Documente Academic

Documente Profesional

Documente Cultură

Mooring Winch Brake Holding Capacity

Încărcat de

sbcheahDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mooring Winch Brake Holding Capacity

Încărcat de

sbcheahDrepturi de autor:

Formate disponibile

Mooring Winch Brake Holding Capacity

Introduction

Recently the Clubs Managers have become aware of a

number of incidents including one that involved a fatality,

resulting from mooring line failure where it appears the

cause was not attributable to poor condition of

equipment but rather the incorrect usage of the mooring

winches.

This Risk Alert seeks to highlight the importance of

ships crews fully understanding the correct operation

and maintenance of mooring winch brakes.

Self-tensioning mooring winches are no longer favoured

by many because of the possibility of a vessel creeping

along docksides and jetties as a winch pays out and

heaves when the ship is affected by some external force.

Instead, many vessels now apply rotating drum style

winch brakes while secured alongside.

Winch Brake Rendering

Winch brake rendering can be considered as a slipping

of the brake band at the points of contact between the

brake band lining and the drum. As a result of rendering

the brake band can be expected to wear and is a part

that should be replaced whenever its condition dictates.

A common misunderstanding is that ships crews appear

to test mooring winch brakes for holding capacity rather

than rendering capacity. The brake is an important

feature of the winch that secures the drum, and

consequently the mooring line, to the ship. Testing for

holding capacity will only confirm that the brake will hold

at the given load. An important safety function of the

brake is to render, allowing the line to release any

excessive load rather than retaining it and leading to the

line ultimately parting if or when the load applied

becomes excessive.

Mooring Winches

Many modern vessels are fitted with powered mooring

winches with lines being stored on a rotating drum which

can be either of the single or split-drum type. Power is

usually provided by steam, hydraulic or electrical motor,

while the drum brake can be either manually or

automatically applied.

Mooring winch capacity is determined at the ship design

stage when factors such as the vessels size, number of

mooring lines to be deployed, anticipated maximum wind

area and anticipated effect of tidal conditions are

considered, together with the mooring lines Mean

Breaking Load (MBL). After selection of the MBL of the

mooring lines the winch heaving load will be set to a

lower value than the MBL to prevent the winch motor

from applying excessive load.

Mooring Winch Brake Settings

After mooring it is standard practice to apply the winch

brake and to take the winch motor out of gear, leaving

friction between the brake lining and the winch drum to

prevent rotation of the drum. Typically, mooring winch

brakes are designed to hold up to 80% of the MBL with

the capability of adjusting these to 60% of the MBL to

allow for a margin of safety.

Winch Brake Setting and Testing

The setting chosen will be proportional to the amount of

pressure (tension or torque) applied to the brake drum,

either by hand, spring or hydraulic activation when the

brake is engaged. The effectiveness of the brake will

also be determined by the condition of the brake lining

and brake drum, as well as the rope being correctly

reeled onto the drum. Regardless of the brake type

fitted, testing and direction of reeling the mooring line on

the drum in accordance with manufacturers instructions

is important to ensure that the brake will hold or render

at the correct load.

RA50 One of a series of Steamship Mutual Loss Prevention Bulletins produced by the Ship Safety Trust

For further information please contact the Loss Prevention Department

Steamship Insurance Management Services Ltd. Tel: +44 20 7247 5490

Email: loss.prevention@simsl.com

Page 1 of 2

www.steamshipmutual.com/loss-prevention/

Each winch should be tested individually when the ship

is new and thereafter following the manufacturers

recommendation. Individual winch brakes should also be

tested after completion of any modification or repair

involving the winch brakes, or upon any evidence of

unexpected rendering or wear. Records of testing should

be maintained that are auditable and can be used to

obtain early signs of brake wear. Markings applied to the

winch drum that show the design holding capacity and in

the case of manual screw down brakes, the torque

required to hand wheel or lever to achieve this are

considered by the Club to be of some benefit.

Recommendations

Mooring winch brakes should be tested in

accordance with winch brake manufacturers or shipbuilders guidance or following repair or modification

of associated parts. The Club recommends tests are

conducted at least annually.

