Documente Academic

Documente Profesional

Documente Cultură

Mahalaxmi Wardha REPORT22222

Încărcat de

Anonymous RXXdbl36ADrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mahalaxmi Wardha REPORT22222

Încărcat de

Anonymous RXXdbl36ADrepturi de autor:

Formate disponibile

REPORT

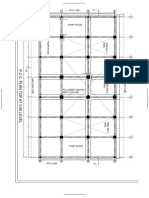

visited site on 24th may 2013 and inspected crane runway girder in sms division.

Findings

4 no 20 ton crane + 2no 100 ton crane + 4no 20 ton

Details of crane runway girder of span 6mts is as follows

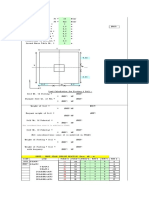

V

Section element

S Shapes ISMC300

Sheet 230 x 16

Sheet 840 x 16

Sheet 230 x 16

Equal Angles ISA100X100X8

Equal Angles ISA100X100X8

Equal Angles ISA100X100X8

Equal Angles ISA100X100X8

Rotation angle

-90.0

0

90.0

0

90.0

180.0

270.0

0

Material

Steel

Steel

Steel

Steel

Steel

Steel

Steel

Steel

E (kN/mm^2)

205.0

205.0

205.0

205.0

205.0

205.0

205.0

205.0

The overall dimensions of the section are 300 x 880 mm

Basic geometry of the composite section is as below

Parameter

A

cross sectional area

angle between y-z and u-v axes

Iy

moment of inertia about axis parallel to y passing through centroid

Iz

moment of inertia about axis parallel to z passing through centroid

It

torsional moment of inertia (st. venant)

iy

radius of gyration about axis parallel to y passing through centroid

iz

radius of gyration about axis parallel to z passing through centroid

Wu+

max elastic modulus about u-axis

Wumin elastic modulus about u-axis

Wv+

max elastic modulus about v-axis

Wvmin elastic modulus about v-axis

Wpl,u plastic modulus about u-axis

Wpl,v plastic modulus about v-axis

Iu

moment of inertia about u-axis

Iv

moment of inertia about v-axis

iu

radius of gyration about u-axis

iv

radius of gyration about v-axis

au+

centroid to edge of compression zone along +ve u-axis

aucentroid to edge of compression zone along -ve u-axis

av+

centroid to edge of compression zone along +ve v-axis

avcentroid to edge of compression zone along -ve v-axis

yM

distance to centroid along y-axis

zM

distance to centroid along z-axis

yP

distance to equal area axis along y-axis

zP

distance to equal area axis along z-axis

1.

2.

3.

4.

5.

6.

Value

31520.0

-0.0

3778983128.11

109575553.01

2009064.81

346.25

58.96

7611443.48

9863887.76

730503.66

730503.66

9951968.72

1183658.17

3778983128.11

109575553.01

346.25

58.96

23.18

23.18

241.48

312.94

-150.0

-383.11

-150.1

-305.3

Welding in crane runway girders are cracked at many places

Joints in rail, cap channel, and built-up girder are not staggered

Fish plate in rail and girders are missing at many places

Lateral bracing is missing (horizontal thrust protection)

Bolts clamping rail and cap channel are loose

Wheels are eating rails on both sides

Recommendations

1. Lateral bracing to be provided

2. Fish plates to be provided IN RAILS AND IN GANTRY GIRDER

mm2

deg

mm4

mm4

mm4

mm

mm

mm3

mm3

mm3

mm3

mm3

mm3

mm4

mm4

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

3. Alignment of rails to be done

4. Diagonal check of crane wheels to be done

5. Welding to be re done using appropriate welding rods (7018

AFTER HEATING)

