternary stereocenter and a cyano functionality without by-product generation.

Introduction

CC bond-forming reactions are among the most important

transformations in organic synthesis. Transition-metal catalysis

has introduced a number of innovative CC bond-forming

reactions by virtue of the unique reactivity associated with

various metallic elements in concert with ligands bound to

the metal center. Cross-coupling reactions and olen metathesis

typically represent the power of transition-metal catalysis to

eect novel and innovative CC bond-forming reactions. The

addition reaction of two organic fragments across an unsaturated

compound via the transition-metal-mediated cleavage of CC

single bonds could be regarded as an ultimate transformation,

because the reaction allows simultaneous formation of two CC

bonds, with no by-product formation (eq 1).1 Nevertheless, the

activation of simple CC single bonds is dicult to achieve due

to inecient overlap of sterically and directionally constrained

CC bonds with d-orbitals of transition metals.1b Successful

examples of such transformations thus far reported relied fully

on the use of three-2 or four-membered-ring3 compounds, in

which the cleavage of CC bonds by transition-metal catalysts

was relatively facile owing to a relief of a ring-strain.4,5 CCN

bonds have also been demonstrated to be activated by various

transition-metal complexes. Two types of CCN bond activation

are available: the oxidative addition of CCN bonds to lowvalent transition-metal complexes,6 and the formation of silyl

isonitrile complexes through cleavage of CCN bonds.7 The

high anity of a cyano group for transition metals, which allows

its coordination to a metal center in either an 1- or 2-fashion,8

acts as a kinetic driving force, whereas the formation of strong

metalCN bonds9 acts as a thermodynamic driving force of the

elementary reaction step. Both reactions have already been

applied to catalytic transformations of nitriles through the

cleavage of CCN bonds.10 For example, the oxidative addition

of CCN bonds is an important process in the second step of

DuPonts adiponitrile process,11 in which 2-methyl-3-butenenitrile isomerizes to 3- and/or 4-pentenenitriles through a allylnickel intermediate generated upon oxidative addition of

the allylic CCN bonds to nickel(0) species.12 More recently, the

nickel-catalyzed cross-coupling reactions of aryl cyanides with

organomagnesium reagents, organozinc reagents, and amines

have been reported to proceed through oxidative addition of the

ArCN bonds.13 The CCN bond activation accompanied by the

formation of silyl cyanides can also be performed in a catalytic

manner, allowing the catalytic conversions of CCN bonds to

CH,14 CC,15 CSi,16 and CB17 bonds.

C + R

metal

catalyst

Given the relatively facile activation of CCN bonds in spite

of their high bond dissociation energies,18 one can imagine

Published on the web June 28, 2012; doi:10.1246/bcsj.20120081

732

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

C N

R

C N

C

AWARD ACCOUNTS

C N

[M]

R

C N

R

[M]

[M]

C N

[M] C N

C

R

[M]

C N

R

Scheme 1. A possible catalytic cycle of the carbocyanation

reaction.

the addition reaction of both organic and cyano groups across

unsaturated bonds, carbocyanation reactions, through the activation of the CCN bonds of nitriles by transition-metal complexes (Scheme 1). The rst report of such transformations, by

Takaya and co-workers, showed that the reaction of benzoyl

cyanide with terminal arylacetylenes proceeded to give cyano-,-unsaturated ketones (eq 2).19 The mechanism of

the reaction was elucidated by the authors to include the

initial acylation of the alkyne terminus to give alkynylketones,

which subsequently undergoes hydrocyanation, followed by the

isomerization of the resultant trisubstituted double bond to

give formal cis-benzoylcyanation products. The activation of

carbonylCN bonds by palladium catalysts has recently

been reinvestigated to allow for the inter- and intramolecular

cyanoesterication of alkenes (eq 3)20 and alkynes (eq 4),21

respectively, and the intramolecular cyanocarbamoylation of

alkenes (eq 5).22 Our focus, on the other hand, has been the use

of nickel, for which abundant examples of both stoichiometric

and catalytic CCN activation have been reported.23 We rst

described that the addition of aryl cyanides across alkynes

proceeded in the presence of a catalyst derived from [Ni(cod)2]

and PMe3 (eq 6).24 Subsequently, we reported the arylcyanation

of bicyclic alkenes such as norbornene and norbornadiene

(eq 7),25 the allylcyanation of alkynes (eq 8),26 and the cyanoesterication of 1,2-dienes (eq 9),27 all catalyzed by nickel,

demonstrating that nickel catalysis is highly versatile in the

carbocyanation reactions of unsaturated compounds. Nevertheless, the scope of useful nitriles was dicult to further

expand with the nickel catalyst alone, and the reaction conditions needed improvement in terms of catalyst loading and

reaction temperature. Meanwhile, theoretical calculations for

all the proposed steps of the arylcyanation of alkynes were

investigated by Sakaki and Ohnishi,28 which revealed that

oxidative addition of ArCN bonds to nickel(0) species

proceeded through 2-nitrile- and then 2-arenenickel intermediates A and B, respectively, and that these two steps

represented the highest barrier to be overcome to drive the

arylcyanation reaction (Scheme 2).29 Given a plausible, detailed

catalytic cycle, we proposed to employ a Lewis acid (LA) as

an additive for the arylcyanation reaction. We hoped that the

intermediates and transition states estimated in the rate-limiting

CCN cleavage could be stabilized through cyano-group

coordination to the LA and potentially result in the acceleration

of the oxidative addition of the CCN bonds. Accordingly,

we found that aluminum- and boron-based LAs were eective

cocatalysts which signicantly promoted the arylcyanation

reaction and expanded the scope of the nitriles, as described

herein. Tolman and co-workers already showed that the

oxidative addition of the CCN bond of allyl cyanide was

accelerated by the coordination of the cyano group to a LA.30

More recently, Jones and co-workers quantitatively investigated

the eect of LA on the oxidative addition of allyl cyanide to

a [Ni0(dippe)] species [dippe: 1,2-bis(diisopropylphosphino)ethane] in the presence of BPh3, demonstrating that CCN

activation was favorable both thermodynamically and kinetically over the competitive oxidative addition of the allylic CH

bond of allyl cyanide, which eventually gives the thermodynamically more favored [(dippe)Ni0(2-crotonitrile)].6l

O

Ph

CN

+

p -tol

Pd(OAc)2/PPh3

(20 mol %)

dppb (10 mol %)

ClCH2CH2Cl,

70 C, 65 h

O

+

Ph

O

Ph

H

isomerization

+

O

Ph

p -tol 1%

HCN,

cat. Pd

p -tol

2%

CN

CN

74%

p -tol

O

O

CN [Pd(PPh3)4] (10 mol %)

EtO

+

toluene, 110 C, 3 h

EtO

3

NC

78%

Ph

Ph

[Pd(PPh3)4] (10 mol %)

CN

O

CN

DMF, W, 200 C, 5 min

O

isomerization

Ph

CN

O

80%

[Pd2(dba)3] (2 mol %)

MonoPhos (16 mol %)

DMPU (1.0 equiv)

NBn

O

CN

O

THF, 100 C

N

Bn

CN

72%, 94% ee

O

P N

O

MonoPhos

Y. Nakao

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

C N

Ni

Me3P PMe3

TSA B

Ph

Ni

Me3P

Ni

Me3P

PMe3

Ea = 24.4

N

Ph

N

PMe3

kcal mol1

Ni

PMe3

Me3P

TSB C

733

C

Ni

Me3P

Ea = 25.1

kcal mol1

PMe3

C

Scheme 2. The rate-limiting oxidative addition of ArCN bonds to nickel(0) via 2-cyano- and -arenenickel intermediates in the

catalytic cycle of the arylcyanation of alkynes.

F

CN

[Ni(cod)2] (10 mol %)

PMe3 (20 mol %)

Pr

toluene, 100 C, 30 h

Pr

CN

Pr

81%

CN

+

+

Pr

CN

Pr

O

EtO

CN

O NC

81%

[Ni(cod)2] (10 mol %)

P(4-CF3 C6H4)3 (20 mol %)

Pr

Pr

78%

[Ni(cod)2] (10 mol %)

PMe2Ph (20 mol %)

CN

t -Bu

EtO

t -Bu

MeO

[Ni(cod)2] (5 mol %)

MeO

CN ligand (10 mol %)

1a (1.0 mmol)

LA (20 mol %)

+

Pr

Pr

toluene, 50 80 C, 24 h

2a (1.0 mmol)

Entry

CN

CH3CN, 80 C, 8 h

toluene, 50 C, 6 h

Pr

[Ni(cod)2] (5 mol %)

PMe3 (10 mol %)

toluene, 100 C, 21 h

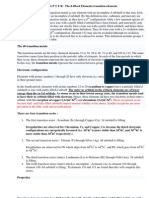

Table 1. Eect of LA Cocatalyst on the Arylcyanation of

2a with 1a

70%

Arylcyanation of Alkynes

The originally developed reaction conditions for the arylcyanation of alkynes suered from low eciency in the

addition reactions of electron-rich aryl cyanides. For example,

the reaction of 4-methoxybenzonitrile (1a) with 4-octyne (2a)

at 80 C for 24 h aorded the corresponding adduct (Z)-3aa

in 36% yield, as estimated by GC (Table 1, Entry 1). More

electron-rich nitriles such as 4-dimethylaminobenzonitrile

did not react at all under these conditions. The addition of

boron- and aluminum-based LA, on the other hand, dramatically promoted the reaction.31 For example, in the presence of a

catalytic amount of AlMe3, the reaction aorded (Z)-3aa in

91% yield accompanied by 6% (E)-3aa, which was derived

from the isomerization of (Z)-3aa under the reaction conditions

(Entry 3). The reaction proceeded smoothly even at 50 C,

to give stereoisomeric mixtures of 3aa in high yields in the

presence of aluminum-based LAs (Entries 48), except for

AlCl3 (Entry 9). The high Lewis acidity of AlCl3 might have

prohibited the turnover of the LA catalyst. The use of milder

boron-based Lewis acids was equally eective and showed no

isomerization of (Z)-3aa (Entries 1013). Again, highly Lewis

acidic BF3 retarded the reaction (Entry 14). In the presence of

LA cocatalysts, the reaction took place in the presence of only

1

2

3

4

5

6

7

8

9

10

11

12

13

14

LA

none

none

AlMe3

AlMe3

AlMe2Cl

AlMe2Cl

AlMeCl2

AlMeCl2

AlCl3

BEt3

BEt3

BPh3

BPh3

BF3OEt2

Temp/C

80

50

80

50

80

50

80

50

80

80

50

80

50

80

CN

Pr

Pr

(Z )-3aa

GC yield/%

(Z)-3aa

(E)-3aa

36

1

7

0

91

6

61

0

79

21

94

1

41

50

82

4

6

0

88

0

82

0

68

0

37

0

1

0

1 mol % of the nickel catalyst with a variety of phosphine

ligands to give (Z)-3aa in modest to good yields (Table 2).

