Documente Academic

Documente Profesional

Documente Cultură

Organitation Precomisionado

Încărcat de

Hugo Ramon Saravia CampelliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Organitation Precomisionado

Încărcat de

Hugo Ramon Saravia CampelliDrepturi de autor:

Formate disponibile

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Cde: NRM-310

Review: 4.1

FACILITIES HANDOVER

FACILITIES HANDOVER

NRM 310

4.1

Rev. Attach. III

Jun. 14

General rev.

Dec. 10

Eva lvaro Gutirrez

Antonio Lozano Saiz

Modesto Fernndez

Eva lvaro Gutirrez

Antonio Lozano Saiz

Manuel Ferrero Ferreras

General rev.

May 00

A.L.S.

M.F.F.

A.G.M.

General rev.

Nov. 96

Dpto. C.O.C.

D.C.

A.G.M.

Review

Description

Date

Prepared by

Checked by

Approved by

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

I.

Review: 4.1

Page 2 of 38

PURPOSE

The goal of this standard is to establish the criteria for the facilities handover, setting the

guidelines and defining the responsibilities for the pre-commissioning, commissioning and startup phases, and specifically:

To define de methodology for transferring the custody and control of the new facilities (and

hence the responsibility) in the most efficient way, defining how and when this transfer will

take place and the technical and economical responsibilities that arise from it.

To establish the criteria for the quality controls and tests recording during the different phases

of the Project: construction, pre-commissioning, commissioning and start-up, and also the

documentation that must be attached to the Handover Notice and to the Handover Certificate

of any system.

To define the type of acceptable defects, pending works and changes at the Handover Notice

and at the Handover Certificate of a system, their priority and the phase in which they must

be solved.

To define the check sheets to record the verifications, that shall be used by all the contractors

and engineering companies working in the project.

To allocate responsibilities and roles for the testing and checking activities during precommissioning, commissioning and start-up, and to establish if Owners attendance is

required for any test or verification performed previous to or during the facilities handover.

To define the safety and environment procedure, setting the criteria that shall be followed as

well as the roles and responsibilities of all parties involved in the commissioning and start-up

phases within the areas partially or fully handed over to the Owner. All of this in a way that will

guarantee that the facilities handover will only take place once all safety & environmental

risks that could affect people, facilities or the environment have been properly identified and

managed.

The aim of this standard is that the organization (Construction, Maintenance, Operation, etc)

more efficient or qualified for each task at each moment must be the organization that will

perform it, so that the job will be done in the best Safety conditions, taking always into account

the contractual scope of Works and conditions of the different parties involved in the facilities

handover process.

II.

SCOPE OF APPLICATION

This standard will apply for the handing over of the facilities of the projects managed by the

Engineering Division of Repsol, except for pipeline projects or LNG plants.

For the facilities handover of EPC projects, please take into account the considerations stated in

Attachment VIII.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

III.

Review: 4.1

Page 3 of 38

REPEALED STANDARDS

With the approval of this standard, the following standards of the Engineering Division get

repealed:

NRM-310 Facilities Handover, rev. 4, dated December 2010

IV.

1.

2.

3.

4.

INDEX

GENERAL ........................................................................................................................................5

DEFINITIONS ..................................................................................................................................5

2.1.

System ...................................................................................................................................5

2.2.

Pre/commissioning check sheets ..........................................................................................5

2.3.

Pre-commissioning ................................................................................................................5

2.4.

Mechanical Completion .........................................................................................................6

2.5.

Commissioning ......................................................................................................................6

2.6.

Start-up ..................................................................................................................................6

2.7.

Oil-in / Gas-in .........................................................................................................................7

2.8.

Defects, Pending Works and Changes. Significant changes. Priorities. Documental

management. ..............................................................................................................7

2.8.1.

Defect ..........................................................................................................................7

2.8.2.

Pending Work ..............................................................................................................7

2.8.3.

Change ........................................................................................................................7

2.8.4.

Priority in defects, pending works and changes solving. .............................................7

SYSTEM HANDOVER PROCESS ..................................................................................................9

3.1.

Warnings during the construction phase.............................................................................9

3.2.

Notice for Inspection of a circuit or element ........................................................................9

3.2.1.

Notice for Inspection submission ..............................................................................10

3.2.2.

Documentation to be submitted attached to the Notice for Inspection of each test

circuit. ........................................................................................................................10

3.2.3.

Documentation to be submitted attached to the Notice for Inspection of each Hold

Point task...................................................................................................................10

3.3.

For Flushing Notice (only for systems that include piping) ................................................11

3.3.1.

For Flushing Notice submission ..............................................................................11

3.3.2.

Documentation to be attached to the For Flushing Notice ........................................12

3.3.3.

Installation of the pending elements after flushing ....................................................12

3.4.

Handover Notice of a system ............................................................................................12

3.4.1.

Handover Notice submission ....................................................................................12

3.4.2.

Documentation to be submitted with a system Handover Notice ..............................13

3.5

System Handover Certificate ............................................................................................13

3.5.1.

Handover Certificate submission ..............................................................................14

3.5.2.

Documentation to be attached to the system Handover Certificate. .........................14

CHANGE MANAGEMENT .............................................................................................................15

4.1.

Economic management of changes ....................................................................................15

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 4 of 38

4.2.

Health, Safety and Environment (HSE) risk management of changes................................15

RESPONSIBILITIES ......................................................................................................................16

5.1.

Economic responsibility .......................................................................................................16

5.2.

Responsibility derived from the system handover and acceptance. ....................................16

5.2.1.

Construction responsibilities......................................................................................16

5.2.2.

Production responsibilities .........................................................................................18

5.3.

Responsibilities in tests and verifications ............................................................................19

6.

HIDDEN DEFECTS .......................................................................................................................19

7.

SAFETY DURING COMMISSIONING AND START-UP ...............................................................19

8.

Coordination Committee ................................................................................................................20

9.

STANDARDS AND SPECIFICATIONS OF REFERENCE ............................................................21

9.1.

