Documente Academic

Documente Profesional

Documente Cultură

Comparison Auditor OHSAS 18001 IRCA SMK3

Încărcat de

Ricky ARIEF100%(1)100% au considerat acest document util (1 vot)

837 vizualizări5 paginiPerbandingan sitem OHSAS dan SMK3 Permenaker No.5/1996

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentPerbandingan sitem OHSAS dan SMK3 Permenaker No.5/1996

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

837 vizualizări5 paginiComparison Auditor OHSAS 18001 IRCA SMK3

Încărcat de

Ricky ARIEFPerbandingan sitem OHSAS dan SMK3 Permenaker No.5/1996

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

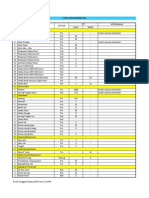

OHSAS (OCCUPATIONAL HEALTH AND SAFETY ASSESSMENT SERIES) 18001

4.1. General Requirements

4.2. OHS Policy

4.3. Planning

4.3.1. Planning for hazard identification, risk assessment and risk control

4.3.2. Legal and other requirements

4.3.3. Objectives

4.3.4. OHS management program(s)

4.4. Implementation and operation

4.4.1. Structure and responsibilities

4.4.2. Training, awareness and competence

4.4.3. Consultation and communication

4.4.4. Documentation

4.4.5. Document and data control

4.4.6. Operational control

4.4.7. Emergency preparedness and response

4.5. Checking and Corrective Action

4.5.1. Performance measurement and monitoring

4.5.2. Accidents, incidents, non-conformances and corrective and preventive action

4.5.3. Records and records management

4.5.4. Audit

4.6. Management review

F:\BASIC INFORMATION\Comparison_Auditor_OHSAS_18001_IRCA___SMK3.doc Page 1 of 5

Comparison of SMK3 Permenaker 05/Men/1996 & OHSAS 18001

SMK3 OHSAS 18001

• Mandatory • Voluntary

• Local regulation (Indonesia) • Standard that has been recognized by

several certification bodies (DNV, JACO,

SGS, BSI, BVQI, LRQA, JQA)

• Based on Safety Map (Australian • Based on several standards such as BS

Standard) and draft AS/NZ 4801 8800 : 1996, Draft AS/NZ 4801, DNV

OHSMS : 1997

• - • More compatible to ISO 9000 series,

ISO 14000

Element comparison of SMK3-OHSAS 18001

OHSAS 18001 Clause SMK3 Sub

Element/

Criteria

General Requirements 4.1 - -

OHS Policy 4.2 OHS Policy 1.1

Planning 4.3 Safety and Health Strategic 2.1

Planning

Planning for hazard identification, 4.3.1 Suitably competent personnel have 2.1.1

risk assessment and risk control identified and assessed the major

safety and health hazards and risks

associated with operations.

An organization-wide safety and 2.1.2

health strategic plan has been

developed and implemented to

control identified safety and health

hazards and risks associated with

operations.

Specific plan associated with 2.1.3

particular products, processes,

projects or sites have been

developed where appropriate.

The plans are based on hazard and 2.1.4

incident data, and other safety and

health records.

F:\BASIC INFORMATION\Comparison_Auditor_OHSAS_18001_IRCA___SMK3.doc Page 2 of 5

OHSAS 18001 Clause SMK3 Sub

Element/

Criteria

Documented procedures require 3.1.1

hazard identification and risk

assessment during the design or

redesign stage.

Documented procedures enable the 3.2.1

identification and assessment of

potential safety and health hazards

including public safety hazards

where it is proposed to supply

goods or services under contract.

Procedures exist for the 9.1.1

identification of hazards and

assessment of risks relating

manually and mechanically

handling.

Legal and other requirements 4.3.2 Relevant acts, regulations, 10.1.2

standards and code of practice are

maintained at accessible location.

Information on safety and health 2.3.1

activities and issues is disseminated

in a systematic manner to all

personnel in the organization.

Objectives 4.3.3 The plans establish measurable 2.1.5

OHS management program(s) 4.3.4 organization objectives for safety

and health, set priorities and

allocate resources.

