Documente Academic

Documente Profesional

Documente Cultură

R Series RP RH Analog

Încărcat de

haggDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

R Series RP RH Analog

Încărcat de

haggDrepturi de autor:

Formate disponibile

Temposonics

Magnetostrictive, Absolute, Non-contact

Linear-Position Sensors

SENSORS

R-Series Models RP and RH

Analog Outputs (Voltage/Current)

Document Part Number

550992 Revision E

Data Sheet

Model RP Profile-style position sensor

Features

Linear, Absolute Measurement

LEDs For Sensor Diagnostics

Non-Contact Sensing Technology

Non-Linearity Less Than 0.01%

Repeatability Within 0.001%

Direct Analog Outputs (Voltage or Current)

Single or Dual Channel Outputs (Position + Speed)

Benefits

Rugged Industrial Sensor

Dual Magnet Position Measurement

100% Field Adjustable Null And Span Setpoints

Model RH Rod-style position sensor

Time-based Magnetostrictive position sensing principle

Movable position magnet

Magnetic field encompasses

entire waveguide - generated

by the interrogation pulse

Interrogation

Return wire

Waveguide

Strain-Pulse detector

Magnetic field from

position magnet

Interaction of magnetic

fields causes waveguide to

generate a strain pulse

Bias magnet

APPLICATIONS

Benefits of Magnetostriction

Continuous Operation In Harsh Industrial Conditions

High Pressure Conditions

For Accurate, Dual-Magnet Position Measurement

Temposonics linear-position sensors use the time-based

magnetostrictive position sensing principle developed by MTS.

Within the sensing element, a sonic-strain pulse is induced in a

specially designed magnetostrictive waveguide by the momentary

interaction of two magnetic fields. One field comes from a moveable

permanent magnet that passes along the outside of the sensor. The

other field comes from an interrogation current pulse applied along

the waveguide. The resulting strain pulse travels at sonic speed along

the waveguide and is detected at the head of the sensing element.

Typical Industries

Fluid Power

Factory Automation

Material Handling and Packaging

Woodworking, Metalworking and Assembly Tools

Plastic Injection and Blow Molding

The position of the magnet is determined with high precision and speed

by accurately measuring the elapsed time between the application of

the interrogation pulse and the arrival of the resulting strain pulse with

a high-speed counter. The elapsed time measurement is directly proportional to the position of the permanent magnet and is an absolute

value. Therefore, the sensor's output signal corresponds to absolute

position, instead of incremental, and never requires recalibration or rehoming after a power loss. Absolute, non-contact sensing eliminates

wear, and guarantees the best durability and output repeatability.

All specifications are subject to change. Contact MTS for specifications and

engineering drawings that are critical to your application. Drawings contained

in this document are for reference only. Go to http://www.mtssensors.com for

the latest support documentation and related media.

Product Overview and Specifications

Product Data Sheet

Product overview

Parameters

R-Series model RH and RP sensors are extremely robust and are

ideal for continuous operation under harsh industrial conditions.

MTS offers two standard sensor housings, rod and profile

extrusion. The rod housing is capable of withstanding high pressures such as those found in hydraulic cylinders. The profile

extrusion housing provides convenient mounting options and

captive sliding magnets which utilize slide bearings of special

material that reduce friction, and help mitigate dirt build up.

The sensor head contains the active signal conditioning and a complete integrated electronics interface. Double shielding is used to ensure EMI protection for unsurpassed reliability and operating safety.

Operating

voltage:

+24 Vdc nominal: -15% or +20%

Polarity protection: up to -30 Vdc

Over voltage protection: up to 36 Vdc

Current drain: 100 mA typical

Dielectric withstand voltage: 500 Vdc

(DC ground to machine ground)

Setpoints:

Setpoint adjustment (Null/Span):

100% of electrical stroke length. 25 mm

(0.98 in.) min. distance between setpoints.

For dual-magnet outputs:

76 mm (3 in.) min. distance between

magnets

ENVIRONMENTAL

Product specifications

Parameters

Operating

conditions:

Operating temperature:

-40 C (-40 F) to +75 C (+167 F)

Relative humidity: 90% no condensation

Temperature coefficient: < 30 ppm/ C

EMC test:

Emissions: IEC/EN 50081-1

Immunity: IEC/EN 50082-2

IEC/EN 61000-4-2/3/4/6, level 3/4

criterium A, CE qualified

Shock rating:

100 g (single hit)/

IEC standard 68-2-27 (survivability)

Vibration rating:

15 g (30 g with HVR option)/10 to 2000 Hz,

IEC standard 68-2-6 (operational)

Specifications

OUTPUT

Measured output

variables:

Position + speed (magnitude) or velocity

(with direction) for single or dual magnets

Resolution:

Position measurement:

16 bit; 0.0015% (minimum 1 m)

Speed measurement:

0.1 mm/s

Specifications

ELECTRONICS

Non-linearity:

< 0.01% full stroke

(minimum 50 m)

Repeatability:

< 0.001% full stroke

(minimum 2.5 m)

Connection type:

Hysteresis:

< 4 m

PROFILE STYLE SENSOR (MODEL RP)

Analog Outputs:

Voltage:

0 to 10, 10 to 0, -10 to +10, +10 to -10 Vdc

(minimum controller load >5k ohms)

Current:

4(0) to 20 mA, 20 to 4(0) mA

(minimum/maximum load 0/500 ohms)

Electronic head:

Aluminum housing with diagnostic LED

display

(LEDs located beside connector/cable exit)

Sealing:

IP 65

Sensor extrusion:

Aluminum (Temposonics profile style)

Range (Profile style):

25 to 5080 mm (1 to 200 in.)

Range (Rod style):

25 to 7620 mm (2 to 300 in.)

Range (Flexible 1tyle):

255 to10,060 mm (10 to 396 in.)

(Contact factory for longer stroke lengths)

Update times:

0.5 ms up to 1200 mm, 1.0 ms up to

2400 mm, 2.0 ms up to 4800 mm, 5.0 ms

up to 7620 mm stroke length

Mounting:

Any orientation. Adjustable mounting feet

or T-slot nut (M5 threads) in bottom groove

Magnet types:

Captive-sliding magnet or open-ring

magnet

Range:

0.025 - 10 m/s (1.0 - 400.0 in./s)

Deviation: <0.5%

Resolution:

0.1 mm/s (0.004 in./s)

Update time:

Refer to update times in

'Position measurement' above

Stroke lengths:

Speed

measurement:

Wiring

ROD STYLE SENSOR (MODEL RH)

Electronic head:

Aluminum housing with diagnostic LED

display

(LEDs located beside connector/cable exit)

Sealing:

IP 67 or IP 68 for integral cable models

Sensor rod:

304L stainless steel

Operating

pressure:

350 bar static, 690 bar peak

(5000 psi static, 10,000 psi peak)

Mounting:

Any orientation. Threaded flange M18 x 1.5

or 3/4 - 16 UNF-3A

Typical

mounting torque:

Magnet types:

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

6-pin male D60 (M16) connector or

integral cable

45 N-m (33 ft. - lbs.)

Ring magnet, open-ring magnet, or magnet

float

MTS Sensors

Product Data Sheet

Analog Output Options, Programmability

Enhanced Monitoring and Diagnostics

Output options

Advanced communication and programmability

R-Series analog sensors provide single or dual-magnet sensor

options along with single or dual-channel outputs (see Figure 1).

