Documente Academic

Documente Profesional

Documente Cultură

A 1302030107

Încărcat de

IOSRjournalDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A 1302030107

Încărcat de

IOSRjournalDrepturi de autor:

Formate disponibile

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 13, Issue 2 Ver. III (Mar- Apr. 2016), PP 01-07

www.iosrjournals.org

Engineering Properties of Soils Reinforced By Recycled Polyester

Fiber

Babak Amini Behbahani1, Hadi Sedaghatnezhad2, Foad Changizi3

1

(Department of civil engineering, Yasooj branch, Islamic Azad University, Yasooj, Name, Iran)

(Department of civil engineering, College of technical and engineering, Gachsaran branch, Islamic Azad

University, Gachsaran, Iran)

3

(Department of civil engineering, Faculty of technical and engineering, South Tehran Branch, Islamic Azad

University, Tehran ,Iran)

2

Abstract: Environmental authorities are concerned about the growing amount of polyethylene (PET) bottles

produced by household sectors. This paper presents results of an investigation into utilization of recycled

polyester fiber that produced of polyethylene (PET) bottles in order to improve engineering properties of

cohesive soils. This research in order to study effect of adding recycled polyester fiber on soil engineering

properties, especially shear strength and California Bearing Ratio (CBR) used clay soil with low liquid limit

(CL) and atterberg limits used high liquid limit (CH). Clay soil with recycled polyester fibers are mixed with

soil in three different percentages 0.1%, 0.3% & 0.5% (the portion of stabilizer matters to soil net weight).

Shear strength, CBR, atterberg limits of stabilizer samples were measured by direct shear test and CBR test and

atterberg limits test. Experiments results show this fact that using of recycled polyester leads to increasing shear

strength and CBR and reduction, plasticity index. It is remarkable that according to economic problems, the

most optimum quantity of recycled polyester is 0.5%.

Keywords: Recycled polyester fiber, Soil reinforced, Shear strength, CBR, Atterberg limits

I.

Introduction

The main reason behind this trend is the excessive production of waste like fly ash, plastics, rice husk

ash which is not only hazards but also creating deposition problems. Using some of these waste materials in

construction practice will reduce the problem in a great extent. One of the main advantages of using randomly

distributed fibers is the maintenance of strength isotropy and the absence of potential planes of weakness that

can develop in soils with oriented reinforcement [1]. Khattab et al. [2] reported that a more limited reduction in

compressive strength was obtained for the samples stabilized with industrial waste lime than those stabilized

with lime. Ghazavi and Lavasan [3] studied the interference effect of shallow foundations constructed on sand

reinforced with geosynthetics and reported that geogrid lead to increases the bearing capacity and decreases the

shear strain transmitted to the soil. Madhavi Latha and Somwanshi [4] studied the effect of reinforcement form

on the bearing capacity of square footings on sand and reported that the bearing capacity improvement factor is

significantly affected by the form of reinforcement. Maliakal et al. [5] studied the properties of coir fibersreinforced clay and reported that for a constant fiber length (aspect ratio), major principal stress at failure

increased with increase in fiber content. Kumar et al. [6] studied the properties of polypropylene reinforced clay

and reported that polypropylene fibers with aspect ratio 100 lead to increase shear peak and residual strength.

Estabragh et al. [7] studied the mechanical behavior of a clay soil reinforced with nylon fibers and reported that

the inclusion of fiber leads to an increase of the excess pore water pressure in undrained conditions. Mohamed

[9] believes that adding dry straw decreases soil dry special weight and also adding straw fibers up to 1.0%,

decreases the soil shrinkage limit. Kamei et al. [9] studied the use of recycled bassanite and coal ash to enhance

the strength of very soft clay in dry and wet environmental conditions and reported that both the recycled

bassanite and coal ash increase strength of very soft clay soils and also the strength of soil decreased with the

increase in the number of the wetdry cycles up to the third cycle. Park [10] reported that the addition of 1%

polyvinyl alcohol (PVA) fiber to 4% cemented sand resulted in a two times increase the axial strain at peak

strength when compared with the non-fiber-reinforced specimen. Jiang et al. [11], by direct shear test, estimated

shear strength of polypropylene fibers-reinforced clay soil and reported that soil shear strength of soil had

increased and this strength increasing was because of increasing cohesive and internal friction angle of soil

respect to natural soil. Maheshwari [12] by model footing tests and determining the bearing capacity of soil

reinforced by Polyester fibers understood that the bearing capacity of polyester fibers- reinforced soil with depth

equaled to 25% of width foundation was 3.53 times of natural soil. A number of factors such as the fiber

characteristics (fiber type, fiber content, fiber length, thickness, aspect ratio, orientation etc.) and the soil

characteristics influence the behavior of the clayfiber composite [13, 14]. The main objective of this study is to

examine the effect of recycled polyester fiber on strength parameters of clay soil and presentation a method

