Documente Academic

Documente Profesional

Documente Cultură

Effect of Polypropylene Fibre On Stability of Expansive Soil

Încărcat de

Innovative Research PublicationsTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Effect of Polypropylene Fibre On Stability of Expansive Soil

Încărcat de

Innovative Research PublicationsDrepturi de autor:

Formate disponibile

International Journal of Engineering Research

Volume No.5, Issue No.8, pp : 651-653

ISSN:2319-6890)(online),2347-5013(print)

1 August 2016

Effect of Polypropylene Fibre on Stability of Expansive Soil

Mr. Naranagowda M J 1, Mr. Rudresh Kumar P 2, Mr. Renuka Prasad K E 3 ,

Mr. Mahesha N 4, Mr. Sashidhar K M 5

Civil Engineering Department, Jain Institute of Technology, Davanagere, Karnataka, India-577005

naranagowda@gmail.com 1, rudri619@gmail.com 2, renukaprasad215@gmail.com 3, mahesh24@gmail.com 4,

shashidharkm1@gmail.com 5

Abstract : Soil stabilization can be explained as the alteration

of the soil properties by chemical or physical means in order to

enhance the engineering quality of the soil. The process of soil

stabilization helps to achieve the required properties in a soil

needed for the construction work. Soil improvement could

either be by modification or stabilization or both. Soil

modification is the addition of a modifier (cement, lime etc.) to

a soil to change its index properties, while soil stabilization is

the treatment of soils to enable their strength and durability to

be improved such that they become totally suitable for

construction beyond their original classification. Expansive

soils also known as swelling soils or shrink-swell soils are the

terms applied to those soils, which have a tendency to swell and

shrink with the variation in moisture content. As a result of

which significant distress in the soil occurs, causing severe

damage to the overlying structure. Soil possesses excellent

performance at the optimum moisture content or below the

optimum moisture content (dry side of optimum); however the

strength and stiffness of soils reduces drastically as the

moisture content increases beyond the optimum (wet side of

optimum).This study is carried out with an intention to

evaluate the effects of polypropylene fiber on the geotechnical

properties of the locally available black cotton soil (Expansive

soil) from Harihara city. Tests which are to be carried out on

the sample of soil dealt with consistency limits, specific gravity,

compaction, California bearing ratio, unconfined compressive

strength and shear strength. These tests are to be conducted at

both non-stabilized and stabilized states by adding 0%, 0.5%,

1%, 1.5%, 2%, 2.5%, 3% of polypropylene fibre. The results

show the effect of polypropylene fibre on geotechnical

properties of the soil samples strength.

Keywords: Stabilization, polypropylene fibre (PPF),

expansive soil, CBR, Unconfined.

I. I nt ro d uct io n

Expansive soils also known as swelling soils or shrink-swell

soils are the terms applied to those soils, which have a tendency

to swell and shrink with the variation in moisture content. Such

tendency of soil is due to the presence of fine clay particles,

Swell, when they come in contact with water, resulting in

alternate swelling and shrinking of soil due to which differential

settlement of structure takes place. As a result of which

significant distress in the soil occurs, causing severe damage to

the overlying structure.

During monsoons, these soils absorbs the water, swell, become

soft and their capacity to bear water is reduced, while in drier

seasons, these soils shrinks and become harder due to

evaporation of water. These types of soils are generally found in

arid and semi-arid regions of the world and are considered as a

IJER@2016

potential natural hazard, which if not treated well can cause

damages to not only to the structures built upon them but also

can cause loss of human life.

Black Cotton Soil are soils or soft bedrock that increases in

volume or expand as they get wet and shrink as they dry out. In

India this Expansive soil is called Black Cotton Soil. Colour of

this soil reddish brown to black and this helps for cultivation of

cotton, so is called black cotton swelling soil covers about 30%

of the land area in India. They are also commonly known as

bentonite, expansive, or Black Cotton soil. In terms of

geotechnical Engineering, Black Cotton soil is one which when

associated with as engineering structure and in presence of water

will show a tendency to swell or shrink causing the structure to

experience moments which are largely unrelated to the direct

effect of loading by the structure.

II. Material and Methodology

Black Cotton Soil: Black cotton soil which is expansive in

nature was collected from Harihara Taluk, Davanagere District,

and Karnataka.

Polypropylene fibre: Polypropylene fibre is the most widely

used in the laboratory testing of soil reinforcement. Currently,

PP fibres are used to enhance the soil strength properties, to

reduce the shrinkage properties and to overcome chemical and

biological degradation.