Sensor field programming

Temposonics R-Series Analog sensors are pre-configured at

the factory by model number designation. For many applications, normal sensor installation and operation does not require

additional adjustment. If however, sensor parameter changes are

required in the field, the R-Series Analog PC Programming Kit,

part no. 253309-1 (see Figure 3) can be used to easily program

the sensor electronically without opening the sensor's housing.

The R-Series analog sensor can be ordered for single-position

magnet applications which provide one position output,

and/or one velocity output over the active stroke length.

The R-Series sensor can also be ordered for dual-position

magnet applications which provide two position outputs, or two

velocity outputs, or one of each.

Single-magnet sensor

M1

R-Series

M1A

Active stroke range

Temposonics

Field programming to adjust the output values is available for

any setting needed, within the selected output range. Each sensors output range is selected from the available options when

ordering a particular sensor model number. There are six different

manufacturing build types available, three single channel and

three dual channel outputs in various ranges as described below:

Position / Speed

Dual-magnet sensor

Single-channel output for either position or speed:

76 mm

(3 in.) min.

M2

M1

M1A

Voltage output between 0 and +10 volts

Voltage output between -10 and +10 volts

Current output between 0 (or 4) and 20 mA

M2A

Temposonics

R-Series

0 Vdc

0%

Dual-channel outputs for position and/or speed:

10 Vdc

0 Vdc

Position 1 / Position 2

Voltage outputs between 0 and +10 volts

Voltage outputs between -10 and +10 volts

Current outputs between 0 (or 4) and 20 mA

10 Vdc

100%

Figure 1. Single and dual-magnet output diagram

Field Programming Notes:

When using dual magnets, the minimum allowed distance between

the magnets is 76 mm (3 in.) to maintain proper sensor output.

Field programming allows for numerous custom sensor configurations, however, please note that field programming can not be used to

change the R-Series Analog sensor from one manufacturing build type

to another.

Enhanced monitoring and diagnostics

Field programming (output voltages):

1. Sensor models ordered with one output channel can not be

reprogrammed in the field to provide a second output channel.

2. Sensor models ordered with positive only output voltages can not

be reprogrammed in the field to include negative output voltages.

3. Sensor models ordered with both positive and negative output

voltages can be reprogrammed in the field for positive only

voltages, or negative only voltages. However, resolution is then

reduced.

Sensor status and diagnostic display

Diagnostic LEDs (green/red), located beside the

or cable exit (see Figure 2), provide basic visual

for normal sensor operation and troubleshooting.

display LEDs indicate four modes described in

connector

monitoring

Diagnostic

Table 1.

Figure 2. R-Series sensor diagnostic LEDs

Green

Red

Operation status/mode

ON

OFF

Normal function (operation mode)

ON

Flashing

Magnet out of setup range

ON

ON

Magnet not detected or wrong

quantity of magnets

Flashing

ON

Programming mode

Figure 3. R-Series Analog PC Programming Kit, Part no. 253309-1

(For single or dual magnet sensor applications)

Table 1. Diagnostic LED codes

MTS Sensors

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

Field Programming

Product Data Sheet

Advanced communication and programmability

R-Series analog handheld programmer for single magnet sensor Applications

Sensor field programming

R-Series Analog PC Programming Kit (Part no.: 253309-1)

includes the following components:

The R-Series Analog Handheld Programmer (see Figure 5) can be

used to program the magnet positions for the start of output,

(0% = 0 Vdc, -10 Vdc, 4 mA, or 0 mA), and the end of output,

(100% = 10 Vdc or 20 mA), for the single magnet version of the

R-Series analog sensor.

Wall adapter style power supply (24 Vdc output)

USB Serial converter box with USB cable to connect to PC

Two connection cables:

Cable with connector if sensor is ordered with the D60

integral connector option.

Cable with quick connects if sensor is ordered with the

integral cable option.

R-Series Analog PC Setup software, on CD-ROM

(for Windows XP or higher)

Figure 5. R-Series Analog Handheld Programmer, Part no.: 253124

Standard factory settings place the setpoint 1 'Null' and setpoint 2

'Span' at the limits of the sensors active stroke range. For example,

a sensor ordered with 4 - 20 mA output will be factory set for 4 mA

output at the bottom limit of the stroke range at the 'Null position.

Likewise, the 20 mA output will be factory set at the top limit of the

stroke range at the 'Span' position.

The R-Series Analog PC Setup software user-friendly interface

(see Figure 4) enables the operator to take advantage of customizing the following settings:

Magnet positions and sensor output values for Setpoint 1 (Null)

and Setpoint 2 (Span) for single or dual magnets. For additional

information about setpoints, refer to section R-Series analog

handheld programmer for single-magnet sensors.

Output range settings for speed, or for speed with direction.

Assign position or velocity output functions for the single or

dual magnets, and for the one or two output channels. Output

function assignments are limited to the manufacturing build

type of the sensor.

Assign error output values when the magnet moves beyond the

programmed setpoints.

Output value

For

war

Rev

ers

Electronics

housing

Single-magnet sensor

Temposonics

R-Series

Dead

zone

Position

Setpoint 1

(Null)

Setpoint 2

(Span)

Figure 6. Standard factory settings

Setpoint 1 and setpoint 2 can be re-positioned for the actual

measuring length needed anywhere within the active stroke range.

Note:

The minimum distance allowed between setpoint 1 and setpoint 2 is

25 mm (0.98 in.).

These adjustments are easily performed, even when the sensor is not

directly accessible, by connecting the analog handheld programmer

to the sensors integral cable or extension cable.

When programming new setpoints, the R-Series Analog Handheld

Programmer adjusts the sensor output values to either 0% or 100%

at the two selected magnet positions. To program other

setpoint output values, use the R-Series Analog PC Programming

Kit (Part no.: 253309-1).

Note:

Figure 4. R-Series PC Setup software interface

The R-Series Analog Handheld Programmer can also be used to change

the output direction from forward-acting (e.g. 4 - 20 mA output) to

reverse-acting (20 - 4 mA output), as well as, reverse-acting to forwardacting.

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

MTS Sensors

Product Data Sheet

Field Programming

Model RP Profile-Style Sensor Dimensions

R-Series Analog Cabinet Programmer For Single

Magnet Sensors

The R-Series Analog Cabinet Programmer (see Figure 7) provides

the same programming functions as the R-Series Analog Handheld

Programmer and is designed to mount in a control cabinet. The

R-Series Analog Cabinet Programmer includes a rear snap-in mounting feature that allows the unit to mount on standard 35 mm DIN rail.

After installation, the programmer can remain wired up to both

the sensor and PLC interface module if reprogramming or a different

machine setup is later required, a built-in Program/Run switch

allows this programmability.

Figure 7. R-Series Analog Cabinet Programmer (two shown) ,

Part no.: 253408 (for single-magnet sensor applications)

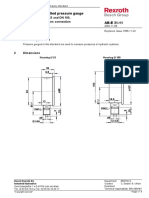

Model RP profile-style sensor dimension references

Model RP, profile-style sensor with captive-sliding magnet

Drawing is for reference only, contact applications engineering for tolerance specific information.

49 mm

(1.92 in.)

Beginning of stroke Null position

12 mm (0.47 in.)

50 mm (1.97 in.)

End of stroke

Span position

Captive-sliding magnet

45 mm

(1.77 in.)

9 mm

(0.36 in.)

Stroke length

Electronics

housing

2 mm

(0.07 in.)

12 mm (0.47 in.)

Mounting foot, moveable

(part no.: 400802)

75 mm

(2.95 in.)

68 mm (2.68 in.)

5.5 mm (0.21 in.) dia.

for M5 or #10 screw

82 mm (3.2 in.)