Several catalyst combinations were examined to investigate the

scope of aryl cyanides (Table 3). With the nickel/LA cooperative catalysis, a number of substituents on benzonitrile were

tolerated to give the corresponding adducts in good yields.

Lewis basic substituents such as alkoxycarbonyl and amino

groups did not aect the reaction (Entries 2 and 6). Of

particular note was the exclusive activation of ArCN bonds

by cooperative catalysis over Arhalogen bonds, which are

commonly reacted with electron-rich nickel(0) catalysts, as can

be seen in cross-coupling reactions32 (Entries 35). Highly

sterically demanding benzonitriles (Entries 7 and 8) as well as

heteroaryl cyanides (Entries 9 and 10) reacted with 2a in good

yields. The high chemoselectivity associated with the nickel/

LA cooperative catalyst system allowed for the reaction of 4-

734

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

AWARD ACCOUNTS

Table 2. Optimization of Ligand/LA Combinations for the

Reaction of 1a with 2a

MeO

[Ni(cod)2] (1 mol %)

CN ligand (2 mol %)

1a (1.0 mmol)

LA (4 mol %)

+

Pr

Pr

toluene, 50 C, 24 h

2a (1.0 mmol)

Ligand

AlMe3

60

63

95

92

95

29

PMe3

P(n-Bu)3

PPhMe2

PPh2Me

PCy2Me

P(p-An)3a)

MeO

CN

Pr

Pr

(Z )-3aa

LA/GC yield/% of (Z)-3aa/%

AlMe2Cl AlMeCl2 BPh3

88

7

31

41

5

39

>99

8

78

98

<1

92

50

<1

79

6

<1

53

BEt3

9

<1

6

<1

1

1

a) p-An: 4-MeOC6H4.

Table 3. Arylcyanation of Alkynes Catalyzed by Ni/LA

[Ni(cod)2] (1 mol %)

ligand (2 mol %)

LA (4 mol %)

Ar CN

1 (1.0 mmol)

+

R1

R2

2 (1.0 mmol)

Ar

CN

Ar

NC

+

toluene

R1

R2

3

Ar = 4-Me2NC6H4 (1b)

4-FC6H4 (1c)

4-ClC6H4 (1d)

4-BrC6H4 (1e)

4-MeO2CC6H4 (1f)

2-MeOC6H4 (1g)

2,6-Me2C6H3 (1h)

2-thienyl (1i)

1-Me3-indolyl (1j)

Entry

Cond.a)

1

2

3

4

5b)

6

7

8b)

9

10

11

12

13

14

15

16

1a

1b

1c

1d

1e

1f

1g

1h

1i

1j

1d

1d

1d

1d

1d

1d

2a

2a

2a

2a

2a

2a

2a

2a

2a

2a

2b

2c

2d

2e

2f

2g

A

A

B

B

A

A

B

A

B

A

C

C

C

C

D

C

R1

R2

3'

R1, R2 = Me (2b)

Me3SiCH2 (2c)

Me, i -Pr (2d)

Me, t -Bu (2e)

Et, p -An (2f)

Me, SiMe3 (2g)

Temp Time

/C

/h 3

50

16 96

80

21 87

50

18 95

50

18 94

50

27 72

80

25 93

80

28 92

100

134 78

50

140 81

50

116 58

60

12 88

60

6 84

60

5 87

60

19 89

60

32 53

80

13 70

Isolated yield/%

3

(3aa)

(3ba)

(3ca)

(3da)

(3ea)

(3fa)

(3ga)

(3ha)

(3ia)

(3ja)

(3db)

(3dc)

(3dd/3dd = 64:36)

(3de/3de = 91:9)

(3df )c) 27 (3df )

(3dg)d) 9 (3dg)

a) Conditions A: PPhMe2/AlMe2Cl; B: PPh2Cy/AlMe3; C:

PPh2(i-Pr)/AlMe2Cl; D: PPh2Me/AlMe2Cl. b) Reaction run

with Ni/PPhMe2/AlMe2Cl = 5/10/20 mol %. c) (E)-Isomer

was also isolated in 5% yield. d) E/Z = 47:53 (78:22 at 5 h).

chlorobenzonitrile (1d) with various internal alkynes (Entries

1116). The observed regioselectivity associated with unsymmetrical alkynes was in accordance with that estimated by

theoretical calculations, which suggested preferable formation

of 3 having a bulkier substituent at the cyano-substituted

carbon through kinetically favored migratory insertion of the

aryl group to the sterically less-hindered carbon of the alkyne

coordinated to the nickel center (Entries 1316).28 Alternative

cyanonickelation was estimated to be unfavorable based on

theoretical calculations in the absence of LA.28 Although

modest selectivity was observed, a single step preparation of

particular tetrasubstituted ethene 3df was achieved, which was

reported to be a synthetic precursor of a potential squalene

synthetase inhibitor P-362233 (Entry 15). The latest synthesis

of 3df relied on a multistep procedure via the cyanoboration of

alkynes developed by Suginome and Murakami.34

Arylcyanation of Alkenes

The arylcyanation across norbornadiene proceeded in an

exo-cis manner with a range of aryl cyanides to give highly

functionalized norbornenes 4 (Table 4), which may nd

applications as monomers in ring-opening metathesis polymerizations.35 The originally reported reaction conditions for this

particular transformation in the absence of LA catalysts

accommodated a narrow scope of aryl cyanides, primarily

electron-poor ones. The use of 1,2-bis(dimethylphosphino)ethane (DMPE) as a ligand was found to be crucial;

monodentate and other bidentate phosphine ligands were

totally ineective. Notably, no double addition products were

observed. Whereas intermolecular arylcyanation of other

alkenes remains elusive even with the newly developed

nickel/LA cooperative catalysis, the intramolecular addition

across unactivated alkenes proceeds eciently with nickel/

AlMe2Cl catalysis (Table 5). The transformations of aryl

cyanides 5 having double bonds tethered through various

linker moieties proceeded in a 5- or 6-exo-trig manner to give

a variety of nitrile products 6 having cyclic structures and

quaternary carbons at a position to the cyano group.36 We

investigated the stoichiometric reaction of substrate 5a with

[Ni(cod)2], P(n-Bu)3, and AlMe2Cl (Scheme 3). Upon mixing,

the immediate formation of 2-nitrilenickel complex 7 was

Table 4. Arylcyanation of Norbornadiene Catalyzed by

Ni/AlMe2Cl

Ar CN

1 (1.0 mmol)

+

[Ni(cod)2] (1 mol %)

DMPE (1 mol %)

AlMe2Cl (4 mol %)

toluene, 80 C

Ar

NC

4

(1.5 mmol)

Entry

1

2a)

3

4

5

1

1a

1b

1d

1e

1g

a) Reaction run at 100 C.

Time/h

4.5

2

2

10

5.5

Yield

69

57

69

59

58

of 4/%

(4a)

(4b)

(4d)

(4e)

(4g)

Y. Nakao

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

5a + [Ni(cod)2] + P(n -Bu)3 + AlMe2Cl

Table 5. Intramolecular Arylcyanation of Alkenes Catalyzed by Ni/AlMe2Cl

R1

CN

[Ni(cod)2] (5 mol %)

PMe3 (10 mol %)

AlMe2Cl (20 mol %)

R4

NC

R2

R1

R3 toluene, 100 C

X

R2

R1,

R2,

R3,

Entry

rt

R3

R4

R4,

Al

X = H, Me, H, H, CH2 (5a)

H, Me, H, H, NMe (5b)

H, Me, H, H, NBn (5c)

Cl, Me, H, H, NBn (5d)

MeO, Me, H, H,NBn (5e)

H, Ph, H, H, NBn (5f)

H, SiMe2Ph, H, H, NBn (5g)

H, Me, Ph, H, NBn (5h)

H, Me, H, Ph, NBn (5i)

H, Me, H, H, (CH2)2 (5k)

H, Me, H, H, BnNCH2 (5l)

Time/h

rt

Ni

Ni

CN

O

C

N

8

7

L = P(n -Bu)3

Al = AlMe2Cl

60 C

Al

ratedetermining

5a

Al

Me

C N

Yield/%

CN

Al

60 C

Ni

10

Product

6a

N

Bn

5j

735

C

Ni

L L

9

Scheme 3. Mechanism of the intramolecular arylcyanation

of alkenes.

1

2a)

3

5a

5b

5c

7

4

7

X = CH2

X = NMe

X = NBn

93 (6a)

86 (6b)

79 (6c)

CN

R

N

Bn

4

5

5d

5e

7

7

R = Cl

R = MeO

R

82 (6d)

85 (6e)

CN

N

Bn

6

7

5f

5g

6

6

R = Ph

R = SiMe2Ph

89 (6f )

84 (6g)

NC

8b)

5h

Ph

H

0.5

88 (6h)c)

N

Bn

NC

9b)

5i

H

Ph

0.5

76 (6i)d)

N

Bn

CN

10e)

5j

74 (6j)

N

Bn

CN

11f )

12

5k

5l

3

3

X = CH2

X = NBn

91 (6k)

96 (6l)

a) Reaction run on a 3.0 mmol-scale. b) PPhMe2 was used as a

ligand. c) dr = 98:2 (>99:1 after isolation). d) dr = 97:3

(>99:1 after isolation). e) PPh3 was used as a ligand. f ) DMPE

was used as a ligand.

noted, which underwent oxidative addition to give nickel(II)

complex 8 after 6 h at room temperature. The structures of both

of the nickel complexes having a cyano group coordinated to

AlMe2Cl were unambiguously conrmed by both NMR

spectroscopy and X-ray crystallography. Accordingly, the

reaction mode by the cooperative action of both the nickel

and aluminum complexes to activate ArCN bonds was

identied experimentally. No 2-arenenickel complexes were

observed, suggesting that the mechanism of ArCN activation

might dier either in the presence or absence of LA catalysts.