Engineering Division Standards...........................................................................................21

ATTACHMENTS .........................................................................................................................................22

ATTACHMENT I: GENERAL CRITERIA FOR THE SYSTEMS HANDOVER .................................23

ATTACHMENT II: REQUIRED DOCUMENTATION FOR THE SYSTEMS HANDOVER ...............25

ATTACHEMENT III: TEST RESPONSIBILITIES .............................................................................26

ATTACHMENT IV: FOR FLUSHING NOTICE FORM .....................................................................27

ATTACHMENT V: HANDOVER NOTICE FORM .............................................................................28

ATTACHMENT VI: HANDOVER CERTIFICATE FORM..................................................................29

ATTACHEMENT VII: CHECK SHEETS INDEX ...............................................................................30

ATTACHMENT VIII: ADAPTATION FOR HANDING OVER FACILITIES UNDER EPC

CONTRACTING ........................................................................................................34

5.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

V.

CONTENTS

1.

GENERAL

Review: 4.1

Page 5 of 38

The start-up group of the Owner, hereafter Production, is a temporal organization, one of its

responsibilities is to accept the new facilities designed and constructed by the Engineering

Division, hereafter Construction (for that department represents the Engineering Division in this

procedure). In this context it must be understood than Construction includes also the engineering

and purchasing of the Project, whereas Production includes Production itself, Maintenance,

Reliability, Safety and all other departments of the Owner.

2.

DEFINITIONS

2.1.

System

It is the group of lines, equipment and instruments whose limits and components are clearly

defined and are not shared with any other system (except for certain elements included in the

generic systems shown in Attachment II, such as multi-cable wirelines, instrumentation boxes,

etc.), and that provides the Plant with a service or conforms an independent and functionally

related group.

Any system shall be able to be isolated from the overall facility to be handed over separately for

independent commissioning.

In certain cases a part of a system could be handed over and accepted before the rest of the

associated system (for example, a column), being referred as subsystems. Those partial

handovers shall have to be specifically agreed between Production and Construction at the time

of the systems definition.

2.2.

Pre/commissioning check sheets

They are the records for the checks, controls and tests that have been performed for verifying the

aptitude of the new facilities, the quality of the execution and its consistency with the design and

construction established criteria.

The different check sheets for the construction, pre-commissioning and commissioning phases

are attached in Attachment VII. The check sheets index shows in which phase of the handing

over process each checklist shall be completed.

2.3.

Pre-commissioning

Activities to be performed on an equipment, system or facility in order to verify that all

components required by design have been correctly installed.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 6 of 38

The verifications to be performed are those that do not require definitive energy or fluid supplies.

These checks and tests will be always carried out with provisional or temporary supplies.

Some examples of pre-commissioning checks are: insulation tests on cables, pre-pop tests on

safety valves, dimensional controls on orifice plates, setting up of instrumentation loops, motors

correct rotation.

Pre-commissioning activities shall be performed by Construction and, when required, supervised

by Production.

NOTE: With the aim of improving the efficiency and getting synergies, piping flushing may be

included in the pre-commissioning phase, only with previous Productions agreement, and always

under his leading.

2.4.

Mechanical Completion

It is the milestone at which a facility or system is prepared to be handed over to Production for

performing the commissioning and start-up tasks, which require the use of definitive fluids and/or

energy.

At mechanical completion all the elements included in the facility or system (static equipment,

machinery, piping, electric equipment, instrumentation, etc.) shall have been installed as per

project drawings and specifications, and all the quality controls and tests required during

construction and pre-commissioning must have been accomplished.

2.5.

Commissioning

Activities to be performed on an equipment, system or facility to get it ready for start-up.

The commissioning activities require the availability of definitive energy or fluids to be carried out.

Some examples of commissioning tasks are: flushing, chemical cleaning, blowing, final leak

testing, purging/inerting, motor solo run, loops test, etc.

When all the systems in a facility have been commissioned, the facility is ready for its start-up, the

usual pattern being that the systems get started-up in a sequential way, so that commissioning

and start-up phases partially overlap.

Commissioning tasks are led by Production and assisted by Construction when required.

2.6.

Start-up

Activities to be performed by Production, overlapping commissioning phase or not, in order to

start up the new facility systems. To accomplish it, under Productions responsibility and leading,

and with Constructions assistance when required, blind discs will be removed, valves will be

opened, electric equipment will be energized, etc. The start-up phase will begin at the moment

that the very first system is started up.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 7 of 38

FACILITIES HANDOVER

The start-up tasks will be performed by Production.

2.7.

Oil-in / Gas-in

It is the milestone at which the facility receives the first feedstock for starting production.

2.8.

Defects, Pending Works and Changes. Significant changes. Priorities. Documental management.

2.8.1.

Defect

Difference between the elements or installed systems and their design, established by the

engineering or vendor drawings approved for construction or for manufacture.

2.8.2.

Pending Work

It is an element that has not been installed or an activity that has not been performed at the

moment of the submission of the system handover notice, and that is well known and properly

identified so that it can be solved after the notice.

2.8.3.

Change

A proposal for changing the approved for construction design, asked for during the construction

phase or during the facility handover. There are two types:

2.8.4.

Necessary change. Modification on the approved for construction design (or on an already

constructed item) that if is not executed would difficult the facilitys operation or

maintenance, or would mean a measurable operative risk or would be out of project

specifications or legal requirements.

Advisable change. Modification that increases the easiness for operating or maintaining the

facility, or the process profitability, but that is not mandatory for the facilitys operation or

safety.

Priority in defects, pending works and changes solving.

The defects, pending works and changes in a system, subsystem or equipment will be classified

in the following types depending on its priority for solving:

Priority A (before test). Defects, pending works or changes that block test execution

(hydraulic, pneumatic, electrical or of any type) of a piping circuit, a static or dynamic

equipment, an electrical facility, a cable, etc.

Examples:

o

o

o

Defects in welding

Defects in supports welded to a pipe.

Defects in NDT or heat treatments.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Page 8 of 38

FACILITIES HANDOVER

Review: 4.1

Defect in a dynamic equipment alignment, before the discharge piping pressure

test.

Priority B (after test):

Priority B1 (before flushing). Mechanical defects, pending works or changes in any part

of a line or system that will be under pressure, that affect the integrity or tightness of the

system and prevent the beginning of the flushing tasks.

Examples:

o

o

A hydraulic vent has not been sealed.

A hydraulic pressure test blind disc has not been removed.

Priority B2 (before commissioning). Those defects, pending works or changes that

prevent the commissioning tasks to begin, such as electrical or instrumentation tests, etc.