Methodology

Following laboratory tests have been carried out as per IS: 2720.

The tests were carried out both on natural soil and stabilized soil

with Lime and Quarry dust.

1.

2.

3.

4.

5.

6.

7.

8.

Differential Free Swell index IS 2720 Part-XI, 1972.

Grain size analysis IS 2720 Part 4, 1985

Specific gravity - IS 2720 Part-3, 1980

Liquid limit - IS 2720 Part-5, 1985

Proctor Compaction IS 2720 Part-8, 1983

CBR test IS 2720 Part-16, 1987

Unconfined compression IS 2720 Part-10, 1991

Direct Shear test - IS: 2720 Part-13, 1986

Sampling of Soil

The laboratory studies were carried out on the samples of Soil,

Soil + polypropylene fibre, for different percentage of Lime and

Quarry dust as shown in the below proportion by weight of the

soil. Soil Particulars

doi : 10.17950/ijer/v5s8/801

Page 651

International Journal of Engineering Research

Volume No.5, Issue No.8, pp : 651-653

ISSN:2319-6890)(online),2347-5013(print)

1 August 2016

Graph 3: Variation of maximum dry density

III. Results and Tables

Following tables and graphs gives the overall results of Specific

gravity, Liquid limit, Maximum dry density, Optimum moisture

content, CBR, Unconfined compressive strength.

Table 1: at end

Following Graph 1 shows the variation of specific gravity for

soil with reference mix of polypropylene fibre.

Following Graph 4 shows the variation of optimum moisture

content for soil with reference mix of polypropylene fibre..

Graph 4: Variation of optimum moisture content

Following Graph 5 shows the variation of CBR value for soil

with reference mix of polypropylene fibre..

Graph 1: Variation of specific gravity

Following Graph 2 shows the variation of liquid limit for soil

with reference mix of polypropylene fibre..

Graph 5: Variation of CBR value

Following Graph 6 shows the variation of unconfined

compressive strength for soil with reference mix of

polypropylene fibre..

Graph 2: Variation of liquid limit

Following Graph 3 shows the variation of maximum dry density

for soil with reference mix of polypropylene fibre..

Graph 6: Variation of unconfined compressive strength

IJER@2016

doi : 10.17950/ijer/v5s8/801

Page 652

International Journal of Engineering Research

Volume No.5, Issue No.8, pp : 651-653

IV. Conclusions

1. Specific gravity of BC soil decreased with the addition of

polypropylene fibre.

2. Maximum dry density (MDD) is observed at soil sample 5 for

addition of polypropylene fibre. Further addition of it, MDD

value decreased. By this it indicates that the, optimum value

would be soil sample 5.

3. Shear parameters such as cohesion, C decreased and angle of

shearing resistance, increased at soil sample 5 compared to

natural soil.

4. The Maximum CBR value is 4.00% which is achieved by soil

sample 4.

5. The maximum compression test value is 8.88 Kg/cm2 which is

achieved by soil sample 5.

So, from our project soil sample 4 and soil sample 5 will give the

better Engineering properties on the addition of admixture.

References

i. Abhinav Nangia, Sudhir Nigam, Dharmendra Kumar,

Shailendra Tiwari, Effect of Polypropylene Fibre on the Strength

Characteristics of the Soils along the Yamuna River Bank in Delhi

City.

ii. Ayyappan S., Hemalatha K. and Sundaram M., June

[2010], Investigation of Engineering Behavior of Soil,

Polypropylene Fibers and Fly Ash -Mixtures for Road

Construction.

iii. Bowles J.E., 1996, Foundation Analysis and Design, 5 th

Edition, McGraw Hill Pub. Co. New York.

iv. Mona Malekzadeh, Huriye Bilsel, 2012, Effect of

Polypropylene Fiber on Mechanical Behaviour of Expansive Soils.

v. Phani Kumar. V, Naga Bharath C.H., Ganga D., Swathi

Priyadarsini P., January 2015, Experimental Investigation on

California Bearing Ratio (CBR) For Stabilizing Silty Sand with Fly

Ash and Waste Polypropylene.