DOI: 10.9790/1684-1302030107

www.iosrjournals.org

1 | Page

Engineering properties of soils reinforced by recycled polyester fiber

practical for stabilization of soil and reduction environmental pollution caused by polyethylene bottles.

Recycled polyester fibers can be used in the design and construction of geotechnical structures such as retaining

walls, foundations, embankments, pavements, etc.

II.

Materials And Test Methods

2.1 Properties of soil and reinforcement

The selection of the soils was based on the difference in their atterberg limits. Soils used in the

investigation were classified as CL and CH according to Unified Soil Classification System. Table 1 presents

data for the properties of A soil and B soil. Picture of recycled polyester fiber is shown in Figure 1. Surface of

fibers are wrinkle. The properties of recycled polyester fiber are presented in Table 2.

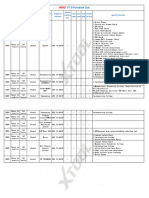

Table 1 properties of A soil and B soil

Properties

Result

Soil A

2.8

33

67

CL

29.6

21.5

18

15

17.68

Specific gravity

Sand (%)

Fine-grained (%)

USCS classification

Liquid limit (%)

Plastic limit (%)

Shrinkage limit (%)

Optimum moisture content (%)

Maximum dry density (kN/m3)

Soil B

2.7

21.5

78.5

CH

54.6

34.2

29.5

21

17.34

Figure1 Picture of recycled polyester fibers

Table 2 Properties of recycled polyester fiber

Properties

Type

Specific Gravity

Moisture content (%)

Tensile Strength (N/mm2)

Length (mm)

Diameter (m)

Color

Result

Recycled polyester

1.22

0.4

200-400

30-40

20-30

Colourless

2.2 Test methods

In this paper effect of the recycled polyester fibers on the strength properties of cohesive soils has been

evaluated. In order to evaluation shear strength parameters of soil by direct shear test were used three normal

stresses: 100, 200 & 300 kPa. Direct shear tests CBR test were done with different percentages of the recycled

polyester (0.1, 0.3 & 0.5 percent of soil dry weight). Atterberg limits test was used to determine liquid limit,

plastic limit and shrinkage limit. Atterberg limits test were done with different percentages of the recycled

polyester (0.5, 1.0 & 1.5 percent of soil dry weight).

2.2.1 Sample preparation

First all the soil was crashed by a hammer. In order to prepare recycled polyester fibers - reinforcement

specimens for Atterberg limits test, at first, the B soil was mixed at 0.5, 1.0 & 1.5% with fibers. Then, the

mixture of soil with fibers was mixed with different water content and stir it 10 min until a homogenous mixture

reached. This composite was used to estimate the liquid limit, the plastic limit and the shrinkage limit of

recycled polyester fibers reinforced soil. Also in order to prepare recycled polyester fibers - reinforcement

specimens for direct shear test and CBR test, at first, the soil A was mixed at 0.1, 0.3 & 0.5% (fiber weight to

DOI: 10.9790/1684-1302030107

www.iosrjournals.org

2 | Page

Engineering properties of soils reinforced by recycled polyester fiber

soil net weight) with fibers. Using more than 0.5% recycled polyester fibers caused sticked fibers to form lumps

and nonuniform distribution in soil; consequently, the density of soil decreased. Then, the mixture of soil with

fibers was mixed with 15% water which was the optimum water due to standard proctor compaction test and stir

it 15min until a homogenous mixture reached. This composite was used to estimate the strength properties of

recycled polyester fibers reinforced soil in direct shear test and CBR test.