If not carried as part of ships equipment, Members

should consider making a brake testing kit available

or arrange for testing to be carried out by

experienced contractors.

Procedures for testing mooring winch brakes should

be made available on board.

Ships crews should be offered guidance, or on board

training in the correct type specific procedures to be

followed for testing and operating mooring winch

brakes.

The designed maximum heaving load of mooring

winch motors, rendering capacity of winch brakes

and direction of heave and lowering should be

clearly marked on the mooring winch.

The torque that is to be applied to the hand wheel or

handle of the brake should be clearly marked on the

winch. An alternative to this may be to fit readily

adjustable stops on the winch brakes screw- thread,

but this method should retain the capability of override which should only be used with extreme care.

Records of winch brake testing, including the torque

required to achieve the correct rendering load, if

required, should be maintained on board.

Visiting superintendents should verify that winch

brake testing is completed in accordance with

company procedures at internal audits.

For further information on this or other Loss Prevention

topics please contact the Loss Prevention Department,

Steamship Insurance Management Services Ltd.

Tel: +44 20 7247 5490

Email: loss.prevention@simsl.com

RA50 One of a series of Steamship Mutual Loss Prevention Bulletins produced by the Ship Safety Trust

For further information please contact the Loss Prevention Department

Steamship Insurance Management Services Ltd. Tel: +44 20 7247 5490

Email: loss.prevention@simsl.com

Page 2 of 2

www.steamshipmutual.com/loss-prevention/

S-ar putea să vă placă și

- Rendering TestDocument7 paginiRendering TestDwiky syamcahyadi rahman100% (1)

- Winch Brake Direction Mooring Line PDFDocument4 paginiWinch Brake Direction Mooring Line PDFNUm SaiChon RTÎncă nu există evaluări

- Brake Holding Power TestDocument6 paginiBrake Holding Power TestCaptIsqanÎncă nu există evaluări

- Mooring Winch Brake TestDocument4 paginiMooring Winch Brake TestAli Punga100% (2)

- Bow Door DesignDocument66 paginiBow Door Designsupriadi90315Încă nu există evaluări

- Program - Winch Tear DownDocument11 paginiProgram - Winch Tear DownAnonymous 1qAH6CKCÎncă nu există evaluări

- 80 Ton AHTS Specification Rev 0Document81 pagini80 Ton AHTS Specification Rev 0Mark Samsel RohanÎncă nu există evaluări

- Anchoring SystemsDocument16 paginiAnchoring SystemsKarim Abd ElazizÎncă nu există evaluări

- February 2013 Wire Rope ExchangeDocument84 paginiFebruary 2013 Wire Rope ExchangeWire Rope ExchangeÎncă nu există evaluări

- HX1 Horizontal Windlass Iss 2Document24 paginiHX1 Horizontal Windlass Iss 2edgar luisÎncă nu există evaluări

- Lubrication Basics For Wire RopesDocument5 paginiLubrication Basics For Wire RopesGuru Raja Ragavendran NagarajanÎncă nu există evaluări

- TSD 0046 NDSC 25 PDFDocument7 paginiTSD 0046 NDSC 25 PDFMico Lazaro100% (1)

- Rescue Boat Launching MethodDocument7 paginiRescue Boat Launching MethodAurvin Singh100% (1)

- 2.0 - Design and Development of Steering System of ShipDocument24 pagini2.0 - Design and Development of Steering System of ShipSandeep MandalÎncă nu există evaluări

- 13.15 A - Forces Experienced by Winch Drums ... - Marius Popa 3-6Document28 pagini13.15 A - Forces Experienced by Winch Drums ... - Marius Popa 3-6MNÎncă nu există evaluări

- Understanding Sacrificial Anodes On ShipsDocument3 paginiUnderstanding Sacrificial Anodes On ShipsVyas SrinivasanÎncă nu există evaluări

- Deck MachineriesDocument44 paginiDeck Machinerieshendrasaputralingga8Încă nu există evaluări

- TestDocument8 paginiTestGeorge Cristian100% (1)

- DY-300 Men Accommodation Work BargeDocument21 paginiDY-300 Men Accommodation Work BargeBinh PhamÎncă nu există evaluări