ISSN:2319-6890)(online),2347-5013(print)

1 August 2016

vi. Punmia B.C., Ashok Kumar Jain, Arun Kumar Jain, Soil

Mechanics and Foundations, Laxmi Publication (P) LTD. 16 th

Edition, 1980.

vii. Sachin N. Bhavsar, Ankit J. Patel, Effect of waste material

on swelling and shrinkage properties of clayey soil.

viii. Twinkle S., Sayida M.K., December 2011, Effect of

polypropylene fibre and lime admixture on engineering properties of

expansive soil.

IS Codes:

i.

IS: 2720 (Part 3) (1980). Methods of Test for Soils:

Determination of Specific Gravity, Bureau of Indian Standards, New

Delhi, India

ii.

IS: 2720 (Part 4) (1985). Methods of Test for Soils:

Determination of Grain Size Analysis, Bureau of Indian Standards,

New Delhi, India

iii.

IS: 2720 (Part 5) (1985). Methods of Test for Soils:

Determination of Liquid and Plastic Limit, Bureau of Indian

Standards, New Delhi, India.

iv.

IS: 2720 (Part 40) (1977). Methods of Test for Soils:

Determination of Free Swell Index of Soils, Bureau of Indian

Standards, New Delhi, India

v.

IS: 2720 (Part 7) (1980). Methods of Test for Soils:

Determination of Water Content-Dry Density Relation Using Light

Compaction, Bureau of Indian Standards, New Delhi, India

vi.

IS: 2720 (Part 16) (1987). Methods of Test for Soils:

Determination of CBR Value, Bureau of Indian Standards, New Delhi,

India

vii.

IS: 2720 (Part 3) (1980). Methods of Test for Soils:

Determination of Unconfined Compression Strength, Bureau of Indian

Standards, New Delhi, India.

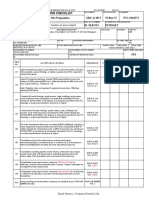

Table 1: Overall results of Experiments.

IJER@2016

doi : 10.17950/ijer/v5s8/801

Page 653

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Original Three ChapterDocument45 paginiOriginal Three ChapterNiyobuhungiro DominiqueÎncă nu există evaluări

- Basic Notes and Interview QuestionsDocument50 paginiBasic Notes and Interview QuestionsRaheel AliÎncă nu există evaluări

- Case Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageDocument6 paginiCase Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageInnovative Research PublicationsÎncă nu există evaluări

- The Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestDocument5 paginiThe Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestInnovative Research PublicationsÎncă nu există evaluări

- Power Transformer Protection Using Fuzzy Logic Based ControllerDocument5 paginiPower Transformer Protection Using Fuzzy Logic Based ControllerInnovative Research PublicationsÎncă nu există evaluări

- Computational EconomicsDocument2 paginiComputational EconomicsInnovative Research PublicationsÎncă nu există evaluări

- 3D Modeling of Complex Structure Based On AutoCAD VBADocument3 pagini3D Modeling of Complex Structure Based On AutoCAD VBAInnovative Research PublicationsÎncă nu există evaluări

- Information EngineeringDocument2 paginiInformation EngineeringInnovative Research PublicationsÎncă nu există evaluări

- Surveillance NetworksDocument2 paginiSurveillance NetworksInnovative Research PublicationsÎncă nu există evaluări

- Role of Coaching Institutes in IndiaDocument5 paginiRole of Coaching Institutes in IndiaInnovative Research PublicationsÎncă nu există evaluări

- Online Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Document2 paginiOnline Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Innovative Research PublicationsÎncă nu există evaluări

- Wearable ComputingDocument3 paginiWearable ComputingInnovative Research PublicationsÎncă nu există evaluări

- Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesDocument3 paginiComparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesInnovative Research PublicationsÎncă nu există evaluări

- Computational ElectromagneticsDocument3 paginiComputational ElectromagneticsInnovative Research PublicationsÎncă nu există evaluări

- Information Security in Cloud Computing: A Systematic Literature Review and AnalysisDocument6 paginiInformation Security in Cloud Computing: A Systematic Literature Review and AnalysisInnovative Research PublicationsÎncă nu există evaluări

- CFD Analysis of A 210 MW Tangential Fired BoilerDocument6 paginiCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsÎncă nu există evaluări

- Experimental Study About Soil Improvement With Glass FibersDocument5 paginiExperimental Study About Soil Improvement With Glass FibersInnovative Research PublicationsÎncă nu există evaluări

- A Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiDocument6 paginiA Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiInnovative Research PublicationsÎncă nu există evaluări

- Consultancy Service For Detailed Engineering Design For Abu Hamad - Karima RoadDocument28 paginiConsultancy Service For Detailed Engineering Design For Abu Hamad - Karima RoadAfolabi OladunniÎncă nu există evaluări