2.2.2 Testing procedure for Atterberg limits test

The liquid limit test is performed according to standard ASTM D 4318-85. Casagrande device is used

to determine liquid limit of natural and stabilized specimen with recycled polyester fibers. To perform the liquid

limit test, the mixture was filled in a Casagrande cup. Then a groove is created at the center of the soil with the

standard grooving tool. By the use of the crank-operated cam, the cup is lifted and dropped from a height of 10

mm. The moisture content, in percent, required to close a distance of 12.7 mm along the bottom of the groove

after 25 blows is defined as the liquid limit. It is difficult to adjust the moisture content in the mixture to meet

the required 12.7 mm closure of the groove in the soil pat at 25 blows. Hence, at least four tests for the same soil

are conducted at varying moisture contents. In total, 16 liquid limit tests were conducted by varying recycled

polyester fibers content. The plastic limit tests are performed under fixed conditions and according to standard

ASTM D 424. The plastic limit test is performed by repeated rollings of an ellipsoidal-sized soil mass by hand

on a ground glass plate. The shrinkage limit test is performed under fixed conditions and according to standard

ASTM D 427-83. This test is performed in the laboratory with a porcelain dish about 44 mm in diameter and

about 12.7 mm high. The inside of the dish was coated with petroleum jelly and was then filled completely with

mixture. Excess soil standing above the edge of the dish was struck off with a straightedge. The mass of the

mixture inside the dish was recorded. The mixture was the dish was then oven-dried. The volume of the ovendried mixture was determined by the displacement of mercury.

2.2.3 Testing procedure for direct shear test

This test is performed under fixed conditions and according to standard ASTM D3080-90. The mixture

was filled in 101.4 mm diameter 116.5 mm high cylindrical mould in three equal layers and each layer was

compacted using a tamping device to attain the maximum dry unit weight determined using the standard Proctor

test. Then the shear ring of 60 60 mm in plan and 25 mm in depth by hydraulic jack were pushed into the soil

mixture. Then the samples were extruded into shear box. In order to prepare the consolidated and saturated

samples, the samples were kept under normal stress for about 24 hours into the shear box bowl filled with water.

The normal stresses in the present study were 100, 200 and 300 kPa, while drainage was allowed from the top

and bottom of the shear box. Since under undrained condition fiber has least effective in increasing in soil

resistance, tests were conducted under undrained condition. Because of the fact that the rate of imposing

horizontal displacement was 1.25mm/min, the sample was sheared under undrained condition by applying the

shear stress. Three specimens were tested for each combination of mixture and the average is obtained. Shear

stresses were recorded as a function of horizontal displacement up to a total displacement of 13 mm. The

relation stress-displacement is plotted.

2.2.4 Testing procedure for CBR test

The CBR test was performed under fixed conditions and according to standard ASTM D 1883-94. The

mixture was filled in 150 mm diameter 180 mm high cylindrical mould in five equal layers and each layer was

compacted using a tamping device. The velocity of test was 1.25mm/min. For each combination of mixture,

three samples were prepared and the average value of test data was obtained. In total, 12 groups of CBR tests

were conducted by varying contents of recycled polyester fibers. In this paper the load-penetration curves were

plotted and the CBR values were computed.

III.

Results And Discussions

3.1 Effect of recycled polyester fibers on the liquid limit of clay

The liquid limit of soil reinforced with varying fiber content, is presented in Figure 2. Observation of

this Table indicates that with increase in fiber content the liquid limit of reinforced soil increase. With inclusion

of fibers, the liquid limit is increase by factors 1.04, 1.13, 1.19 respectively for fiber content of 0.5, 1.0 and

1.5%. The observed changes are attributed to the replacement of soil grains by fibres. The soil reinforced is

more continuity then the soil non- reinforced; consequently, the liquid limit of soil reinforced increase. This

result contrasts with the result Kinjal et al. [15] in regard to behavior of soil.

