Documente Academic

Documente Profesional

Documente Cultură

5

Încărcat de

suraj dhulannavarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5

Încărcat de

suraj dhulannavarDrepturi de autor:

Formate disponibile

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X

PP 20-23

www.iosrjournals.org

Modified Type Intelligent Digital Fuel Indicator System

Nitin Jade1, Pranjal Shrimali2, Asvin Patel3, Sagar Gupta4

1, 2, 3

B.E. scholar, Mechanical, S.D.I.T.S. Khandwa/ R.G.P.V. Bhopal, INDIA

Associate Professor, Mechanical, S.D.I.T.S. Khandwa/ R.G.P.V. Bhopal, INDIA

ABSTRACT: There are many sensor based techniques available in the market to measure the liquid level and

gives you a close idea of quantity of the liquid, however can provide you an exact approximation of quantity as

in cars by fuel meters by which we can get an idea of whether tank is full, half full or empty etc. The liquid level

detector and optimizer play an important role in tanks to indicate the level of liquid of a particular density. In

this paperwe have proposed a technique to measure the amount of liquid available in tank also give the

knowledge about their chemical composition as well as purity level of fuel & it is the first device which can give

the accurate knowledge about of how much the vehicle can run. This device digitally displays the level of liquid

inside the tank, fuel composition & running capability of vehicle by using load sensors. The measurements are

taken so the accuracy level is of 95% - 98%. Thus it is an efficient device made by keeping in mind the

petroleum thefts at the various petrol pumps at the time of filling of tanks.

Keywords: A fuel level detector, C.P.U. (Central Processing Unit), E.C.U. (Electronic Control Unit), indicator,

modulator, sensing.

I. INTRODUCTION

A fuel level detector (fuel gauge) is a device inside of a car or other vehicle that measures the amount

of fuel still in the vehicle. This type of system can be used to measure the amount of gasoline or some other type

of liquid. It will typically consist of a sensing or sending unit that measures the amount of fuel actually left and a

gauge or indicator that relays this information outside the fuel container. A fuel gauge can be designed in a

number of different ways and many gauges have several flaws that can make the readings less than accurate.

The two parts of a fuel gauge are the sensing or sending unit and the indicator or gauge.

A sensing unit is the part of a fuel gauge found within or connected to the actual fuel storage container

on a vehicle. In a car these days, for example, the sensing unit will consist of a float inside the fuel tank, which

is connected to a metal rod that runs to a small electrical circuit. The float raises or lowers depending on the

amount of gasoline in the fuel tank.

But in our case there are three basic parts of fuel gauge

Sensing

Computing ( E.C.U. + C.P.U. + modulator)

Indicator

A sensing unit is the part of a fuel gauge found within or connected to the actual fuel storage container

on a vehicle. In a car these days, for example, the sensing unit will consist of a float inside the fuel tank, which

is connected to a metal rod that runs a small electrical circuit. The float raises or lowers depending on the

amount of gasoline in the fuel tank, wheel speed, braking torque, load (vehicle itself + occupants + luggage) &

acceleration ratio etc. We are introducing one more element in the branch of fuel gauges is the COMPUTER

which is a programmed based micro processing unit. It is consist of E.C.U., C.P.U. & modulator.

E.C.U. receives information from each individual sensor, the signal is sent to the C.P.U. which collects

data & computes it then send to the modulator which module the signals and display it to the indicator. It works

as a computer for fuel gauge.

International Conference on Advances in Engineering & Technology 2014 (ICAET-2014) 20 | Page

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X

PP 20-23

www.iosrjournals.org

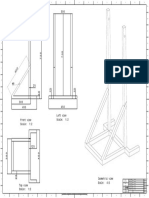

Fig. 1 modified type intelligent digital fuel indicator from reference no. [3]

Background

Some Major Factors That Have The Greatest Impact On Fuel Consumption AreQuick acceleration, Heavy braking, Speeds, Weather, Cargo or cargo racks, Towing a trailer or carrying

excessive weight, Electrical accessories, Hilly or mountainous terrain, Four wheel drive, Temperature.

There are so many other factors also which are responsible in reduction of fuel economy but due to the

very small range it does not much more affect the fuel economy but still reduces it. They are called

immeasurable factors. It reduces fuel economy as 3% of all other factors. Those factors areDisplacement, Gearing, Aerodynamics, Induction, Intake and Exhaust restrictions, Rolling resistance,

Mechanical Resistance, Altitude.

In These Gauge System There Are So Many Sensors Are Used To Measure That Factors Introducing One By

OneAcceleration sensors

Acceleration sensors measure relative acceleration as a state variable for linear and rotary drives and analyze the

dynamic behavior of a drive system.