Examples:

o

o

o

o

o

o

o

Some instruments from the Attachment I are not installed yet.

Some pneumatic connections are still undone.

Defects in trenches covering

Defects in equipment grounding.

Defects in equipment grouting.

Defects in spring supports/hangers

Defects in the equipment cleaning.

Priority C (before start-up). Those defects, pending works or changes that must be solved

before the system start-up.

Examples:

o

o

o

o

o

o

o

Defects in piping isolation.

Defects in structure fireproofing.

Defects in equipment labeling

Column manholes unclosed.

Cable labeling and/or installation of cable clips unfinished

Spring supports/hangers stops not removed

Finishing works on structure

Priority D (after start-up). Those defects, Pending Works or changes that do not prevent

the system start-up to begin (mainly documentation issues such as as-built issuing, lack of

certificates, minor touch up painting, etc).

Type D issues must be solved in a period no longer than six months after start-up.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

3.

Review: 4.1

Page 9 of 38

SYSTEM HANDOVER PROCESS

Units will be handed over on a system by system basis. Therefore, systems shall be defined

following a process and commissioning approach. Subsystems may be handed over in advance,

but only with the previous consent from Production.

This procedure will simplify the scheduling for both Production and Construction and will make

possible a systematic and controlled handover, with the performing of the tests and checks in a

logical and sequential way, which will allow to establish priorities, to overlap tasks and to shorten

the timing.

Construction shall be responsible of establishing the database with all the elements for each

system, using for that the software tools agreed.

Production shall be responsible of defining the number of systems for each unit, the scope of

each system, and the handover priority for each system, marking them on the Project P&IDs. All

of this in such a way that none of the elements will belong to two different systems (except from

those exceptions included in the Attachment II generic operative systems, such as multi-cables,

instrumentation boxes, rack rooms, etc).

The systems shall be defined by Production and sent to Construction before the Mechanical

Works begin and at least four to eight months (depending on the project size) ahead of

mechanical completion. Construction shall accept the systems definition within a month. During

this time, Construction will analyze them with a constructability approach and will suggest the

subsystem definition to Production, if any. All this will allow the scheduling of the construction

works from the early steps, in such a way that the completion and handover of the different

systems would follow a logical sequence for pre-commissioning, commissioning and start-up.

Construction shall prepare the system database uploading all the information associated to each

system and subsystem as soon as posible, and always no longer than two to six months

(depending on the project size) after the systems definition reception. This will allow to record in

the database all the pre-commissioning and commissioning verifications and tests (and even the

checks done during the construction phase). Production shall upload in this database all the

defects, Pending Works and changes that would detect during the facilities handover process.

Construction shall submit, two months before the first system handover notice is expected, a

handover detailed Schedule that will be periodically updated, taking always into account

Productions priorities.

3.1.

Warnings during the construction phase

During the construction phase, Production could perform routine inspections prior to any

inspection or handover notice, with the aim of detecting defects in an early stage. All those

defects, including any change asked for by Production, will be managed in a Construction

Warnings database.

3.2.

Notice for Inspection of a circuit or element

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 10 of 38

During the last stages of construction, Construction shall formally invite Production, by means of

a Notice for Inspection of a circuit or element, to perform the inspection prior to the formal

handover of the equipment and facilities that, according to Attachment III, have any hold points

for Production, and also to all the circuits inspection before its pressure test takes place, so that if

any defect should exist it could be solved in advance, thus not making it necessary for the

pressure test to be repeated. All those defects or changes identified by Production shall be

managed in the system database.

Those inspections will be noticed in detail by email for each element. However, for the witness

points only the beginning and end of the global activity will be noticed (for example, beginning and

ending of the task Instruments pre-calibration) but there will be no notice for the individual

elements to be inspected.

Construction shall send the notice email to Production at least three working days before each

pressure test and hold point.

In addition to those notices, Construction shall submit to Production the monthly test schedule

forecast.

At this stage, Production will notice to Construction for solving:

Execution defects.

Documental defects.

Necessary and advisable changes.

Pending works shall not be noticed at this stage.

3.2.1.

Notice for Inspection submission

Construction shall submit the Notice for Inspection to those responsible roles from Production

that must be informed (the distribution list shall be previously agreed between Construction and

Production).

3.2.2.

Documentation to be submitted attached to the Notice for Inspection of each test circuit.

With the Notice for Inspection the following documentation shall be attached:

3.2.3.

The Notice for Inspection itself.

The cover of the test dossier.

P&IDs (last revision) with the test circuit marked on.

A copy of the isometric drawings (or field drawings) in their last revision (or as-built) with the

welding, material casting and supports information on them.

Documentation to be submitted attached to the Notice for Inspection of each Hold Point task.

Of an equipment or package:

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 11 of 38

General drawing of the equipment.

Data sheet.

Others:

No information to be attached.

3.3.

For Flushing Notice (only for systems that include piping)

With the aim of bringing forward the flushing activities, overlapping them with the construction

activities without waiting for the handover certificate and only with mutual agreement between

Production and Construction, a For Flushing Notice shall be issued for piping systems or

subsystems.

In those systems that include some of the elements listed in Attachment I (items that could be

damaged during flushing if they were already installed), to bring forward the flushing activities will

be very useful, because it will allow installing these items only once, after finishing the piping

flushing activities.

Once all type A and B1 defects and Pending Works have been solved (that is, when the whole

system is ready in terms of pressurized piping), Construction shall submit the for flushing notice

(if it applies) using the Attachment IV form.

Within seven (7) working days Production shall give its acceptance (with or without conditions) or

rejection for the flushing beginning. If Production rejects the beginning of the flushing activities,

then it shall return the notice attaching a punch list showing any outstanding or unacceptable

work.

Once the for flushing notice has been submitted, Production shall be informed in writing of any

Construction activity on the system.

Production shall formally inform Construction of the flushing activities conclusion by submitting to

Construction the same for flushing notice with the flushing finished signed, in order for

Construction to perform the Attachment I items installation.

The systems already flushed shall not be considered ready for commissioning until all the

Attachment I items have been installed, checked and without A or B defects.

If it is agreed not to do the flushing at this point, but to do it during the commissioning phase,

Construction shall finish the construction Works by installing also the Attachment I items. Those

of them that Production considers so, shall have to be removed later on, prior to carrying out the

flushing activities.