DOI: 10.9790/1684-1302030107

www.iosrjournals.org

3 | Page

Engineering properties of soils reinforced by recycled polyester fiber

Figure 2 Variation of liquid limit with recycled polyester fibers content

3.2 Effect of recycled polyester fibers on the plastic limit of clay

The plastic limit of soil reinforced with varying fiber content, is presented in Figure 3. Observation of

this Table indicates that the increase in fiber content be responsible for increase in the plastic limit of reinforced

soil. With inclusion of fibers, the plastic limit is increased by factors 1.29, 1.42, 1.44 respectively for fiber

content of 0.5, 1.0 and 1.5%. With compare of Table 3 and Table 4, it can be observed that increase in recycled

polyester fiber content lead to decrease in the plasticity index (PI) of soil. With inclusion of fibers, the plasticity

index (PI) is decreased by factors 0.65, 0.7, 0.8 respectively for fiber content of 0.5, 1.0 and 1.5%. This result

somewhat similar to results Fauzi et al. [16] that studied the atterberg limits of high density polyethylene

reinforced clay and reported that, with inclusion of (HDPE), the plasticity index (PI) is decreased by factors

0.93, 0.81, 0.79 respectively for (HDPE) content of 1, 4 and 8%.

3.3 Effect of recycled polyester fibers on the shrinkage limit of clay

Shrinkage limit, one of the Atterberg limits, is pertaining with plasticity-based soil behaviors. The

shrinkage limit of soil reinforced with varying fiber content is presented in Figure 5. Observation of this Table

indicates that increase in fiber content be the reason for increase in the shrinkage limit of reinforced soil. With

inclusion of fibers, the shrinkage limit is increased by factors 1.36, 1.41, 1.45 respectively for fiber content of

0.5, 1.0 and 1.5%. Therefore, it can be concluded that random fiber inclusion seems to be a practical and

effective method of increasing tensile strength of the clayey soils to resist volumetric changes.

Figure 3 Variation of plastic limit with recycled polyester fibers content

Figure 4 Variation of shrinkage limit with recycled polyester fibers content

DOI: 10.9790/1684-1302030107

www.iosrjournals.org

4 | Page

Engineering properties of soils reinforced by recycled polyester fiber

3.4 Effect of recycled polyester fibers on the shear parameters of clay

The stress-displacement behaviour of soil reinforced with varying fiber content, obtained from direct

shear tests is presented in Figure 5. From this Fig, it can be observed that the peak strength of fiber-reinforced

soil occured at higher horizontal displacement in majority of specimens investigated compared to the

unreinforced soil. Observation of this Figure indicates that with increase in normal stress and fiber content

contribute to increase in the peak strength of reinforced soil. With inclusion of recycled polyester fibers in the

soil, the maximum increase in the peak strength is observed at normal stress 300 kPa. With inclusion of fibers,

in normal stress 300 kPa, the peak shear stress is increased by factors 1.36, 1.63, 1.83 respectively for fiber

content of 0.1, 0.3 and 0.5%. The shear parameters presented in Table 3. From this Table, it is observed that

recycled polyester fibers are responsible for increase the angle of internal friction and the cohesion. The angle of

internal friction and the cohesion are increased by factors 1.46, 1.77, 2.01 and 1.20, 1.31, 1.41 respectively for

fiber content of 0.1, 0.3 and 0.5%. It increase in the shear parameters may be due to interaction between the soil

particles and recycled polyester fibers. With compare of results the angle of internal friction and results the

cohesion, it can be observed that in increase the shear strength of fiber-reinforced soil the angle of internal

friction is more efficiently then the cohesion. The previous research results show that the interaction mechanism

between soil and fiber is influenced by many factors. These can be illustrated by the confinement, reinforcement

surface roughness, shape. Interlock between soil particles and fiber surface is the reason for improvement the

strength of soil. From the sketch drawing of Figure 6 can be observed that the fiber surface is attached by some

soil particle and produces bonding and friction between the fiber and soil matrix. Several previous research

results show that the fiber sliding resistance is influenced by the fiber surface roughness [17, 18]. The recycled

polyester fiber surface roughness contributes to an increase in interfacial interlock force. Consequently, the

fibers in the soil are difficult to slide and resisted the relative movement of fibers in the soil. This result and

results Yan et al. [19] have attitudes in common. Interlock between soil particles and fiber surface are the

reason for improvement the shear strength. Similar results were obtained by Tang et al. [20].

