Documente Academic

Documente Profesional

Documente Cultură

Adhesive Anchor Examples

Încărcat de

Josue LewandowskiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Adhesive Anchor Examples

Încărcat de

Josue LewandowskiDrepturi de autor:

Formate disponibile

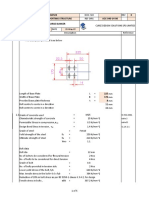

Adhesive Bonded Anchor Design Examples

Design Procedure Example 1

See Figure 1

Calculation

Step 1 - Determine required rod diameter

Determine the required diameter of the

threaded rod by setting the factored

tension load equal to the design steel

strength.

Nu = Ns

The effective area for the threaded rod

Ns = s Ae fy

may be taken as 75% of the gross area.

2

As with reinforcing bars, the minimum

Where:

s = 0.9 ; Ae = 0.75 d 4 ;

specified yield strength of the rod is used to

and f y = 100 ksi

determine the required diameter.

18 = 0.9 d 2 4 100

d = 0.583 in. therefore, use 5/8

Substituting and solving for d:

threaded rod.

Step 2 - Determine required embedment length to ensure steel failure

c e gn No

Where: c = 0.85 ;

Nc =

Basic equation for embedment length

calculation. Since there are no edge or

spacing concerns, e and gn may be

taken as unity.

e , gn

= 1.0 (no edge/spacing

concern); and N o = T ' d h e

N c req'd = 1.25 A e f y A e f u

For ductile behavior it is necessary to

embed the anchor sufficiently to develop

125% of the yield strength or 100% of the

ultimate strength, whichever is less.

A e = 0.75 0.625 2 4

Determine the effective area for a 5/8"

threaded rod:

Determine the required tension force,

Nc req'd , to ensure ductile behavior.

(for embedment)

A e = 0.23 in 2

N c req'd = 1.25 A e f y A e f u

Nc req'd =1.25 0.23 100 0.23 125

N c req'd = 28.75 kips = 28.75 kips

therefore, use N c req'd = 28.75kips

28.75 = 0.85 (1.0) (1.0) (1.08)

Substituting and solving for he :

he = 16 in

1

(.625)he

Adhesive Bonded Anchor Design Examples

Figure 1

Adhesive Anchors Design Example 1

Adhesive Bonded Anchor Design Examples

Design Procedure Example 2

See Figure 2

Calculation

Step 1 - Determine required rod diameter

Determine the required diameter of the

threaded rod by setting the factored

tension load equal to the design steel

strength.

Nu = Ns

The effective area for the threaded rod

Ns = s Ae fy

may be taken as 75% of the gross area.

2

As with reinforcing bars, the minimum

Where:

s = 0.9 ; Ae = 0.75 d 4 ;

specified yield strength of the rod is used to

and f y = 100 ksi

determine the required diameter.

18 = 0.9 0.75 d 2 4 100

d = 0.583 in. therefore, use 5/8

Substituting and solving for d:

threaded rod.

Step 2 - Determine required embedment length to ensure steel failure

c e gn No

Where: c = 0.85 ;

Basic equation for embedment length

calculation. Since there are no spacing

concerns, gn may be taken as unity,

and, since the edge distance (4 in) is less

Nc =

gn

(for embedment)

= 1.0 (no spacing concern); and

than 8d (5 in), the edge effect, e , will

need to be evaluated.

No = T ' d he

For ductile behavior it is necessary to

embed the anchor sufficiently to develop

125% of the yield strength or 100% of the

ultimate strength, whichever is less.

N c req'd = 1.25 A e f y A e f u

A e = 0.75 0.625 2 4

Determine the effective area for a 5/8"

threaded rod:

Determine the required tension force,

Nc req'd , to ensure ductile behavior.

A e = 0.23 in 2

N c req'd = 1.25 A e f y A e f u

Nc req'd =1.25 0.23 100 0.23 125

N c req'd = 28.75 kips = 28.75 kips

therefore, use N c req'd = 28.75kips

Adhesive Bonded Anchor Design Examples

Design Procedure Example 2

See Figure 2

Calculation

e

e

e

Determine edge effect factor, e .

