Documente Academic

Documente Profesional

Documente Cultură

IWIS Form AF-01 Rev 2 - Final - 18 April 2013 PDF

Încărcat de

Laohan LiuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

IWIS Form AF-01 Rev 2 - Final - 18 April 2013 PDF

Încărcat de

Laohan LiuDrepturi de autor:

Formate disponibile

~ WTIA OzWeld School of Welding Technology (SWT) ~

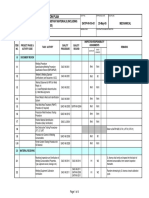

AF-01: SELF-ASSESSMENT CHECKLIST FOR CLAIMING EXEMPTION FROM TRAINING FOR MODULE SWT16A

FOR INTERNATIONAL WELDING INSPECTOR STANDARD LEVEL (IWI S) QUALIFICATION

This form can be used to guide students in self-assessing their qualifications and experience to exempt themselves from Module SWT-16A of the IWI S training

programme. See also Factsheet IWI S -01 & IWI S -02. The following notes apply:

Note 1: Candidates may decide after self-assessment, on the basis of prior learning and/or experience, whether to take the Welding Technology Module (SWT 16A) first or proceed

directly to the Welding Inspection Module (SWT 16B).

Note 2: A pass in the WTS examination is required before results of the Welding Inspection Module examinations can be released to the candidate.

Note 3: If the candidate fails the WTS examination, having exercised an option to proceed directly to that examination, he/she must take the omitted training module SWT-16A before

re-sitting the examination.

Note 4: The number of training hours are indicated against each topic of the SWT-16A syllabus, in the table given below to assist in the self-assessment process.

Name: ________________________________________________

Course Venue: ________________

Course Date: ___________________

Please submit this form with your enrolment.

Subject

No

1

1.1

1.2

1.4

1.5

1.6

1.7

1.8

1.9

1.13

1.16

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

Course Subjects

Welding Processes and Equipment

General Introduction to Welding Technology

Oxy-gas Welding and Related Processes

The Arc

Power Sources for Arc Welding

Introduction to Gas-shielded Arc Welding

Tungsten-inert Gas Welding

MIG/MAG & Flux Cored Welding

Manual Metal Arc Welding

Cutting and Other Edge Preparation Processes

Brazing and Soldering

Materials and Their Behaviour During Welding

Manufacture and Designation of Steels

Testing Materials and the Weld Joint

Structure and Properties of Pure Metals

Alloys and Phase Diagrams

Iron-Carbon Alloys

Heat Treatments of Base Materials and Welded Joints

Structure of the Welded Joints

Plain Carbon and Carbon-Manganese Steels

IWI S

(hrs)

13

1

1

1

1

1

1

2

2

2

1

41

1

7

1

2

2

2

2

2

Supporting evidence to meet each syllabus item

eg. courses attended, work experience, qualifications

G:\Users\School Welding Technology\Fact Sheets\Fact Sheets - Working files\IWIS-01\2013\IWIS Form AF-01 rev 2 - Final - 18 April 2013.doc

Page 1 of 2

~ WTIA OzWeld School of Welding Technology (SWT) ~

Subject

No

2.9

2.10

2.11

2.13

2.15

2.16

2.18

2.19

2.20

2.22

2.23

2.25

2.26

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

4

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.9

4.10

Course Subjects

Fine-grained Steels

Thermo-mechanically Treated Steels (TMCP-Steels)

Cracking Phenomena in Steels

Low Alloy Steels for very low temperature applications

Introduction to Corrosion

High-alloyed (Stainless Steel)