Dead zone

Figure 8. R-Series Model RP Profile-style sensor dimension reference (Shown with the D60 integral connection type option)

Model RP, profile-style sensor with open-ring magnet

Drawing is for reference only, contact applications engineering for tolerance specific information.

28 mm

(1.1 in.)

Electronics

housing

30 mm

(1.2 in.)

Beginning of stroke Null Position

Open-ring magnet

Mounting support

(non-ferrous material)

Mounting foot, moveable

(part no.: 400802)

28 mm

(1.1 in.)

Stroke length

28 mm

(1.1 in.)

Dead zone

66 mm

(2.6 in.)

Figure 9. R-Series Model RP Profile-style sensor dimension reference (Shown with the R05 integral cable connection type option)

MTS Sensors

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

Model RP Profile-Style Sensor

Standard Magnet Selections

Product Data Sheet

Standard magnet selections (Model RP)

Selection of position magnets (One magnet included with Model RP sensor)

A choice of two magnet mounting configurations are available with the profile-style sensor; A captive-sliding magnet, Styles S or V or

an open-ring magnet, Style M. Captive-sliding magnets utilize slide bearings of special material that reduce friction, and if required, help

mitigate dirt build up. The slide bearings are designed to operate dry, requiring no external lubrication or maintenance.

The Style M open-ring magnet mounts on the moving machine part and travels just above the sensors profile extrusion. The open-ring

magnet requires a minimum distance away from ferrous metals to allow proper sensor output. It must be mounted using non-ferrous screws

and a non-ferrous support bracket, or utilize a non-ferrous spacer of at least 5 mm (0.2 in.) thickness.

POSITION MAGNET SELECTIONS (One Magnet included with each Model RP sensor)

(Drawing dimensions are for reference only)

Magnet dimensions

14 mm

(0.55 in.)

Mounted magnet dimensions

43 mm

(1.69 in.)

Rotation:

Vertical: 18

Horizontal: 360

20 mm

(0.79 in.)

52 mm

(2.05 in.)

45 mm

(1.77 in.)

24 mm

(0.95 in.)

Ball-jointed arm

(M5 thread)

Description

Part number

Captive-sliding magnet,

Style S

For Model RP profile-style

sensor

252182

Captive-sliding magnet,

Style V

For Model RP profile-style

sensor

252184

40 mm

(1.58 in.)

14 mm

(0.55 in.)

57 mm

(2.24 in.)

Rotation:

Vertical: 18

Ball-jointed arm

(M5 thread) 9 mm

(0.35 in.)

24 mm

(0.95 in.)

40 mm

(1.58 in.)

2 Holes

Each 4 mm

(0.17 in.) dia. on

24 mm (0.94 in.) dia.

60

25 mm

(0.97 in.)

14 mm

(0.55 in.)

21 mm

(0.81 in.)

36 mm

(1.41 in.)

Non-ferrous mounting support

and screws

21 mm

(0.81 in.)

Max gap

3 mm 1 mm

(0.12 in. 0.04 in.)

29 mm

(1.14 in.)

Open-ring magnet, Style M

I.D.: 13.5 mm (0.53 in.)

O.D.: 33 mm (1.3 in.)

Thickness: 8 mm (0.31 in.)

Operating temperature:

- 40 C to +100 C

251416-2

Open-ring magnet Style M

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

MTS Sensors

Product Data Sheet

Model RP Profile-Style Sensor

Mounting Methods

Sensor mounting

Model RP profile-style sensor mounting Flexible installation in any position!

Temposonics model RP profile-style sensors offer two basic mounting methods; side grooves for use with mounting feet or a bottom groove

that accepts special T-Slot nuts. Both the mounting feet and T-Slot nuts can be positioned along the sensor extrusion to best secure the

sensor for each particular application.

Notes:

1. Model RP sensors include two mounting feet, (part no. 400802) for sensors stroke lengths up to 1250 mm (50 in.)

2. One additional mounting foot is included for stroke lengths over 1250 mm (50 in.) and for each additional 500 mm (20 in.),

thereafter.

3. MTS recommends using 10-32 cap screws (customer supplied) at a maximum torque of 44 in. lbs. when fastening mounting feet.

Profile-Style sensor mounting and installation reference

4 Holes

5.3 mm

(0.21 in.) dia.

2 mm

(0.08 in.)

Mounting method

28 mm

(1.1 in.)

50 mm

(1.97 in.)

Part number

9 mm

(0.36 in.)

68 mm

(2.68 in.)

9 mm

(0.36 in.)

Mounting feet, standard (304 SS)

Profile-style sensor mounting for

sensor model RP

400802

Mounting feet, Insulated (304 SS)

Profile-style sensor mounting for

sensor model RP. Nylon washers

and cloth tape on the bottom provide

electrical isolation.

252004

Mounting feet and screws

Profile-style sensor foot installation

See

Mounting

Feet

part

numbers:

400802 and

252004

T-Slot nut

Nut for mounting model RP sensor.

M5 thread

(optional, ordered separately)

401602

(Width = 14.5 mm (0.57 in.)

5 mm

(0.196 in.) I.D.

2 mm

(0.08 in.)

28 mm

(1.1 in.)

50 mm

(1.97 in.)

9 mm

(0.36 in.)

68 mm

(2.68 in.)

9 mm

(0.36 in.)

(Width = 14.5 mm (0.57 in.)

10-32 Cap screws

recommended

(customer supplied)

Mounting foot and screws

5 mm (0.20 in.)

T-Slot nut, M5 thread

Detail

MTS Sensors

M5 Threaded

stud and nut

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

Model RH Rod-Style Sensor

Dimension References

Product Data Sheet

Model RH rod-style sensor dimension references

The Temposonics R-Series rod-style sensor (Model RH) offers modular construction, flexible mounting configurations, and easy installation.

The Model RH sensor is designed for mounting in applications where high pressure conditions exist, (5000 psi continuous, 10,000 psi

spike), such as inside hydraulic cylinders. The Model RH sensor (see Figure 10) may also be mounted externally in many applications.

Stroke-dependent Dead Zones:

Stroke length:

Dead zone:

25 mm (1 in.) - 5000 mm (197 in.)

63.5 mm (2.5 in.)

5005 mm (197.1 in.) - 7620 mm (300 in.)

66 mm (2.6 in.)

Model RH, ROD-style sensor WITH RING magnet (Magnet ordered separately)

Drawing is for reference only, contact applications engineering for tolerance specific information.

Beginning of stroke Null position

Male, 6-Pin (D60)

Integral connector

Diagnostic

LEDs

68 mm

(2.7 in.)

M4 x 59 mm

Button-head

hex screws (2X)

Flat-faced hex

flange type S

(refer to Notes

Stroke dependent

dead zones)

Ring magnet

10 mm

(0.39 in.) dia.

Electronics

housing

44 mm

(1.7 in.)

End of stroke Span position

Dead zone

Stroke length

51 mm

(2 in.)

Null zone

O-Ring

Refer to Table 2 for

(A) Flange threads

25 mm

(0.98 in.)

Sensor rod

Figure 10. Model RH Rod-style sensor dimension reference (shown with the D60 integral connection)

Model RH, ROD-style sensor WITH 6-PIN DIN mating CABLE connector (Magnet ordered separately)

Drawing is for reference only, contact applications engineering for tolerance specific information.

Beginning of stroke Null position

76 mm (3 in.)

68 mm (2.7 in.)

51 mm (2 in.)