Note: C cr = 8d

28.75 = 0.85 (1.0) (0.94) (1.08)

Substituting and solving for he :

Figure 2

= 0.70 + 0.30 c 8d

= 0.70 + 0.30 4 8 0.625

= 0.94

he = 16.98 in

Adhesive Anchors Design Example 2

(.625) he

Adhesive Bonded Anchor Design Examples

Design Procedure Example 3

See Figure 3

Calculation

Step 1 - Determine required rod diameter

Determine the required diameter of the

threaded rod by setting the factored

tension load equal to the design steel

strength.

Nu = Ns

The effective area for the threaded rod

Ns = s Ae fy

may be taken as 75% of the gross area.

Where:

As with reinforcing bars, the minimum

2

s = 0.9 ; Ae = 2 0.75 d 4 ;

specified yield strength of the rod is used to

determine the required diameter.

and f y = 100 ksi

18 = 0.9 2 0.75 d 2 4 100

d = 0.412 in. Although a 1/2 threaded

Substituting and solving for d:

rod is OK, use 5/8 threaded rod to

minimize embedment length.

N s = 0.9 2 0.75 d 2 4 100

N s = 41.4 kips > 18 kips

Design steel strength

therefore: OK

Step 2 - Determine required embedment length

c e gn No

Where: c = 0.85 ;

Nc =

Basic equation for embedment length

calculation. Since there are edge or

spacing concerns, e and gn will need

to be determined.

(for embedment)

e and gn are calculated below; and

No = T ' d he

e = 0.70 + 0.30 c 8d

e = 0.70 + 0.30 4 8 0.625

e = 0.94

gn = An Ano

gn = 4 + 8d 8 + 2 8d 16d 2

Determine edge effect factor, e .

Determine group effect factor, gn .

gn = 4 + 8 0.625 8+2 8 0.625 16 0.625 2

gn

= 1.62

Adhesive Bonded Anchor Design Examples

Design Procedure Example 3

See Figure 3

Calculation

18 = 0.85 (1.62) (0.94) (1.08)

Substituting and solving for he :

(.625) he

he = 6.55 in (say 7)

therefore: OK

N c = 0.85 1.62 094 1.08

0.625 7

Design adhesive bond strength.

N c = 19.21 18 therefore: OK

Step 3 - Final Design Strength

Strength as controlled by steel.

N s = 41.4 kips 18 kips therefore: OK

Strength as controlled by adhesive bond.

N c = 19.21 kips 18 kips therefore: OK

Final Design.

Two 5/8" anchors embedded 7 in.

Adhesive Bonded Anchor Design Examples

Figure 3

Adhesive Anchors Design Example 3

S-ar putea să vă placă și

- Unistrut CalcDocument12 paginiUnistrut Calcjacs127Încă nu există evaluări

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Orion Whats NewDocument15 paginiOrion Whats NewAnthony Quintua PatinoÎncă nu există evaluări

- British Comparison EC3 and EC4 381324Document55 paginiBritish Comparison EC3 and EC4 381324borisbelevÎncă nu există evaluări

- ConSteel 14 User ManualDocument359 paginiConSteel 14 User ManualsamiÎncă nu există evaluări

- Verification Examples AxisvmDocument138 paginiVerification Examples AxisvmCarlos GonçalvesÎncă nu există evaluări

- Loads For BuildingsDocument9 paginiLoads For Buildingsburntbread90Încă nu există evaluări

- Ec9 Ex56 Compression OrthotropicDocument6 paginiEc9 Ex56 Compression OrthotropicimotalpÎncă nu există evaluări

- AD 261 - Elastic Modulus of AnglesDocument1 paginăAD 261 - Elastic Modulus of Anglessymon ellimacÎncă nu există evaluări

- Extracts From Ec3 For Students 2012Document6 paginiExtracts From Ec3 For Students 2012Alexandru MarincuÎncă nu există evaluări

- Cold Steel Designers ManualDocument73 paginiCold Steel Designers Manualearthboy2uÎncă nu există evaluări

- Tied Foundations-Portal FrameDocument3 paginiTied Foundations-Portal FrameJaime Manalili LandinginÎncă nu există evaluări

- Unistrut Engineering DataDocument18 paginiUnistrut Engineering DatazaxaxazÎncă nu există evaluări

- Concrete For StartersDocument38 paginiConcrete For StartersUmpahPah75Încă nu există evaluări