Implementation and operation 4.4

Structure and responsibilities 4.4.1 Responsibilities and Authority To 1.2

Take Action

Training, awareness and 4.4.2 Developing Skill & Competencies 12 (all)

competence Personnel Selection and Placement 6.3

Consultation and communication 4.4.3 Employee involvement and 1.4.1 & 1.4.2

consultation arrangements are

documented.

Procedures exist to enable

consultation regarding changes

which have health and safety

implications.

F:\BASIC INFORMATION\Comparison_Auditor_OHSAS_18001_IRCA___SMK3.doc Page 3 of 5

OHSAS 18001 Clause SMK3 Sub

Element/

Criteria

Information on safety and health 2.3.1 & 2.3.2

activities and issues is disseminated

in a systematic manner to all

personnel in the organization.

Records of safety and health

information are maintained and

provided to all personnel and others

visiting the workplace.

Regular reports on safety and 10.2.2

health performance are produced

and distributed within the

organization.

Documentation 4.4.4 Document Approval and Issue 4.1

Document Change and Modification 4.2

Document and data control 4.4.5 Document Approval and Issue 4.1

Document Change and Modification 4.2

Operational control 4.4.6 Design Control 3.1

Contract review 3.2

Specification for the Purchase Of 5.1

Goods and Services

Verification Systems for Purchased 5.2

Goods and Services

System works 6.1

Maintenance, Repair and Alteration 6.5

of Plant

Workplace Environment 6.4

Services 6.6

Manually and Mechanically 9.1

Handling

Transport, Storage and Disposal 9.2

Systems

Hazardous Substances 9.3

Emergency preparedness and 4.4.7 Emergency Preparedness 6.7

response

Checking and Corrective Action 4.5 Monitoring Standard & Reporting 7 & 8 (all)

And Correcting Deficiencies

Performance measurement and 4.5.1 Supervision 6.2

monitoring Hazard Inspections 7.1

Work Environment Monitoring 7.2

F:\BASIC INFORMATION\Comparison_Auditor_OHSAS_18001_IRCA___SMK3.doc Page 4 of 5

OHSAS 18001 Clause SMK3 Sub

Element/

Criteria

Inspection, Measuring and Test 7.3

Equipment

Health Surveillance 7.4

Safety and Health Data and Reports 10.2

Accidents, incidents, non- 4.5.2 Emergency Reporting 8.1

conformances and corrective and Incident Reporting 8.2

preventive action. Accident Investigation 8.3

Handling problems 8.4

Records and records management 4.5.3 Safety and Health Records 10.1

Audit 4.5.4 OSHMS Internal Audit 11.1

Management review 4.6 Review and Evaluation 1.3

F:\BASIC INFORMATION\Comparison_Auditor_OHSAS_18001_IRCA___SMK3.doc Page 5 of 5

S-ar putea să vă placă și

- Ebay Business ModelDocument29 paginiEbay Business ModelPALAK PANTHIÎncă nu există evaluări

- JSA For SRP Instolation and DismentlingDocument17 paginiJSA For SRP Instolation and DismentlingShekh BabulÎncă nu există evaluări

- FAS08-111 Standard FinalDocument12 paginiFAS08-111 Standard FinalAnn Beck100% (1)

- HIRA Working at HighDocument15 paginiHIRA Working at HighToga NainggolanÎncă nu există evaluări

- Safety RegisterDocument6 paginiSafety RegisterSukhdeb BiswakarmaÎncă nu există evaluări

- Sullivan Ford Auto WorldDocument15 paginiSullivan Ford Auto WorldMahrosh BhattiÎncă nu există evaluări

- DUDUTECH SITE MAINTENANCE TASKSDocument4 paginiDUDUTECH SITE MAINTENANCE TASKSEmmanuelÎncă nu există evaluări

- SE PDC-CENTRAL HSE Weekly Summary Report: (Overall)Document5 paginiSE PDC-CENTRAL HSE Weekly Summary Report: (Overall)ابو محمد عليÎncă nu există evaluări

- PRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureDocument30 paginiPRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureGustavo Alonso BerettaÎncă nu există evaluări

- OSH Risk Register - 01Document28 paginiOSH Risk Register - 01M.usmanÎncă nu există evaluări