6. Crane load test to be done

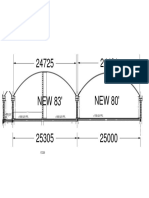

Crane runway furnace side at ends was calculated for loads as

suggested by mahalaxmi management ie: 20 ton lifting load and found

to be safe in vertical direction

0.837 utilization ratio

Assuming crane dead wt as

Crab weight

End carriage weight

Lifting weight

Rail height from ground

Rail c/c

End carriage wheel to wheel

Min hook approach

5

17.5

15

ton

3

23

mts

25.03

5.5

1.2

ton

ton each

ton

mts

mts

mts

Calculations attached in pdf format

But still runway girder requires lateral support (HORIZONTAL SUPPORT) due to

weak base plate arrangement

TENTATIVE LATERAL BRACING DETAILS ATTACHED

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Footing Details Control BLDDocument1 paginăFooting Details Control BLDAnonymous RXXdbl36AÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument4 pagini68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36AÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Construction estimate for internal road and labour quartersDocument1 paginăConstruction estimate for internal road and labour quartersAnonymous RXXdbl36AÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Truck load and unload dates reportDocument2 paginiTruck load and unload dates reportAnonymous RXXdbl36AÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument6 pagini68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36AÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Sbi Sunita Income TaxwasteDocument2 paginiSbi Sunita Income TaxwasteAnonymous RXXdbl36AÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- To Intrest CertificateDocument1 paginăTo Intrest CertificateAnonymous RXXdbl36AÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Water Tank Rev PCC Top Detail at 0.6 LevDocument1 paginăWater Tank Rev PCC Top Detail at 0.6 LevAnonymous RXXdbl36AÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Old Old: +850 Lev FFL +1000 Lev FFL +1000 Lev FFL +1150 Lev FFLDocument1 paginăOld Old: +850 Lev FFL +1000 Lev FFL +1000 Lev FFL +1150 Lev FFLAnonymous RXXdbl36AÎncă nu există evaluări

- Sbi Sunita Income TaxwasteDocument2 paginiSbi Sunita Income TaxwasteAnonymous RXXdbl36AÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Waste2 Steel Making and Beam Design2333444Document12 paginiWaste2 Steel Making and Beam Design2333444Anonymous RXXdbl36AÎncă nu există evaluări

- STAAD Support Reaction AnalysisDocument4 paginiSTAAD Support Reaction AnalysisAnonymous RXXdbl36AÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Waste2 Steel Making and Beam Design23335555Document5 paginiWaste2 Steel Making and Beam Design23335555Anonymous RXXdbl36AÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Waste2 Steel Making and Beam Design2333Document8 paginiWaste2 Steel Making and Beam Design2333Anonymous RXXdbl36AÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Waste2 Steel Making and Beam Design2Document4 paginiWaste2 Steel Making and Beam Design2Anonymous RXXdbl36AÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Waste2 Steel Making and Beam DesignDocument4 paginiWaste2 Steel Making and Beam DesignAnonymous RXXdbl36AÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Staad Support Reaction AnalysisDocument31 paginiStaad Support Reaction AnalysisAnonymous RXXdbl36AÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- 3 Tundish Well Block High Grog Quality Fire Clay Bulk Density-38 To 42 4 Tundish Bricks IS8 - 58%ALUMINA 230X115X25 230X115X25Document4 pagini3 Tundish Well Block High Grog Quality Fire Clay Bulk Density-38 To 42 4 Tundish Bricks IS8 - 58%ALUMINA 230X115X25 230X115X25Anonymous RXXdbl36AÎncă nu există evaluări

- Load Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Document31 paginiLoad Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Anonymous RXXdbl36AÎncă nu există evaluări

- Load Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Document31 paginiLoad Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Anonymous RXXdbl36AÎncă nu există evaluări

- STAAD Support Reaction AnalysisDocument4 paginiSTAAD Support Reaction AnalysisAnonymous RXXdbl36AÎncă nu există evaluări

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument6 pagini68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36AÎncă nu există evaluări

- SR Ingot Footing Was2Document30 paginiSR Ingot Footing Was2Anonymous RXXdbl36AÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K UrlaDocument2 paginiSteel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K UrlaAnonymous RXXdbl36AÎncă nu există evaluări

- Waste 5Document2 paginiWaste 5Anonymous RXXdbl36AÎncă nu există evaluări

- Waste 6Document2 paginiWaste 6Anonymous RXXdbl36AÎncă nu există evaluări

- S.N. Description Detail NO. NO. L BDocument2 paginiS.N. Description Detail NO. NO. L BAnonymous RXXdbl36AÎncă nu există evaluări

- Steel Sections and Plates InventoryDocument2 paginiSteel Sections and Plates InventoryAnonymous RXXdbl36AÎncă nu există evaluări

- S.N. Detail NO. NO. L B H/D Std. WTDocument2 paginiS.N. Detail NO. NO. L B H/D Std. WTAnonymous RXXdbl36AÎncă nu există evaluări

- Waste 2222Document2 paginiWaste 2222Anonymous RXXdbl36AÎncă nu există evaluări

- Ficha Tecnica Equipo Bombeo 250 GPM San SalvadorDocument31 paginiFicha Tecnica Equipo Bombeo 250 GPM San Salvadorgabriel240371100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Microscopy Lm1Document43 paginiMicroscopy Lm1SalimuÎncă nu există evaluări

- NTTF Press Tool Standards Ebook GeneralDocument207 paginiNTTF Press Tool Standards Ebook GeneralRagunathan GÎncă nu există evaluări

- 01 Physics ALPS For 2023 Batches - QuestionDocument29 pagini01 Physics ALPS For 2023 Batches - QuestionDevansh DuhanÎncă nu există evaluări

- Kinematics Speed and AccelerationDocument2 paginiKinematics Speed and AccelerationAhmad OmarÎncă nu există evaluări