O-Ring

Grounding lug

Refer to Table 2

(A) Flange threads

Electronics

housing

Mating connector

6-pin DIN style

Raised-face hex

flange type T

B

25 mm

(1 in.)

25 mm (1 in.)

C

Refer toTable 2

(B) dimensions and (C) dimensions

2.5 mm (0.1 in.)

Figure 11. Model RH Rod-style sensor dimension reference (shown with mating cable connector)

Housing style

Flange type

Description

(A) Flange threads

(B) Dimensions

(C) Dimensions

US customary threads with raised-face flange

3/4" - 16 UNF-3A

1.75 in.

2 in.

US customary threads with flat-faced flange

3/4" - 16 UNF-3A

1.75 in.

2 in.

Metric threads with flat-faced flange

M18 x 1.5

46 mm

53 mm

Table 2. Model RH Rod-style sensor housing style and flange type references

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

MTS Sensors

Product Data Sheet

Model RH Rod-Style Sensor

Magnets and Mounting

Standard magnet selectionss (Model RH)

Magnets must be ordered separately with model RH position sensors. The standard ring magnet (part number 201542-2) is suitable for

most applications.

POSITION MAGNET SELECTIONS (Magnet must be ordered separately) (Drawing dimensions are for reference only)

Magnet

Magnet dimensions

Description

4 Holes

Each 4.3 mm (0.17 in.) dia.

90 apart on

24 mm (0.94 in.) dia.

2 Holes

Each 4 mm

(0.17 in.) dia. on

24 mm (0.94 in.) dia.

60

Standard ring magnet

I.D.: 13.5 mm (0.53 in.)

O.D.: 33 mm (1.3 in.)

Thickness: 8 mm (0.3 in.)

Operating temperature:

- 40 C to +100 C

201542-2

Ring magnet

I.D.: 13.5 mm (0.53 in.)

O.D.: 25.4 mm (1 in.)

Thickness: 8 mm (0.3 in.)

Operating temperature:

- 40 C to +100 C

400533

Open-ring magnet, Style M

I.D.: 13.5 mm (0.53 in.)

O.D.: 33 mm (1.3 in.)

Thickness: 8 mm (0.3 in.)

Operating temperature:

- 40 C to +100 C

25 mm

(0.97 in.)

14 mm

(0.55 in.)

Part number

21 mm

(0.81 in.)

251416-2

Magnet spacer

(Non-ferrous, use with ring magnet part

no.: 201542-2)

I.D.: 14 mm (0.56 in.)

O.D.: 32 mm (1.25 in.)

Thickness: 3.2 mm (0.125 in.)

4 Holes

Each 4.3 mm (0.17 in.) dia.

90 apart on

24 mm (0.94 in.) dia.

400633

MAGNET FLOAT SELECTION (Drawing dimensions are for reference only)

14 mm (0.55 in.) Min. I.D.

Magnet float

(Level sensing applications)

Specific gravity: 0.70 maximum

Pressure: 870 psi maximum

51 mm (2 in.)

Spherical O.D.

53 mm C

(2.1 in.) L

251447

(This float is used with the Model RH

rod-style sensors for hydraulic fluid or fresh

water applications only)

3.4 mm (0.13 in.)

Model RH Rod-Style sensor mounting

Model RH sensor mounting

Cylinder end cap

n

so

s

ic

rie

Se

R-

po

m

Te

The position magnet requires minimum distances away from

ferrous metals to allow proper sensor output. The minimum

distance from the front of the magnet to the cylinder end cap is 15

mm (0.6 in.).

R

magnet

Ring m

Piston head

The minimum distance from the back of the magnet to the piston

head is 3.2 mm (0.125 in.). The non-ferrous spacer (part no.

400633), provides this minimum distance when used along with the

standard ring magnet (part no.: 201542-2).

ferrous

Nonn fer

cer

spa

spacer

> 15 mm

.)

(0.6 in.)

Min. 3.2 mm

(0.125 in.)

Figure 12. Model RH rod-style mounting

MTS Sensors

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

Model RH Rod-Style Sensor, Cylinder Installation

Models RP and RH Sensors, Connections and Wiring

Product Data Sheet

Model RH Rod-Style sensor cylinder installation

When used for direct-stroke measurement in fluid cylinders,

the sensor's high pressure, stainless steel rod installs into a

bore in the piston head/rod assembly as illustrated. This method

guarantees a long-life and trouble-free operation.

The sensors rod housing and flange can remain

permanently installed in the cylinder

The sensor cartridge can be removed from the flange and rod housing

while still installed in the cylinder. This procedure allows quick and easy

sensor cartridge replacement, without the loss of hydraulic pressure.

Ring magnet

The sensor cartridge, consisting of the electronics housing

and sensing element, is easy to replace by removing

(2) M4 thread 2.5 mm hex socket head screws

Figure 13. Fluid cylinder installation

Models RP and RH connections and wiring

Standard male (D60) 6-pin DIN integral connector (M16)

Note:

When using the single channel output,

(pins 1 and 2), the unused pins for output 2

(pins 3 and 4) should be left floating (unconnected), unless sensor programming is being

performed.

5 4

6 3

1 2

Male, 6-pin (D60) integral connector pin-out as viewed from the

end of the sensor

Pin Number

Wire Color

Function / Analog outputs

Gray

Output 1/ Position 1:

0 to 10, 10 to 0, -10 to +10, +10 to -10 Vdc

4 to 20 , 20 to 4, 0 to 20, 20 to 0 mA

(Required for programming mode / 0% setting)

Pink

Return for pin 1

Yellow

Output 2/ Position 2 or Speed:

0 to 10, 10 to 0, -10 to +10, +10 to -10 Vdc

4 to 20, 20 to 4, 0 to 20, 20 to 0 mA

(Required for programming mode / 100% setting)

Green

Return for pin 3

Red or

Brown

+24 Vdc (-15/+20%)

(Required for programming mode)

White

DC ground (for supply)

(Required for programming mode)

Cable connector Options (field installable) 6-pin DIN (D60) female

(Drawing dimensions are for reference only)

Connector

Connector dimensions

Description

54 mm

(2.1 in.)

18 mm

(0.7 in.) dia.

Part number

Cable Connector, Female, Straight Exit

(Field installable)

6-Pin DIN (D60)

Mates with standard male (M16) integral connector

560700

Cable Connector, Female, 90 Exit

(Field installable)

6-Pin DIN (D60)

Mates with standard male (M16) integral connector

560778

37 mm

(1.5 in)

18 mm

(0.7 in.) dia.

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

54 mm

(2.1 in.)