- PPE Request Form (New)Document1 paginăPPE Request Form (New)Syafrial AnasÎncă nu există evaluări

- Risk / Opportunities Analysis Risk Management Measure Monitoring of Effectiveness Preventive Action 1Q 2Q 3Q 4QDocument2 paginiRisk / Opportunities Analysis Risk Management Measure Monitoring of Effectiveness Preventive Action 1Q 2Q 3Q 4Qjai ebuenÎncă nu există evaluări

- Monsoon Extreme Weather Plan p-06,07Document6 paginiMonsoon Extreme Weather Plan p-06,07khurram shahzadÎncă nu există evaluări

- Updated 25-Apr-2023 HSE Observation Sheet and Action Tracker 9:39 AMDocument3 paginiUpdated 25-Apr-2023 HSE Observation Sheet and Action Tracker 9:39 AMAnna EmelineÎncă nu există evaluări

- 17 Subcon RequirementsDocument38 pagini17 Subcon RequirementsMohammed MinhajÎncă nu există evaluări

- Risk Registry Sample - PUBLICDocument8 paginiRisk Registry Sample - PUBLICMelissa CruzÎncă nu există evaluări

- Jojonomic HSE Solution - Package-RevisiDocument4 paginiJojonomic HSE Solution - Package-Revisihimawan sutantoÎncă nu există evaluări

- Water blasting SWMSDocument5 paginiWater blasting SWMSjohney2Încă nu există evaluări

- Effective Safety Management Systems: by George RobothamDocument33 paginiEffective Safety Management Systems: by George RobothamLoganathan DharmarÎncă nu există evaluări

- FILE-3.1.3-SCT-BAR-C2170-VOL-ID-SCC-HSEP14 - HSE Plan For Subcontractor - ERDocument170 paginiFILE-3.1.3-SCT-BAR-C2170-VOL-ID-SCC-HSEP14 - HSE Plan For Subcontractor - ERHitesh KoolwalÎncă nu există evaluări

- HSE List Request For HighlandDocument36 paginiHSE List Request For HighlandSeptian SuryanandaÎncă nu există evaluări

- Ppe Issue ListDocument9 paginiPpe Issue ListMohd Khairul AnwarÎncă nu există evaluări

- Sheqxel Bbs Participation Dashboard TemplateDocument39 paginiSheqxel Bbs Participation Dashboard TemplateMuhammad Adytio DarmawanÎncă nu există evaluări

- HSE-RA-030 Bulk Excavation With Excavator - Rev 0Document9 paginiHSE-RA-030 Bulk Excavation With Excavator - Rev 0عمروÎncă nu există evaluări

- EHS Observation & Corrective Action Report (Template)Document13 paginiEHS Observation & Corrective Action Report (Template)Tolentino Frias JezreelÎncă nu există evaluări

- Monthly HSE Report - Oktober2019 - Aneka CoffeeDocument57 paginiMonthly HSE Report - Oktober2019 - Aneka CoffeeKikie KieeÎncă nu există evaluări

- (598295696) 08.0 Article 3.0 Section D - HSE (27012015)Document17 pagini(598295696) 08.0 Article 3.0 Section D - HSE (27012015)NabilahÎncă nu există evaluări

- 2.2 C New Safety Dashboard Nov2022Document1 pagină2.2 C New Safety Dashboard Nov2022subodh kumarÎncă nu există evaluări

- Critical Project ActivitiesDocument29 paginiCritical Project ActivitiesAtemp-mail.orgInboxÎncă nu există evaluări

- SAP Cash ManagementDocument13 paginiSAP Cash ManagementBülent Değirmencioğlu100% (1)

- SOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Document1 paginăSOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Amit BhadauriaÎncă nu există evaluări

- Hazard analysis and risk assessment for material handling and loading/unloadingDocument2 paginiHazard analysis and risk assessment for material handling and loading/unloadingRais ZaynÎncă nu există evaluări

- HSE Engineer ProfileDocument2 paginiHSE Engineer ProfileAbdellatef HossamÎncă nu există evaluări

- Leadership' Role in Driving A Safety Culture: Tata Steel ExperienceDocument27 paginiLeadership' Role in Driving A Safety Culture: Tata Steel ExperiencefullaÎncă nu există evaluări