- Analysing Winch Systems With Finite Element AnalysisDocument5 paginiAnalysing Winch Systems With Finite Element AnalysisBen RuffellÎncă nu există evaluări

- Mobile Crane Training Course-Velosi Part2Document27 paginiMobile Crane Training Course-Velosi Part2shahbaz akramÎncă nu există evaluări

- Choosing The Right Windlass For Your BoatDocument32 paginiChoosing The Right Windlass For Your BoatAlexEcnomÎncă nu există evaluări

- Basic Load Line PP PDFDocument111 paginiBasic Load Line PP PDFEnrique100% (3)

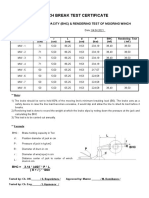

- Break TestDocument2 paginiBreak Testbehzad parsi100% (2)

- DigiMoorX7 Software IntroductionDocument24 paginiDigiMoorX7 Software IntroductionSachin SikkaÎncă nu există evaluări

- H2 Folding Hatch Covers - Original - 30544 PDFDocument8 paginiH2 Folding Hatch Covers - Original - 30544 PDFGILL2013Încă nu există evaluări

- Sheave Manual SMDocument8 paginiSheave Manual SMLutfi IsmailÎncă nu există evaluări

- Winch Brake Holding Capacity TestDocument2 paginiWinch Brake Holding Capacity TestDenis Mihin83% (6)

- Double Bollards - Din 82607Document1 paginăDouble Bollards - Din 82607Anca GeaninaÎncă nu există evaluări

- Launching Chapter13Document14 paginiLaunching Chapter13Md Raisul Islam100% (2)

- Mooring Winch Brake Capacity Calculation PDFDocument1 paginăMooring Winch Brake Capacity Calculation PDFMorozan C Si DÎncă nu există evaluări

- Sill Height of Watertight Door and HatchesDocument3 paginiSill Height of Watertight Door and HatchesOzata Tersanesi100% (1)

- Casar RotationDocument50 paginiCasar RotationmarketakisioannisÎncă nu există evaluări

- Muir 500 ManualDocument28 paginiMuir 500 ManualLight HouseÎncă nu există evaluări

- Minimum Breaking Force of Wire RopeDocument23 paginiMinimum Breaking Force of Wire RopeHuruk BrosnanÎncă nu există evaluări

- Wegemt 20Th Graduate School Fishing Vessel Technology: J. Panadero PastranaDocument40 paginiWegemt 20Th Graduate School Fishing Vessel Technology: J. Panadero PastranaJuan SilvaÎncă nu există evaluări

- Damage Stability Assessment of ContainershipDocument18 paginiDamage Stability Assessment of ContainershipgksahaÎncă nu există evaluări

- Mooring Winch Brake Capacity Calculation PDFDocument1 paginăMooring Winch Brake Capacity Calculation PDFvdeviv100% (1)

- Winch Brake Test Certificate 1Document1 paginăWinch Brake Test Certificate 1Владимир МищенкоÎncă nu există evaluări

- Mooring Winch Tests1Document7 paginiMooring Winch Tests1RachitÎncă nu există evaluări

- Design Verification of Winch For Offshore Cranes PDFDocument4 paginiDesign Verification of Winch For Offshore Cranes PDFtonyÎncă nu există evaluări

- Safe Working Load CalculationsDocument3 paginiSafe Working Load CalculationsShanAlanÎncă nu există evaluări

- RoroDocument29 paginiRoroEko SuherÎncă nu există evaluări

- Auto Load: By: Sardar Sirajul IslamDocument3 paginiAuto Load: By: Sardar Sirajul IslamSardar Sirajul IslamÎncă nu există evaluări

- Padeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsDocument5 paginiPadeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsKarun Das0% (1)

- Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed InstallationsDocument3 paginiSafe Approach, Set-Up and Departure of Jack Up Rigs To Fixed InstallationsanhlhÎncă nu există evaluări

- Inclining TestDocument6 paginiInclining TestVanjimuthu VelusamyÎncă nu există evaluări