10

MTS Sensors

Product Data Sheet

Models RP and RH Sensors

Extension Cables with Connector Assemblies

EXTENSION CABLE WITH CONNECTORS FOR D6, (D60), CONNECTION TYPES

Extension Cable and Connector Assemblies

Connection

Type

Description

Connector, Straight Exit

with Standard PVC Jacket Cable

(Assembly Includes D6 Connector, Part No.: 560700

and Cable, Part No.:530026)

D6

Connector, 90 Exit

with Standard PVC Jacket Cable

(Assembly Includes D6 Connector, Part No.: 560778

and Cable, Part No.:530026)

DA

Connector, Straight Exit

with Black Polyurethane Jacket Cable (for higher

resistance to moisture, oil and cold temperatures)

(Assembly Includes D6 Connector, Part No.: 560700

and Cable, Part No.:530045)

DJ

Connector, 90 Exit

with Black Polyurethane Jacket Cable (for higher

resistance to moisture, oil and cold temperatures)

(Assembly Includes D6 Connector, Part No.: 560778

and Cable, Part No.:530045)

DK

Ordering Information

Extension Cable with Connector for a D6 (D60) Connection Type

D

1

SENSOR CONNECTION TYPES

D6

= Female connector, straight exit (part no. 560700), and PVC jacket cable (part no. 530026)

DA

DJ

= Female connector, 90 exit (part no. 560788), and PVC jacket cable (part no. 530026)

= Female connector, straight exit (part no. 560700), and black polyurethane jacket cable (part no. 530045)

DK

= Female connector, 90 exit (part no. 560788), and black polyurethane jacket cable (part no. 530045)

CABLE LENGTHS

1-2

3-5

For standard length cables up to 100 ft

005

= 5 ft

015

025

050

100

= 15 ft

= 25 ft

= 50 ft

= 100 ft

For custom length cables over 100 ft

= Cable length (maximum cable length is dependent on the output selected; consult MTS Applications Engineering)

CABLE TERMINATION

P0

= Pigtail cable without connector (2 digit code)

D6M

= D6 male connector (straight exit). Only available with the D6 option above.

D6F

= D6 female connector (straight exit). Only available with the D6 option above.

DAF

= D6 female connector (90 exit). Only available with the DA option above.

MTS Sensors

11

6-8

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

Models RP and RH Sensors

Ordering Information

Product Data Sheet

R

(3 to 7 digit code, defined by the output option selected)

1

10

SENSOR MODEL

RP

RH

= Profile style

= Hydraulic rod style

11

12

13

14

15

16

17

18

19

=

RF

= Flexible style

For more information about the model RF,

refer to specification part no.: 551081 or

Industrial Product Catalog, part no.: 551075

HOUSING STYLE

Model RP profile-style sensor (includes one magnet):

Captive-sliding magnet with ball joint V

= Captive-sliding magnet with ball M

at top (part no. 252182)

joint at front (part no. 252184)

Model RH rod-style sensor (magnet(s) must be ordered separately):

US customary threads, raised-faced U

= Same as option T, except uses B

flange and pressure tube, standard

fluoroelastomer seals for the

electronics housing

US customary threads, flat-faced

H

= Same as option S, except uses

flange and pressure tube, standard

fluoroelastomer seals for the

electronics housing

Metric threads, flat-faced flange and V

= Same as option M, except uses

pressure tube, standard

fluoroelastomer seals for the

electronics housing

Model RF Flexible housing style sensor, (magnet(s) must be ordered separately):

US customary threads, flat-faced

M

= Metric threads, flat-faced flange

flange

= Sensor cartridge only (no flange

and pressure tube, stroke length

< 1830 mm (72 in.))

.U

= Inches and tenths

(Encode in 0.1 in. increments)

1. Profile-style sensor (model RP) stroke range = 25 mm (1 in.) - 5080 mm. (200 in.)

2. Rod-style sensor (model RH) stroke range = 25 mm (1 in.) - 7620 mm (300 in.)

3. Flexible housing style sensor (model RF) stroke range = 255 mm (10 in.) 10,060 mm (396 in.)

(Contact factory for longer stroke lengths.)

CONNECTION TYPE

Integral connector:

= 6-pin DIN (M16), male, standard

Integral cables:

= Integral cable, PVC jacket, pigtail termination, standard

Cable Length Note:

= Integral cable, black polyurethane jacket with pigtail termination

Cable length:

Encode in feet if using US customary stroke length

Encode in meters if using metric stroke length

> =

1 (01) to 99 (99) ft. or 1 (01) to 30 (30) meters.

MTS recommends the maximum integral cable

length to be 10 meters (33 ft.). Cables greater

than 10 m (33 ft.) in length are available,

however, proper care must be taken during

handling and installation.

INPUT VOLTAGE

1

= +24 Vdc (+20% - 15%)

= Same as option 1 except includes the High

Vibration-Resistant (HVR) option for Model

RH only, limited to stroke range = 50 mm (2

in.) - 2000 mm (78.7 in.), Refer to HVR Option

Note.

12

HVR Option Note:

The High Vibration-Resistant (HVR) option provides the model RH

rod-style sensors with increased resistance to shock and vibration for use

in heavy duty machinery. Refer to G-Series and R-Series Sensors for

High Shock and Vibration Applications, document part no.: 551073 for

more information.

OUTPUT (13 - 19)

3 to 7 digit code defined by the output option selected from pages 12 and 13

1 Output channel with 1 magnet (3 digit code).

Output #1 = Magnet position

V01

= 0 to +10 Vdc

A01

= 4 to 20 mA

V11

= +10 to 0 Vdc

A11

= 20 to 4 mA

V21

= -10 to +10 Vdc

A21

= 0 to 20 mA

= 20 to 0 mA

V31 = +10 to -10 Vdc

A31

9-11

D60

4-8

= Millimeters (Encode in 5 mm increments)

Stroke Length Notes:

= Open-ring magnet

(part no. 251416-2)

STROKE LENGTH

M

1-2

13-19

Continued on page 13

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

12

MTS Sensors

Product Data Sheet

Models RP and RH Sensors

Ordering Information, Connector and Cable Options

R

(3 to 7 digit code, defined by the output option selected)

1

10

11

12

13

14

15

16

2 Output channels with 2 magnets (3 digit code)

17

18

19

13 - 15

Choose a value described below to encode 3 digits (sensor part number boxes 13-15) refer to Setpoint Note

Output #1 = Magnet #1 position

V02

= 0 to +10 Vdc

Output #2 = Magnet #2 position

0 to +10 Vdc

V12

= +10 to 0 Vdc

+10 to 0 Vdc

Setpoint Note:

V22

= -10 to +10 Vdc

-10 to +10 Vdc

V32

= +10 to -10 Vdc

+10 to -10 Vdc

A02

= 4 to 20 mA

4 to 20 mA

A12

= 20 to 4 mA

20 to 4 mA

A22

= 0 to 20 mA

0 to 20 mA

A32

= 20 to 0 mA

20 to 0 mA

Standard factory settings for the setpoint positions

are the same for both magnets, i.e. both magnets

have setpoint 1 at the Null position, and setpoint

2 at the Span position. If needed, the setpoint

positions for each magnet can be reprogrammed in

the field to best fit the application, (see page 4 for

more information). For proper sensor output, the

minimum allowed distance between magnets is 3 in.

(76 mm).

2 Output channels with 1 magnet (7 digit code)

13 - 19

(Choose a maximum speed value described below in Table 3 to encode all 7 digits (sensor part number boxes 13 - 19)

Output #1 = Magnet position

v01 = 0 to +10 Vdc

v11 = +10 to 0 Vdc

a01 = 4 to 20 mA

a11 = 20 to 4 mA

Output #1 = magnet position

v41 = 0 to +10 Vdc

v51 = +10 to 0 Vdc

v61 = 0 to +10 Vdc

v71 = +10 to 0 Vdc

v81 = -10 to +10 Vdc

v91 = +10 to -10 Vdc

a41 = 4 to 20 mA

a51 = 20 to 4 mA

Output #1 = Magnet position (forward-acting)

V03

= 0 to +10 Vdc (3 digit code)

Output #2 = Speed magnitude

+10 (towards head)

0 (at rest)

+10 (towards head)

0 (at rest)

20 (towards head)

4 (at rest)

20 (towards head)

4 (at rest)

Output #2 = Velocity (speed with direction)

0 (towards head)

5 (at rest)

+10 (towards head)

5 (at rest)

-10 (towards head)

0 (at rest)

+10 (towards head)

0 (at rest)

-10 (towards head)

0 (at rest)

+10 (towards head)

0 (at rest)

4 (towards head)

12 (at rest)

20 (towards head)

12 (at rest)

Output #2 = Magnet position (reverse-acting)

+10 to 0 Vdc

+10 (towards tip) Vdc

+10 (towards tip) Vdc

20 (towards tip) mA

20 (towards tip) mA

+10 (towards tip) Vdc

0 (towards tip) Vdc

+10 (towards tip) Vdc

-10 (towards tip) Vdc

+10 (towards tip) Vdc

-10 (towards tip) Vdc

20 (towards tip) mA

4 (towards tip) mA

TABLE 3. FOR SENSOR MODELS WITH SPEED OUTPUT

(Choose a maximum speed value described below to encode the last 4 digits (sensor part number boxes 16-19)

For US customary stroke lengths, encode speed for in./s.