For rotative applications.

High sensitivity.

Wide range.

Brake caliper LVDT sensor

High brake disc wear is required to monitor by race engineers by using a miniature linear position sensor in the

brake caliper. High performance contactless LT series LVDT sensor is specified in this application. Caliper

piston movement is measured by LVTD sensor. At hard braking circuits disc wear is calculated by using this

information.

High temperature operation.

Very compact designs.

Multiple mounting options.

Long operational life.

Raychem signal cabling.

Optional in-line electronics.

Speed sensors

For control and measurement systems this sensor provides speed and direction information. Between sensor face

and a target, a target induced magnetic field is detected by rotational speed sensors. The operating temperature

of the sensors is about 200oC.

The temperature performance of the inductive (ISS) sensor is about 200 oC. The output voltage of the sensor is

proportional to the target speed and air gap. Crank and cam speed are the applications.

Displacement sensors

Digital dial gauges

To save space and enable flexible configuration, slim body design.

Eliminates to readjust whenever power is turned off.

In order to solve the problem of over tightening the stem portion a nut installed type is available.

Sensors for air conditioning

Evaporator sensors

International Conference on Advances in Engineering & Technology 2014 (ICAET-2014) 21 | Page

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X

PP 20-23

www.iosrjournals.org

In air conditioning systems the most important functions of temperature sensors is controlling the temperature of

the evaporator. Thus it gives knowledge about fuel consumption. Some part of fuel is also consumes by A.C.

and affect the mileage.

Digital temperature sensors

High measurement accuracy accompanied by low power consumption and user friendly system integration

capability is provided by digital temperature sensors.

High accuracy.

16/24 bit resolution

Low power

Density sensors

A unique fluid density sensor has developed by ISSYS. A small, hollow silicon micro tube is uses by this

sensing approach. At a given frequency this small tube vibrates. The vibration frequency will change as the

density or concentration of the liquid in the tube changes.

By using the vibrational frequency of the micro tube the density of the fluid can be measured. The density or

API output can be used by petrochemicals and biofuels to indicate the type of fuel, its purity and to blend fuels

together.

II. METHODOLOGY

In sense of the mileage of any vehicle is affected by some factors which we have consider in and also

take most economical, useful, intelligent and quick responding sensors to calculate the effect of the all the

factors directly as well as indirectly too.

All the sensors are situated on their particular separate place to perform their operation. Sensors are

very efficient quick responding units. The sensors collect all the data in running vehicle and then the collected

information moves up to the E.C.U.

E.C.U. is controlling unit which make command on all the individual sensors give them power to run

and forward the collected data to the C.P.U. The E.C.U. is electronic control unit. Then the data moves up to the

central processing unit i.e. C.P.U. at this unit the data finally computed into the numeric form by the mean of

programming. All the data from the sensors is converted into the one form of mileage means HOW MUCH

VEHICLE CAN RUN? All the information is in coded form which moves towards the modulator.

Modulator is the unit to modulate the information and finally the data in display on the digital fuel indicator in a

numeric form.

To maintain the accuracy level the C.P.U. has designed. By providing the clearance in data

computation there is 3% to 4% of clearance for sensors errors and immeasurable factors so the information as

given by system as near as actual. Thus the modified type intelligent fuel indicator system operates.

FIGURES AND TABLES

Figure

Fig.2 fuel gauge methodology from reference no. [13]

Table

International Conference on Advances in Engineering & Technology 2014 (ICAET-2014) 22 | Page

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X

PP 20-23

www.iosrjournals.org

Fuel Gauge Methodology

SENSOR NAME

SITUATION

Fuel tank

SPECIFICATION

ISSYS

Flywheel

FISCHER

Brake caliper sensor

WORKING ON

Fuel

quality

measurement

Acceleration

fluctuation

measurement

Braking torque

Brake caliper

LVDT

Speed sensors

Wheel speed

Propeller shaft

ISS

Displacement sensors

Cargo or cargo racks

& terrain

Suspensions

DDG

Air-conditioning

inputs

Weather

& engine

temperature

Compressor

ES

Engine case & vehicle

body

DTS

Density sensors

Acceleration sensors

Air-conditioning sensors

Temperature sensors

CONCLUSION

The modified type intelligent fuel indicator is very advance type indicating system. The main

advantages of the system are that it can give the accurate value of remaining fuel as well as the vehicle running

capacity in K.M. The accuracy level is up to 95% to 98% because of advance type C.P.U. is preferred. It also

gives the knowledge about the fuel quality due to the density sensors which is highly advance sensor for fuel

composition detection. The operation time taken is very less in micro seconds. All the equipments have long

life, durable & quality material.

