Documente Academic

Documente Profesional

Documente Cultură

Analysis of Deep Beams and Shear Walls by Finite Strip Method With C0 Continuous Displacement Functions

Încărcat de

Sam BeeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Analysis of Deep Beams and Shear Walls by Finite Strip Method With C0 Continuous Displacement Functions

Încărcat de

Sam BeeDrepturi de autor:

Formate disponibile

Thin-Walled Structures 32 (1998) 289303

Analysis of deep beams and shear walls by

finite strip method with C 0 continuous

displacement functions

Y.K. Cheung*, F.T.K. Au, D.Y. Zheng

Department of Civil Engineering, The University of Hong Kong, Pokfulam Road, Hong Kong, PR

China

Abstract

This paper presents a new finite strip method for the analysis of deep beams and shear

walls. The essence of the method lies in the adoption of displacement functions possessing

the right amount of continuity at the ends as well as at locations of abrupt changes of thickness.

The concept of periodic extension in Fourier series is utilized to improve the accuracy of the

stresses at the strip ends. The equilibrium conditions at locations of abrupt changes of thickness

are taken into account by the incorporation of piecewise linear correction functions. As these

displacement functions are built up from harmonic functions with appropriate corrections, they

possess both the advantages of fast convergence of harmonic functions as well as appropriate

order of continuity. Numerical results also show that the method is versatile, efficient and

accurate. 1998 Elsevier Science Ltd. All rights reserved.

Keywords: Deep beam; Shear wall; Finite strip method; C 0-continuous function

1. Introduction

In the analysis of plane elasticity problems by the finite strip method, the choice

of longitudinal interpolation functions is of utmost importance. In the semi-analytical

finite strip method [1], the interpolation functions have to satisfy a priori the boundary conditions in the longitudinal direction and they are normally the eigen-functions

of vibration or stability of an Euler beam. In the spline finite strip method [2], C2* Corresponding author.

0263-8231/98/$ - see front matter 1998 Elsevier Science Ltd. All rights reserved.

PII: S 0 2 6 3 - 8 2 3 1 ( 9 8 ) 0 0 0 2 4 - X

290

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

continuous B3-spline functions are chosen instead. However, these methods are not

capable of dealing with problems involving abrupt changes of thickness because of

the excessive continuity inherent in the longitudinal interpolation functions. More

recently, Cheung and Kong [3] developed a new set of displacement functions for

the analysis of two-dimensional elasticity problems. Computed shape functions are

used longitudinally whereas Lagrangian shape functions are adopted in the transverse

direction. In this way, C 0 continuity across all boundaries between adjacent strips

is maintained. A strip with abrupt changes in rigidity is made up of component strips

stitched together at the ends.

This paper presents a new finite strip method for the analysis of deep beams and

shear walls. The use of finite strips with abrupt changes in rigidity is made possible

by displacement functions possessing the right amount of continuity at the ends as

well as at locations of abrupt changes of thickness. The concept of the periodic

extension of Fourier series is extended beyond the normal half-range expansions to

ensure that the first derivatives and hence the stresses at the end points of the halfrange are well defined. In addition, piecewise linear augmenting functions are superimposed on the basic harmonic functions making the resulting interpolation function

C 0-continuous at locations of abrupt changes of thickness, so that the equilibrium

conditions there are satisfied. The application of similar approaches to beams with

abrupt changes of cross-sections has been rather successful [4].

The chosen interpolation functions therefore possess both the advantages of fast

convergence of harmonic functions and the appropriate order of continuity at the

locations of abrupt changes of sectional properties. The method allows the extensive

use of matrix notations and programming is rather straightforward. The present

method can cope with strips with abrupt changes of rigidity as well as rectangular

domains with re-entrant corners. A few numerical examples are given to demonstrate

the versatility, efficiency and accuracy of the method.

2. Basic harmonic functions

An arbitrary function f(y) continuous over the interval [0,l] may be written in

terms of the basic trigonometric functions as

f (y)

a0

ancos

n1

ny

ny

bnsin

l

l

(1)

in which periodic extension is implicit [5]. This form of periodic extension is superior

to the normal form of half-range expansions involving either odd or even components, as the function and its derivatives are well defined at the end points of the

interval. In the analysis of cantilever deep beams and shear walls, it is often more

convenient to adopt an equivalent set of displacement functions Ym(y),m

1,2, with zero values at the base, i.e.