- CE429 - U08 - Day1 - Segmented - ShearwallsDocument41 paginiCE429 - U08 - Day1 - Segmented - Shearwallsnick gomezÎncă nu există evaluări

- Gce Al 2022 MPDocument10 paginiGce Al 2022 MPJamunanantha PranavanÎncă nu există evaluări

- Design and Analysis of Seismic Resistant Apartment BuildingDocument12 paginiDesign and Analysis of Seismic Resistant Apartment BuildingMunzuara AktherÎncă nu există evaluări

- ICTAD Measurement GuideDocument80 paginiICTAD Measurement GuideSachira PalliyaguruÎncă nu există evaluări

- Boq FormatDocument79 paginiBoq FormatacroxmassÎncă nu există evaluări

- Ec9 Ex44 Bending Trapez Class 4Document7 paginiEc9 Ex44 Bending Trapez Class 4imotalpÎncă nu există evaluări

- Topic 2 - Analysis of Rect Sections (Ec2)Document6 paginiTopic 2 - Analysis of Rect Sections (Ec2)RCdesign2012Încă nu există evaluări

- Steel Frame Design Manual: Italian NTC 2008Document99 paginiSteel Frame Design Manual: Italian NTC 2008Angel VargasÎncă nu există evaluări

- Seismic Design of Composite Metal Deck and Concrete Filled Diaphragms A Discussion Paper Cowie Hicks Macrae Clifton FussellDocument11 paginiSeismic Design of Composite Metal Deck and Concrete Filled Diaphragms A Discussion Paper Cowie Hicks Macrae Clifton Fussellmongkol_1001Încă nu există evaluări

- S-Frame Theory ManualDocument81 paginiS-Frame Theory ManualriefsaldyÎncă nu există evaluări

- Handbook To Bc1 2023Document59 paginiHandbook To Bc1 2023cklconÎncă nu există evaluări

- Design BaseplateDocument34 paginiDesign BaseplatefarhanÎncă nu există evaluări

- Lecture 2 Materials, Cover and Some Definitions CG 28 Sep 2016Document32 paginiLecture 2 Materials, Cover and Some Definitions CG 28 Sep 2016je311Încă nu există evaluări

- EN 1997-1 Eurocode 7: Section 3 - Geotechnical Data Section 6 - Spread FoundationsDocument26 paginiEN 1997-1 Eurocode 7: Section 3 - Geotechnical Data Section 6 - Spread FoundationsNeven Ahmed HassanÎncă nu există evaluări

- Spandrel Flexural Design: Technical NoteDocument11 paginiSpandrel Flexural Design: Technical Notetomxxx34Încă nu există evaluări

- Load Combinations For ULS To EurocodeDocument7 paginiLoad Combinations For ULS To EurocodeMilan StojanovicÎncă nu există evaluări

- Composite Columns Design GuideDocument66 paginiComposite Columns Design Guideabdelrahman emadÎncă nu există evaluări

- CMM Hybrid Columns: Brochure 38-01 EDocument4 paginiCMM Hybrid Columns: Brochure 38-01 EGurpreet Singh BhatiaÎncă nu există evaluări

- Software Verification: EXAMPLE Eurocode 2-04 PT-SL-001Document7 paginiSoftware Verification: EXAMPLE Eurocode 2-04 PT-SL-001võ hoàng thái100% (1)

- PRORAČUN STUBIŠTADocument29 paginiPRORAČUN STUBIŠTAfk0205Încă nu există evaluări

- 0302 Wind Loads On The Building With Flat RoofDocument2 pagini0302 Wind Loads On The Building With Flat RoofFrank George Crema CremaÎncă nu există evaluări

- Tower 6: Uputstvo Za Rad Sa ProgramomDocument209 paginiTower 6: Uputstvo Za Rad Sa ProgramomperocÎncă nu există evaluări

- Gy Nju T TPDH: Khztu KD NDHB TPDHF Fs A/L2015/SFT/PhysicsDocument2 paginiGy Nju T TPDH: Khztu KD NDHB TPDHF Fs A/L2015/SFT/PhysicsSinthuNathanÎncă nu există evaluări

- Design Guide BC05 - 2019Document89 paginiDesign Guide BC05 - 2019rameshkaaÎncă nu există evaluări