- Light and Smoke Signal: Warning DisposalDocument1 paginăLight and Smoke Signal: Warning Disposalariesyiha100% (1)

- CranesDocument36 paginiCranesgaziahmad100% (2)

- 15.1.1d Bulkheads 2Document14 pagini15.1.1d Bulkheads 2vickyÎncă nu există evaluări

- Hatch Covers SeohaeDocument3 paginiHatch Covers SeohaecarlocftÎncă nu există evaluări

- Escor Winch Analysis-Robert Allan PDFDocument128 paginiEscor Winch Analysis-Robert Allan PDFtonyÎncă nu există evaluări

- Winch Drum Capacity CalculationsDocument2 paginiWinch Drum Capacity CalculationsDwi ArifÎncă nu există evaluări

- Hatch Cover and Its Types - by AfsarDocument16 paginiHatch Cover and Its Types - by AfsarMohammed AfsarÎncă nu există evaluări

- Lessons Learned - What Is Render Testing - RightshipDocument5 paginiLessons Learned - What Is Render Testing - RightshipKriskos KriskosÎncă nu există evaluări

- Mooring WinchesDocument1 paginăMooring WinchesAnonymous JZFSB3DÎncă nu există evaluări

- 2021-036 Fleetwide Sharing - Safe Mooring and Winch Brake Rendering Test - CompressedDocument14 pagini2021-036 Fleetwide Sharing - Safe Mooring and Winch Brake Rendering Test - CompressedAbhilashÎncă nu există evaluări

- Brake Rendering TestDocument6 paginiBrake Rendering TestAtesh RanaÎncă nu există evaluări

- Safe Mooring OpsDocument11 paginiSafe Mooring OpsWyn PriceÎncă nu există evaluări

- Operation of Cargo Crane On ShipsDocument5 paginiOperation of Cargo Crane On ShipsRose AriantiÎncă nu există evaluări

- CATZOCDocument52 paginiCATZOCsbcheah100% (1)

- Chevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPDocument32 paginiChevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPNamal FernandoÎncă nu există evaluări

- ISM Code 2015Document18 paginiISM Code 2015Gaurav HarjaiÎncă nu există evaluări

- What A Marine Surveyor Needs To Know About Working in Enclosed SpacesDocument54 paginiWhat A Marine Surveyor Needs To Know About Working in Enclosed Spacesacere18Încă nu există evaluări

- Fleet Management Zones and Industry Zones User Guide: Issue Jan 2012Document18 paginiFleet Management Zones and Industry Zones User Guide: Issue Jan 2012sbcheahÎncă nu există evaluări

- Final Transportation ManagerDocument8 paginiFinal Transportation ManagersbcheahÎncă nu există evaluări

- Muster List Sigloo NorseDocument2 paginiMuster List Sigloo Norsesbcheah100% (10)

- 005 - Chapter 4 - Appendix 2 - Emergency PlanDocument1 pagină005 - Chapter 4 - Appendix 2 - Emergency Plansbcheah100% (1)

- DNV Competence ManagementDocument22 paginiDNV Competence Managementbill baileyÎncă nu există evaluări

- ABB Turbocharger Tips For The OperatorDocument44 paginiABB Turbocharger Tips For The Operatorsevero97100% (4)

- West of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFDocument6 paginiWest of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFsbcheahÎncă nu există evaluări

- Ycnsunom 3. Hull FoulingDocument22 paginiYcnsunom 3. Hull Foulingswapneel_kulkarniÎncă nu există evaluări

- SKF Roller Bearing Handbook PDFDocument42 paginiSKF Roller Bearing Handbook PDFsureshnfclÎncă nu există evaluări

- CIM Question BankDocument5 paginiCIM Question Bankselvi6496Încă nu există evaluări

- Java CoDocument3 paginiJava CojoooomÎncă nu există evaluări

- 295 - 2012!08!16 - Inspection of The Flap Support Arm Attachments - SB57-006Document5 pagini295 - 2012!08!16 - Inspection of The Flap Support Arm Attachments - SB57-006Elijah Paul MertoÎncă nu există evaluări

- TI TV SchneiderDocument48 paginiTI TV SchneiderAnonymous qDCftTW5MÎncă nu există evaluări