Y2n 1(y) 1 cos

ny

ny

sin

l

l

n 1,2,,r/2

(2)

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

Y2n(y) 1 cos

ny

ny

sin

l

l

n 1,2,,r/2

291

(3)

This set of functions is a complete set to describe an arbitrary function f(y) in

which f(y)y=0 0. It is important to note that, unlike vibration functions obtained

from cantilever beams, the slope of the resulting displacement function may be nonzero at the starting point. This is essential to structures in which shear effect is significant.

3. C 0 modified harmonic function set

A shear wall can be sub-divided into finite strips extending from the base to the

top. Fig. 1 shows a typical strip of width b comprising s segments of different thicknesses t t1,t2,,ts with step change of thickness at locations y y2,y3,,ys. The

displacements u and v in x and y directions, respectively, at an arbitrary point (x,y)

within the strip can be written in series form as

u(x,y)

Ymu(y)M(x)um

(4)

Ymv(y)M(x)vm

(5)

m1

r

v(x,y)

m1

where Ymu(y) and Ymv(y) are the mth terms of the series part of the displacement

function, M(x) is a row vector containing the shape functions, and um and vm are

vectors containing the corresponding displacement parameters associated with the

nodal lines. They are further elaborated below in Eqs. (6)(10).

Ymu(y) Ym(y)

(6)

Ymv(y) Ym(y) Ym(y)

(7)

Fig. 1. A cantilever strip comprising s segments of thicknesses t1,t2,, ts and with step changes in

thickness at locations y2,y3,,ys.

292

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

M(x) 1

x x

b b

(8)

um [u1 u2]Tm

(9)

vm [v1 v2]Tm

(10)

The functions Ymu(y) for displacements in the x direction can be simply taken as

the functions Ym(y) defined in Eqs. (2) and (3). However, the functions Ymv(y) used

to describe displacements in y direction should be capable of satisfying the equilibrium conditions at step change of thickness, and hence piecewise linear augmenting

functions Ym(y) are incorporated to satisfy C 0-continuity conditions at locations y

y2,y3,,ys. In a plane stress problem, the equilibrium condition at a step change of

thickness can be written as

Y m (t)y yj 0

tj

Y m(y)y yj 0 (j 2,3,,s)

tj 1

(11)

The properties of the augmenting function Ym(y) can be obtained from Eqs. (8)

and (11), i.e.

Y m (y)y yj 0

tj

tj 1

Y m(y)y yj 0

tj

tj 1

1 Y m(y)y yj

(j

(12)

2,3,,s)

If we set f j Ym(y)y yj and hk yk 1 yk, then the augmenting function

Ym(y) can be written as:

s1

Ym(y)

fj lj (y)

(13)

j1

where

y yj 1

yj yj 1

l (y) y y

y 0y

j1

j1

yj 1 y yj (omitted if j 1)

yj y yj 1 (omitted if j s 1)

(14)

y [yj 1,yj 1]

Introducing the parameters j and j defined as follows

tj

tj 1

(j 2,3,,s)

(15)

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

j (j 1)Y m(y)y yj

293

(j 2,3,,s)

(16)

Eq. (12) can be written as

hj fj 1 + [hj + hj 1j ]fj hj 1j fj + 1 = hj 1hj j

(j = 2,3,,s)

(17)

The augmenting function is also prescribed to be zero at the two ends, i.e.

f 1 fs 1 0

(18)

Eqs. (17) and (18) represent (s 1) conditions whereby the augmenting function

Ym(y) can be uniquely determined.

4. Finite strip formulation

The displacement functions given in Eqs. (4) and (5) can be expressed in matrix

form as

U(x,y)

Nm(x,y)m

(19)

m1

where U(x,y) is the vector containing displacements at the point (x,y), Nm(x,y) is the

mth the shape function matrix and m is the displacement vector associated with it.