- 12 Panhard Place 2 - Structural CalculationsDocument39 pagini12 Panhard Place 2 - Structural CalculationsmarkomarkomarkomarkoÎncă nu există evaluări

- Pile Design & Analysis of Single Piles. ExamplesDocument61 paginiPile Design & Analysis of Single Piles. ExamplesMohammed HussainÎncă nu există evaluări

- SEISMIC ANALYSIS OF RECTANGULAR TANKS - COMPARISON OF MALHOTRA AND HOUSNER MODELSDocument4 paginiSEISMIC ANALYSIS OF RECTANGULAR TANKS - COMPARISON OF MALHOTRA AND HOUSNER MODELSilijarskÎncă nu există evaluări

- Structural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorDocument174 paginiStructural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorZuhal ZaeemÎncă nu există evaluări

- Design and Behavior of Gusset Plate Connections PDFDocument12 paginiDesign and Behavior of Gusset Plate Connections PDFAnkit GuptaÎncă nu există evaluări

- Vulcraft Deck CATDocument116 paginiVulcraft Deck CATerleenhat8056Încă nu există evaluări

- Basic Data:: Calculation of Gust Effect FactorDocument1 paginăBasic Data:: Calculation of Gust Effect FactorYaser ShabasyÎncă nu există evaluări

- 2018 - 0510 AAD Gebze - IMO - TBDY2018 GDTDocument46 pagini2018 - 0510 AAD Gebze - IMO - TBDY2018 GDTdrsteelÎncă nu există evaluări

- EN1999 5 HoglundDocument79 paginiEN1999 5 HoglundPeter DudasÎncă nu există evaluări

- Calculation Sheet DetailsDocument3 paginiCalculation Sheet DetailsShamik GhoshÎncă nu există evaluări

- Lecture 1 Basics CG Apr 2013 SOLUTIONSDocument8 paginiLecture 1 Basics CG Apr 2013 SOLUTIONShuo lenghakÎncă nu există evaluări

- Adhesive Anchor Design Examples ExplainedDocument7 paginiAdhesive Anchor Design Examples Explainedahm2011Încă nu există evaluări

- Structural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesDocument122 paginiStructural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesPascasio PascasioÎncă nu există evaluări

- Chapter J Design of ConnectionsDocument16 paginiChapter J Design of Connectionsghosh73Încă nu există evaluări

- Tutorial 2 - Axially Loaded Members-TensionDocument27 paginiTutorial 2 - Axially Loaded Members-TensionChan Keng ChunÎncă nu există evaluări

- 1030 - Embedded Plate Design - 4 - S7.00Document9 pagini1030 - Embedded Plate Design - 4 - S7.00rajedmaglinte100% (2)

- RCD Chapter 7Document40 paginiRCD Chapter 7jereck loquisoÎncă nu există evaluări

- SMCH 12Document42 paginiSMCH 12royÎncă nu există evaluări

- Dme Question BankDocument4 paginiDme Question BankRavi Patil100% (1)

- Tut 2 CH 7Document4 paginiTut 2 CH 7SpidyÎncă nu există evaluări

- 77-9 Design of CranesDocument10 pagini77-9 Design of Cranesrip111176Încă nu există evaluări

- Lattice Girder Design for Roof StructureDocument12 paginiLattice Girder Design for Roof StructureMock Khang Hi100% (1)

- LRFD Design Example Nº1. Prestressed Prescast Concrete Beam Bridge Design (MATLAB)Document347 paginiLRFD Design Example Nº1. Prestressed Prescast Concrete Beam Bridge Design (MATLAB)rapaigÎncă nu există evaluări

- Bracind of Steel Beams in Bridges PDFDocument96 paginiBracind of Steel Beams in Bridges PDFAndré Luiz NogueiraÎncă nu există evaluări

- Guide to Cross-Frame Diaphragms in Steel BridgesDocument16 paginiGuide to Cross-Frame Diaphragms in Steel BridgesTrung LeÎncă nu există evaluări

- Section14 PDFDocument16 paginiSection14 PDFBALRAJÎncă nu există evaluări

- Adhesive Anchor Design Examples ExplainedDocument7 paginiAdhesive Anchor Design Examples Explainedahm2011Încă nu există evaluări

- Flat Slab ExampleDocument103 paginiFlat Slab ExampleShishir Kumar Nayak100% (3)