Figure 5 Stress-displacement curves for recycled polyester fiber reinforced soil

Table 3 Shear parameters of fiber reinforced soil

Specimens

1

2

3

4

Fiber content (%)

0.0

0.1

0.3

0.5

DOI: 10.9790/1684-1302030107

Cohesion (c), kPa

63

76

83

89

Angle of internal friction (), degrees

14.3

21

25.4

28.8

www.iosrjournals.org

5 | Page

Engineering properties of soils reinforced by recycled polyester fiber

Figure 6 Sketch drawing of interfacial mechanical behavior between soil particles and fiber surface

3.5 CBR test

The results of CBR tests are presented in Figure 7. The results indicate that the inclusion of fiber

content contribute to increase in the CBR values. With inclusion of fiber, the CBR values is 6.7, 8.9 and 9.8

MPa respectively for fiber content of 0.1, 0.3 and 0.5% and the CBR value of unreinforced soil is 5.4. Thus with

inclusion of recycled polyester fibers, the CBR values is increased by factors 1.24, 1.64 and 1.81 respectively

for fiber content of 0.1, 0.3 and 0.5%.From these results one can conclude that the best ratio of recycled

polyester fiber addition is about 0.5%. This agrees with the work of Fauzi et al. [16].

Figure 7 CBR values for fiber reinforced soil at different fiber contents

IV.

Conclusion

This study investigated the effect of adding recycled polyester fibers on the strength behavior of clay

soil. The effects of fiber reinforcement on clayey soil were studied by using results obtained from a series of,

Atterberg limits and direct shear and CBR tests. Based on the results presented in this paper the following

conclusions are drawn:

1-

2-

3-

45-

Due to the increase in fiber content, the liquid limit of reinforced soil increases, also the plastic limit of

reinforced soil increases. With inclusion of fibers, the plasticity index is decreased by factors 0.65 for fiber

content of 0.5%.

Increase in recycled polyester fiber content contribute to increase the peak shear stress. Better result of the

peak shear stress was observed by 0.5% of recycled polyester fiber content that under this condition, the

peak shear strength is increased by factors 1.83.

The increase in fiber content lead to increase both angle of internal friction and cohesion. With inclusion

0.5% of recycled polyester fibers the angle of internal friction and the cohesion are increased by factors

2.01 and 1.41 respectively.

In view of increase in fiber content, the CBR values of reinforced soil increases, in such a way that with

inclusion of 0.5% recycled polyester fibers, the CBR of reinforced-soil is increased by factors 1.81.

Due to the fact that the recycled polyester fibers covers around soil particles, the interlock force between

soil particles increases and bond characteristics improves.

This investigation, it is clearly indicated that the technique of the mixture soil and recycled polyester fibers

is a very effective method of ground improvement, which improves the shear strength, the CBR values and

the plasticity index of soil and consequently, enhance the stability of infrastructures such as foundation and

roadbed. With the development of the construction technology, this improvement technique can be

considered as a practical method for improvement of strength behavior of clay in many fields of

DOI: 10.9790/1684-1302030107

www.iosrjournals.org

6 | Page

Engineering properties of soils reinforced by recycled polyester fiber

geotechnical engineering, such as foundation, roadbed and slope engineering.

V.

Acknowledgements

This study has performed in soil mechanical laboratory of Semnan University. The authors

appreciate the head of soil mechanics laboratory of Semnan University, Mr Doost Mohammadi for his

cooperation in this research.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

[11].

[12].

[13].

[14].

[15].

[16].

[17].

[18].

[19].

[20].

D. H. Gray, and M. H. Maher, Admixture stabilization of sand with discrete randomly distributed fibers, Proc International Conf.

on Soil Mechanics and Foundation Engineering, Riode Janeiro, Brazil, 1, 1982, 13631366.

S. A. A. Khattab, K. A. K. Al-Juari, and I. M. A. Al-Kiki, Strength, durability and hydraulic properties of clay soil stabilized with

lime and industrial waste lime, Al-Rafidain Engineering Journal, 16(1), 2008, 102116.

M. Ghazavi, and A. Alimardani Lavasan, Interference effect of shallow foundations constructed on sand reinforced with

geosynthetics, Geotextiles and Geomembranes, 26, 2008, 404415.

G. M. Madhavi Latha, A. Somwanshi, Effect of reinforcement form on the bearing capacity of square footings on sand, Geotextiles

and Geomembranes, 27, 2009, 409422.

T. Maliakal, and S. Thiyyakkandi, Influence of randomly distributed coir fibers on shear strength of clay, Geotechnical and

Geological Engineering, 31, 2013, 425433.

P. Kumar, R. Kar, and A. Naik, Effect of random inclusion of polypropylene fibers on strength characteristics of cohesive soil,

Geotechnical and Geological Engineering, 30, 2012, 15-25.