Their explicit forms are given below:

U(x,y)

u(x,y)

(20)

v(x,y)

m [u1v1u2v2]Tm

Nm(x,y)

x

Y (y)

b mu

0

(21)

0

x

Y (y)

b mu

x

1 Ymv(y)

b

x

Y (y)

b mv

(22)

Following the normal formulation procedures, the strain vector (x,y) can be written in terms of the strain matrices Bm(x,y) as

(x,y) DiffU(x,y) Diff

m1

Nm(x,y)m

Bm(x,y)m

(23)

m1

where the explicit forms of the differential operator Diff and the strain matrix

Bm(x,y) are

294

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

Diff 0

(24)

1

Y

b mu

Bm(x,y)

x

Y

b mu

1

Y

b mu

x

Y

b mv

1

Y

b mv

x

Y

b mv

(25)

x

1

Y

Y

b mu b mv

The equilibrium equation can be written as

Kmnn Fm m 1,2,,r

(26)

n1

where Kmn is a stiffness sub-matrix and Fm is a load sub-vector. The stiffness submatrix Kmn is obtained from integrating over the volume V of the strip, i.e.

Kmn BTmDBndV

(27)

The elasticity matrix D for an orthotropic material used in plane stress problems is

k1 k2 0

D k2 k3 0

(28)

0 0 k4

where the elements are expressed in terms of the moduli of elasticity Ex and Ey, the

shear modulus Gxy and the Poissons ratio x and y

k1

xEy

Ex

Ey

, k2

, k3

, k Gxy

1 xy

1 xy

1 xy 4

(2932)

Substituting Eqs. (25) and (28) into Eq. (27), the explicit form of the stiffness

sub-matrix Kmn can be worked out as

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

3k1I1 + k4b2I2

3b

Kmn =

k2I5 + k4I6

2

6k1I1 + k4b2I2

6b

k2I5 k4I6

2

295

k 2 I3 k 4 I4

2

6k1I1 + k4b2I2

6b

k3b2I7 + 3k4I8

3b

k2I5 k4I6

2

k3b2I7 6k4I8

6b

k2I3 k4I4

2

3k1I1 + k4b2I2

3b

k2I3 k4I4

2

k3b2I7 6k4I8

6b

k2I5 + k4I6

2

k2I3 + k4I4

2

k3b2I7 + 3k4I8

3b

(33)

where

(3437)

(3841)

I1 = tYmuYnudy, I2 = tY muY nudy, I3 = tYmuY nvdy, I4 = tY muYnvdy,

0

l

0

l

0

l

0

l

I5 = tY mvYnudy, I6 = tYmvY nudy, I7 = tY mvY nvdy, I8 = tYmvYnvdy,

0

5. Numerical examples

A number of numerical examples are given to demonstrate the versatility of the

present method. Results obtained by the present method are compared with solutions

published before if available or solutions obtained by finite element method [6]. As

some of the examples published before were presented using imperial units, these

units are omitted altogether for simplicity.

5.1. Example 1: rectangular shear wall supported on two wide columns

Fig. 2 shows a rectangular shear wall supported on two wide columns of the same

thickness. The material is isotropic with Youngs modulus E of 471 000 and Poissons ratio of 0.375. A horizontal point load of 20 is applied to its top left corner.

This structure can be considered as a shear wall with a large rectangular opening at

the base. This problem has been studied by various researchers [3,7]. The shear wall

was discretized into 16 strips of equal width and solved by the present method using

16 terms. The first category of strips are the four strips going through the two wide

columns, and they run from the base to the top. The other category of 12 strips are

those above the opening. The boundary conditions at the three edges adjacent to the

opening are natural boundary conditions. As this formulation is of the Rayleigh

Ritz type, the natural boundary conditions are therefore automatically dealt with.

However, in the formulation of the stiffness matrices for the 12 strips above the

296

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

Fig. 2.

Shear wall supported on two wide columns.

opening, integration is only carried out over the solid height above the opening. The

problem was also solved by the finite element method using 2528 QM6 incompatible

elements [6]. The vertical stresses over the horizontal cross-section at y 4 are

shown in Fig. 3 and compared with the finite element solution [6] as well as those

from finite strips with computed shape functions [3]. Sharp variation of stresses is

observed as the cross-section is close to the wall-frame interfaces. Very good agreement is observed between the present results and the reference results.