Upon heating at 60 C for 46 h, nickel(II) complex 8 was

converted to another 2-nitrilenickel complex 10, possibly via

the migratory insertion of the double bond in 8 to the ArNi

bond to give alkyl(cyano)nickel species 9 and the subsequent

reductive elimination of the C(sp3)CN bond. Treatment of 10

with 5a resulted in the regeneration of 8, thus showing

snapshots of the proposed catalytic cycle. These data also

suggested that the rate-limiting step of this particular intramolecular transformation was either the substitution of the

bound phosphorus with the tethered alkene or the migratory

insertion. With the scope and detailed mechanism of the

intramolecular arylcyanation reaction of alkenes established,

we next studied a synthetically intriguing enantioselective

variant. After extensive screening of known chiral ligands, we

found that i-Pr-Foxap37 showed high enantioselectivity in the

formation of various indolines having a quaternary stereocenter

at the C-3 position in good yields (Table 6).38 In some cases,

related chiral P,N ligand i-Pr-Phox39 showed better enantioselectivity. Optically active indolines thus obtained served as

synthetic precursors for biologically active alkaloids such as

()-esermethole (Scheme 4), which reportedly led to potent

acetylcholinesterase inhibitors such as ()-physostigmine40

and ()-phenserine.41 Likewise, a chiral ligand for the

enantioselective construction of a tetrahydronaphthalene having a benzylic quaternary stereocenter was identied to be

ChiraPhos.42 This allowed for the formal total synthesis of

()-eptazocine,43 an analgesic substance available commercially, by taking advantage of the enantioselective intramolecular arylcyanation of alkenes followed by the subsequent

reduction of the cyano group (Scheme 5). A closely related

enantioselective intramolecular arylcyanation of alkenes focus-

736

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

AWARD ACCOUNTS

Table 6. Enantioselective Intramolecular Arylcyanation of

Alkenes Catalyzed by Ni/AlMe2Cl

[Ni(cod)2] (10 mol %)

(S,S )-i -Pr-Foxap (20 mol %)

AlMe2Cl (40 mol %)

CN

N

Me

MeO

DME, 100 C

Entry

1

2

3

4

5

6a)

7

5

5m

5n

5o

5p

5q

5r

5s

N

(S )-i -Pr-Phox

Time/h

40

40

40

160

120

80

40

Yield/%

87 (6m)

87 (6n)

93 (6o)

88 (6p)

46 (6q)

91 (6r)

55 (6s)

Ee/%

93

93

96

95

93

73

97

a) Reaction run with (S)-i-Pr-Phox.

CN

MeO

CN

MeO

5b

O

N

Me

(S )-6b

88%, 96% ee

c

N

Me

40%, 96% ee

MeO

NH

N H

Me

64%, 96% ee

HO

83%, 92% ee

NMe

()-eptazocine

Scheme 5. Formal synthesis of ()-eptazocine via the

enantioselective intramolecular arylcyanation of alkenes.

Reagents and conditions: (a) [Ni(cod)2] (5 mol %), (R,R)ChiraPhos (6 mol %), AlMe2Cl (20 mol %), 120 C, 1 h;

(b) DIBAL-H (2.0 equiv), toluene, 78 C, 2 h, then 1 M

HCl aq., THF, 0 C to rt, 2 h.

PPh2

(S,S )-i -Pr-Foxap

CHO ref 44

N

PPh2

Fe

CN

MeO

(R )-6t

98%, 92% ee

MeO

R = Me (5m); Et (5n); i -Pr (5o); Bn (5p); Me2C=CHCH2 (5q);

CH2OSiMe2t -Bu (5r); Ph (5s)

O

5t

CN

N

Me

6

CN

MeO

NMe

N H

Me

()-esermethole

92%, 96% ee

Scheme 4. Total synthesis of ()-esermethole via the

enantioselective intramolecular arylcyanation of alkenes.

Reagents and conditions: (a) [Ni(cod)2] (10 mol %), (R,R)i-Pr-Foxap (20 mol %), AlMe2Cl (40 mol %), DME, 100

C, 10 h; (b) PhIO (6.0 equiv), CH2Cl2, rt, 2.5 h; (c) LiAlH4

(4.0 equiv), THF, rt, 1 h, then reux, 0.5 h; (d) HCHO aq.

(5.0 equiv), NaBH(OAc)3 (5.0 equiv), MeOH, 0 C to rt,

1.5 h.

ing on substrates having a methylene linker was reported

by Jacobsen and Watson, also with a chiral nickel catalyst

and BPh3 as a LA cocatalyst.44 These enantioselective intramolecular carbocyanation reactions across alkenes, including

the aforementioned intramolecular cyanocarbamoylation of

alkenes catalyzed by palladium,22 can be powerful synthetic

alternatives to the enantioselective intramolecular Heck reactions.45 Whereas a requisite functionality must be preinstalled

onto an olen moiety in the Heck strategy, the carbocyanation

allows the use of simple alkenes because the cyano group is

retained in the resultant cyclization products.

Alkenylcyanation of Alkynes

With the highly eective nickel/LA cooperative catalysis

system in hand, we hoped to expand the scope of the nitriles

in the carbocyanation chemistry as mentioned above. Indeed,

alkenyl cyanides 11, which do not participate in the carbocyanation reaction in the absence of LA cocatalysts, undergo the

transformation by the cooperative catalysis to give variously

substituted 1,3-dienenitriles 12 (Table 7).31 The use of BPh3

as a LA catalyst was crucial to prevent the double bond

isomerization of 12 under the reaction conditions. The reason

that only the starting alkenyl cyanides participated in the

transformation, while the adducts were inert toward further

activation and the possible formation of polymeric products,

Table 7. Alkenylcyanation of Alkynes Catalyzed by Ni/BPh3

R3

R5

[Ni(cod)2] (2 mol %)

R4

CN PMe3 (4 mol %)

R3

11 (1.0 mmol) BPh3 (8 mol %)

+

R4

R1

R2 toluene, 80 C

2 (1.2 mmol)

R5

R5

CN + NC

R1

12

R2

R1

R3

R4

R2

12'

R3, R4, R5 = Ph, H, H (11a)

H, Et, H (11b)

(CH2)5, H (11c)

Ph, Ph, H (11d)

Ph, H, CN (11e)

Entry

11

1

2

3

4

5b)

6

7

11a

11b

11c

11d

11e

11a

11a

2a

2a

2a

2a

2a

2dd)

2gd)

Time/h

20

15

21

46

13

3

15

12

94

78

91

94

81

44

66

Isolated yield/%

12

(12aa)

(12ba)a)

(12ca)

(12da)

(12ea)c)

(12ad)

37 (12ad)

(12ag)e) <5

a) 4Z/4E = 84:16. b) Reaction run with Ni/Ph2P(CH2)4PPh2/

BPh3 = 4/4/16 mol %. c) An isomer was isolated in ca. 2%

yield. d) 2.0 mmol. e) A mixture of isomers was isolated in ca.

7% yield.

Y. Nakao

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

Table 8. Alkynylcyanation

Ni/BPh3

of

Alkynes

Catalyzed

by

3

R3

[Ni(cod)2] (1 mol %) R

R3

CN Xantphos (1 mol %)

13 (1.0 mmol) BPh3 (3 mol %)

CN NC

+

+

R1

R2 toluene

R1

R2

R1

R2

2 (1.0 mmol)

PPh2

PPh2

14'

14

O

Xantphos

R3 = t -BuMe2Si (13a)

Et3Si (13b)

t -BuMe2SiC C (13c)

Ph (13d)

cyclohexen-1-yl (13e)

n -Hex (13f)

Cl(CH2)3 (13g)

NC(CH2)3 (13h)

MeCH(OSiMe2t -Bu) (13i)

Entry

1

2

3a)

4b)

5b)

6b)

7b)

8b)

9b)

10

11

12

13

14

15

16

17

18

13

13a

13b

13c

13d

13e

13f

13g

13h

13i

13a

13a

13a

13a

13a

13a

13a

13a

13a

2

Temp/C

2a

80

2a

80

2a

80

2ac)

100

2ac)

80

2ac)

100

2ac)

100

2ac)

100

2ac)

100

2d

80

2h

80

2i

80

2k

40

2l

40

2md)

40

2n

40

2o

40

2p

40

R1, R2 = Me, CH(OEt)2 (2h)

Me, Ph (2i)

4-MeOC6H4 (2j)

H, n -Hex (2k)

H, (CH2)3Cl (2l)

H, (CH2)3CO2Me (2m)

H, (CH2)3CN (2n)

H, cyclohexen-1-yl (2o)

H, 4-NCC 6H4 (2p)

Time/h

21

24

21

3

2

3

3

4

1

49

39

56

15

15

17

15

15

17

Yield/% 14:14

95

95

72

69

67

72

54

35

47

82

22:78

84

13:87

94

60:40

96

83:13

79

82:18

93

87:13

99

88:12

86

95:5

96

>95e):5

a) Reaction run with Ni/Xantphos/BPh3 = 3/3/9 mol %.

b) Reaction run with Ni/Xantphos/BPh3 = 10/10/30 mol %.

c) 2.0 mmol. d) 1.1 mmol. e) E/Z = 2:98.