A. R. Estabragh, A. T. Bordbar, and A. A. Javadi, Mechanical Behavior of a Clay Soil Reinforced with Nylon Fibers, Geotechnical

and Geological Engineering, 29, 2011, 899908.

A. E. M. Mohamed, Improvement of swelling clay properties using hay fibers, Construction and Building Materials, 38, 2013, 242247.

A. Kamei, A. Ahmed, and T. Shibi, The use of recycled bassanite and coal ash to enhance the strength of very soft clay in dry and

wet environmental conditions, Construction and Building Materials, 38, 2013, 224235.

S. S. Park, Effect of fiber reinforcement and distribution on unconfined compressive strength of fiber-reinforced cemented sand,

Geotextiles and Geomembranes, 27(2), 2009, 162166.

H. Jiang, Y. Cai, and J. Liu, Engineering properties of soils reinforced by short discrete polypropylene fiber, Journal of Materials in

Civil Engineering (ASCE), 22(12), 2010, 1315.

K. Maheshwari, A. Desai, and C. H. Solanki, Performance of fiber reinforced clayey soil, Electronic Journal of Geotechnical

Engineering, 16, 2011, 1067-1082.

M. H. Maher, Y. C. Ho, Mechanical properties of kaolinite/ fiber soil composite, Journal of Geotechnical and Geoenvironmental

Engineering, 120(8), 1994, 13811393.

M. D. T. Casagrande, M. R. Coop, and N. Consoli, Behavior of a fiber reinforced bentonite at large shear displacements, Journal of

Geotechnical and Geoenvironmental Engineering, 132(11), 2006, 15051508.

Sh. Kinjal, A. K. Desai, and C. H. Solanki, Experimental study on the Atterberg limits of expansive soil reinforced with polyester

triangular fibers, International Journal of Engineering Research and Applications, 2(4), 2012, 636-639.

A. Fauzi, W. M. N. Abdul Rahman, and Z. Jauhari, Utilization waste material as stabilizer on kuantan clayey soil stabilization,

Jouranl of Processing Engineering, 53, 2013, 42 47.

D. J. Frost, and J. Han, Behavior of interfaces between fiber-reinforced polymers and sands. Journal of Geotechnical and

Geoenvironmental Engineering, 125 (8), 1999, 633640.

S. P. Shah, Do fibers increase the tensile strength of cement-based matrixes?, ACI Materials Journal, 88 (6), 1991, 595602.

L. F. Yan, and R. L. Pendleton, C. H. M. Jenkins, Interface morphologies in polyolefin fiber reinforced concrete composites.

Composites Part A, 29, 1998, 643650.

Ch. Sh. Tang, B. Shi, and L. Z. Zhao, Interfacial shear strength of fiber reinforced soil, Geotextiles and Geomembranes, 28, 2010,

54-62.

DOI: 10.9790/1684-1302030107

www.iosrjournals.org

7 | Page

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocument6 paginiThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocument5 pagini"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocument7 paginiSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocument5 paginiAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocument7 paginiA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Impact of Technologies On Society: A ReviewDocument5 paginiThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Document15 paginiA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocument6 paginiImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocument9 paginiTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocument4 paginiInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocument14 paginiAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocument7 paginiComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Assessment of The Implementation of Federal Character in Nigeria.Document5 paginiAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocument5 paginiRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocument5 paginiEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Lute Against Doping in SportDocument5 paginiThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocument7 paginiTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocument6 paginiRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Human Rights and Dalits: Different Strands in The DiscourseDocument5 paginiHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocument11 paginiSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocument9 paginiClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocument3 paginiBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Women Empowerment Through Open and Distance Learning in ZimbabweDocument8 paginiWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocument3 paginiMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocument7 paginiA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocument8 paginiMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocument6 paginiAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocument5 paginiDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocument6 paginiKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocument6 paginiDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- American University of Beirut Aub Thesis TemplateDocument12 paginiAmerican University of Beirut Aub Thesis TemplateHassane EzzeddineÎncă nu există evaluări

- Different Type of ChillersDocument7 paginiDifferent Type of ChillersMAGDY KAMEL100% (3)

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocument15 pagini000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- Body of Knowledge PDFDocument1 paginăBody of Knowledge PDFAda RamirezÎncă nu există evaluări