5.2. Example 2: deep cantilever beam with step change in thickness

Fig. 4 shows a deep cantilever beam made of isotropic material with step change

in thickness. The Youngs modulus E is 1.0 and Poissons ratio is 0.15. The

beam supports a downward unit point load at the top right corner. Two schemes of

discretization were tried. The deep beam was respectively discretized into four and

10 strips of equal widths. The number of terms used was varied to study the convergence of the present method. The deflections at two points of the tip are summarized

in Table 1 and compared with the reference solution obtained using 1800 QM6

incompatible elements [6]. Very good agreement is observed. Incidentally, the results

obtained from the coarse mesh comprising four strips are only 1.6% less than the

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

297

Fig. 3. Shear wall supported on two wide columns, distribution of vertical stresses (y) over the horizontal cross section at y = 4.

Fig. 4.

Cantilever deep beam with step change in thickness.

reference solution. The stresses computed using 10 strips and 10 terms are presented

in Figs. 5 and 6. In particular, Fig. 5 shows the bending stresses at the vertical crosssections just adjacent to the step change in thickness. The bending stresses along

the centre line of the lowest strip (i.e. at x 9.5) are shown in Fig. 6. Both figures

show very good agreement between the present results and the finite element

results [6].

298

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

Table 1

Deep cantilever beam with step change in thickness, deflections at two points of the tip

Scheme used in the present

method

4 strips, 12 terms

4 strips, 14 terms

4 strips, 16 terms

4 strips, 18 terms

4 strips, 20 terms

10 strips, 12 terms

10 strips, 14 terms

10 strips, 16 terms

10 strips, 18 terms

10 strips, 20 terms

FEM [6]

Deflection at x = 5, y = 20

212.88

212.94

212.97

212.99

213.01

215.54

215.61

215.63

215.65

215.68

216.31

Deflection at x = 10, y = 20

208.86

208.91

208.94

208.96

208.97

211.58

211.67

211.68

211.71

211.74

212.36

Fig. 5. Cantilever deep beam with step change in thickness, bending stresses (y) adjacent to step change

in thickness.

5.3. Example 3: deep cantilever beam with step change in depth

Fig. 7 shows a deep cantilever beam of unit thickness but with step change in

depth. The material is isotropic with a Youngs modulus E of 1.0 and Poissons ratio

of 0.15. The beam is subjected to a unit point load at the top of the cantilever

tip. It is discretized into 10 strips of equal width. Twenty terms were used in the

present analysis. The beam was also analysed by the finite element method [6] using

3200 QM6 incompatible elements. Figs. 8 and 9 show the bending stresses at the

root (y 0) and the section at y 9.5. The present method is capable of predicting

stress concentration around the re-entrant corner, and good agreement is observed

between the present results and the reference solution.

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

Fig. 6.

299

Deep cantilever beam with step change in thickness, bending stresses (y) along the line x = 9.5.

Fig. 7.

Cantilever deep beam with step change in depth.

5.4. Example 4: asymmetrical coupled shear wall with step change in thickness

Fig. 10(a) shows an asymmetrical coupled shear wall with step change in thickness

previously studied by Chan and Cheung [8] by higher order finite elements. The

wall is subjected to a unit horizontal uniformly distributed load at the left side. The

wall is assumed to be made of isotropic material having Youngs modulus E of

463 000 and Poissons ratio of 0.0. In the analysis of coupled shear walls, the

spandrel beams and openings between the coupled shear walls are very often represented by an orthotropic continuum with equivalent elastic properties. Referring

to Fig. 10(b), the equivalent Youngs moduli of the continuum in the x and y direc-

300

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

Fig. 8. Cantilever deep beam with step change in depth, bending stresses (y) at the base (y = 0).

Fig. 9.

Cantilever deep beam with step change in depth, bending stresses (y) at y = 9.5.

tions, as well as the equivalent shear rigidity of the continuum [8] are given, respectively, by

Ex

d

d

E

E, Ey 0, G .

2

h

h c

2.4

d

where c c d is the effective span length of the spandrel beam. The adjustment

to the span length of the spandrel beam is to allow for the fact that the rigid-end

condition could not possibly occur immediately at the junction of the wall and beam.

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

301

Fig. 10. (a) Asymmetrical coupled shear wall of step change in thickness; (b) Geometric dimensions of

the openings and spandrel beams.