13a

+

[Ni(cod)2]

+

Xantphos benzene, rt

+

84%

BPh3

t -BuMe2Si

737

N

Ni

O

Ph2P

BPh3

PPh2

15

2a (5.0 equiv)

BPh3 (2.0 equiv)

toluene, 80 C, 14 h

81% (GC)

15 (1 mol %)

t -BuMe2Si

BPh3 (2 mol %)

1a

+

toluene, 80 C, 21 h

2a

(1.0 mmol each)

Pr

94%

14aa

CN

Pr

Scheme 6. Synthesis of trans-(xantphos)Ni(CNBPh3)(CCSiMe2t-Bu) (15) and its stoichiometric and catalytic

reactions.

and BPh3 to give highly functionalized conjugated enyne

products 14 stereo- and regioselectively (Table 8).47 In the

absence of BPh3, the reaction gave poor yields of 14, and the

co-trimerization of both alkyne substrates to form substituted

benzenes was a major reaction pathway. Various functional

groups were tolerated under the reaction conditions: the

exclusive activation of C(sp)CN bonds over C(sp2)CN and

C(sp3)CN bonds highlights this aspect (Entries 8, 16, and 18).

The stoichiometric reaction of 13a with [Ni(cod)2], Xantphos,

and BPh3 allowed us to identify trans-nickel(II) complex 15

in 84% yield, and obtain unambiguous structural conrmation

by NMR spectroscopy and X-ray crystallography (Scheme 6).

Treatment of 15 with 5.0 molar equivalents of 2a in the

presence of added BPh3 gave 14aa in 81% yield as estimated

by GC. Alternatively, 15 served as a catalyst for the reaction

of 13a with 2a to give 14aa in 94% isolated yield, showing

that 15 was likely an intermediate in the catalytic cycle of the

reaction.

Alkynylcyanation of 1,2-Dienes and Norbornadiene

should be the dierent number of substituents attached to the

double bond of the alkenyl cyanides: adducts 12 always

possess a substituent at the -position, which should sterically

retard further activation of their CCN bonds, whereas substrates 11 have no -substituents. Indeed, the reactions of alkyl-substituted alkenyl cyanides were sluggish. Nevertheless,

the -cyano-substituent of benzylidenemalononitrile 11e did

not aect the reaction, and the CCN bond trans to the

-phenyl substituent was exclusively activated to give 1,3dicyano-substituted 1,3-diene product 12ea stereoselectively

(Entry 5).

Alkynylcyanation of Alkynes

Alkynyl cyanides 13 participated in the carbocyanation reaction with the cooperative catalyst derived from [Ni(cod)2], 4,5bis(diphenylphosphino)-9,9-dimethylxanthene (Xantphos),46

Under the conditions of the alkynealkynylcyanation reaction, 1,2-dienes 16 also underwent the addition of the alkynyl

and cyano groups of 13a exclusively across their internal

double bond, to give another type of conjugated enyne product 17 regioselectively (Table 9). A possible catalytic cycle

for the reaction should also involve 15 as an intermediate,

which undergoes the coordination and the subsequent migratory insertion of the 1,2-diene into the alkynylNi bond

to give a -allylnickel intermediate (Scheme 7). Reductive

elimination closes the catalytic cycle to generate functionalized enyne 17. The origin of the reverse regioselectivity

with silylallene 16e is yet to be understood (Entry 5). While

the alkynylcyanations of 1,3-dienes and simple alkenes are

elusive, norbornadiene undergoes the transformation, again

in an exo-cis fashion, to give functionalized norbornene 18

(eq 10).

738

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

AWARD ACCOUNTS

Table 9. Alkynylcyanation of 1,2-Diene Catalyzed by

Ni/BPh3

[Ni(cod)2] (2 mol %)

Xantphos (2 mol %) Si

13a (0.80 mmol) BPh3 (6 mol %)

+

toluene, 50 C

R

16 (0.80 mmol) Si = SiMe2t -Bu

Table 10. Cyanoesterication of Alkynes Catalyzed by

Ni/BAr3

Si

CN + NC

17

17'

R = n -Hex (16a); (CH2)2Ph (16b); (CH2)2OSiMe2t-Bu (16c);

Cy (16d); SiMe2n -Bu (16e)

Entry

1

2

3

4

5

Time/h

19

24

17

59

66

16

16a

16b

16c

16d

16e

Yield/%

73

82

75

74

55

17:17

93:7

91:9

92:8

>95:5

5:>95

Si

17

P

13a

Ni

C

N

B

P

P

Ni

Si

Si

Ni

P

C

N

B

P

R

NC

R2

OEt

R1

R2

19'

R1, R2 = n -Hex, SiMe3 (2q)

geranylCH2, SiMe3 (2r)

MeO2C(CH2)3, SiMe3 (2s)

t -BuMe2SiO(CH2)3, SiMe3 (2t)

PhthN(CH2)3, SiMe3 (2u)

Entry

1

2

3

4

5

6

7

8

2

2a

2c

2e

2q

2r

2s

2t

2u

Cond.a)

A

A

A

B

B

B

B

B

Time/h

18

21

46

22

22

41

46

51

Yield/%

80

75

49

75

64

62

67

67

19:19

>95:5

5:>95

5:>95

5:>95

5:>95

5:>95

16

= Xantphos

P

B = BPh3

Si = SiMe2t -Bu

O

CN

15

[Ni(cod)2] (5 mol %)

CN PAr13 (20 mol %)

EtO

O

(1.0 mmol) BAr23 (20 mol %)

EtO

+

R1

R2 solvent, 35 C

R1

2 (1.0 mmol)

19

1

Ar = 3,5-(CF3)2C6H3

Ar2 = Ph or C6F5

a) Conditions A: B(C6F5)3/toluene; B: BPh3/1,4-dioxane.

Si

R

Ni

P

C

Si

R

P

P

N

B

Ni

C

N

B

Scheme 7. A plausible mechanism for the alkynylcyanation

of 1,2-dienes.

[Ni(cod)2] (2 mol %)

Xantphos (2 mol %)

13a (1.0 mmol) AlMe2Cl (4 mol %)

t -BuMe2Si

+

NC

toluene, 80 C, 17 h

18, 89%

10

(1.0 mmol)

Cyanoesterification of Alkynes

The cleavage of the CCN bond of cyanoformates and the

addition of both alkoxycarbonyl and cyano groups across

unsaturated bonds should give access to highly functionalized

products. The double functionalization reactions were originally achieved across 1,2-dienes by nickel catalysis,27 and

across norbornene and norbornadiene by palladium catalysis.20

Although the cyanoesterication of alkynes has recently been

achieved in an intramolecular manner by palladium catalysis,21

the intermolecular reactions have been developed in the

authors laboratory using the nickel/Lewis acid catalyst.48

Thus, the addition of ethyl cyanoformate across 2a proceeded

stereoselectively in the presence of catalytic amounts of

[Ni(cod)2], [3,5-(CF3)2C6H3]3P, and B(C6F5)3 at 35 C to give

-cyano-substituted ,-unsaturated ester 19aa in 80% yield

(Table 10, Entry 1). The identical reaction in the absence

of B(C6F5)3 gave only a 4% yield of 19aa even at 100 C.

The cyanoesterication proceeds across a variety of alkynes

with excellent stereo- and regioselectivities (Table 10). In

contrast, the addition of thiocyanoformates was accompanied

by decarbonylation to give a thiocyanation product in the

presence of a similar set of catalysts (eq 11). This particular

transformation was found to be catalyzed more eectively by

palladium, whereas the thiocyanation of terminal alkynes was

previously reported by Ogawa and co-workers by directly using

phenyl thiocyanate and a palladium catalyst.49

O

cat. M (5 mol %)

CN P(4-CF3C6H4)3 (10 mol %)

PentS

(1.0 mmol)

B(C6F5)3 (20 mol %)

PentS

CN

+

11

2a (1.0 mmol) toluene, 100 C, 24 h

Pr

Pr

M = [Ni(cod)2]: 68%

[CpPd(allyl)]: >95%

Cyanocarbamoylation of Alkynes

Similarly, cyanoformamides 20 underwent the addition

across alkynes to give -cyano-substituted ,-unsaturated

amides 21 stereo- and regioselectively (Table 11). The stoi-

Y. Nakao

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

Table 11. Cyanocarbamoylation of Alkynes Catalyzed by

Ni/BPh3

Table 12. Allylcyanation

Ni/AlMe2Cl

Alkynes

Catalyzed

by

R5

O

R3

N

CN

R4

20 (1.0 mmol)

+

R1

R2

2 (1.0 mmol)

[Ni(cod)2] (5 mol %)

PPh2R5 (10 mol %)

BPh3 (15 mol %)

solvent, 80 C

20

20a

20b

20c

20a

20a

20a

20a

20a

R3

R3

N

R4

CN

R2

2

2a

2a

2a

2d

2q

2r

2t

2u

R1

21

R5 = Cy or i -Pr

R3

N

R4

R3, R4 = Me (20a)

Me, Bn (20b)

(CH2)2O(CH2)2 (20c)

Entry

1

2

3

4

5

6

7

8

of

739

O

CN

R1

R2

not observed

Cond.a)

A

A

A

A

B

B

B

B

Time/h

17

27

23

24

22

41

39

50

Yield/%

92

82

87

31

66

56

66

42

a) Conditions A: PPh2Cy/toluene; B: PPh2i-Pr/1,4-dioxane.

20a

+

[Ni(cod)2]

+

2 PPh2Cy

+

BPh3

CN

R4

23 (1.0 mmol)

+

R1

R2

2 (1.0 mmol)

[Ni(cod)2] (2 mol %)

P(4-CF3C6H4)3 (4 mol %)

AlMe2Cl (6 mol %)

R5

R3

CN

toluene, 50 C

R4

R1

24

R2

R5

R3, R4, R5 = H (23a)

Ph, H, H (23b)

(CH2)3, H (23c)

Me, H, Me (23d)

R3

NC

R4

R2

24'

rarely observed

R1

Entry

1

2

3

4a)

5

6

7

8

23

23a

23b

23c

23d

23a

23a

23a

23a

2

2a

2a

2a

2a

2i

2k

2l

2n

Time/h

24

72

48

24

24

4

4

4

Yield/%

96

74

82

61

64

67

60

46

24:24

92:8

>95:5

>95:5

>95:5

a) Reaction run with Ni/Ligand/AlMe2Cl = 20/40/60 mol %.