3.3.1.

For Flushing Notice submission

Construction shall submit the for flushing notice to the designated responsible Production

people.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

3.3.2.

Review: 4.1

Page 12 of 38

Documentation to be attached to the For Flushing Notice

The list of those Attachment I items pending from installation in the system.

3.3.3.

Installation of the pending elements after flushing

Tras los lavados de las lneas, Operacin comunicar oficialmente, devolviendo el Aviso para

Lavados, como se ha indicado con anterioridad, la terminacin de los lavados de un sistema o

subsistema operativo, sealando que el mismo est listo para realizar los montajes pendientes

de los elementos indicados en el Anexo I.

After piping flushing, Production shall officially inform about the flushing conclusion for the system

or subsystem giving back the for flushing notice form, as it has previously explained, marking on

it that the system or subsystem is ready for the installation of the Attachment I items.

Construction will proceed to install and pre-commission those elements according to the Project

requirements and specifications.

3.4. Handover Notice of a system

Between two to three weeks before the expected date for a system handover, Construction shall

submit the Notice for Handover (see Attachment V) which will allow Production to begin with their

system checking previous to the definitive system handover.

In this notice the estimated submission date for the Handover Certificate shall be indicated.

If there would be any defects, pending works or changes (type B, C or D), these will be detailed

on the DI-A.01 check sheet Punch list and/or on the DI-A.02 Change list, including their

solving date forecast. Typical pending activities could be, for example, the final cold alignment of

pumps, assembly of the motor-pump coupling and installation of control valves after piping

flushing, painting touchup or some isolation works, or finishing works on structures.

Handover Notices shall be submitted to Production with all the A defects, pending works or

changes already solved.

Once the handover notice has been received, Production shall start the whole system inspection

for identifying any possible defects or changes. These defects or changes shall be forwarded to

Construction through the Owners Project Coordinator and uploaded in the agreed management

software.

Within a seven (7) working days period from the handover notice, Production shall submit the

punch list and the changes list.

3.4.1.

Handover Notice submission

The site engineering shall submit to Construction the Handover Notice and a soft copy of the

dossier with all the documentation included in Attachment II, while guarding the original hard

copy.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 13 of 38

The following sender and recipients shall be stated at the header of the Handover Notice:

From: Repsol DI Construction Manager

To: Owners Commissioning Manager (Unit or Project shall be indicated)

cc: Owners Project Coordinator (idem)

Construction shall check the documentation and once approved, they shall sign the Handover

Notice and submit it together with the documentation dossier to Production. The documentation

dossier shall be issued as agreed between Construction and Production at the beginning of the

facilities handover process (soft copy, hard copy or any other way agreed).

3.4.2.

Documentation to be submitted with a system Handover Notice

The documentation that must be attached to a system handover notice for each of the elements

that the system could include, as well as the check sheet that shall be used for each element, are

indicated on Attachment II.

The site engineering has the responsibility to gather all data and prepare a soft copy (scanned

documents) of all check sheets, drawings, data sheets, etc, from all contractors and detail

engineering, to build up the documentation dossier to be attached to the handover notice.

Should any of such documentation not be available to be sent attached to the handover notice, it

shall be sent attached to the handover certificate, always with prior Production consent

(verification, electrical workshop, etc).

The original dossier, with the original check sheets, shall be guarded by the site engineering at

their site office and be submitted later on to Repsol Engineering Division and finally forwarded to

the Owner at the end of the project as part of the Final Quality Book.

For the recording of the commissioning tasks, Construction shall submit to Production the

corresponding unfilled commissioning check sheets for their filling and signing by Production.

Once they are filled in and issued, Construction shall upload them into the management software

and also shall include them in the corresponding system dossier.

3.5

System Handover Certificate

Once the Attachment I items have been installed, all type A, B1 and B2 defects, pending works

and changes have been solved, and at least seven (7) working days after the Handover Notice

submission, Construction will issue the Handover Certificate (using attachment IV form) attaching

a list of the remaining defects, pending works and changes, if any, which should not affect the

conditional acceptance of the system. These type C or D defects, pending works or changes shall

be recorded on the Punch list check sheet DI-A.01 or on the Change list DI-A.02.

Production will have a seven (7) working days period for the system handover acceptance

(conditional or definitive) or rejection. In case of rejection of the system, Production shall return

the handover notice, attaching a punch list to be solved. Once all these defects or pending works

are solved to Productions satisfaction, the system shall be unavoidably accepted. All system

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 14 of 38

handover certificates must be signed by Production before the start-up beginning.

With the system (or subsystem) acceptance, Production undertakes the whole system (or

subsystem) responsibility, not only the operative responsibility, but also preventive and corrective

maintenance, safety and economic responsibility.

Any Construction task over an already handed over system shall require the corresponding work

permit.

The final acceptance of the new facility follows automatically once all systems have been handed

over and accepted.

The acceptance of a system or facility does not relieve Construction or the organizations

underneath (field engineering, site contractors) from their responsibilities about mechanical

completion of all the remaining Works under the Project scope (painting touch ups, fire proofing

or isolation finishing works, etc.).

3.5.1.

Handover Certificate submission

The field engineering shall submit to Construction the Handover Certificate and a soft copy of the

dossier with all the required documentation detailed below, while guarding the original hard copy.

The following sender and recipients shall be stated at the header of the Handover Certificate:

From: Repsol DI Construction Manager

To: Owners Commissioning Manager (Unit or Project shall be indicated)

cc: Owners Project Coordinator (idem)

Construction shall check the documentation and once approved, they shall sign the Handover

Certificate and submit it to Production together with the documentation reviewed or additional to

that sent with the Handover Notice. The documentation dossier shall be issued as agreed

between Construction and Production at the beginning of the facilities handover process (soft

copy, hard copy or any other way agreed).

3.5.2.

Documentation to be attached to the system Handover Certificate.

With the system handover, the already previously submitted documentation shall not be resent.

Only the following documentation shall be attached:

The Handover Certificate itself (Attachment VI form)

Punch list (DI-A.01 check sheet) updated with the already solved defects or pending works,

and with the remaining type C or D defects or pending works, if any.

Necessary or advisable Change list (DI-A.02 check sheet), updated with the changes

already performed.

Change control documentation, involving all significant changes, as per NRM-251. This is a

documental proof for the Safety and Environmental Risk Management (see forward).