- Bearing Pad Design ExampleDocument16 paginiBearing Pad Design ExampleAhirul Yahya100% (1)

- MURODocument5 paginiMUROJosue LewandowskiÎncă nu există evaluări

- Analysis of Long Span Suspension Bridges Using Series MethodDocument12 paginiAnalysis of Long Span Suspension Bridges Using Series MethodJosue LewandowskiÎncă nu există evaluări

- Simplified Numerical Analysis of Suspension Bridges: Diego Cobo Del Arco and Angel C. Aparicio, Technical University ofDocument11 paginiSimplified Numerical Analysis of Suspension Bridges: Diego Cobo Del Arco and Angel C. Aparicio, Technical University ofJosue LewandowskiÎncă nu există evaluări

- 5966-Article Text-13618-1-10-20181008Document9 pagini5966-Article Text-13618-1-10-20181008BenjaminÎncă nu există evaluări

- Simplified Engineering Method of Suspension Bridges With Rigid Cables Under Action of Symmetrical and Asymmetrical LoadsDocument10 paginiSimplified Engineering Method of Suspension Bridges With Rigid Cables Under Action of Symmetrical and Asymmetrical LoadsJosue LewandowskiÎncă nu există evaluări

- VSL Strand Post Tensioning Systems PDFDocument41 paginiVSL Strand Post Tensioning Systems PDFJonathan GallegosÎncă nu există evaluări

- Structural Model and AnalysisDocument54 paginiStructural Model and AnalysisYoshua YangÎncă nu există evaluări

- 751.9 LFD Seismic PDFDocument157 pagini751.9 LFD Seismic PDFAri PranantaÎncă nu există evaluări

- Vlasov Torsion Theory CT5141 Chap7Document12 paginiVlasov Torsion Theory CT5141 Chap7Anonymous 1rLNlqUÎncă nu există evaluări

- CIE 525 HW 3 - Mkumar2Document13 paginiCIE 525 HW 3 - Mkumar2xxazninvasionxx2697Încă nu există evaluări

- Bridge Deck Analysis Through The Use of Grillage ModelsDocument7 paginiBridge Deck Analysis Through The Use of Grillage ModelslucasgambiÎncă nu există evaluări

- Researchpaper Comparative Study of Grillage Method and Finite Element Method of RCC Bridge DeckDocument10 paginiResearchpaper Comparative Study of Grillage Method and Finite Element Method of RCC Bridge DeckyudhishkarthickÎncă nu există evaluări

- Worked Example 3 Crib WallDocument13 paginiWorked Example 3 Crib WallJosue LewandowskiÎncă nu există evaluări

- (Asce) em 1943-7889 0000203Document12 pagini(Asce) em 1943-7889 0000203Josue LewandowskiÎncă nu există evaluări

- ASCEevaluacion de PuentesDocument8 paginiASCEevaluacion de PuentesJosue LewandowskiÎncă nu există evaluări

- BM 3.15 Seismic Design PDFDocument138 paginiBM 3.15 Seismic Design PDFmumarbsc7244Încă nu există evaluări

- Grillage Analogy C.S.surana R.agrawal PDFDocument272 paginiGrillage Analogy C.S.surana R.agrawal PDFJosue LewandowskiÎncă nu există evaluări

- 2000 - Recent Research Advances in Cold-Formed Steel StructuresDocument22 pagini2000 - Recent Research Advances in Cold-Formed Steel StructuresJosue Lewandowski100% (1)

- Analysis Notes Sap Curve For CrackDocument19 paginiAnalysis Notes Sap Curve For CrackDemçe FlorjanÎncă nu există evaluări

- 2-14-1392951839-20. Applied-Human Resource Management A Challenging Scenario-M.ravi Babu ForDocument9 pagini2-14-1392951839-20. Applied-Human Resource Management A Challenging Scenario-M.ravi Babu ForEkky CecilÎncă nu există evaluări

- 1994 - Second-Order Generalised Beam TheoryDocument21 pagini1994 - Second-Order Generalised Beam TheoryJosue LewandowskiÎncă nu există evaluări

- Distorsion PDFDocument7 paginiDistorsion PDFJosue LewandowskiÎncă nu există evaluări

- Chapter 3. Failure of MaterialsDocument20 paginiChapter 3. Failure of MaterialsVishal ShuklaÎncă nu există evaluări