= Speed output maximum

Available range for US customary stroke lengths is 1.0 to 400.0 in./s, (0010 4000)

Example:

Maximum speed of 12.0 in./s, and output produced for velocity = [-10(towards head) 0(at rest) +10(towards tip)

Volts]

Encode: V 6 1 0 1 2 0 or V 8 1 0 1 2 0

For metric stroke lengths, encode speed for m/s (range #1) or mm/s (range #2) using the information provided below:

Speed range #1, ( 0 . )

= Speed output maximum

0 .

Speed range #1 for metric stroke lengths is 0.1 to 10.0 m/s, (0001 0100)

Example:

Maximum speed of 5.5 m/s, and output produced for speed = [+10(towards head) 0(at rest) +10(towards tip) Volts],

Encode: V 0 1 0 0 5 5

Speed range #2, ( 1 )

1 = Speed output maximum.

Speed range #2 for metric stroke lengths is 25 to 90 mm/s, (1025 1090)

Example:

Maximum speed of 50 mm/s, and output produced for velocity = [4(towards head) 12(at rest) 20(towards tip)

mA]

Encode: A 4 1 1 0 5 0

MTS Sensors

13

R-Series Models RP and RH Temposonics Linear-Position Sensors - Direct Analog Output

Product Data Sheet, Document Part No.: 550992, Revision E 02-10

Document Part Number: 550992, Revision E 02-10

MTS and Temposonics are registered trademarks of MTS Systems Corporation.

All other trademarks are the property of their respective owners.

All Temposonics sensors are covered by US patent number 5,545,984. Additional patents are pending.

Printed in USA. Copyright 2010 MTS Systems Corporation. All Rights Reserved in all media.

SENSORS

MTS Systems Corporation

Sensors Division

MTS Sensor Technologie

GmbH & Co. KG

MTS Sensors Technology

Corporation

3001 Sheldon Drive

Cary, North Carolina

27513, USA

Tel.: +1-800-633-7609

Fax: +1-919-677-2343

+1-800-498-4442

e-mail: sensorsinfo@mts.com

http://www.mtssensors.com

Auf dem Schffel 9

D - 58513 Ldenscheid, Germany

Tel.: +49-2351-9587-0

Fax: +49-2351-56491

e-mail: info@mtssensor.de

http://www.mtssensor.de

737 Aihara-cho, Machida-shi

Tokyo 194-0211, Japan

Tel.: +81-42-775-3838

Fax: +81-42-775-5516

e-mail: info@mtssensor.co.jp

http://www.mtssensor.co.jp

S-ar putea să vă placă și

- Pooyan Hydraulics: Description Symbol ApplicationDocument20 paginiPooyan Hydraulics: Description Symbol Applicationrmajdi2000100% (2)

- Math 10 Learning PlanDocument11 paginiMath 10 Learning PlanmichaelÎncă nu există evaluări

- RF DC Bias TeeDocument15 paginiRF DC Bias TeechrisjennÎncă nu există evaluări

- Hydraulic piston pressure switches with electrical outputsDocument2 paginiHydraulic piston pressure switches with electrical outputshagg100% (1)

- Audio Encryption Optimization: Harsh Bijlani Dikshant Gupta Mayank LovanshiDocument5 paginiAudio Encryption Optimization: Harsh Bijlani Dikshant Gupta Mayank LovanshiAman Kumar TrivediÎncă nu există evaluări

- Hive Tutorial PDFDocument14 paginiHive Tutorial PDFbewithyou2003Încă nu există evaluări

- Basic InstrumentationDocument55 paginiBasic InstrumentationvenkatsubbuÎncă nu există evaluări

- Solucionario Econometría Jeffrey M. WooldridgeDocument4 paginiSolucionario Econometría Jeffrey M. WooldridgeHéctor F Bonilla3% (30)

- G Series GP GH Analog DPulseDocument18 paginiG Series GP GH Analog DPulseVayu Laxman BÎncă nu există evaluări

- R Series RD4 FlexDocument8 paginiR Series RD4 FlexskumarÎncă nu există evaluări

- Espesificación de TemposonicsDocument10 paginiEspesificación de TemposonicsKARYMEN1998Încă nu există evaluări

- Tzid Data SheetDocument12 paginiTzid Data SheetMohamed MeeranÎncă nu există evaluări

- Gs01c50h01-01en 001Document13 paginiGs01c50h01-01en 001Alvaro Quinteros CabreraÎncă nu există evaluări

- High Precision Pressure Transmitter: Main Features Electrical Connections (Left: 2-Wire, Right: 3-Wire)Document4 paginiHigh Precision Pressure Transmitter: Main Features Electrical Connections (Left: 2-Wire, Right: 3-Wire)Solihin VJÎncă nu există evaluări

- Speed Sensors Line GuideDocument6 paginiSpeed Sensors Line GuideHernan GirautÎncă nu există evaluări

- ATS692 H DatasheetDocument12 paginiATS692 H Datasheetshivani_mehrotra_8Încă nu există evaluări

- R Series SSI OutputDocument10 paginiR Series SSI OutputAditya DarmawanÎncă nu există evaluări

- GS01C25B01 01eDocument14 paginiGS01C25B01 01epredrag123Încă nu există evaluări

- Cat OptoNCDT enDocument36 paginiCat OptoNCDT enNikhil SharmaÎncă nu există evaluări

- Pressure Sensor MPS20N0040D-S: Product FeaturesDocument3 paginiPressure Sensor MPS20N0040D-S: Product Featuresluis alfonsoÎncă nu există evaluări

- 1460 mps20n0040d-s DatasheetDocument3 pagini1460 mps20n0040d-s DatasheetAmir VatanÎncă nu există evaluări

- Pressure Sensor MPS20N0040D-S: Product FeaturesDocument3 paginiPressure Sensor MPS20N0040D-S: Product FeaturesRubens Tadeu Passos CarneiroÎncă nu există evaluări

- Compact Pressure Sensor Measures Up to 580 PSIGDocument3 paginiCompact Pressure Sensor Measures Up to 580 PSIGLUIS CARLOS ARCINIEGAS REMOLINAÎncă nu există evaluări

- Ultrasonic Anemometer Thies 3D S83100H/S83300H SpecsDocument4 paginiUltrasonic Anemometer Thies 3D S83100H/S83300H SpecsdiCoutiÎncă nu există evaluări

- MPU-A Series Hall Effect Geartooth Sensor Pick-Up: FeaturesDocument2 paginiMPU-A Series Hall Effect Geartooth Sensor Pick-Up: FeaturesmcarrillogÎncă nu există evaluări