- TR CD 04e - Compex Ex01 04Document1 paginăTR CD 04e - Compex Ex01 04Ullas KrishnanÎncă nu există evaluări

- 16 LossesDocument26 pagini16 LossesAbhijit Bhattacherjee100% (1)

- Steinway & Sons: Buying A Legend: Presented By: Group 4Document20 paginiSteinway & Sons: Buying A Legend: Presented By: Group 4adiÎncă nu există evaluări

- General Process Audit QuestionsDocument8 paginiGeneral Process Audit QuestionsTracy TreacherÎncă nu există evaluări

- Asme II - A - Sa 276-1Document10 paginiAsme II - A - Sa 276-1Nilson ConradoÎncă nu există evaluări

- EI 1581 SummaryDocument2 paginiEI 1581 SummarywholenumberÎncă nu există evaluări

- Essen Industries PVT - Ltd. AddressDocument4 paginiEssen Industries PVT - Ltd. AddressChava RaviÎncă nu există evaluări

- Aircraft Pressurization SystemDocument13 paginiAircraft Pressurization Systemviba1995100% (2)

- 1st ModuleDocument26 pagini1st Modulemuniraju mÎncă nu există evaluări

- Aakarsha Maharjan (Running Case Dirtbike)Document13 paginiAakarsha Maharjan (Running Case Dirtbike)Aakarsha MaharjanÎncă nu există evaluări

- D46 Seam3 5 3 05Document3 paginiD46 Seam3 5 3 05James SilvozaÎncă nu există evaluări

- As 1172.2-1999 Water Closet (WC) Pans of 6 3 L Capacity or Proven Equivalent CisternsDocument7 paginiAs 1172.2-1999 Water Closet (WC) Pans of 6 3 L Capacity or Proven Equivalent CisternsSAI Global - APACÎncă nu există evaluări

- Dual Stack Ip-Mpls and MPLS-TPDocument6 paginiDual Stack Ip-Mpls and MPLS-TPFelipe A. PérezÎncă nu există evaluări

- C M S College of Engineering, Namakkal - 637 003 Department of Management Studies BA9265 Organizational Theory, Design and Development Unit - IDocument2 paginiC M S College of Engineering, Namakkal - 637 003 Department of Management Studies BA9265 Organizational Theory, Design and Development Unit - IsudhaaÎncă nu există evaluări

- BMI Vietnam Oil and Gas Report Q2 2014Document137 paginiBMI Vietnam Oil and Gas Report Q2 2014Phạm ThaoÎncă nu există evaluări

- PHM - Clyde Engineering Photographic Collection Railway and Rolling StockDocument9 paginiPHM - Clyde Engineering Photographic Collection Railway and Rolling Stock4493464100% (1)

- Mj19 Sample Apm QuestionsDocument9 paginiMj19 Sample Apm QuestionsAakash AadeezÎncă nu există evaluări

- Alu Alu Cold-Forming FoilDocument1 paginăAlu Alu Cold-Forming FoilManivannan KathirvelÎncă nu există evaluări

- Pulse Jet Bag Filters PDFDocument12 paginiPulse Jet Bag Filters PDFPetros IosifidisÎncă nu există evaluări

- PEO Referee QuestionnaireDocument2 paginiPEO Referee QuestionnaireVineeth Kumar C G100% (1)

- Work Permit SystemDocument3 paginiWork Permit SystemwallascoÎncă nu există evaluări

- BMW 745i E65 4.4 Valvetronic: Digital Adrenaline For YourDocument11 paginiBMW 745i E65 4.4 Valvetronic: Digital Adrenaline For YourPOCHOLO1968Încă nu există evaluări

- Transportation Manager or International Manager or Logistics SupDocument3 paginiTransportation Manager or International Manager or Logistics Supapi-78592002Încă nu există evaluări

- Disc How Ships FloatDocument1 paginăDisc How Ships FloatThe Calgary SunÎncă nu există evaluări

- Electronics Projects Volume 15.bakDocument178 paginiElectronics Projects Volume 15.bakGabriel Sarmiento94% (16)