- HRB - CompactionDocument92 paginiHRB - CompactionyawhgihÎncă nu există evaluări

- Saic Q 1011Document2 paginiSaic Q 1011Shazab NawazÎncă nu există evaluări

- Indian Standard: Code of Practice For Use of Screed Board Concrete VibratorsDocument10 paginiIndian Standard: Code of Practice For Use of Screed Board Concrete VibratorsRajashekar.PÎncă nu există evaluări

- Tension Cracks in A Compacted Clay Embankment: Technical NoteDocument4 paginiTension Cracks in A Compacted Clay Embankment: Technical NoteAminulIslamÎncă nu există evaluări

- Best Practice Guideline 2 Labour-Based Construction Methods For EarthworksDocument23 paginiBest Practice Guideline 2 Labour-Based Construction Methods For EarthworksdmeharyÎncă nu există evaluări

- Is.13094.1992 Ground ImprovementDocument15 paginiIs.13094.1992 Ground ImprovementHajarath Prasad AbburuÎncă nu există evaluări

- Asphalt Foamed MixDocument13 paginiAsphalt Foamed MixCristian OJÎncă nu există evaluări

- Pbq-2Document14 paginiPbq-2Ir Ahmad AfiqÎncă nu există evaluări

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 paginiWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainÎncă nu există evaluări

- Date: JULY 25 2019 Project: Two-Storey House Subject: Cost EstimatesDocument1 paginăDate: JULY 25 2019 Project: Two-Storey House Subject: Cost EstimatesRM DM GonzalesÎncă nu există evaluări

- Standard Proctor TestDocument8 paginiStandard Proctor TestGrace OdiamarÎncă nu există evaluări

- PROJECT NO:61-2014 Boq For Materials & Workmanship International Park Office BuildingDocument73 paginiPROJECT NO:61-2014 Boq For Materials & Workmanship International Park Office Buildingaya osmanÎncă nu există evaluări

- Lecture 3 Design of Flexible and Rigid PavementsDocument47 paginiLecture 3 Design of Flexible and Rigid PavementsGriffithsÎncă nu există evaluări

- SAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioDocument3 paginiSAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioAbdul Hannan0% (1)

- 14-Appendix-A-Geotech-Bridge - by Terraprobe 2019Document34 pagini14-Appendix-A-Geotech-Bridge - by Terraprobe 2019Chachi CÎncă nu există evaluări

- Stabilization of Black Cotton SoilDocument44 paginiStabilization of Black Cotton SoilBhavya N Kotian100% (9)

- A Review On Effects of Stabilizing AgentsDocument7 paginiA Review On Effects of Stabilizing AgentsGabriel SalgadoÎncă nu există evaluări

- STP24222S Effect of Aggregate Size and Other Factors On Refusal Density of Asphalt Concrete by Vibratory CompactionDocument13 paginiSTP24222S Effect of Aggregate Size and Other Factors On Refusal Density of Asphalt Concrete by Vibratory Compactionanant11235Încă nu există evaluări

- L-8 Collapsible SoilsDocument27 paginiL-8 Collapsible SoilsAshebirÎncă nu există evaluări

- Granular Sub-Base (GSB) - Specification and Construction ProcedureDocument6 paginiGranular Sub-Base (GSB) - Specification and Construction ProcedureKumar SachinÎncă nu există evaluări

- Syllabus For: Applied Mathematics-III (Civil Engineering) Unit - I: Fourier Series (06Hrs)Document28 paginiSyllabus For: Applied Mathematics-III (Civil Engineering) Unit - I: Fourier Series (06Hrs)girirajvyas2Încă nu există evaluări

- Sand DensityDocument2 paginiSand DensityChowdhury PriodeepÎncă nu există evaluări

- Construction Material and Methods in AfghanDocument54 paginiConstruction Material and Methods in AfghanVictor394100% (1)

- CM & CD EstimateDocument130 paginiCM & CD EstimateSaiteja PanyamÎncă nu există evaluări

- PT 2023 Past QuestionDocument7 paginiPT 2023 Past QuestionTSOG MHÎncă nu există evaluări

- Diagnostic Test (Question)Document20 paginiDiagnostic Test (Question)Jomar D. MarquezÎncă nu există evaluări

- Whitetopping NRRDADocument78 paginiWhitetopping NRRDAsombansÎncă nu există evaluări