- Soft Switching DC DC Converter With MPPT For Solar 2 PDFDocument56 paginiSoft Switching DC DC Converter With MPPT For Solar 2 PDFAnonymous Z1RHn9EÎncă nu există evaluări

- Cambridge IGCSEDocument20 paginiCambridge IGCSEVarvaraÎncă nu există evaluări

- 11.5 Applications of Right-And Non-Right-Angled TrigonometryDocument2 pagini11.5 Applications of Right-And Non-Right-Angled TrigonometryAanya RalhanÎncă nu există evaluări

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Document1 paginăASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Anonymous 0x2pwMCWgjÎncă nu există evaluări

- Bomb Hidraulic BCRDocument88 paginiBomb Hidraulic BCRAlexis BriceñoÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Cet-Iv - MCQDocument6 paginiCet-Iv - MCQRohit Ramesh KaleÎncă nu există evaluări

- Geothermal Drilling and Well Design (SE-830-DR2) : CementingDocument43 paginiGeothermal Drilling and Well Design (SE-830-DR2) : CementingERICK GUSTAVO QUINTANILLA GARCIAÎncă nu există evaluări

- Realandcomplexanalysis: Gabrielribeiro & Thiago LandimDocument109 paginiRealandcomplexanalysis: Gabrielribeiro & Thiago LandimMichael GregoryÎncă nu există evaluări

- Datasheet SolarEdge Power-Optimizer P650-P1100 07-2021 ENG EuropeDocument4 paginiDatasheet SolarEdge Power-Optimizer P650-P1100 07-2021 ENG Europebabu sundaranÎncă nu există evaluări

- Past Boards 2011 2017Document18 paginiPast Boards 2011 2017AkiÎncă nu există evaluări

- Magnetic IDocument34 paginiMagnetic IDeepesh SureshÎncă nu există evaluări

- AD 2000-Merkblatt: Pressure Vessels in Glass Fibre Reinforced Thermosetting Plastics N1Document16 paginiAD 2000-Merkblatt: Pressure Vessels in Glass Fibre Reinforced Thermosetting Plastics N1Ray100% (1)

- Design of Foundation For Nifps Panel: Approval Status: Approval StatusDocument10 paginiDesign of Foundation For Nifps Panel: Approval Status: Approval StatusARUN RAWATÎncă nu există evaluări

- LE13-038-R04a (TECHNICAL SHEET)Document83 paginiLE13-038-R04a (TECHNICAL SHEET)Sermchart PakumÎncă nu există evaluări

- My Detailed Lesson PlanDocument11 paginiMy Detailed Lesson PlanNovy-Ann Sancho94% (16)

- 9.0 Stability of Floating BodiesDocument12 pagini9.0 Stability of Floating BodiesAcharaÎncă nu există evaluări

- 1 s2.0 S1110093112000312 MainDocument11 pagini1 s2.0 S1110093112000312 Maindanielafarmacie_1617Încă nu există evaluări

- Important Terms and Concepts: Chapter 6 / Mechanical Properties of MetalsDocument19 paginiImportant Terms and Concepts: Chapter 6 / Mechanical Properties of MetalsRonald SalapareÎncă nu există evaluări

- 3K04 Assignment 1Document7 pagini3K04 Assignment 1Yousef HassaninÎncă nu există evaluări

- Ophthalmic and Diagnostic Instruments: Ophthalmoscope / Retinoscope / OtoscopeDocument37 paginiOphthalmic and Diagnostic Instruments: Ophthalmoscope / Retinoscope / OtoscopeKhelifa RadiaÎncă nu există evaluări

- Transformer stability testing and commissioningDocument4 paginiTransformer stability testing and commissioningraul116574480% (5)

- Preliminary Design Approach of The Wing BoxDocument3 paginiPreliminary Design Approach of The Wing BoxWhyDirgantara IDÎncă nu există evaluări

- Physics 11-02 The EM Spectrum and EnergyDocument2 paginiPhysics 11-02 The EM Spectrum and EnergyBALI RAOÎncă nu există evaluări

- How To Design and Install A Solar PV System - Solved ExampleDocument16 paginiHow To Design and Install A Solar PV System - Solved ExampleSteveÎncă nu există evaluări

- Manual of M7000 Veterinary Monitor PDFDocument89 paginiManual of M7000 Veterinary Monitor PDFbiomedicaÎncă nu există evaluări

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDe la EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureEvaluare: 4.5 din 5 stele4.5/5 (2)

- Artificial You: AI and the Future of Your MindDe la EverandArtificial You: AI and the Future of Your MindEvaluare: 4 din 5 stele4/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsDe la EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsÎncă nu există evaluări

- Offshore Pipelines: Design, Installation, and MaintenanceDe la EverandOffshore Pipelines: Design, Installation, and MaintenanceEvaluare: 4.5 din 5 stele4.5/5 (2)

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)