Due to the best quality assurance it is costly and only favorable for luxury vehicle. It is not suitable for low &

medium class vehicle. Thus it increases the cost of the luxury vehicle and in case of sensor failure of any one of

them can stop working system fully, these are the main drawback of system.

It is applicable for all the vehicle which can afford, all the fuel conserving machines, all type of fluid

indication. In present time there are so many fuel gauges are available which is digital but they can only give the

remaining fuel identification in percentage, engine speed and wheel speed but in our system we can get direct

value of remaining fuel with the running capacity of the vehicle, fuel quality and also ultra sharp L.E.D.

display.

Thus the modified type intelligent fuel indicator system is best in the field and will be most advance gauge

indicator in future.

REFERENCES

[1] http://www.wisegeek.com/what-is-a-fuel-gauge.htm.

[2]Ti-Ho Wanga, Ming-Chih Lua and Chen-Chien Hsu, 2009. Liquid-level measurement using a single digital camera, Elsevier,

Measurement, 42(4): 604-610.

[3] http://www.proton.com.sg/img/preve_if_01.jpg.

[4] Stephen A. Dyer, 2001. Survey of Instrumentaion and Measurement, Wieley Interscience.

[5] Atkinson, S F and Halvorsen, R., A new hedonic technique for estimating attribute demand an application to the demand for automobile

fuel efficiency, The Review of Economics and Statistics, 66 (1984), 417-26.

[6]http://www.activesensors.com/products/speed-sensor.

[7] Betta, G., A. Pietrosanto and A. Scaglione, 1996. A digital liquid level transducer based on opticalfiber, IEEE Trans. Instrum. Meas.,

45: 551-555.

[8] http://www.classictiger.com/mustang/OilPressureGauge/OilPressureGauge.htm.

[9] http://en.wikipedia.org/wiki/Atmel_AT89_series.

[10] Wilcox, James A., Automobile Fuel Efficiency: Measurement and Explanation, Economic Inquiry 22 (1984) 375-385.

[11] http://www.naturalgas.org/environment/naturalgas.asp.

[12] Renshaw, Edward, Fuel Efficiency Standards and the Motor Vehicle Explosion, Challenge (May-June 1990) 56-58.

[13]http://www.sensorsmag.com/files/sensor/nodes/2002/1088/fig1.gif.

[14]Executive Summary, Light-Duty Automotive Technology and Fuel Economy trends: 1975 through 2008, United States Environmental

Protection Agency (2008).

International Conference on Advances in Engineering & Technology 2014 (ICAET-2014) 23 | Page

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Wind Driven Mobile Charging of Automobile BatteryDocument7 paginiWind Driven Mobile Charging of Automobile Batterysuraj dhulannavarÎncă nu există evaluări

- Visvesvaraya Technological University BelgaumDocument2 paginiVisvesvaraya Technological University Belgaumsuraj dhulannavarÎncă nu există evaluări

- Left View Scale: 1:2: 1:1 XXX A0Document1 paginăLeft View Scale: 1:2: 1:1 XXX A0suraj dhulannavarÎncă nu există evaluări

- 1:1 XXX A1: Toshavi PCDocument1 pagină1:1 XXX A1: Toshavi PCsuraj dhulannavarÎncă nu există evaluări

- FrameDocument1 paginăFramesuraj dhulannavarÎncă nu există evaluări

- M.H.Saboo Siddik PolytechnicDocument5 paginiM.H.Saboo Siddik Polytechnicsuraj dhulannavarÎncă nu există evaluări

- D e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N eDocument13 paginiD e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N esuraj dhulannavarÎncă nu există evaluări

- 1:1 XXX A1: Toshavi 5/3/2016Document1 pagină1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarÎncă nu există evaluări

- 1:1 XXX A4: Designed By: DateDocument1 pagină1:1 XXX A4: Designed By: Datesuraj dhulannavarÎncă nu există evaluări

- FrameDocument1 paginăFramesuraj dhulannavarÎncă nu există evaluări

- WWW Mechengg Net 2015 09 Design and Fabrication of InjectionDocument17 paginiWWW Mechengg Net 2015 09 Design and Fabrication of Injectionsuraj dhulannavarÎncă nu există evaluări

- 1:1 XXX A4: Toshavi 4/8/2016Document1 pagină1:1 XXX A4: Toshavi 4/8/2016suraj dhulannavarÎncă nu există evaluări