- Sensor Selecccion Magneto-ResistivosDocument10 paginiSensor Selecccion Magneto-ResistivosMarco Martinez SantiagoÎncă nu există evaluări

- Micro EpsilonDocument36 paginiMicro EpsilonOrnélio ClossÎncă nu există evaluări

- Micropulse Linear Transducer: Sensors WorldwideDocument12 paginiMicropulse Linear Transducer: Sensors WorldwideAlexander GochevÎncă nu există evaluări

- Catalog ION 6200Document12 paginiCatalog ION 6200eltromeÎncă nu există evaluări

- UK HO1 Speed Range DSDocument6 paginiUK HO1 Speed Range DSIsabelaSandovalÎncă nu există evaluări

- ASC DriveBay BrochureDocument2 paginiASC DriveBay Brochureaudy2010Încă nu există evaluări

- RSF Electronik MS3x Series CatalogDocument20 paginiRSF Electronik MS3x Series CatalogElectromateÎncă nu există evaluări

- Frequency Counter 1601Document15 paginiFrequency Counter 1601Miguel Angel Lazarte ChavezÎncă nu există evaluări

- Advanced Micro ScannerDocument2 paginiAdvanced Micro Scannersatyendrapatil88Încă nu există evaluări

- Electromagnetic-Flow Meter-Data SheetDocument8 paginiElectromagnetic-Flow Meter-Data SheetAhmed S ElalaftyÎncă nu există evaluări

- Renishaw Encoders RGH41 Series ReadheadDocument4 paginiRenishaw Encoders RGH41 Series ReadheadjuliangoalÎncă nu există evaluări

- D2440-01-01 Sem203p Data SheetDocument2 paginiD2440-01-01 Sem203p Data SheetbrusarpÎncă nu există evaluări

- MAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetDocument4 paginiMAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetSebastián Alexander Flores OroscoÎncă nu există evaluări

- Digital Transmitter 2010TD-TA SeriesDocument14 paginiDigital Transmitter 2010TD-TA SeriesMargaret DaughertyÎncă nu există evaluări

- Inductive SensorsDocument96 paginiInductive SensorsMoustapha SeyeÎncă nu există evaluări

- FT2 Measures Gas Flow & TemperatureDocument4 paginiFT2 Measures Gas Flow & TemperatureMonica AguilarÎncă nu există evaluări

- Product Data Sheet: M-Series® M5000Document4 paginiProduct Data Sheet: M-Series® M5000Carlos GilÎncă nu există evaluări

- Eds 3400Document2 paginiEds 3400Marlon CalixÎncă nu există evaluări

- Instruction Manual: The Magnetostrictive Position SensorsDocument19 paginiInstruction Manual: The Magnetostrictive Position SensorsJoe Santi LozanoÎncă nu există evaluări

- SR4000 Data SheetDocument8 paginiSR4000 Data Sheetn4arjun123Încă nu există evaluări

- General Specifications: EJA115E Low Flow TransmitterDocument12 paginiGeneral Specifications: EJA115E Low Flow TransmitterJorge GuerreroÎncă nu există evaluări

- Traductor de PresiuneDocument22 paginiTraductor de PresiuneCamelia PăduraruÎncă nu există evaluări

- Inclinometer Lca326t PDFDocument10 paginiInclinometer Lca326t PDFManasi NaikÎncă nu există evaluări

- Sensor Capacitivo Omron E2k-CDocument8 paginiSensor Capacitivo Omron E2k-CClaudiney de SantanaÎncă nu există evaluări

- LVDT Displacement SensorsDocument8 paginiLVDT Displacement SensorslelixÎncă nu există evaluări

- G Series GP GH Analog DPulseDocument17 paginiG Series GP GH Analog DPulsekqarlitosÎncă nu există evaluări

- Memograph rsg40 Ti133ren - 0707Document20 paginiMemograph rsg40 Ti133ren - 0707cristianmihaiÎncă nu există evaluări

- Wind Warning System Specifications and ModelsDocument8 paginiWind Warning System Specifications and Modelschristianson_87Încă nu există evaluări

- RISH EM 3490 SS - Digital Multifunctional Energy Meters With RS 485 CommunicationDocument6 paginiRISH EM 3490 SS - Digital Multifunctional Energy Meters With RS 485 CommunicationAarif PatelÎncă nu există evaluări

- D Agent - 1 - Work 135 S Upload 141618L1Document18 paginiD Agent - 1 - Work 135 S Upload 141618L1ap16484Încă nu există evaluări

- 177232D1Document6 pagini177232D1Muhammad Usman SindhuÎncă nu există evaluări

- Catalog Megger Mto210Document2 paginiCatalog Megger Mto210leha_pc3Încă nu există evaluări

- Hall Effect GT1Document2 paginiHall Effect GT1Luz RiosÎncă nu există evaluări

- Wide Bandwidth LVDT/RVDT Input 3B17: FeaturesDocument8 paginiWide Bandwidth LVDT/RVDT Input 3B17: FeaturesCuter HsuÎncă nu există evaluări

- Sensor de Toner Ts0524lbDocument5 paginiSensor de Toner Ts0524lbjaag93Încă nu există evaluări

- Proximity Sensors Capacitive High-Temperature Type ECH, M 30Document2 paginiProximity Sensors Capacitive High-Temperature Type ECH, M 30elyuyaÎncă nu există evaluări

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocument24 paginiTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarÎncă nu există evaluări

- ATV32HD15N4Document12 paginiATV32HD15N4gasm22Încă nu există evaluări

- General Specifications: EJA110E Differential Pressure TransmitterDocument14 paginiGeneral Specifications: EJA110E Differential Pressure TransmitterHaryadi WirawanÎncă nu există evaluări

- Servo Actuator POS 100Document2 paginiServo Actuator POS 100haggÎncă nu există evaluări

- STEP 7 - Working With STEP 7Document108 paginiSTEP 7 - Working With STEP 7saranjit1Încă nu există evaluări

- Accumulator PDFDocument25 paginiAccumulator PDFJuan Alejandro Cañas ColoradoÎncă nu există evaluări

- Pressure SwitchesDocument4 paginiPressure SwitcheshaggÎncă nu există evaluări

- ITI - Sim: SimulationDocument13 paginiITI - Sim: SimulationhaggÎncă nu există evaluări

- Abe33 22 2001 08 27Document12 paginiAbe33 22 2001 08 27haggÎncă nu există evaluări

- ITI - Sim: Simulation ApplicationDocument5 paginiITI - Sim: Simulation ApplicationhaggÎncă nu există evaluări

- ITI - Sim: Simulation ApplicationDocument3 paginiITI - Sim: Simulation ApplicationhaggÎncă nu există evaluări

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDocument30 paginiE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggÎncă nu există evaluări

- Pressure Switch For Panel Mounting: Cutout in The Panel Section A-ADocument4 paginiPressure Switch For Panel Mounting: Cutout in The Panel Section A-AhaggÎncă nu există evaluări

- Catalogo de AcumuladoresDocument65 paginiCatalogo de Acumuladoresingenioso23Încă nu există evaluări

- Abe32 10 2002 11 14Document4 paginiAbe32 10 2002 11 14haggÎncă nu există evaluări

- Piston Pressure Switch Hydraulic-ElectricDocument2 paginiPiston Pressure Switch Hydraulic-ElectrichaggÎncă nu există evaluări

- Oil Level Indicator AB-E 31-21: ND3 Sheet 1Document5 paginiOil Level Indicator AB-E 31-21: ND3 Sheet 1hagg0% (1)