- Movile Plataform IncidentDocument34 paginiMovile Plataform IncidentAnonymous GfPSYi4nÎncă nu există evaluări

- Permit To Work GuidelinesDocument12 paginiPermit To Work GuidelinesalanjcherryÎncă nu există evaluări

- T Mobile Usa.2023Document1 paginăT Mobile Usa.2023applelog100% (2)

- Safety and Health PolicyDocument10 paginiSafety and Health Policynurul lovelymineÎncă nu există evaluări

- Ho 89Document1 paginăHo 89Shanmugam AnnamalaiÎncă nu există evaluări

- Information:: YellowDocument6 paginiInformation:: YellowSHRISH SHUKLAÎncă nu există evaluări

- PDF Masa Amended PPP Moa Lgu Malapatan MTCDC 101723 Word 2Document14 paginiPDF Masa Amended PPP Moa Lgu Malapatan MTCDC 101723 Word 2dexterbautistadecember161985Încă nu există evaluări

- PPE MatrixDocument50 paginiPPE MatrixdigiarkanandÎncă nu există evaluări

- Basic Elements of A Successful Safety and Health Program: Frank Dobson, CHSTDocument46 paginiBasic Elements of A Successful Safety and Health Program: Frank Dobson, CHSTRoslanÎncă nu există evaluări

- Pricing Model For Infosys BPO LimitedDocument4 paginiPricing Model For Infosys BPO LimitedAdil JahangeerÎncă nu există evaluări

- Master Plan to Reduce Construction Accidents in MalaysiaDocument6 paginiMaster Plan to Reduce Construction Accidents in MalaysiaJafar Sedek OmbitÎncă nu există evaluări

- Packing ProcedureDocument24 paginiPacking ProcedureAditya NugrahaÎncă nu există evaluări

- Project EHS KPI - 24 Agustus 2013Document1 paginăProject EHS KPI - 24 Agustus 2013Crystin Rotua Hasmi PanjaitanÎncă nu există evaluări

- CEP2010 Heat TransferDocument8 paginiCEP2010 Heat TransferamsukdÎncă nu există evaluări

- ToolsDocument1 paginăToolsDepi HerdianaÎncă nu există evaluări

- 10-TEC-BFM-F24 - Access Permit - R7 Dec 5 2020Document1 pagină10-TEC-BFM-F24 - Access Permit - R7 Dec 5 2020Design Xess EventsÎncă nu există evaluări

- CC 27 EhspDocument88 paginiCC 27 EhspABHISHEK BHARTIÎncă nu există evaluări

- PMBOK 7th Edition - ENG-6Document5 paginiPMBOK 7th Edition - ENG-6Felipe Guimaraes Pazin0% (2)

- Excavator ChecklistDocument2 paginiExcavator ChecklistJansen SungaÎncă nu există evaluări

- International Audit CharterDocument9 paginiInternational Audit CharterUlambayar AltangerelÎncă nu există evaluări

- RKABDocument5 paginiRKABMuhammad DailamiÎncă nu există evaluări

- Marketing ControlDocument49 paginiMarketing Controlsurchi shahÎncă nu există evaluări

- Peachtree Plumbing Valuation ReportDocument40 paginiPeachtree Plumbing Valuation ReportBobYu100% (1)

- Implementation of A QMS Within The MRF IndustryDocument35 paginiImplementation of A QMS Within The MRF IndustryAlexis RancesÎncă nu există evaluări

- DAILY INSPECTION CHECKLIST FOR MOBILE ELEVATING WORK PLATFORMSDocument6 paginiDAILY INSPECTION CHECKLIST FOR MOBILE ELEVATING WORK PLATFORMSJeremia SamosirÎncă nu există evaluări

- Industrial Safety Management Using Innovative and Proactive StrategiesDocument20 paginiIndustrial Safety Management Using Innovative and Proactive StrategiesUdit chaudharyÎncă nu există evaluări

- Effective Safety Management SystemsDocument34 paginiEffective Safety Management SystemsAmir SherafatipourÎncă nu există evaluări

- SOP 4 - Coal Bed Leveling in PGPDocument18 paginiSOP 4 - Coal Bed Leveling in PGPfaraz ahmedÎncă nu există evaluări