O

benzene, rt

Me2N

PPh2Cy

Ni C N BPh3

PPh2Cy

22

2a (5.0 equiv)

benzene, 60 C, 1 h

22 (5 mol %)

BPh3 (10 mol %)

20a

+

toluene, 80 C, 17 h

2a

(1.0 mmol each)

40% (GC)

O

Me2N

CN

Pr

21aa

Pr

Scheme 8. Synthesis of trans-(CyPh2P)2Ni(CNBPh3)(CONMe2) (22) and its stoichiometric reaction with 2a.

chiometric reaction of 20a, [Ni(cod)2], PPh2Cy, and BPh3 gave

nickel(II) complex 22, which was unambiguously identied

by both NMR spectroscopy and X-ray crystallography

(Scheme 8). Of particular note is the coordination of the cyano

group to BPh3 even in the presence of the Lewis basic

aminocarbonyl moiety. Oxidative adduct 22 reacted with

2a to give 21aa, suggesting its intermediacy in the catalytic

cycle of the cyanocarbamoylation reaction. The origin of the

regioselectivity with sterically biased alkynes that favors the

formation of 19 (cyanoesterication) and 21 (cyanocarbamoylation) remains elusive, whereas interaction of the carbonyl

functionalities with the silyl group and/or an alternative

cyanonickelation pathway could be operative in the reversal

of the regioselectivity.

Allylcyanation of Alkynes

Although the allylcyanation of alkynes could be catalyzed

by a nickel catalyst alone (eq 8), the presence of a LA

cocatalyst allowed the carbocyanation to proceed with reduced

nickel catalyst loading at a lower reaction temperature

(Table 12).50 Owing to the milder reaction conditions, excellent

stereo- and regioselectivities were achieved to give disubstituted acrylonitriles 24 with a variety of functional groups,

starting from a range of allyl cyanides 23 and alkynes. The

synthetic utility of the methodology for the synthesis of

trisubstituted ethenes was highlighted by the total synthesis

of plaunotol, an antibacterial natural product active against

Helicobacter pylori (Scheme 9). Thus, the trisubstituted C6

C7 double bond of the target natural product was successfully

constructed by the stereo- and regioselective allylcyanation of

alkyne 2v with -siloxyallyl cyanide 23e. The CC bond

formation at the -position of the cyano group of 23e suggested

the intermediacy of a -allylnickel intermediate.

Alkylcyanation of Alkynes

The CCN bond of acetonitrile (25a) was eciently

activated by nickel/LA cooperative catalysis to achieve the

methylcyanation of alkynes (Table 13), whereas the alkyl cyanide substrate was completely inert under the reaction conditions in the absence of LA cocatalysts. Particularly eective as

LA catalysts were AlMe3 and AlMe2Cl, whose methyl groups

were found irrelevant to those in the methylcyanation products

26 as evidenced by complete incorporation of the CD3 group

from acetonitrile-d3 (eq 12). Although the excellent regioselectivity of the addition reaction was established, partial

740

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

AWARD ACCOUNTS

OSiMe3

NC

23e (40 mmol)

+

a

64%

[Ni(cod)2] (5 mol %)

D3C CN

PPh2t -Bu (10 mol %)

(1.0 mmol)

AlMe3 (20 mol %)

+

2a (1.0 mmol) toluene, 80 C, 5 h

CN

24ev

regioselectivity = 96:4

2v (40 mmol)

b

Et CN

25b (1.0 mmol)

+

2a (2.0 mmol)

CN

61%

93%

D3C

CN

12

Pr

Pr

66%, 99%D

[Ni(cod)2] (10 mol %)

SPhos (20 mol %)

AlMe3 (40 mol %)

toluene, 50 C, 8 h

OMe

CHO

Et

93%

Pr

Pr CN

25c (1.0 mmol)

+

2a (2.0 mmol)

59%

Me

e, quant

RO

Zr

HO

R = Sii -Pr3

R = H: Plaunotol

g, 89%

Cl

Cl

Zr catalyst

Scheme 9. Total synthesis of plaunotol via allylcyanation.

Reagents and conditions: (a) [Ni(cod)2] (2 mol %), P(4CF3C6H4)3 (4 mol %), AlMe3 (8 mol %), toluene, 35 C,

8 h, then 1 M HCl aq., THF, 0 C to rt; (b) AcC(N2)P(O)(OMe)2, K2CO3, MeOH, 0 C to rt, 24 h; (c) DIBAL-H,

toluene, 78 C, 1.5 h, then SiO2; (d) LiAlH4, THF, 0 C to

rt, 20 min; (e) TIPS-Cl, imidazole, DMF, rt, 3 h; (f ) AlMe3,

Zr catalyst (5 mol %), MAO (5 mol %), rt, 48 h, then

n-BuLi, (HCHO)n, THF, rt, 1.5 h; (g) TBAF, THF, rt, 12 h.

Table 13. Methylcyanation of Alkynes Catalyzed by Ni/LA

[Ni(cod)2] (5 mol %)

Me CN

ligand (10 mol %)

25a (1.0 mmol) LA (20 mol %)

Me

R2

CN Me

+

+

R1

R2 toluene, 80 C

R1

R2

R1

CN

2 (1.0 mmol)

26

26'

R1, R2 = Et, Ph (2w)

Entry

1b)

2

3c)

4

5

6

7

2

2a

2c

2w

2q

2r

2s

2t

Cond.a)

A

A

B

C

C

C

C

Time/h

4

10

23

12

24

21

24

Yield/%

71

91

49

74

63

38

60

Pr

13

Pr

Pr

27, 1%

78%

SPhos

R=H

R = Sii -Pr3

CN

+

MeO PCy2

RO

CN

26/26

>95:5

88:12

61:39

91:9

86:14

91:9

75:25

a) Conditions A: PPh2t-Bu/AlMe3; B: PPh3/AlMe3;

PPh2t-Bu/AlMe3 with 10 mol % [Ni(cod)2]. b) Reaction run

on a 10.0 mmol scale. c) Reaction run using 25a as a solvent.

isomerization of the initial cis-adducts was observed to give

stereoisomeric mixtures of the methylcyanation products. The

use of the biarylphosphine ligands developed by Buchwald51

[Ni(cod)2] (10 mol %)

SPhos (20 mol %)

AlMe3 (40 mol %)

toluene, 50 C, 30 h

Pr

Pr

CN

Pr

+

+

27

H

Pr (19% by GC)

10%

Pr

CN 14

Pr

15%

Pr

was found to be eective for the ethylcyanation of alkynes

using propionitrile (25b) (eq 13). A small amount of hydrocyanation product 27 was observed, derived from the -hydride

elimination of an ethylnickel intermediate generated upon the

oxidative addition of propionitrile to nickel(0). This unwanted

reaction pathway competed with the carbocyanation reaction

when nitriles having higher alkyl chains, such as butyronitrile

25c, were used (eq 14). Alkyl cyanides having no -hydrogen,

however, eciently reacted with alkynes under nickel/LA

catalysis. Arylacetonitriles added across a range of alkynes to

give the corresponding alkylcyanation products in good yields

(Table 14).52 Heteroaryl moieties, even with unprotected NH,

were also tolerated under the reaction conditions (Entries 6 and

7). Terminal alkynes also participated in the alkylcyanation

reaction, although the origin for the reversed regioselectivity

remained elusive (Entries 1315). Other substituted acetonitriles, including phthalimidyl, THP-protected hydroxymethyl, and trimethylsilyl ones, participated in the carbocyanation

reaction (eqs 1517). The addition of (S)--phenylpropionitrile

25n of 85% ee with 2a was investigated to gain mechanistic

insights into the alkylcyanation reaction (eq 18). The corresponding adduct (S)-26na of 41% ee was obtained in 22%

yield, and its absolute conguration was determined based on

the reported optical rotation of (R)-2-phenyl-3-hexanone53 after

oxidative cleavage of the double bond in (S)-26na. Also

obtained were hydrocyanation product 27, styrene, and hydrocinnamonitrile in 35%, 44%, and 3% yields, respectively,

as estimated by GC. Recovered (S)-25n indicated 80% ee,

suggesting that background racemization under these conditions was likely slower than the racemization during the

carbocyanation process. No further racemization of (S)-25n

was noted under the present reaction conditions. These results

suggested the oxidative addition of a CCN bond of alkyl

Y. Nakao

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

Table 14. Alkylcyanation of Alkynes Using Arylacetonitriles Catalyzed by Ni/AlMe2Cl

[Ni(cod)2] (2 mol %)

Ar1

CN PAr2Cy2 (4 mol %)

25 (1.0 mmol) AlMe2Cl (8 mol %)

+

R1

R2 toluene

2 (1.0 mmol)

Ar2 = 2-mesityl

Ar1 = Ph (25d)

4-MeOC6H4 (25e)

4-ClC6H4 (25f)

2-MeO2CC6H4 (25g)

3-thienyl (25h)

2-pyrrolyl (25i)

3-indolyl (25j)

Entry

25

1

2

3

4

5

6a)

7a)

8

9

10

11

12a)

13c)

14c)

15c)

25d

25e

25f

25g

25h

25i

25j

25d

25d

25d

25d

25d

25d

25d

25d

2a

2a

2a

2a

2a

2a

2a

2c

2x

2i

2e

2g

2kd)

2yd)

2zd)

Ar1

CN

Ar1

NC

+

R1

26

R2

R1

Me3Si

CN

Pr

89%

[Ni(cod)2] (20 mol %)

XPhos (40 mol %)

AlMe2Cl (20 mol %)

R2

26'

+

2a

Ph

CN

(5.0 equiv)

(S )-25n, 85% ee

R1, R2 = Ph (2x)

H, Cy (2y)

H, t -Bu (2z)

Temp

/C

35

35

80

80

80

35

35

80

80

35

35

35

35

35

35

[Ni(cod)2] (5 mol %)

CN PCyp3 (10 mol %)

Me3Si

25m (1.0 mmol) BPh3 (20 mol %)

+

2a (1.5 mmol) toluene, 80 C, 13 h

741

17

Pr

toluene, 80 C, 0.5 h

83% conv. of 25n

Ph

Time

/h

8

8

18

5

2

10

48

70

73

24

21

53

11

9

9

Yield

/%

90

93

74

56

95

54

69

93

86

85

94

56

48

61

54

Pr

26:26

b)

92:8

>95:5

81:19

12:88

8:92

5:>95

a) Reaction run with Ni/PAr2Cy2/AlMe2Cl = 10/20/40

mol %. b) E/Z = 79:21 (82:18 at 1.5 h). c) Reaction run with

Ni/PPh2Me/AlMe2Cl = 10/20/40 mol %. d) 3.0 mmol.