- Thermostat AB-E 31-32: Adjustment Range 5 To 100°CDocument2 paginiThermostat AB-E 31-32: Adjustment Range 5 To 100°ChaggÎncă nu există evaluări

- Resistance Thermometer AB-E 31-17: 1 Area of ApplicationDocument3 paginiResistance Thermometer AB-E 31-17: 1 Area of Applicationhagg0% (1)

- Heat Exchanger AB-E 32-09: Oil / Water System: Single TubeDocument7 paginiHeat Exchanger AB-E 32-09: Oil / Water System: Single TubehaggÎncă nu există evaluări

- Glycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionDocument4 paginiGlycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionhaggÎncă nu există evaluări

- Float Switches AB-E 31-06: Without Protective Tube, With One or Two Switching Contacts Sheet 1Document6 paginiFloat Switches AB-E 31-06: Without Protective Tube, With One or Two Switching Contacts Sheet 1haggÎncă nu există evaluări

- SolenoidsDocument12 paginiSolenoidshaggÎncă nu există evaluări

- Abe21 14 2002 11 06Document2 paginiAbe21 14 2002 11 06haggÎncă nu există evaluări

- Technical Catalogue FPDocument100 paginiTechnical Catalogue FPhaggÎncă nu există evaluări

- 2-Conceptos y Principios GeneralesDocument65 pagini2-Conceptos y Principios GeneralesMichael Mejia MoraÎncă nu există evaluări

- D O Cetop 3/Ng6: Irectional Control Valves Ther Operator IDocument3 paginiD O Cetop 3/Ng6: Irectional Control Valves Ther Operator IhaggÎncă nu există evaluări

- The Oil Level Switch With Technical and Economical Advantages!Document2 paginiThe Oil Level Switch With Technical and Economical Advantages!haggÎncă nu există evaluări

- IGCDocument10 paginiIGChaggÎncă nu există evaluări

- Catalogo VL Cepto3 y Cepto4Document274 paginiCatalogo VL Cepto3 y Cepto4paula vergaraÎncă nu există evaluări

- Technical Catalogue: June JuneDocument9 paginiTechnical Catalogue: June JunehaggÎncă nu există evaluări

- AZ - D361BC00001 Evening Diary eCOA Handheld ScreenshotsDocument4 paginiAZ - D361BC00001 Evening Diary eCOA Handheld ScreenshotsIslam TahaÎncă nu există evaluări

- STRATOS MGM 160 Biogas Cogeneration UnitDocument11 paginiSTRATOS MGM 160 Biogas Cogeneration UnitGeorge PircalabuÎncă nu există evaluări

- Characterization of SPT Grain Size Effects in GravDocument9 paginiCharacterization of SPT Grain Size Effects in Gravstefanus fendisaÎncă nu există evaluări

- FLS DemonstrationDocument30 paginiFLS DemonstrationLeah UljerÎncă nu există evaluări

- Power Point Chapter - 15Document6 paginiPower Point Chapter - 15Shahwaiz Bin Imran BajwaÎncă nu există evaluări

- ISTQB Foundation Exam Format andDocument17 paginiISTQB Foundation Exam Format andapi-3806986Încă nu există evaluări

- Careerride Com Electrical Engineering Interview Questions AsDocument21 paginiCareerride Com Electrical Engineering Interview Questions AsAbhayRajSinghÎncă nu există evaluări

- Emenuhan Kebutuhan Nutrisi Balita Yang Dirawat Inap Di Rumah SakitDocument7 paginiEmenuhan Kebutuhan Nutrisi Balita Yang Dirawat Inap Di Rumah SakitAnnisa Nur Majidah100% (1)

- Rajant VHDC-24V-50W and VHDC-24V-50W-LC Data Sheet PDFDocument2 paginiRajant VHDC-24V-50W and VHDC-24V-50W-LC Data Sheet PDFMaxtreme0070% (1)

- MSI Packaging Questions: What Is Application Packaging?Document33 paginiMSI Packaging Questions: What Is Application Packaging?supraja shettyÎncă nu există evaluări

- Implementation Guide C2MDocument127 paginiImplementation Guide C2MLafi AbdellatifÎncă nu există evaluări

- IT0089 (Fundamentals of Analytics Modeling) : ExerciseDocument6 paginiIT0089 (Fundamentals of Analytics Modeling) : ExerciseAshley De JesusÎncă nu există evaluări

- Langdo Led Lighting Co.,LimitedDocument24 paginiLangdo Led Lighting Co.,LimitedRudi CressaÎncă nu există evaluări

- Computers & Geosciences Volume 37 Issue 2 2011 [Doi 10.1016%2Fj.cageo.2010.06.008] Faisal Shahzad; Richard Gloaguen -- TecDEM- A MATLAB Based Toolbox for Tectonic Geomorphology, Part 1- Drainage Network Preprocessing AnDocument11 paginiComputers & Geosciences Volume 37 Issue 2 2011 [Doi 10.1016%2Fj.cageo.2010.06.008] Faisal Shahzad; Richard Gloaguen -- TecDEM- A MATLAB Based Toolbox for Tectonic Geomorphology, Part 1- Drainage Network Preprocessing AnCristina CristeaÎncă nu există evaluări

- Eclipse PDFDocument18 paginiEclipse PDFanjaniÎncă nu există evaluări

- CSS 10-Summative TEST 1Document4 paginiCSS 10-Summative TEST 1herbert reblora100% (1)

- Analysis of Cylinder in AnsysDocument14 paginiAnalysis of Cylinder in AnsysSrinivas NadellaÎncă nu există evaluări

- Bio Data Cum Declaration Form of Scribe/WriterDocument1 paginăBio Data Cum Declaration Form of Scribe/WriterGajendrashih ParmarÎncă nu există evaluări

- FALLSEM2020-21 CSE2002 TH VL2020210106983 Reference Material III 27-Aug-2020 CFGPDANOTES PDFDocument79 paginiFALLSEM2020-21 CSE2002 TH VL2020210106983 Reference Material III 27-Aug-2020 CFGPDANOTES PDFAditya100% (1)

- Kinematic Analysis of Open-Source 5 DoF Robot Arm (#843139) - 1456378Document10 paginiKinematic Analysis of Open-Source 5 DoF Robot Arm (#843139) - 1456378Mohammad GamalÎncă nu există evaluări

- Fertilizer Information System For Banana PlantatioDocument5 paginiFertilizer Information System For Banana PlantatioHazem EmadÎncă nu există evaluări

- Modumate Raises $1.5M Seed Funding To Automate Drafting For ArchitectsDocument2 paginiModumate Raises $1.5M Seed Funding To Automate Drafting For ArchitectsPR.comÎncă nu există evaluări

- Bi Weekly Budget TrackerDocument22 paginiBi Weekly Budget TrackeranamarieÎncă nu există evaluări

- Communication Signal Processing I Mini-ExamDocument1 paginăCommunication Signal Processing I Mini-ExamSadiqur Rahaman SumonÎncă nu există evaluări

- Conversor para PFO (Fibra Optica Plastica)Document2 paginiConversor para PFO (Fibra Optica Plastica)madmax258Încă nu există evaluări

![Computers & Geosciences Volume 37 Issue 2 2011 [Doi 10.1016%2Fj.cageo.2010.06.008] Faisal Shahzad; Richard Gloaguen -- TecDEM- A MATLAB Based Toolbox for Tectonic Geomorphology, Part 1- Drainage Network Preprocessing An](https://imgv2-1-f.scribdassets.com/img/document/283133569/149x198/8e251c988e/1443552163?v=1)