Pending documentation that, after agreement between both parts, has not been sent before

with the Handover Notice (including remaining check sheets, in any).

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

4.

CHANGE MANAGEMENT

4.1.

Economic management of changes

Review: 4.1

Page 15 of 38

Any modification to the approved for construction design implies an extra cost to the Project,

because it is a refundable change in scope to the contractor or to the design engineering.

Therefore, they have to be limited to the indispensable minimum, and should be restricted

preferably to only the necessary changes.

Construction shall evaluate the impact in cost and schedule of each change requested by

Production, and shall report it to the DI Project Manager and the Owners Project Coordinator.

Prior to their execution, both necessary and advisable changes require their acceptance as such

by the DI Project Manager.

Necessary changes require the Owners Project Coordinator approval. Advisable changes require

the Owners Project Coordinator approval as change in scope and also, depending on their

execution estimated cost, they will require the corresponding approval according to the Owners

budget approval limits.

Changes shall be processed by opening the corresponding Change Order to the contract that will

execute it.

Approvals within the Engineering Division shall be ruled by the requirements stated in standard

NRM-373 Construction Works Certification regarding approval limits.

Advisable changes should be requested at least six weeks ahead of the expected handover

certificate date of issuing, and making sure that the execution time for the change is shorter than

that period. Advisable changes requested later than that shall have to be agreed between

Construction and Production.

An advisable change yet not executed shall not be a reason for rejecting a system handover,

except if it has been previously agreed so between Construction and Production.

The execution costs of advisable changes or any assistance asked for by Production shall be

charged to the assistance for commissioning and start-up budget.

Construction shall execute any necessary changes, even those identified late (but always before

start-up). Delays resulting therefrom shall be evaluated by Construction and approved and agreed

with Production.

4.2.

Health, Safety and Environment (HSE) risk management of changes

Any change, necessary or advisable, which implies a modification of the Approved for

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 16 of 38

Construction drawings could become a significant change from the HSE point of view, as defined

in standard NRM-251.

All significant changes, from the HSE point of view, shall be highlighted on the DI-A.02 check

sheet (Change list).

Significant changes require a documented and systematic analysis in order to manage the

associated HSE risk, as per procedure established in NRM-251.

Together with a system handover, the responsibilities in managing its associated HSE risk shall

be transferred to Production. Requirements stated in NRM-251 in this regard shall have to be

followed.

5.

RESPONSIBILITIES

5.1.

Economic responsibility

By accepting a system, Production assumes its related economic responsibilities, but not the

remaining construction works, nor those indicated in the pending Works lists neither any other

task defined on Attachment III as Construction responsibility during the construction or precommissioning phases.

Construction will be responsible of repairing any damage resulting from the construction activities

under its responsibility, even after the system handover.

Any works requested by Production after the system handover and until the start-up shall be

charged to the commissioning & start-up budget. Expenditures coming from power, utilities or

products consumption or from wastage, or any operating cost shall not be charged to that budget

but to Productions operating budget.

5.2.

Responsibility derived from the system handover and acceptance.

5.2.1.

Construction responsibilities

Safety:

It shall be forbidden for Construction and the organizations answerable to them (site engineering

or contractor companies) to energize with definitive energy supply or to feed with definitive fluids

(even utilities) by means of valve opening, switching switches or switchgears, etc. Every start-up,

even for testing, and even with harmless fluids, gases or electrical or any other type of supply

shall be made by Production people.

Construction people shall never work on a handed over system without a work permit (or a

working authorization for a noticed-for-flushing system), and shall strictly follow the safety

procedure developed by Production for the commissioning and start-up period.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 17 of 38

The contractor companies will be the performers in the work permits required for finishing any

works under Constructions scope. The Engineering Division or the site engineering will act as

petitioners.

Construction will be responsible for repairing any handed over elements if the damage has been

made by a Construction job or by Construction people or a contractor performing tasks under

Constructions scope of work.

Construction will get from Production any working permit (either regular or hot) required by the

established safety procedure, for any work needed to be done on an already handed over system

or within its area of influence.

Cleaning:

Construction shall continue being responsible for the area cleaning (including the drainage

system) until all the construction works have been finished.

Conclusion and scope of work:

Construction shall be responsible of solving all the defects and pending works (including the

installation of the Attachment I list items) stated in the punch list attached to the system handover

notice.

Construction shall be responsible of the proper execution, supervision and scheduling of all

Works requested by Production for the commissioning phase. Those works will be charged to the

commissioning $ start-up budget. Construction will issue estimated budgets for those works when

requested so by Production.

Construction will try to finish before start-up all the advisable changes that have been approved

by the respective responsible people from Construction and Production, even if it is needed to do

the works during the commissioning phase.

Construction shall be responsible to identify the need and dates and define the vendor technical

assistance for construction scope of work. The time sheets for these technical assistances need

be approved only by Construction and their cost will be included in the construction budget.

Construction shall coordinate also the vendor technical assistance for commissioning required by

Production. In this case, Production shall be responsible of the scope of work and dates definition

for the assistances.

Construction shall manage and provide the access documentation, PPE's and safety information

required for the vendors or licensors to perform their assistances in the facilities.

For the payment of the commissioning and start-up assistances, all time sheets from vendors

shall be signed by both Construction and Production.

Construction shall issue and submit the required construction documentation for the facility

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 18 of 38

legalization.

Assistances:

Production could require Constructions assistance to perform tasks on handed over systems. In

those cases Construction will assist if it does not affect its own tasks. The costs derived from

these assistances would be charged to the commissioning & start-up budget.

5.2.2.

Production responsibilities

Safety:

Production will issue and authorize all work permits required for the execution of any task after a

system handover following the safety procedure developed by Production for the commissioning

and start-up phase.

Production shall assume the whole responsibility of the handed over system, including safety

responsibility.

Production shall be responsible for the handed over system operation. Construction shall assist

Maintenance when requested until the start-up beginning, charging the economic costs derived to

the commissioning & start-up budget.

For the execution of the commissioning and start-up tasks, Maintenance contractors or

Construction contractors performing commissioning & start-up assistances will be the performers

in the corresponding work permits. Maintenance (from the Owner) will be the petitioner. But in

any case, all of it as per the safety procedure developed by Production for the commissioning &

start-up phase.