Protective Layers

High Alloy Creep Resistant and Heat Resistant Steels

Cast Irons and Steels

Nickel and Nickel Alloys

Aluminium and Aluminium Alloys

Joining Dissimilar Materials

Metallographic examinations

Construction and Design

Fundamentals of the Strength of Materials

Basics of Weld Design

Design Principles of Welded Structures

Joint Design

Introduction to Fracture Mechanics

Design of Welded Structures Under Different Types of Loading

Design of Welded Structures with Predominantly Static Loading

Behaviour of Welded Structures Under Dynamic Loading

Design of Dynamically Loaded Welded Structures

Design of Thermo-dynamically Loaded Welded Structures

Design of Structures in Aluminium and its Alloys

Reinforcing-steel Welded Joints

Fabrication Applications Engineering

Introduction to Quality Assurance in Welded Constructions

Quality Control during Manufacture

Welding Stresses and Distortion

Plant Facilities, Welding Jigs and Fixtures

Health and Safety

Measurement, control and recording in welding

Non-destructive Testing

Repair Welding

Fitness-for-Purpose

Course Totals

IWI S

(hrs)

2

1

2

1

2

2

1

2

1

1

3

2

2

17

2

1

1

2

1

2

1

2

1

1

1

1

23

5

6

2

1

2

2

1

2

2

94

Supporting evidence to meet each syllabus item

e.g. courses attended, work experience, qualifications

G:\Users\School Welding Technology\Fact Sheets\Fact Sheets - Working files\IWIS-01\2013\IWIS Form AF-01 rev 2 - Final - 18 April 2013.doc

Page 2 of 2

S-ar putea să vă placă și

- Southern Polytechnic State University MET 1321 - Machining and WeldingDocument4 paginiSouthern Polytechnic State University MET 1321 - Machining and WeldingIbraheem KhressÎncă nu există evaluări

- IAB-041-02 (IW Inspection Personnel)Document43 paginiIAB-041-02 (IW Inspection Personnel)Teddy TP100% (1)

- Pipefitting - ICE Level 2 - 01 07 14 PDFDocument5 paginiPipefitting - ICE Level 2 - 01 07 14 PDFCarlos JesseÎncă nu există evaluări

- Rigging - ICE Level 2 - 01 07 14Document5 paginiRigging - ICE Level 2 - 01 07 14Agustua RXÎncă nu există evaluări

- The Indian Institute of WeldingDocument11 paginiThe Indian Institute of WeldingNnamdi Celestine NnamdiÎncă nu există evaluări

- CP2 Part 3 Plate Welding Practical 2nd Edition July 2015Document20 paginiCP2 Part 3 Plate Welding Practical 2nd Edition July 2015sathishvpÎncă nu există evaluări

- You Will LearnDocument7 paginiYou Will Learnhareesh13hÎncă nu există evaluări

- IwipDocument3 paginiIwipkishoreardentÎncă nu există evaluări

- AB 094WeldingExaminerAndWeldingExaminerInTrainingSyllabusVersion2 PDFDocument8 paginiAB 094WeldingExaminerAndWeldingExaminerInTrainingSyllabusVersion2 PDFAnonymous RW2RxeÎncă nu există evaluări

- Wtia Training Program 2014Document6 paginiWtia Training Program 2014Syed Mahmud Habibur RahmanÎncă nu există evaluări

- 1143 EWF IIW Diploma Overview - August 2013Document2 pagini1143 EWF IIW Diploma Overview - August 2013Sean ฌอนÎncă nu există evaluări

- Saep 321Document28 paginiSaep 321brecht1980Încă nu există evaluări

- Welding Technology: WELD 115 QC10Document52 paginiWelding Technology: WELD 115 QC10usto2014Încă nu există evaluări

- IIW/EWF Diploma in Welding QualificationDocument8 paginiIIW/EWF Diploma in Welding Qualificationreezman100% (1)

- GFDS, Mnbfdlkyfdsdfgbn NgregnDocument13 paginiGFDS, Mnbfdlkyfdsdfgbn NgregnAnonymous 7YilBuIuQm100% (1)

- 1143 Ewf Iiw Diploma August 2013Document4 pagini1143 Ewf Iiw Diploma August 2013Marcus BarberÎncă nu există evaluări

- Development of An Undergraduate Welding Laboratory For Research and EducationDocument7 paginiDevelopment of An Undergraduate Welding Laboratory For Research and Educationahmed jemalÎncă nu există evaluări