- DW-143 - Leakage Factor As Per Calculation FormulaDocument2 paginiDW-143 - Leakage Factor As Per Calculation Formulasandeep7426Încă nu există evaluări

- Survey MODULE 4Document16 paginiSurvey MODULE 4InsurrectionÎncă nu există evaluări

- Pure Sine Wave Inverter For House BackupDocument44 paginiPure Sine Wave Inverter For House BackupKrista Jackson100% (1)

- Trimyristin From NutmegDocument5 paginiTrimyristin From NutmegArsandi Widitya0% (1)

- Legend:-: General Arrangement ACS550-124A-4 YN3A205086-GAADocument12 paginiLegend:-: General Arrangement ACS550-124A-4 YN3A205086-GAANeeraj SharmaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Implementing Routing Facilities For Branch Offices and Mobile WorkersDocument180 paginiImplementing Routing Facilities For Branch Offices and Mobile WorkersAlejandro Cordero OrdoñezÎncă nu există evaluări

- V7.0 Function ListDocument48 paginiV7.0 Function ListInyectronix VyhÎncă nu există evaluări

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document5 paginiAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarÎncă nu există evaluări

- LiftingLugStress Rev 1.5Document17 paginiLiftingLugStress Rev 1.5mohdshakir bahariÎncă nu există evaluări

- Rossler Chaotic Circuit and It's Application For Communication SecureDocument10 paginiRossler Chaotic Circuit and It's Application For Communication SecureMada Sanjaya WsÎncă nu există evaluări

- Standards of MeasurementDocument12 paginiStandards of MeasurementShubham KheraÎncă nu există evaluări

- A Simulation of Attempts To Influence Crowd Dynamics'Document6 paginiA Simulation of Attempts To Influence Crowd Dynamics'KhairulÎncă nu există evaluări

- Roland Sands Design US CatalogDocument56 paginiRoland Sands Design US Catalogsema2210Încă nu există evaluări

- Nirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVDocument2 paginiNirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVKartik aminÎncă nu există evaluări

- Agc-4 DRH 4189340686 UkDocument222 paginiAgc-4 DRH 4189340686 UkGiangDoÎncă nu există evaluări

- Muhammad Akif Naeem Open Ended Lab Signals and SystemDocument20 paginiMuhammad Akif Naeem Open Ended Lab Signals and SystemMuhammad Akif NaeemÎncă nu există evaluări

- Continuous Thread Stud Double End Stud ADocument11 paginiContinuous Thread Stud Double End Stud AMarius Mihai Buzduga0% (1)

- STK412 150 Sanyo PDFDocument4 paginiSTK412 150 Sanyo PDFroger.Încă nu există evaluări

- ORT ReportDocument71 paginiORT ReportNaveen ChodagiriÎncă nu există evaluări

- RA 7920 Section 33Document1 paginăRA 7920 Section 33Renz Emil ReyesÎncă nu există evaluări

- Dual Draw/Dual Return Fuel System TroubleshootingDocument4 paginiDual Draw/Dual Return Fuel System Troubleshootinginformer techÎncă nu există evaluări

- MRT PrjectDocument59 paginiMRT PrjectFahrul 2394Încă nu există evaluări

- Poloyagan Integrated School Monitoring Tool On Aip ImplementationDocument3 paginiPoloyagan Integrated School Monitoring Tool On Aip ImplementationLALAINE BONILLAÎncă nu există evaluări

- Keystone - GR SeriesDocument16 paginiKeystone - GR SeriesMohd Khairi Mohd NorzianÎncă nu există evaluări

- Patentes 2012Document33 paginiPatentes 2012Carlín CastromanÎncă nu există evaluări

- Lab 3 SST 4303Document5 paginiLab 3 SST 4303Muazrul MangsorÎncă nu există evaluări

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÎncă nu există evaluări

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDe la EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsÎncă nu există evaluări

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDe la EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetEvaluare: 4.5 din 5 stele4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansEvaluare: 4.5 din 5 stele4.5/5 (21)

- Geotechnical Engineering Calculations and Rules of ThumbDe la EverandGeotechnical Engineering Calculations and Rules of ThumbEvaluare: 4 din 5 stele4/5 (17)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDe la EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyEvaluare: 4.5 din 5 stele4.5/5 (5)