- 1:1 XXX A1: Designed By: DateDocument1 pagină1:1 XXX A1: Designed By: Datesuraj dhulannavarÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Mustang 2005Document40 paginiMustang 2005Ramon SanchezÎncă nu există evaluări

- Fuel LeveDocument4 paginiFuel LeveAram MorenoÎncă nu există evaluări

- SM 38.cDocument228 paginiSM 38.cKovács EndreÎncă nu există evaluări

- Smart Fuel Gauge With Intelligent Headlamp Beam Control Using Raspberry PiDocument5 paginiSmart Fuel Gauge With Intelligent Headlamp Beam Control Using Raspberry Pikssrao13Încă nu există evaluări

- Harley Diagnostic Touble CodesDocument40 paginiHarley Diagnostic Touble CodesLeandro Lima100% (7)

- Milege Level ReportDocument5 paginiMilege Level ReportIyappanÎncă nu există evaluări

- BCM Inspection Mazda CX.5Document10 paginiBCM Inspection Mazda CX.5Nur Haeru NasrulÎncă nu există evaluări

- Checking Fuel Gauge Sender - G-: Hand-Held Multimeter - V.A.G 1526CDocument4 paginiChecking Fuel Gauge Sender - G-: Hand-Held Multimeter - V.A.G 1526CSpiekis SPÎncă nu există evaluări

- Jeep GaugesDocument1 paginăJeep GaugesOmar MondragónÎncă nu există evaluări

- Instrument Panel Analog - Nissan Sentra 1993Document8 paginiInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaÎncă nu există evaluări

- 1991 Ford Festiva ManualDocument454 pagini1991 Ford Festiva Manualkianoy75% (8)

- Fiat Barchetta: Electrical SystemDocument12 paginiFiat Barchetta: Electrical SystemHallex OliveiraÎncă nu există evaluări

- 90-25 Instrument Cluster Location Diagram From M.Y. 2000 PDFDocument28 pagini90-25 Instrument Cluster Location Diagram From M.Y. 2000 PDFmefisto06cÎncă nu există evaluări

- Autoflug Fuel en 2016 RZ WebDocument2 paginiAutoflug Fuel en 2016 RZ WebanuradhaÎncă nu există evaluări

- Focus2 Műszercsoport TesztDocument12 paginiFocus2 Műszercsoport TesztDávid MolnárÎncă nu există evaluări

- INstrument Cluster Test PDFDocument122 paginiINstrument Cluster Test PDFryanhartery100% (1)

- Aircraft Instruments DataDocument61 paginiAircraft Instruments DataGabriel DediuÎncă nu există evaluări

- Evoque 2011-13 - Fuel Tank and Lines - TD4 2.2L DieselDocument47 paginiEvoque 2011-13 - Fuel Tank and Lines - TD4 2.2L DieselAliÎncă nu există evaluări

- EXJ - 14A99 Jeep XJ Service ManualDocument38 paginiEXJ - 14A99 Jeep XJ Service ManualhottubdocÎncă nu există evaluări

- All Vdo Sensors CatalogueDocument96 paginiAll Vdo Sensors CatalogueAdeel0% (1)

- Vehicle Electrical GaugesDocument13 paginiVehicle Electrical GaugesSimon Mwangi kabauÎncă nu există evaluări

- 00an 14Document68 pagini00an 14Drod HertzerÎncă nu există evaluări

- Flow Meter and Arduino Based Fuel Gauge For Automotive VehiclesDocument8 paginiFlow Meter and Arduino Based Fuel Gauge For Automotive Vehicleshusam haiderÎncă nu există evaluări

- 022 - 01 - 03 - Fuel GaugeDocument2 pagini022 - 01 - 03 - Fuel GaugeJaucafoÎncă nu există evaluări

- Section 4: Airframe Fuel SystemDocument20 paginiSection 4: Airframe Fuel SystemrobbertmdÎncă nu există evaluări

- Electrical DiagnosticsDocument480 paginiElectrical DiagnosticsEd PerryÎncă nu există evaluări

- Driver Information System PDFDocument60 paginiDriver Information System PDFAriel Mercocha100% (1)

- Infiniti FX DI Manual 2006Document134 paginiInfiniti FX DI Manual 2006Marius DeacÎncă nu există evaluări

- Smart Fuel Level Indication SystemDocument5 paginiSmart Fuel Level Indication SystemGRD JournalsÎncă nu există evaluări

- AUDI A4 B5 - Quattro Fuel System Servicing 1.8T & 2.8Document55 paginiAUDI A4 B5 - Quattro Fuel System Servicing 1.8T & 2.8AdrianLungoci100% (2)