- Training Course Adtec Shah AlamDocument26 paginiTraining Course Adtec Shah AlammynurulÎncă nu există evaluări

- TRAINING PLAN FOR EACH WORK PACKAGEDocument10 paginiTRAINING PLAN FOR EACH WORK PACKAGEDalia PrinceÎncă nu există evaluări

- API 653 Tank Inspection RDocument203 paginiAPI 653 Tank Inspection Ralgore100% (4)

- IAB 252r8-07Document24 paginiIAB 252r8-07Jayanta82Încă nu există evaluări

- FEE2015 Fundamentals of Engineering ExaminationDocument40 paginiFEE2015 Fundamentals of Engineering ExaminationFu AunÎncă nu există evaluări

- 0101e - Guide For Applicant CosDocument14 pagini0101e - Guide For Applicant Cos99demonÎncă nu există evaluări

- Sandeep Kumar CVDocument3 paginiSandeep Kumar CVWeld Bro SandeepÎncă nu există evaluări

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Document4 pagini1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnÎncă nu există evaluări

- International Welding Qualification GuideDocument28 paginiInternational Welding Qualification GuideJamesÎncă nu există evaluări

- SMAW Welding GuideDocument3 paginiSMAW Welding GuideOdlnayer Allebram100% (2)

- Ab-094 Welding Examiner SyllabusDocument8 paginiAb-094 Welding Examiner SyllabusRavindra LeleÎncă nu există evaluări

- CBLM Smaw NciiDocument44 paginiCBLM Smaw NciiJacaskills Jstac50% (2)

- Headquarters Office Personnel BranchDocument21 paginiHeadquarters Office Personnel Branchaathavan1991Încă nu există evaluări

- Fabrication Technology Course GuideDocument11 paginiFabrication Technology Course Guidehiren mandaliaÎncă nu există evaluări

- Welding Inspector May 2021Document8 paginiWelding Inspector May 2021SUNIL BABURAO GAVADEÎncă nu există evaluări

- Rigging - ICE Level 3 - 01 07 14Document5 paginiRigging - ICE Level 3 - 01 07 14Dak KaizÎncă nu există evaluări

- Time Duration Each ActivityDocument10 paginiTime Duration Each ActivityKhairel RiezzalÎncă nu există evaluări

- Edited Metal IcfipDocument2 paginiEdited Metal Icfipapi-200253170Încă nu există evaluări

- API 510 Pressure Vessel Inspector CertificationDocument6 paginiAPI 510 Pressure Vessel Inspector CertificationvkumaranÎncă nu există evaluări

- Api 510, 2015Document5 paginiApi 510, 2015Mohmed AllamÎncă nu există evaluări

- 05-Welder Certification PDFDocument11 pagini05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- Tuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & MetallurgyDocument5 paginiTuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & Metallurgyzulfadli izaraeeÎncă nu există evaluări

- 112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Document33 pagini112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Carlos Nombela PalaciosÎncă nu există evaluări

- 0196E - Exam Request Form PDFDocument4 pagini0196E - Exam Request Form PDFAnonymous hRUdbQOmcÎncă nu există evaluări

- TECHNICAL EDUCATION AND VOCATIONAL TRAINING COUNCIL'S MECHANICAL ENGINEERING CURRICULUMDocument22 paginiTECHNICAL EDUCATION AND VOCATIONAL TRAINING COUNCIL'S MECHANICAL ENGINEERING CURRICULUMTabish SamarÎncă nu există evaluări

- Eks Motor Management LevelDocument3 paginiEks Motor Management LevelRatish VaingankarÎncă nu există evaluări

- GWS 1 05 Procedure R3Document12 paginiGWS 1 05 Procedure R3bub1ll4Încă nu există evaluări

- Engineering Workshop Practice PDFDocument8 paginiEngineering Workshop Practice PDFGeorge Camacho0% (1)

- API 510 Training CourseDocument320 paginiAPI 510 Training Coursehiram89100% (2)

- Hauaond JaijanDocument4 paginiHauaond JaijanAashay MohareÎncă nu există evaluări