The equivalent properties of the continuum are therefore calculated as Ex 115 750,

Ey 0 and G 2251.9. In the analysis by the present method, the shear wall was

first discretized into 14 strips of equal widths. In addition, a very coarse mesh comprising only three strips (one for the equivalent continuum and two for the walls)

was tried. The number of terms used in the analysis ranges from 12 to 20. The

problem was also solved using 1512 QM6 incompatible finite elements [6]. Table

2 shows the convergence of the deflection at the top right corner of the shear wall

Table 2

Asymmetrical coupled shear wall with step change in thickness, deflection at top right corner

Scheme used in the present method

3 strips, 12 terms

3 strips, 14 terms

3 strips, 16 terms

3 strips, 18 terms

3 strips, 20 terms

14 strips, 12 terms

14 strips, 14 terms

14 strips, 16 terms

14 strips, 18 terms

14 strips, 20 terms

FEM [6]

Deflection at x = 7, y = 21

9.6485

9.6489

9.6492

9.6494

9.6495

9.6887

9.6909

9.6922

9.6928

9.6936

9.6974

103

103

103

103

103

103

103

103

103

103

103

302

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

Fig. 11. Coupled shear wall with step change in thickness, horizontal deflections along the right edge

(x = 7).

as compared with the finite element results [6]. The horizontal deflection of the right

side of the wall is shown in Fig. 11. The vertical stresses at the horizontal cross

section at y 3.375 are plotted in Fig. 12. The vertical stresses along the centre

line of the rightmost strip (i.e. at x 6.75) are shown in Fig. 13. It is observed that

results from the present method agree very well with those obtained by the finite

element method [6] and the higher order finite elements [8]. The accuracy of the

deflections obtained from the very coarse mesh is also striking.

Fig. 12. Coupled shear wall with step change in thickness, bending stress (y) at horizontal section at

y = 3.375.

Y.K. Cheung et al. / Thin-Walled Structures 32 (1998) 289303

303

Fig. 13. Coupled shear wall with step change in thickness, bending stresses (y) along vertical line at

x = 6.75.

6. Conclusions

A new finite strip method has been developed for the analysis of deep beams and

shear walls. The use of piecewise linear augmenting functions in conjunction with

the basic harmonic functions results in displacement functions with the appropriate

order of continuity at the locations of abrupt changes of sectional properties. It therefore allows the use of continuous finite strips with step changes in thickness. The

present method can also cope with rectangular domains with re-entrant corners. A

few numerical examples have been given to demonstrate the versatility, efficiency

and accuracy of the method.

References

[1] Cheung YK. Finite strip method in structural analysis. Oxford: Pergamon Press, 1977.

[2] Fan SC. Spline finite strip in structural analysis. PhD thesis, The University of Hong Kong, Hong

Kong, 1982.

[3] Cheung YK, Kong J. An accurate finite strip for analyzing deep beams and shear walls. Commun

Numer Methods Engng 1995;11:64353.

[4] Au FTK, Zheng DY, Cheung YK. Vibration and stability of non-uniform beams with abrupt changes

of cross-section by using C1 modified beam vibration functions. Applied Mathematical Modeling,

in press.

[5] Liu JY, Zheng DY, Mei ZJ. Practical integral transforms in engineering. Huazhong University of

Science and Technology Press, 1995.

[6] Cosmos User Manual. Structural research and analysis cooperation. Santa Monica, CA 90404,

USA, 1991.

[7] Cheung YK, Swaddiwudhipong S. Analysis of frame shear wall structures using finite strip elements.

Proc Instn Civ Engrs 1978;65:51735.