Production shall be responsible of defining the work permit system and shall establish the safety

measures required as the commissioning phase moves forward (valve wheels removal, electrical

lock outs, blind discs, etc.) and during the start-up.

Production shall install the required warnings and lock outs to assure the safety of the people and

facilities in the area, following always the approved safety procedure.

Production shall be responsible of the preparation of the list of all the blind discs required for

flushing, and, in general, for all the commissioning and start-up, and also of their installation and

removal. Construction shall assist with the manpower requested.

Conclusion and scope of work:

Production shall energize all electric systems, and shall also start-up and shut-down all rotating

equipment, shall open and close all valves and shall pressurize and depressurize all the elements

included in any handed over system.

Production shall issue and submit the required maintenance documentation and shall perform the

administrative procedure to legalize the installation and get the Start-up Certificate.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 19 of 38

Assistances:

Production shall be responsible of defining the assistances that they will require (from

Construction, suppliers, Construction contractors, etc.) including the number of people, the length

of the assistance and its starting date.

Operacin ser responsable de las relaciones tcnicas con los representantes de

suministradores de equipos que pueden ser necesarios para el comisionado y la puesta en

marcha. Podrn solicitar ayuda a Construccin para gestionar la presencia de estos

representantes (as como representantes de ingenieras y personal de contratistas de

construccin con sus equipos). Los costes incurridos se cargarn a la cuenta de puesta en

marcha.

Production shall be responsible of the technical relationship with the suppliers required for the

commissioning and start up. They could request Construction assistance for managing the

suppliers representatives attendance (and also for managing the engineering representatives

attendance or construction contractors). The derived cost will be charged to the commissioning &

start-up budget.

5.3.

Responsibilities in tests and verifications

The different tests and checks that must be performed as part of the construction quality control,

as well as the pre-commissioning and commissioning tasks for the new facilities are defined in

Attachment III. Also the responsibilities and roles for each task are defined there.

In addition, it is indicated in which phase (construction, pre-commissioning, commissioning or

start-up) each test or check shall be performed and recorded (if required).

6.

HIDDEN DEFECTS

Construction shall be responsible of solving any hidden defects in equipment directly purchased

to the suppliers, which would be discovered prior to the acceptance of the guarantee tests.

7.

SAFETY DURING COMMISSIONING AND START-UP

Within the areas identified as Construction areas, that means there where it has been in writing

agreed with Production that the Owners work permit procedure does not apply, Constructions

safety rules and the local regulation shall be followed.

However, Production shall propose and agree with Construction a regulated procedure for setting

the safety rules in those areas while the works move forward, and mainly once the flushing,

commissioning and start-up phases have started, taking also into account the transferring of the

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 20 of 38

HSE risk management.

Within the operating areas the Owners safety procedures shall apply, and they shall be strictly

followed, especially in anything related to work permits.

In general terms, the transition from the safety rules in the construction phase to the Owners

safety rules to be followed once the facility has been handed over shall be done by stages,

according to Productions criteria, as follows:

A work permit shall be required for any work to be done on a totally or partially handed over

system.

A confined space entering permit shall be required to enter any drum, column, tank, etc

(even in those not yet handed over). This entering permit shall be approved by Construction

during the execution phase. However, once the nitrogen system or other utilities are in

service in the new facility, or once the system the equipment belongs to has been handed

over (or its for flushing notice has been issued), the approval for the confined space entering

permit shall be given by Production.

The safety procedure established for the commissioning & start-up phase shall state the

renewal frequency for the work permits, taking into account the risk, the environment

conditions, the progress of works and the start-up of new systems.

The operating unit ordinary safety rules shall be imposed at least one week ahead of the unit

feeding with process fluid or even of introducing in the new facility utilities with a certain

associated risk (steam, nitrogen, etc).

The area already under operation (facility in service) shall be clearly marked on site by

Production. Construction shall install portable fences, markers, etc, as requested, to prevent

the access of non-authorized personnel hanging signs showing that the area inside is

already in service.

Production shall install signs on every line, valve, etc, clearly showing that they are in

service as soon as the system had been handed over. Following Productions criteria block

valves wheels will be removed or locks installed on valves, manholes will be sealed,

electrical interlocks will be set, blind discs will be installed, etc.

Safety agreements between Production and Construction shall be recorded in writing and shall be

greatly advertised. Both organizations shall commit to bring their answerable personnel to fulfil

them.

8.

Coordination Committee

From the date agreed between Production and Construction on, a weekly meeting shall be held

to review the progress, coordinate the common Works and assure that all contents stated in the

present standard will be accomplished. All involved parts shall attend. The minutes of that

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 21 of 38

FACILITIES HANDOVER

meeting will have binding character 24 hours after their distribution to the attendees.

9.

STANDARDS AND SPECIFICATIONS OF REFERENCE

9.1.

Engineering Division Standards

NRM-373

NRM-251

Construction Works Certification

HSE risk management in Projects

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 22 of 38

FACILITIES HANDOVER

ATTACHMENTS

ATTACHMENT I.

General criteria for the systems handover

ATTACHMENT II.

Required documentation for the systems handover

ATTACHMENT III.

Tests Responsibilities (Hold points and witness points criteria)

ATTACHMENT IV.

For Flushing Notice form

ATTACHMENT V.

Handover Notice form

ATTACHMENT VI.

Handover Certificate form

ATTACHMENT VII.

Check sheets

ATTACHMENT VIII.

Adaptation for handing over facilities under EPC contracting

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 23 of 38

ATTACHMENT I: GENERAL CRITERIA FOR THE SYSTEMS HANDOVER

After the pressure tests, Construction shall remove all the pressure tests blind discs. The

pressure test will be considered completed when the blind disc removing had been recorded on

its check sheet. Production could ask to leave some of these discs installed if required for

flushing, defining which ones and being responsible of their removing after the flushing tasks.

The battery limit blind discs (in addition to the discs required for flushing) will be defined,

recorded, labeled, installed and removed by Production (with Construction assistance, if

required).

The instrumentation piping hook ups must be welded at least to the manifold before starting the

flushing activities.

The following equipment and instruments (if to bring forward the flushing tasks until the precommissioning period has been agreed) will be installed only after flushing for avoiding damages

during the construction period.