- WTIA IIW IWE Face-to-Face Training Modules and ExaminationsDocument2 paginiWTIA IIW IWE Face-to-Face Training Modules and ExaminationsRizwan NazirÎncă nu există evaluări

- Saep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsDocument12 paginiSaep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsShajin Mohammed Shamsudhin88% (8)

- Outline PDFDocument4 paginiOutline PDFGreg LoncaricÎncă nu există evaluări

- Welder Level C Program OutlineDocument185 paginiWelder Level C Program OutlineRon Carlo DiosoÎncă nu există evaluări

- IAB 089r4 12 PartII International Welders Guideline January 2012 PDFDocument119 paginiIAB 089r4 12 PartII International Welders Guideline January 2012 PDFIgor GrujićÎncă nu există evaluări

- Eslam Soliman PDFDocument5 paginiEslam Soliman PDFmohammedmahmoud5096374Încă nu există evaluări

- Aviation Mechanic Oral & Practical Exam Guide: Comprehensive preparation for the FAA Aviation Mechanic General, Airframe, and Powerplant Oral & Practical ExamsDe la EverandAviation Mechanic Oral & Practical Exam Guide: Comprehensive preparation for the FAA Aviation Mechanic General, Airframe, and Powerplant Oral & Practical ExamsÎncă nu există evaluări

- Spot Welding Interview Success: An Introduction to Spot WeldingDe la EverandSpot Welding Interview Success: An Introduction to Spot WeldingÎncă nu există evaluări

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersDe la EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersEvaluare: 3.5 din 5 stele3.5/5 (19)

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIDe la EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemÎncă nu există evaluări

- Training Facility Norms and Standard Equipment Lists: Volume 2---Mechatronics TechnologyDe la EverandTraining Facility Norms and Standard Equipment Lists: Volume 2---Mechatronics TechnologyÎncă nu există evaluări

- Training Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningDe la EverandTraining Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningÎncă nu există evaluări

- JSA006 - Vacuum Box TestingDocument5 paginiJSA006 - Vacuum Box TestingLaohan LiuÎncă nu există evaluări

- Ultrasonics Focal RadiusDocument4 paginiUltrasonics Focal RadiusLaohan LiuÎncă nu există evaluări

- Inductioncourserecord 1378962 BDocument1 paginăInductioncourserecord 1378962 BLaohan LiuÎncă nu există evaluări

- NDT301 FRM - Renewal Application For NDT Certification L12 3 Issue 1 Rev 4Document7 paginiNDT301 FRM - Renewal Application For NDT Certification L12 3 Issue 1 Rev 4Laohan LiuÎncă nu există evaluări

- 1111Document1 pagină1111Laohan LiuÎncă nu există evaluări

- Supply Chain Course Completion RecordDocument1 paginăSupply Chain Course Completion RecordLaohan LiuÎncă nu există evaluări

- NDT301 FRM - Renewal Application For NDT Certification L12 3 Issue 1 Rev 4Document7 paginiNDT301 FRM - Renewal Application For NDT Certification L12 3 Issue 1 Rev 4Laohan LiuÎncă nu există evaluări

- 1111Document1 pagină1111Laohan LiuÎncă nu există evaluări

- API 510 Study PlanDocument7 paginiAPI 510 Study Plankoib789100% (2)

- ATTAR - UT Pulse Length With RFDocument30 paginiATTAR - UT Pulse Length With RFLaohan LiuÎncă nu există evaluări

- IWIS Form AF-01 Rev 2 - Final - 18 April 2013Document2 paginiIWIS Form AF-01 Rev 2 - Final - 18 April 2013Laohan LiuÎncă nu există evaluări

- ATT00001Document1 paginăATT00001Laohan LiuÎncă nu există evaluări

- As 4041-2006 Pressure PipingDocument10 paginiAs 4041-2006 Pressure PipingThitikorn WassanarpheernphongÎncă nu există evaluări

- UT PCN NotesDocument113 paginiUT PCN NotesThiru Raja95% (19)