[8] Chan HC, Cheung YK. Analysis of shear walls using higher order finite elements. Building Environ

1979;14:21724.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- C-2 Limit State Design of Beams For Flexure Chap2Document58 paginiC-2 Limit State Design of Beams For Flexure Chap2Boopathi YoganathanÎncă nu există evaluări

- Materials of Construction For Pressure VesselsDocument54 paginiMaterials of Construction For Pressure Vesselsjishnunelliparambil83% (6)

- Miyazaki & Fu & Huang - Thin Film Shape Memory AlloysDocument487 paginiMiyazaki & Fu & Huang - Thin Film Shape Memory Alloyseduardo0% (1)

- Hudson - Engineering Rock Mechanics 2Document528 paginiHudson - Engineering Rock Mechanics 2Anthony Raskolnikov Fierro QuispeÎncă nu există evaluări

- NEW SYLLABUS in Strength of MaterialsDocument14 paginiNEW SYLLABUS in Strength of MaterialsJohn Henry TampoyÎncă nu există evaluări

- Post and Core Materials and Bonding 2Document21 paginiPost and Core Materials and Bonding 2jassÎncă nu există evaluări

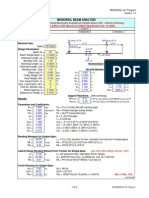

- MonorailDocument3 paginiMonorailHelard AlvarezÎncă nu există evaluări

- C 651Document4 paginiC 651Asep TheaÎncă nu există evaluări

- Electroactive Polymers As Artificial Muscles - Reality and ChallengesDocument10 paginiElectroactive Polymers As Artificial Muscles - Reality and Challengesq12wertyÎncă nu există evaluări

- Analysis of Single Row Deep Groove Ball BearingDocument5 paginiAnalysis of Single Row Deep Groove Ball BearingKIRUBHAKARANÎncă nu există evaluări

- The Design of Cooling Towers in Extremely Severe Earthquake ConditionsDocument8 paginiThe Design of Cooling Towers in Extremely Severe Earthquake ConditionsSanjeev KulkarniÎncă nu există evaluări

- Basics of LPIDocument21 paginiBasics of LPISuresh RathodÎncă nu există evaluări

- 07 Thermal StressDocument13 pagini07 Thermal StressSundaravathanan ChellappanÎncă nu există evaluări

- Jis G3112 - Sd295aDocument1 paginăJis G3112 - Sd295aWin Than100% (1)

- ตัวอย่างการคำนวณ การออกแบบพื้นDocument13 paginiตัวอย่างการคำนวณ การออกแบบพื้นchakfarmer2-1Încă nu există evaluări

- BucklingDocument11 paginiBucklingwsÎncă nu există evaluări

- Chapter 3 MFG IIDocument145 paginiChapter 3 MFG IITiliksew Wudie Assabe100% (1)

- Elastic Plastic NotesDocument89 paginiElastic Plastic NotesFlorin BucÎncă nu există evaluări

- MENG410 Syllabus Mechanics of Materials II: Course DescriptionDocument4 paginiMENG410 Syllabus Mechanics of Materials II: Course DescriptionHussein MokbelÎncă nu există evaluări

- Blasius PDFDocument2 paginiBlasius PDFsanketdange2007Încă nu există evaluări

- Repair and Strengthening Methods of Flat Slabs For Punching - António M. P. Ramos, Válter J.G. Lúcio, Paul ReganDocument9 paginiRepair and Strengthening Methods of Flat Slabs For Punching - António M. P. Ramos, Válter J.G. Lúcio, Paul ReganVálter LúcioÎncă nu există evaluări

- Reinforced Concrete PDFDocument394 paginiReinforced Concrete PDFRhonoelle Reevenujlah100% (1)

- PMMADocument14 paginiPMMAjuliborgonovoÎncă nu există evaluări

- Aircraft Materials EASA Model TestDocument4 paginiAircraft Materials EASA Model TestSeanRiniFernandoÎncă nu există evaluări

- Triaxial Test IntroductionDocument4 paginiTriaxial Test IntroductionAshadi Hamdan100% (2)

- Kayla LoveladyDocument8 paginiKayla LoveladyGanesh LohakareÎncă nu există evaluări

- Strain Tensor - Mohrs CircleDocument7 paginiStrain Tensor - Mohrs CircleSWAPNILÎncă nu există evaluări

- Rubber ElasticityDocument39 paginiRubber ElasticityMAURICIO NICARAGUA MENDEZÎncă nu există evaluări

- Concrete Design 1 - R2Document14 paginiConcrete Design 1 - R2Waleed KokabÎncă nu există evaluări

- Plexiglas MCDocument2 paginiPlexiglas MCMarco Ngawang KeelsenÎncă nu există evaluări