Control valves

Pressure safety valves and rupture discs

On off valves

Coriolis type mass flowmeters

Wedge type flowmeters

Magnetic type flowmeters

Thermal dispersion type flowmeters

Vortex type flowmeters

Pitot tubes and anubar instruments

Orifice plates and restriction orfices

Insert-mounted analyzer tubes

Process rotameters

Flame arrestors

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Static mixers

Desuperheaters

Diaphragm and capillary instruments

Review: 4.1

Page 24 of 38

Construction contractors will install provisional spacers where required instead of these elements,

taking into account their dimensions for avoiding any future interference.

Removing the clapper of a check valve is forbidden. If the flushing flow direction is opposite to the

valve flow direction, the whole valve must be inverted or removed.

Construction shall proceed, after the flushing activities, to reinstall the system, removing flushing

spools, blind discs, checking bolts torqueing and installing all the elements that might have been

removed for the flushing activities. Exceptionally, Production could decide to keep any paddle

disc in a position different from its P&ID position if it is required for safety or operative reasons.

Following, Construction shall proceed to install the above listed elements, in accordance to the

contract unit prices, under their scope and responsibility, and with the previous approval by

Production of the corresponding work permits.

If it were not agreed to flush the lines immediately after the pressure test, Construction shall

install the above listed items (but orifice plates and restriction orifices) for finishing his work.

Afterwards, at the moment of flushing beginning, items that could be damaged by flushing

activities shall be removed (for instance, control valves and mass flow meters).

The spring supports shall remain with their pins installed during the construction and precommissioning phases. After flushing, Production will confirm to Construction when they can

proceed to remove the pins and check the cold position of the springs.

If Production decides that a thermocouple could be a problem for the flushing activities, it would

be removed by the Commissioning and Start up assistance team (under Production

responsibility). The same assistance team will reinstall it after flushing.

The drainage valves will be handed over opened, if there is not any different Production

instruction.

If there is any line that requires that the insulation boxes of valves and flanges remain uninstalled

until the leakage test before start-up has been done, the installation of these boxes will be

performed by the commissioning and start-up assistance team and the cost derived will be

charged to the commissioning & start-up budget.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 25 of 38

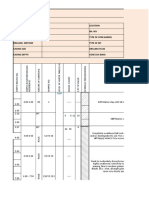

ATTACHMENT II: REQUIRED DOCUMENTATION FOR THE SYSTEMS HANDOVER

The documentation defined in the following table will be attached to the Handover Notice of the system.

The table itself will be attached also, as a table of contents, marking on it (in the Included column) which

documentation is attached.

The documentation required by this Attachment and also the documentation indicated at chapter I.

General will be attached for each system.

If any of the documents is not available at the moment it would be attached to the Handover Certificate

(with Productions agreement).

(SEE TABLE IN SEPARATE EXCEL FILE)

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Review: 4.1

Page 26 of 38

ATTACHEMENT III: TEST RESPONSIBILITIES

(Criteria for hold points and witness points)

Those tests and checks defined as HOLD POINT require inexcusably the presence of the

organization for which they are hold point (Site Engineering, Topography team, Notified Body, or

Production), and which shall sign on the corresponding check sheet.

Those tests and checks defined as WITNESS POINT could be performed with or without the

presence of the organization for which they are witness points (Notified Body, Site Engineering,

Production, etc), but if they do witness the test or check, they shall sign in the corresponding boxes on

the check sheet.

For both the hold points and the witness points the involved organization must be noticed at least

three (3) days before the activity beginning. Also a general schedule for the tests and checks must be

sent and periodically updated.

(SEE TABLE IN SEPARATE EXCEL FILE)

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 27 of 38

FACILITIES HANDOVER

ATTACHMENT IV: FOR FLUSHING NOTICE FORM

From: Repsol DI Construction Manager

To: Production Start-up Manager Project

CC: Production Project Coordinator

Owner

Owner

.

.

FOR FLUSHING NOTICE

Partial

Total

System Number:

Description:

Flushing circuit #

Description

______________

_____________________________________

______________

_____________________________________

______________

_____________________________________

Noticing

Already noticed

Outstanding

We hereby notify that the specified flushing circuits are ready for flushing, and that there are not A or B punches unsolved

or A or B outstanding changes.

Some items from Annex I have not been installed yet (see attached list).

REMARKS:

_________________________________________________________________________________________________

_________________________________________________________________________________________________

You are kindly requested to inform US once the flushing works (including the required reinstallation) have been finished,

by sending back this document signed

Signed:

.

Date:

Signed:

Date:

On behalf of Production:

Flushing finished

Rejected. Find attached a list of necessary modifications.

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 28 of 38

FACILITIES HANDOVER

ATTACHMENT V: HANDOVER NOTICE FORM

From: Repsol DI Construction Manager

To: Production Start-up Manager Project

CC: Production Project Coordinator

Owner

Owner

.

.

SYSTEM HANDOVER NOTICE

Partial

Total

System Number:

Description:

Subsystem Number

Description

______________

_____________________________________

______________

_____________________________________

______________

_____________________________________

______________

_____________________________________

______________

_____________________________________

Noticing

Already

Noticed

Outstanding

We hereby notify that we are going to issue the specified system / subsystem Handover Certificate on _____________.

Punch list and/or change list is attached

The system is delivered without remaining works

REMARKS:

_________________________________________________________________________________________________

_________________________________________________________________________________________________

_________________________________________________________________________________________________

Please, study the system in detail and inform us of any detected anomaly that needs a modification.

Signed:

Date:

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 29 of 38

FACILITIES HANDOVER

ATTACHMENT VI: HANDOVER CERTIFICATE FORM

From: Repsol DI Construction Manager

To: Production Start-up Manager Project

CC: Production Project Coordinator

Owner

Owner

SYSTEM HANDOVER CERTIFICATE

Partial

Total

System Number:

Description:

Subsystem Number

Description

Handing

Over

______________

_____________________________________

______________

_____________________________________

______________

_____________________________________

Already

Handed Over

Outstanding

By means of this document you are kindly requested to accept the indicated system/subsystems, signing and sending

back the present System Handover Certificate.

The system is Handed Over without any punch list or remaining work.

Punch list and/or change list is attached. In our opinion the Hand Over acceptance is not affected by these

punch list and/or changes

REMARKS:

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

__________________________________________________________________________________________________________

If there is no counter notification before ____________________, the Handover will be considered as accepted for all

purposes.