CN

CN

CN

+

Pr

Pr

Ph

Pr

Ph

44% (GC)

27

35% (GC)

(S )-26na

22%, 41% ee

18

+

3% (GC)

i -Pr

i -Pr

i -Pr PCy2

XPhos

R4

L

R3

L

Ni

R1

R3

R1

C

R2

N

LA

LA

R4

R2

R1

Ni

R3

Ni

R4L

L

R4

R3 = Ar, PhthN, THPO, SiMe3

R4 = H, Me

L = phosphine

R2

LA

R3

CN

O

N

R1

CN

O

25k (1.0 mmol)

+

2a (2.0 mmol)

[Ni(cod)2] (5 mol %)

PAr3 (10 mol %)

BPh3 (20 mol %)

toluene, 80 C, 30 h

LA

R4

O

CN 15

Pr

O Pr

64%

+

isomeric mixture

of 1:2 adducts

(1020%)

R2

N

C

R3

L

Ar = 3,5-Me2 4-MeO C6H2

R3

retention of

stereochemistry

Ni

R4

R4

N

C

L

Ni

R3 = Ph; R4 = Me

LA

N styrene 2a

C

Ph

Ni

H

CN

R1

LA

Pr

Pr

LA

R3

N

C

Ni

+L

styrene 2a

[Ni(cod)2] (10 mol %)

CN P(p -An)3 (20 mol %)

O

O

25l (1.0 mmol) BPh3 (40 mol %)

+

2a (1.5 mmol) toluene, 80 C, 3 h

O

O

CN

16

cyanides with retention of conguration, in contrast to the

nonstereospecic oxidative addition of benzyl halides to

nickel(0).54 The oxidative addition of acetonitrile to nickel(0)

LA

Pr

Pr

N

C

Pr

Pr

82%

+

isomeric mixture

of 1:2 adducts

(1020%)

+L

LA

N

Ph

Ni

L

Ni

L

27 + L2Ni0 + LA

Ph(CH2)2CN

+ L2Ni0 + LA

pathways for by-product formation in Eq. 18

Scheme 10. A plausible mechanism for the alkylcyanation

of alkynes.

R2

742

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

AWARD ACCOUNTS

Table 15. Alkylcyanation of Alkynes Using -HeteroatomSubstituted Alkanenitriles Catalyzed by Ni/AlMe3

R3

[Ni(cod)2] (10 mol %)

P(o -An)3 (10 mol %)

AlMe3 (40 mol %)

X

CN

28 (1.0 mmol)

+

R1

R2

2 (2.0 mmol)

Y

CN

28f

CN

toluene

X, R3 = BnMeN, H (28a)

pyrrolidin-1-yl, H (28b)

pyrrolidin-1-yl, Et (28c)

pyrrolidin-1-yl, Ph (28d)

pyrrolidin-1-yl, OSiMe2t -Bu (28e)

BnO, H (28j)

t -BuMe2SiO, H (28k)

BnS, H (28n)

BnN

R3

CN

R1

29

+

R3

R2

NC

R1

R2

29'

BnN

CN

X

X, Y = NMe, CH2 (28g)

O, CH2 (28l)

O (28m)

CN

28h

28i

Entry

1a)

2c)

3

4

5

6a)

7a)

8

9a)

10

11

12a)

13

14e)

15f )

16c)

17

18c)

19g)

28

28a

28b

28c

28d

28e

28f

28g

28h

28i

28j

28k

28l

28m

28n

28a

28b

28d

28b

28b

2

Temp/C

b)

2a

80

2ab)

80

2a

60

2a

60

2a

60

2ab)

80

2ab)

80

2a

60

2ad)

50

2a

50

2a

50

2a

50

2a

50

2ab)

50

2b

50

2cb)

80

2d

60

2eb)

80

2zb)

50

Time/h

20

9

8

31

3

3

9

111

4

20

40

40

22

24

10

5

14

13

26

Yield/%

88

88

89

90

90

79

82

49

94

64

65

47

66

79

72

94

87

88

74

29:29

91:9

>95:5

>95:5

a) Reaction run with Ni/P(o-An)3/AlMe3 = 5/5/20 mol %.

b) 1.4 mmol. c) Reaction run with Ni/P(o-An)3/AlMe3 =

3/3/12 mol %. d) 1.1 mmol. e) Reaction run with Ni/P(t-Bu)3/

AlMe3 = 5/5/20 mol % as a ligand. f ) Reaction run with 60

mol % AlMe3. g) Reaction run with Ni/AsPh3/B(C6F5)3 =

3/3/12 mol %.

with retention of conguration was also suggested by theoretical calculations.6o Coordination and then migratory insertion

of alkynes into the ArC(R)HNi bond are followed by

reductive elimination to give rise to the alkylcyanation products

(Scheme 10).55 The absolute conguration can be retained

during the catalytic cycle. The observed partial loss of % ee,

nevertheless, can be ascribed to the -hydride elimination from

the alkylnickel intermediate followed by the reinsertion of

the coordinated olen and/or the reversible exchange of the

olen ligand by alkynes. The formation of the aforementioned

side products supported the occurrence of these possible side

reactions. The competitive -hydride elimination from the

alkylnickel intermediates in the alkylcyanation can be partially

suppressed by introducing a coordinating functionality at the

-position of the cyano group in the alkyl cyanide substrates

(Table 15).56 The intramolecular coordination of heteroatom

functionalities such as nitrogen, oxygen, and sulfur should

occupy the vacant coordination site requisite for the unwanted

-hydride elimination. It is worth noting, nevertheless, that

such substrate design allowed the addition of even secondary

alkyl cyanides across alkynes (Entries 35). The location of the

amino-substituents aects the reaction course: an amino group

at the -position of alkylnitriles retarded the reaction, whereas

its location at the - or -position directed the CC bond

formation at the -position of the amino group, possibly

through ve-membered aza-nickelacycle intermediates generated through the oxidative addition of the CCN bonds

followed by the -hydride elimination and the subsequent

reinsertion of the coordinating double bonds (eqs 19 and 20).57

N

CN

28o (1.0 mmol)

+

2a (2.0 mmol)

[Ni(cod)2] (10 mol %)

SPhos (20 mol %)

AlMe3 (40 mol %)

N

CN

toluene, 50 C, 11 h

77%

Pr

19

Pr

CN [Ni(cod) ] (10 mol %)

2

SPhos (20 mol %)

28p (1.0 mmol)

AlMe3 (60 mol %)

+

toluene, 80 C, 45 h

2a (2.0 mmol)

N

CN

20

45% Pr

Pr

+ 27 (9% by GC)

Summary

In conclusion, we have achieved the carbocyanation reaction

of alkynes with a diverse range of nitriles. In addition to the

reactions across alkynes, the carbocyanation reactions of other

unsaturated compounds, such as norbornadiene and 1,2-dienes,

with some nitriles were also eected. The intramolecular

arylcyanation of alkenes has been developed to allow access

to nitriles having benzylic quaternary stereocenters with high

enantioselectivities. All the developments rely wholly on the

invention of the nickel/LA cooperative catalyst systems, which

signicantly promote the oxidative addition of unreactive

CCN bonds to nickel(0), whereas the reductive elimination of

CCN can also be promoted by LA through the coordination

of a cyano group to the LA.58 We have also discerned the

mechanism of CCN activation by the cooperative catalysis, by

characterizing some nitrilenickel complexes in which cyano

groups coordinate to the LA additives. Nevertheless, to

advance carbocyanation reactions as fully general methods

for CC bond formation, several issues remain to be solved: 1)

the limited scope of alkyl cyanides, and 2) the general intermolecular carbocyanation reactions of alkenes, both of which

should rely on a catalyst design to promote the reductive

elimination of C(sp3)CN bonds over competitive -hydride

elimination. Another issue is the rather limited scope of alkynes

excluding terminal ones, which often suered from competitive

alkyne trimerization and/or oligomerization, particularly in

Y. Nakao

the presence of nickel catalysts coordinated by electrondonating phosphine ligands. These goals will be pursued in

our laboratories to establish the carbocyanation protocol as a

highly general and practical synthetic tool for chemists.

The author is grateful to Profs. Tamejiro Hiyama, Sensuke

Ogoshi, Masaki Shimizu, and Masato Ohashi for their kind

support and fruitful discussions. The author also acknowledges

Profs. Timothy F. Jamison and William D. Jones for stimulating discussions regarding the reaction mechanisms. I appreciate

experimental and intellectual contributions by my co-workers,

Dr. Yasuhiro Hirata, Dr. Akira Yada, Dr. Jen-Chieh Hsieh, Mr.

Shinichi Oda, Mr. Jun Satoh, Mr. Tomoya Yukawa, Mr. Shiro

Ebata, Mr. Masaaki Tanaka, Mr. Hiroaki Idei, Mr. Yuuya

Yamada, and Mr. Eiji Morita. This work has been supported

nancially by a Grant-in-Aid for Creative Scientic Research

(No. 16GS0209), Scientic Research (S) (No. 21225005),

Young Scientists (Nos. 19750076 and 21685023), Priority

Areas Chemistry of Concerto Catalysis (Nos. 19028030

and 20037035) and Molecular Theory for Real Systems

(Nos. 19029024 and 20038027), and Scientic Research

on Innovative Areas Molecular Activation Directed toward

Straightforward Synthesis (No. 22105003) by MEXT and

JSPS. The author also acknowledges Mitsubishi Chemical

Corporation Fund, Japan Chemical Innovation Institute, Showa

Shell Sekiyu Foundation for Promotion of Environmental

Research, The Sumitomo Foundation, The Uehara Memorial

Foundation, General Sekiyu Research & Development Encouragement & Assistance Foundation, Kurata Memorial Hitachi

Science and Technology Foundation, and Takeda Science

Foundation for support.