- SP 1190 4Document35 paginiSP 1190 4shahaludeen ummarÎncă nu există evaluări

- Manufacturing Data Folder IndexDocument4 paginiManufacturing Data Folder Indexer_paramjeetgillÎncă nu există evaluări

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 paginiKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelÎncă nu există evaluări

- FRM-EHS-PRO-05 Hazard Identification & Risk Assessment (HIRA)Document1 paginăFRM-EHS-PRO-05 Hazard Identification & Risk Assessment (HIRA)Venkatesan DÎncă nu există evaluări

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDocument6 paginiHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineÎncă nu există evaluări

- OHSAS Vs SMK3Document5 paginiOHSAS Vs SMK3Mohammad AfiantoÎncă nu există evaluări

- HSE-003-HSE Plan - RV-02Document53 paginiHSE-003-HSE Plan - RV-02Jomy JohnyÎncă nu există evaluări

- Ma 2Document30 paginiMa 2Tausif NarmawalaÎncă nu există evaluări

- UntitledDocument12 paginiUntitledSHER LYN LOWÎncă nu există evaluări

- Chapter 8 FranchisorDocument11 paginiChapter 8 FranchisorNiño Rey LopezÎncă nu există evaluări

- Labor Law - Sample Bar Questions (MCQs & Essay)Document8 paginiLabor Law - Sample Bar Questions (MCQs & Essay)A Febb M. VillarÎncă nu există evaluări

- Centre Sales JDDocument3 paginiCentre Sales JDSarahÎncă nu există evaluări

- BOOKSDocument31 paginiBOOKSTiganasu ViorelÎncă nu există evaluări

- Social Media Metrics: Digital Marketing: Review Activity (Nykaa)Document3 paginiSocial Media Metrics: Digital Marketing: Review Activity (Nykaa)yashvi bansalÎncă nu există evaluări

- SWOT RelianceJIoDocument5 paginiSWOT RelianceJIoRaj GuptaÎncă nu există evaluări

- Islamic Banking Topics Research Good For PHD ThesisDocument9 paginiIslamic Banking Topics Research Good For PHD Thesisvotukezez1z2Încă nu există evaluări

- MetaLink Notes 24-01-2017Document29 paginiMetaLink Notes 24-01-2017Mohamed AwadÎncă nu există evaluări

- IAS 36 - Presentation PDFDocument17 paginiIAS 36 - Presentation PDFRizwanChowdhuryÎncă nu există evaluări

- Direct Deposit FormDocument1 paginăDirect Deposit Formandrewdallas948Încă nu există evaluări

- Cour S E Syllabus: The University of Jordan Accreditation & Quality Assurance CenterDocument6 paginiCour S E Syllabus: The University of Jordan Accreditation & Quality Assurance CenterDania Al-ȜbadiÎncă nu există evaluări

- Coca Cola Balance Sheet Horizontal Analysis Balan - HorizonDocument2 paginiCoca Cola Balance Sheet Horizontal Analysis Balan - Horizonalisheikh12Încă nu există evaluări

- Service Capability Presentation - MXDMDocument16 paginiService Capability Presentation - MXDMAlwin SamuelÎncă nu există evaluări

- Chapter 8 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Document47 paginiChapter 8 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Falah Ud Din SheryarÎncă nu există evaluări

- Shakeel Carpentry Works For Finest Joinery For Homes, Villas, Offices, Buildings, Hotels, and InteriorsDocument44 paginiShakeel Carpentry Works For Finest Joinery For Homes, Villas, Offices, Buildings, Hotels, and InteriorsShakeel Ahmad100% (1)

- 5081 16361 1 PBDocument31 pagini5081 16361 1 PBamri alkaromiÎncă nu există evaluări

- Futures Markets IntroductionDocument49 paginiFutures Markets IntroductionVaidyanathan RavichandranÎncă nu există evaluări

- Fundamentals of Financial Management Concise 8Th Edition PDF Full ChapterDocument41 paginiFundamentals of Financial Management Concise 8Th Edition PDF Full Chaptersheryl.bates344100% (26)

- Customer SatisfactionDocument4 paginiCustomer SatisfactionrolandÎncă nu există evaluări