- What Is An EarthquakeDocument2 paginiWhat Is An EarthquakeFahad RadiamodaÎncă nu există evaluări

- Rotary kiln stressDocument6 paginiRotary kiln stressRachid Kheir100% (1)

- P&B m1Document5 paginiP&B m1Andrizal ChaidarÎncă nu există evaluări

- Ansys ManualDocument31 paginiAnsys Manualpriyadharshini natarajanÎncă nu există evaluări

- Slip-Line Field TheoryDocument21 paginiSlip-Line Field TheoryDiahAyuSafitriÎncă nu există evaluări

- Mechanics of Materials Lab Fall 2018Document52 paginiMechanics of Materials Lab Fall 2018Hammad RazaÎncă nu există evaluări

- Challenging Foundations for Tall BuildingsDocument27 paginiChallenging Foundations for Tall BuildingsRENZZ IRVIN DELA TORREÎncă nu există evaluări

- Design Method of Equal Strength Rim Based on Stress and Fatigue AnalysisDocument11 paginiDesign Method of Equal Strength Rim Based on Stress and Fatigue AnalysisVashishth KushwahaÎncă nu există evaluări

- Connection Surge Bin Supp Beam1Document5 paginiConnection Surge Bin Supp Beam1Venkatesh HebbarÎncă nu există evaluări

- Lamina Stiffness and Compliance MatricesDocument43 paginiLamina Stiffness and Compliance MatricesDemonic ZealotÎncă nu există evaluări

- VecTor4 Product SheetDocument1 paginăVecTor4 Product SheetCristian Camilo Londoño PiedrahítaÎncă nu există evaluări

- CH 04Document135 paginiCH 04RODRIGO JAVIER BRIZUELA PADILLAÎncă nu există evaluări

- Connection 2Document19 paginiConnection 2Der3'am Al m7armehÎncă nu există evaluări

- Legaspi, Giamaica - PrestreesdDocument3 paginiLegaspi, Giamaica - PrestreesdGiamaica LegaspiÎncă nu există evaluări

- TOPIC 10 Foundation PDFDocument24 paginiTOPIC 10 Foundation PDFnasyahrahÎncă nu există evaluări

- Moment Redistribution Effects in BeamsDocument13 paginiMoment Redistribution Effects in BeamstavialimÎncă nu există evaluări

- Pile Under Cyclic Axial Loading ISA Hypoplastic ModelDocument11 paginiPile Under Cyclic Axial Loading ISA Hypoplastic ModelSahil Wani ce20d750Încă nu există evaluări

- A Sliding-Consolidation Model For Flow Slides - J. N. HUTCHINSONDocument12 paginiA Sliding-Consolidation Model For Flow Slides - J. N. HUTCHINSONMichaell Steven Chaparro LopezÎncă nu există evaluări

- MD AssignmentsDocument2 paginiMD Assignmentsvikramsingh1011Încă nu există evaluări

- Steel Structures Tension Members 2Document24 paginiSteel Structures Tension Members 2Nafi AykutÎncă nu există evaluări

- Take Home Quiz 3Document5 paginiTake Home Quiz 3Penuel G. BantogÎncă nu există evaluări

- Soil Modulus and Undrained Cohesion of Clayey Soils From Stress-Strain ModelsDocument10 paginiSoil Modulus and Undrained Cohesion of Clayey Soils From Stress-Strain ModelsTerry CheungÎncă nu există evaluări

- Design of BeamDocument204 paginiDesign of BeamPete BasÎncă nu există evaluări

- Influence of Non-Glide Stresses On Plastic Flow: From Atomistic To Continuum ModelingDocument7 paginiInfluence of Non-Glide Stresses On Plastic Flow: From Atomistic To Continuum ModelingGURUDAS KARÎncă nu există evaluări

- Euler Column Theory PDFDocument2 paginiEuler Column Theory PDFDeeÎncă nu există evaluări

- Waves in Three-Dimensional Solid: A ElasticDocument22 paginiWaves in Three-Dimensional Solid: A ElasticaguiiahimÎncă nu există evaluări

- Taller de Esfuerzo en VigasDocument2 paginiTaller de Esfuerzo en VigasJhonatan VargasÎncă nu există evaluări