Signed:

Date:

On behalf of Production:

Accepted (as per proposal). The transfer of Safety and Environmental management responsibilities is accepted.

Rejected. A list of necessary changes is attached

Signed:

Date:

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 30 of 38

FACILITIES HANDOVER

ATTACHEMENT VII: CHECK SHEETS INDEX

(Important: See the check sheets details in the separate documents)

Check Sheet

(*)

Description

Speciality

Period for filling

DI-A.01

Punch list

General

N/A

DI-A.02

Changes list

General

N/A

Static equipment

Construction / Pre-commissioning

Static equipment

Commissioning

DI-C.01

DI-C.02

Vessels, reactors, columns, heat exchangers,

air coolers and others check sheet (Precommissioning)

Vessels, reactors, columns, heat exchangers,

air coolers and others check sheet

(Commissioning)

DI-C.03

Static equipment pressure test check sheet

Static equipment

Construction

DI-D.01

Storage tanks check sheet (Precommissioning)

Static equipment

Pre-commissioning

DI-D.02

Storage tanks check sheet (Commissioning)

Static equipment

Commissioning

DI-D.03

Storage spheres check sheet (Precommissioning)

Static equipment

Pre-commissioning

DI-D.04

Storage spheres check sheet

(Commissioning)

Static equipment

Commissioning

DI-F.01

Furnaces, boilers and chimney ducts check

sheet (Pre-commissioning)

Static equipment

Pre-commissioning

DI-F.02

Furnaces, boilers and chimney ducts check

sheet (Commissioning)

Static equipment

Commissioning

DI-I.01

Smoke detection system check sheet

Electricity

Pre-commissioning /

Commissioning

DI-I.02

Fire and Gas check sheet

Instrumentation

Pre-commissioning /

Commissioning

DI-I.03

PLC/SCD/F&G systems check sheet

Instrumentation /

Electricity

Pre-commissioning /

Commissioning

DI-I.04

Verification of installation of the Safety

Instrumented System (SIS) check sheet

Instrumentation

Pre-commissioning

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

FACILITIES HANDOVER

Check Sheet

(*)

Description

Review: 4.1

Page 31 of 38

Speciality

Period for filling

DI-J.01

Instruments calibration check sheet

Instrumentation

Pre-commissioning

DI-J.02

Pressure transmitters and pressure switches

field operation check sheet

Instrumentation

Commissioning

DI-J.03

Single cables inspection check sheet

Instrumentation

Pre-commissioning

DI-J.04

Multicables and juction boxes check sheet

Instrumentation

Pre-commissioning

DI-J.05

Orifice plates and restriction orifices check

sheet (Precom)

Instrumentation

Pre-commissioning

DI-J.06

Orifice plates and restriction orifices check

sheet (Com)

Instrumentation

Commissioning

DI-J.07

Loop test check sheet

Instrumentation

Commissioning

DI-J.08

Control valves and On - off valves check sheet

Instrumentation

Pre-commissioning

DI-J.09

Analyzer system and shelter check sheet

Instrumentation

Pre-commissioning /

Commissioning

DI-J.10

Electronic scales check sheet

Instrumentation

Pre-commissioning /

Commissioning

DI-J.11

Safety valves check sheet

Instrumentation

Pre-commissioning

DI-J.12

Skin points integrity check before pressure

test in furnaces or boilers check sheet

Instrumentation

Pre-commissioning

Dynamic equipment

Pre-commissioning

Dynamic equipment

Commissioning

DI-K.01

DI-K.02

Installation and alignment checking for pumps,

blowers, air-coolers and mixers check sheet

(Pre-commissioning)

Installation and alignment checking for pumps,

blowers, air-coolers and mixers check sheet

(Commissioning)

DI-K.03

Special equipment check sheet

Dynamic equipment

Pre-commissioning /

Commissioning

DI-K.04

Oil mist lubrication system check sheet

Dynamic equipment

Pre-commissioning /

Commissioning

DI-K.05

Turbines and gears check sheet

Dynamic equipment

Pre-commissioning /

Commissioning

DI-K.06

Diesel engines check sheet

Dynamic equipment

Pre-commissioning /

Commissioning

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 32 of 38

FACILITIES HANDOVER

Check Sheet

(*)

Description

Speciality

Period for filling

DI-L.01

Welding map

Static equipment /

piping

Construction

DI-L.02

Pressure test check sheet

Static equipment /

piping

Construction

DI-L.03

Flange torqueing check sheet

Static equipment /

piping

Pre-commissioning

DI-L.05

Pipe cleaning check sheet (flushing, steam/air

blowing, chemical cleaning)

Static equipment /

piping

Commissioning

DI-P.01

Power cables check sheet

Electricity

Construction / Pre-commissioning

DI-P.02

Motor operated valves check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.03

Motors check sheet (Precom))

Electricity

Pre-commissioning

DI-P.04

Motors check sheet (Com)

Electricity

Commissioning

DI-P.05

Lighting check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.06

Grounding system check sheet

Electricity

Pre-commissioning

DI-P.07

Lighting arrester system check sheet

Electricity

Pre-commissioning

DI-P.08

Switchyard check sheet

Electricity

Pre-commissioning

DI-P.09

Power transformers check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.10

Power Center and Hight Voltage Swithgear

check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.11

Motor Control Center check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.12

Switchgears check sheet

Electricity

Pre-commissioning

DI-P.13

Emergency Switchgear and Auxiliary Services

Switchgear check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.14

Relays check sheet

Electricity

Pre-commissioning

Type of document: CONSTRUCTION STANDARD

Scope of application: Engineering Division

ENGINEERING

Issuer: Construction Department

DIVISION

Code: NRM-310

Review: 4.1

Page 33 of 38

FACILITIES HANDOVER

Check Sheet

(*)

Description

Speciality

Period for filling

DI-P.15

Speed variators check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.16

Bus bar check sheet

Electricity

Pre-commissioning

DI-P.17

Uninterruptible Power Supply (UPS) and

Direct Current (DC) rectifiers check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.18

Capacitor banks check sheet

Electricity

Pre-commissioning /

Commissioning

DI-P.19

Emergency diesel generator check sheet

Electricity

Pre-commissioning /

Commissioning

DI-Q.01