References

1 a) R. H. Crabtree, Chem. Rev. 1985, 85, 245. b) B.

Rybtchinski, D. Milstein, Angew. Chem., Int. Ed. 1999, 38, 870.

c) M. Murakami, Y. Ito, in Activation of Unreactive Bonds and

Organic Synthesis in Topics in Organometallic Chemistry, ed.

by S. Murai, Spriger-Verlag, Berlin, 1999, Vol. 3, pp. 97129.

doi:10.1007/3-540-68525-1_5. d) C.-H. Jun, Chem. Soc. Rev.

2004, 33, 610. e) M. Murakami, T. Matsuda, Chem. Commun.

2011, 47, 1100. f ) K. Ruhland, Eur. J. Org. Chem. 2012, 2683.

2 a) R. Noyori, T. Odagi, H. Takaya, J. Am. Chem. Soc. 1970,

92, 5780. b) R. Noyori, Y. Kumagai, I. Umeda, H. Takaya, J. Am.

Chem. Soc. 1972, 94, 4018. c) A. Baba, Y. Ohshiro, T. Agawa,

J. Organomet. Chem. 1976, 110, 121. d) P. Binger, B. Schfer,

Tetrahedron Lett. 1988, 29, 4539. e) T. Kondo, Y. Kaneko, Y.

Taguchi, A. Nakamura, T. Okada, M. Shiotsuki, Y. Ura, K. Wada,

T.-a. Mitsudo, J. Am. Chem. Soc. 2002, 124, 6824. f ) S. Saito, M.

Masuda, S. Komagawa, J. Am. Chem. Soc. 2004, 126, 10540. g) S.

Komagawa, S. Saito, Angew. Chem., Int. Ed. 2006, 45, 2446. h) S.

Saito, K. Takeuchi, Tetrahedron Lett. 2007, 48, 595. i) K. Maeda,

S. Saito, Tetrahedron Lett. 2007, 48, 3173.

3 a) R. Noyori, T. Suzuki, H. Takaya, J. Am. Chem. Soc.

1971, 93, 5896. b) M. A. Human, L. S. Liebeskind, J. Am. Chem.

Soc. 1991, 113, 2771. c) B. L. Edelbach, R. J. Lachicotte, W. D.

Jones, Organometallics 1999, 18, 4040. d) C. N. Iverson, W. D.

Jones, Organometallics 2001, 20, 5745. e) C. Mller, R. J.

Lachicotte, W. D. Jones, Organometallics 2002, 21, 1975. f ) T.

Kondo, Y. Taguchi, Y. Kaneko, M. Niimi, T.-a. Mitsudo, Angew.

Chem., Int. Ed. 2004, 43, 5369. g) M. Murakami, T. Itahashi, Y.

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

743

Ito, J. Am. Chem. Soc. 2002, 124, 13976. h) T. Matsuda, A.

Fujimoto, M. Ishibashi, M. Murakami, Chem. Lett. 2004, 33, 876.

i) M. Murakami, S. Ashida, T. Matsuda, J. Am. Chem. Soc. 2005,

127, 6932. j) T. Schaub, M. Backes, U. Radius, Organometallics

2006, 25, 4196. k) M. Murakami, S. Ashida, T. Matsuda, J. Am.

Chem. Soc. 2006, 128, 2166. l) M. Murakami, S. Ashida, Chem.

Commun. 2006, 4599. m) M. Murakami, S. Ashida, T. Matsuda,

Tetrahedron 2006, 62, 7540. n) S. Ashida, M. Murakami, Bull.

Chem. Soc. Jpn. 2008, 81, 885.

4 For exceptional examples involving the cleavage of nonstrained CC bonds of carbonyl compounds that have been

reported recently, see: a) V. Nair, A. N. Pillai, R. S. Menon, E.

Suresh, Org. Lett. 2005, 7, 1189. b) Y. Kuninobu, A. Kawata, K.

Takai, J. Am. Chem. Soc. 2006, 128, 11368. c) Y. Kuninobu, A.

Kawata, M. Nishi, H. Takata, K. Takai, Chem. Commun. 2008,

6360. d) A. N. Pillai, C. H. Suresh, V. Nair, Chem.Eur. J. 2008,

14, 5851. e) A. M. Dreis, C. J. Douglas, J. Am. Chem. Soc. 2009,

131, 412. f ) M. T. Wentzel, V. J. Reddy, T. K. Hyster, C. J.

Douglas, Angew. Chem., Int. Ed. 2009, 48, 6121. g) Y. Kuninobu,

A. Kawata, M. Nishi, S. Yudha S., J. Chen, K. Takai, Chem.

Asian J. 2009, 4, 1424.

5 For the insertion reactions of arynes into non-strained CC

bonds, see: a) M. Guyot, D. Molho, Tetrahedron Lett. 1973, 14,

3433. b) M. D. Shair, T. Y. Yoon, K. K. Mosny, T. C. Chou, S. J.

Danishefsky, J. Am. Chem. Soc. 1996, 118, 9509. c) Y. Kita, K.

Higuchi, Y. Yoshida, K. Iio, S. Kitagaki, K. Ueda, S. Akai, H.

Fujioka, J. Am. Chem. Soc. 2001, 123, 3214. d) U. K. Tambar,

B. M. Stoltz, J. Am. Chem. Soc. 2005, 127, 5340. e) H. Yoshida,

M. Watanabe, J. Ohshita, A. Kunai, Chem. Commun. 2005, 3292.

f ) H. Yoshida, M. Watanabe, J. Ohshita, A. Kunai, Tetrahedron

Lett. 2005, 46, 6729. g) H. Yoshida, M. Watanabe, T. Morishita, J.

Ohshita, A. Kunai, Chem. Commun. 2007, 1505.

6 a) J. L. Burmeister, L. M. Edwards, J. Chem. Soc. A 1971,

1663. b) E. L. Muetterties, D. H. Gerlach, A. R. Kane, G. W.

Parshall, J. P. Jesson, J. Am. Chem. Soc. 1971, 93, 3543. c) G. W.

Parshall, J. Am. Chem. Soc. 1974, 96, 2360. d) D. A. Clarke,

M. M. Hunt, D. W. Kemmitt, J. Organomet. Chem. 1979, 175,

303. e) A. Morvillo, A. Turco, J. Organomet. Chem. 1981, 208,

103. f ) G. Favero, A. Morvillo, A. Turco, J. Organomet. Chem.

1983, 241, 251. g) C. Bianchini, D. Masi, A. Meli, M. Sabat,

Organometallics 1986, 5, 1670. h) M. Abla, T. Yamamoto,

J. Organomet. Chem. 1997, 532, 267. i) D. Churchill, J. H. Shin, T.

Hascall, J. M. Hahn, B. M. Bridgewater, G. Parkin, Organometallics 1999, 18, 2403. j) J. J. Garca, N. M. Brunkan, W. D.

Jones, J. Am. Chem. Soc. 2002, 124, 9547. k) Q.-X. Liu, F.-B. Xu,

Q.-S. Li, H.-B. Song, Z.-Z. Zhang, Organometallics 2004, 23, 610.

l) N. M. Brunkan, D. M. Brestensky, W. D. Jones, J. Am. Chem.

Soc. 2004, 126, 3627. m) J. J. Garca, A. Arvalo, N. M. Brunkan,

W. D. Jones, Organometallics 2004, 23, 3997. n) X. Li, H. Sun,

F. Yu, U. Flrke, H.-F. Klein, Organometallics 2006, 25, 4695.

o) T. A. Atein, T. Li, S. Lachaize, W. W. Brennessel, J. J. Garca,

W. D. Jones, J. Am. Chem. Soc. 2007, 129, 7562. p) T. Schaub, C.

Dring, U. Radius, Dalton Trans. 2007, 1993. q) A. AcostaRamrez, M. Flores-lamo, W. D. Jones, J. J. Garca, Organometallics 2008, 27, 1834. r) T. A. Atein, T. Li, S. Lachaize, J. J.

Garca, W. D. Jones, Organometallics 2008, 27, 3811. s) B. D.

Swartz, N. M. Reinartz, W. W. Brennessel, J. J. Garca, W. D.

Jones, J. Am. Chem. Soc. 2008, 130, 8548. t) T. Li, J. J. Garca,

W. W. Brennessel, W. D. Jones, Organometallics 2010, 29, 2430.

u) M. E. Evans, T. Li, W. D. Jones, J. Am. Chem. Soc. 2010, 132,

16278. v) M. E. Evans, W. D. Jones, Organometallics 2011, 30,

3371.

744

Bull. Chem. Soc. Jpn. Vol. 85, No. 7 (2012)

AWARD ACCOUNTS

7 a) F. L. Taw, P. S. White, R. G. Bergman, M. Brookhart,

J. Am. Chem. Soc. 2002, 124, 4192. b) F. L. Taw, A. H. Mueller,

R. G. Bergman, M. Brookhart, J. Am. Chem. Soc. 2003, 125, 9808.

c) H. Nakazawa, T. Kawasaki, K. Miyoshi, C. H. Suresh, N. Koga,

Organometallics 2004, 23, 117. d) H. Hashimoto, A. Matsuda,

H. Tobita, Organometallics 2006, 25, 472. e) M. Ochiai, H.

Hashimoto, H. Tobita, Angew. Chem., Int. Ed. 2007, 46, 8192.

8 B. N. Storho, H. C. Lewis, Jr., Coord. Chem. Rev. 1977,

23, 1.

9 a) L. H. Jones, Inorg. Chem. 1963, 2, 777. b) J. Halpern, G.

Guastalla, J. Bercaw, Coord. Chem. Rev. 1972, 8, 167. c) L. H.

Jones, B. I. Swanson, Acc. Chem. Res. 1976, 9, 128. d) H. E.

Bryndza, P. J. Domaille, W. Tam, L. K. Fong, R. A. Paciello, J. E.

Bercaw, Polyhedron 1988, 7, 1441. e) V. M. Rayn, P. Redondo,

H. Valds, C. Barrientos, A. Largo, J. Phys. Chem. A 2007, 111,

6334.

10 M. Tobisu, N. Chatani, Chem. Soc. Rev. 2008, 37, 300.

11 a) A. Chaumonnot, F. Lamy, S. Sabo-Etienne, B.

Donnadieu, B. Chaudret, J.-C. Barthelat, J.-C. Galland, Organometallics 2004, 23, 3363. b) J. I. van der Vlugt, A. C. Hewat,

S. Neto, R. Sablong, A. M. Mills, M. Lutz, A. L. Spek, C. Mller,

D. Vogt, Adv. Synth. Catal. 2004, 346, 993. c) J. Wilting, C.

Mller, A. C. Hewat, D. D. Ellis, D. M. Tooke, A. L. Spek, D.

Vogt, Organometallics 2005, 24, 13. d) A. Acosta-Ramrez, M.

Muoz-Hernndez, W. D. Jones, J. J. Garca, J. Organomet. Chem.

2006, 691, 3895. e) A. Acosta-Ramrez, A. Flores-Gaspar, M.

Muoz-Hernndez, A. Arvalo, W. D. Jones, J. J. Garca,

Organometallics 2007, 26, 1712. f ) A. Acosta-Ramrez, M.

Muoz-Hernndez, W. D. Jones, J. J. Garca, Organometallics

2007, 26, 5766. g) M. E. Tauchert, T. R. Kaiser, A. P. V. Gthlich,

F. Rominger, D. C. M. Warth, P. Hofmann, ChemCatChem 2010,

2, 674. h) T. Li, W. D. Jones, Organometallics 2011, 30, 547.

12 R. J. McKinney, in Homogeneous Catalysis: The Applications and Chemistry of Catalysis by Soluble Transition Metal

Complexes, ed. by G. W. Parshall, S. D. Ittel, Wiley, New York,

1992, pp. 4250.

13 a) J. A. Miller, Tetrahedron Lett. 2001, 42, 6991. b) J. A.

Miller, J. W. Dankwardt, Tetrahedron Lett. 2003, 44, 1907. c) J. A.

Miller, J. W. Dankwardt, J. M. Penney, Synthesis 2003, 1643.

d) J. M. Penney, J. A. Miller, Tetrahedron Lett. 2004, 45, 4989.

e) D.-G. Yu, M. Yu, B.-T. Guan, B.-J. Li, Y. Zheng, Z.-H. Wu,

Z.-J. Shi, Org. Lett. 2009, 11, 3374. f ) M. Sun, H.-Y. Zhang, Q.

Han, K. Yang, S.-D. Yang, Chem.Eur. J. 2011, 17, 9566.

14 a) H. Nakazawa, K. Kamata, M. Itazaki, Chem. Commun.

2005, 4004. b) H. Nakazawa, M. Itazaki, K. Kamata, K. Ueda,

Chem.Asian J. 2007, 2, 882. c) M. Tobisu, R. Nakamura, Y. Kita,

N. Chatani, J. Am. Chem. Soc. 2009, 131, 3174. d) M. Tobisu, R.

Nakamura, Y. Kita, N. Chatani, Bull. Korean Chem. Soc. 2010, 31,

582.

15 a) M. Tobisu, Y. Kita, Y. Ano, N. Chatani, J. Am. Chem.

Soc. 2008, 130, 15982. b) Y. Kita, M. Tobisu, N. Chatani, Org.

Lett. 2010, 12, 1864.

16 M. Tobisu, Y. Kita, N. Chatani, J. Am. Chem. Soc. 2006,

128, 8152.

17 M. Tobisu, H. Kinuta, Y. Kita, E. Rmond, N. Chatani,

J. Am. Chem. Soc. 2012, 134, 115.

18 S. J. Blanksby, G. B. Ellison, Acc. Chem. Res. 2003, 36,

255.

19 a) K. Nozaki, N. Sato, H. Takaya, J. Org. Chem. 1994, 59,

2679. b) K. Nozaki, N. Sato, H. Takaya, Bull. Chem. Soc. Jpn.

1996, 69, 1629.

20 a) Y. Nishihara, Y. Inoue, M. Itazaki, K. Takagi, Org. Lett.

2005, 7, 2639. b) Y. Nishihara, Y. Inoue, S. Izawa, M. Miyasaka,

K. Tanemura, K. Nakajima, K. Takagi, Tetrahedron 2006, 62,

9872. c) Y. Nishihara, M. Miyasaka, Y. Inoue, T. Yamaguchi, M.

Kojima, K. Takagi, Organometallics 2007, 26, 4054.

21 N. R. Rondla, S. M. Levi, J. M. Ryss, R. A. V. Berg, C. J.

Douglas, Org. Lett. 2011, 13, 1940.

22 a) Y. Kobayashi, H. Kamisaki, R. Yanada, Y. Takemoto,

Org. Lett. 2006, 8, 2711. b) Y. Kobayashi, H. Kamisaki, H. Takeda,

Y. Yasui, R. Yanada, Y. Takemoto, Tetrahedron 2007, 63, 2978.

c) Y. Yasui, H. Kamisaki, Y. Takemoto, Org. Lett. 2008, 10, 3303.

d) Y. Yasui, T. Kinugawa, Y. Takemoto, Chem. Commun. 2009,

4275. e) V. J. Reddy, C. J. Douglas, Org. Lett. 2010, 12, 952. f ) Y.

Yasui, H. Kamisaki, T. Ishida, Y. Takemoto, Tetrahedron 2010, 66,

1980. g) V. J. Reddy, C. J. Douglas, Tetrahedron 2010, 66, 4719.

23 For previous accounts, see: a) Y. Nakao, T. Hiyama, Pure

Appl. Chem. 2008, 80, 1097. b) Y. Nakao, T. Hiyama, J. Synth.

Org. Chem., Jpn. 2007, 65, 999.

24 a) Y. Nakao, S. Oda, T. Hiyama, J. Am. Chem. Soc. 2004,

126, 13904. b) Y. Nakao, S. Oda, A. Yada, T. Hiyama, Tetrahedron

2006, 62, 7567.

25 Y. Nakao, A. Yada, J. Satoh, S. Ebata, S. Oda, T. Hiyama,

Chem. Lett. 2006, 35, 790.

26 Y. Nakao, T. Yukawa, Y. Hirata, S. Oda, J. Satoh, T.

Hiyama, J. Am. Chem. Soc. 2006, 128, 7116.

27 a) Y. Nakao, Y. Hirata, T. Hiyama, J. Am. Chem. Soc. 2006,

128, 7420. b) Y. Hirata, T. Inui, Y. Nakao, T. Hiyama, J. Am.

Chem. Soc. 2009, 131, 6624.

28 Y.-y. Ohnishi, Y. Nakao, H. Sato, Y. Nakao, T. Hiyama, S.

Sakaki, Organometallics 2009, 28, 2583.

29 Formation of a similar 2-arenenickel intermediate was also

suggested to precede the PhCN -bond activation by Ni(dmpe),

see Ref. 6r.

30 C. A. Tolman, W. C. Seidel, J. D. Druliner, P. J. Domaille,

Organometallics 1984, 3, 33.

31 a) Y. Nakao, A. Yada, S. Ebata, T. Hiyama, J. Am. Chem.

Soc. 2007, 129, 2428. b) A. Yada, S. Ebata, H. Idei, D. Zhang, Y.

Nakao, T. Hiyama, Bull. Chem. Soc. Jpn. 2010, 83, 1170.

32 K. Tamao, K. Sumitani, Y. Kiso, M. Zembayashi, A.

Fujioka, S.-i. Kodama, I. Nakajima, A. Minato, M. Kumada, Bull.

Chem. Soc. Jpn. 1976, 49, 1958.

33 a) H. J. Harwood, Jr., E. G. Barbacci-Tobin, S. F. Petras, S.

Lindsey, L. D. Pellarin, Biochem. Pharmacol. 1997, 53, 839.

b) S. K. Figdor, E. C. Schreiber, R. B. Stebbins, P. F. Moore, R.

Pinson, Jr., J. Med. Chem. 1964, 7, 508.

34 M. Suginome, A. Yamamoto, M. Murakami, Angew.

Chem., Int. Ed. 2005, 44, 2380.

35 a) Y. Nishihara, Y. Inoue, Y. Nakayama, T. Shiono, K.

Takagi, Macromolecules 2006, 39, 7458. b) Y. Nishihara, Y. Inoue,

A. T. Saito, Y. Nakayama, T. Shiono, K. Takagi, Polym. J. 2007,

39, 318. c) Y. Nishihara, S. Izawa, Y. Inoue, Y. Nakayama, T.

Shiono, K. Takagi, J. Polym. Sci., Part A: Polym. Chem. 2008, 46,

3314. d) Y. Nishihara, Y. Doi, S. Izawa, H.-Y. Li, Y. Inoue, M.

Kojima, J.-T. Chen, K. Takagi, J. Polym. Sci., Part A: Polym.

Chem. 2010, 48, 485.

36 Y. Nakao, S. Ebata, A. Yada, T. Hiyama, M. Ikawa, S.

Ogoshi, J. Am. Chem. Soc. 2008, 130, 12874.

37 Y. Miyake, Y. Nishibayashi, S. Uemura, Synlett 2008, 1747.

38 J.-C. Hsieh, S. Ebata, Y. Nakao, T. Hiyama, Synlett 2010,

1709.

39 a) J. M. J. Williams, Synlett 1996, 705. b) G. Helmchen, A.

Pfaltz, Acc. Chem. Res. 2000, 33, 336.