Documente Academic

Documente Profesional

Documente Cultură

Asce 6005 9780784480021

Încărcat de

shadabg04Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Asce 6005 9780784480021

Încărcat de

shadabg04Drepturi de autor:

Formate disponibile

Selected Papers from the Proceedings of the

Fourth Geo-China International Conference

Geotechnical Special

Publication No. 259

Behavior of Geomaterials

and Foundations for Civil

Infrastructure Applications

Edited by

Behzad Fatahi, Ph.D.

Tamer Sorour, Ph.D.

Zhen Leng, Ph.D.

GEOTECHNICAL

SPECIAL

PUBLICATION

NO.

259

GEO

O-CHINA

H A 2016

BEHAVIIOR OF GEOMATTERIALSS AND FO

OUNDAT

TIONS

FOR CIVIL INFRASTR

N

TRUCTUR

RE APPL

LICATION

NS

SE

ELECTED PAPERS FROM TH

HE PROCE

EEDINGS OF THE F

FOURTH

GE

EO-CHINA

A INTERN

NATIONA

AL CONFE

ERENCE

July 2527,

2

20116

Shandong, Chinna

SPON

NSORED BY

Y

Shando

ong Univerrsity

Shando

ong Deparrtment of T

Transportattion

University of Oklahhoma

Chineese Nation

nal Sciencee Foundatioon

Geo--Institute of

o the American Socieety of Civiil Engineerrs

ED

DITED BY

Behzad

d Fatahi, Phh.D.

Tamer Sorour, Phh.D.

Zhen Leng, Ph.D

D.

Published

P

by

b the Amerrican Societyy of Civil En

ngineers

Published by American Society of Civil Engineers

1801 Alexander Bell Drive

Reston, Virginia, 20191-4382

www.asce.org/publications | ascelibrary.org

Any statements expressed in these materials are those of the individual authors and do not

necessarily represent the views of ASCE, which takes no responsibility for any statement

made herein. No reference made in this publication to any specific method, product, process,

or service constitutes or implies an endorsement, recommendation, or warranty thereof by

ASCE. The materials are for general information only and do not represent a standard of

ASCE, nor are they intended as a reference in purchase specifications, contracts, regulations,

statutes, or any other legal document. ASCE makes no representation or warranty of any

kind, whether express or implied, concerning the accuracy, completeness, suitability, or

utility of any information, apparatus, product, or process discussed in this publication, and

assumes no liability therefor. The information contained in these materials should not be used

without first securing competent advice with respect to its suitability for any general or

specific application. Anyone utilizing such information assumes all liability arising from such

use, including but not limited to infringement of any patent or patents.

ASCE and American Society of Civil EngineersRegistered in U.S. Patent and Trademark

Office.

Photocopies and permissions. Permission to photocopy or reproduce material from ASCE

publications can be requested by sending an e-mail to permissions@asce.org or by locating a

title in ASCE's Civil Engineering Database (http://cedb.asce.org) or ASCE Library

(http://ascelibrary.org) and using the Permissions link.

Errata: Errata, if any, can be found at http://dx.doi.org/10.1061/9780784480021

Copyright 2016 by the American Society of Civil Engineers.

All Rights Reserved.

ISBN 978-0-7844-8002-1 (PDF)

Manufactured in the United States of America.

Geo-China 2016 GSP 259

iii

Preface

As a result of increasing and continuous social and infrastructural growth, appropriate

ground for living and development becomes progressively scanty. Thus, engineers

have been considering constructing buildings and infrastructure at locations with less

favorable geotechnical conditions and in some cases in seismically active regions.

Therefore, proper understanding of the soil behavior has become significantly

important to optimize the design and construction of foundations. This Geotechnical

Special Publication (GSP) contains 30 papers that were accepted and presented at the

GeoChina International Conference on Sustainable Civil Infrastructures: Innovative

Technologies for Severe Weathers and Climate Changes, held in Shandong, China on

July 25-27, 2016. Major topics covered in this GSP are dynamic behavior of soils and

foundations, and physical, numerical, constitutive modeling of soil behavior. The

overall theme of the GSP is Behaviour of Geomaterials and Foundations for Civil

Infrastructure Applications, and all papers address different research findings of this

theme. It provides an effective mean of sharing recent technological advances,

engineering applications and research results among scientists, researchers and

engineering practitioners. All abstracts and full papers have been peer-reviewed prior

to their acceptance and inclusion in this publication. We are most grateful to all

authors and reviewers who have contributed to this Geotechnical Special Publication.

ASCE

Geo-China 2016 GSP 259

iv

Contents

Offshore Foundations Applied to Renewable Energy Infrastructure (RES) ........ 1

Luisa N. Equihua-Anguiano, Marcos Orozco-Caldern, Carlos Chavez-Negrete,

and Jos Roberto Prez-Cruz

Study on the Property and Analysis of DX Pile Bearing Capacity ........................ 9

Po Lin Chen, Da-Wei Jian, De-Xin He, and Dave Ta-Teh Chang

Influence of Soft Soil Shear Strength on the Seismic Response of Concrete

Buildings Considering Soil-Structure Interaction ................................................. 17

Ruoshi Xu, Behzad Fatahi, and Aslan S. Hokmabadi

Validation of the Structural Analysis by PLAXIS2D Geotechnical Software ...... 25

Mahbubeh Mortezaee and Ali Akhtarpour

Nonlinear Behavior of a 2 2 Pile Group under Rotating Machine-Induced

Vertical Vibrations ................................................................................................... 33

S. Biswas and B. Manna

Pile-Soil Interactions under Thermo-Mechanical Conditions Imposed by

Geothermal Energy Piles in Sand ........................................................................... 41

Rajni Saggu and Tanusree Chakraborty

Experimental Study on the Dynamic Response of PHC Pipe-Piles in

Liquefiable Soil ......................................................................................................... 49

Fuyun Huang, Haimin Qian, and Yizhou Zhuang

The Elastodynamic Interaction of a Rigid Circular Foundation Embedded

in a Functionally Graded Transversely Isotropic Half-Space .............................. 57

Reza Yaghmaie and Hamidreza Asgari

Axisymmetric Vibration of an Elastic Circular Plate in an

Inhomogeneous Half-Space...................................................................................... 65

Reza Yaghmaie and Hamidreza Asgari

Numerical Study on a Novel Vibration Screening Technique Using

Intermittent Geofoam ............................................................................................... 73

M. Majumder and P. Ghosh

Seismic Resistance of Batter Pile Foundations in Peaty Soft Ground ................. 81

Koichi Tomisawa and Koichi Isobe

ASCE

Geo-China 2016 GSP 259

Variation in a Shear Modulus of Enzyme-Treated Soil under Cyclic

Loading ...................................................................................................................... 88

Ansu Thomas, R. K. Tripathi, and L. K. Yadu

Numerical Modeling of a Dynamic PileSoil Interaction in Layered Soil

Media ......................................................................................................................... 96

Mohsen Mohammadizadeh and Moein Mohammadizadeh

Study on the 3D Nonlinear Artificial Boundary of Viscoelastic Media with

the Standard Linear Solid Model .......................................................................... 104

Bo Zhang, Xueying Yang, Jie Li, Wentao Dong, Ruisong Pan, Weimin Yang,

Lei Yang, and Dunfu Zhang

Shaking Table Investigation on the Seismic Failure Mode of PHC

Pipe-Piles Considering Liquefaction ..................................................................... 108

Xingwu Wen, Jiesheng Zheng, Fuyun Huang, and Haimin Qian

Influence of Shallow Foundation Characteristics on the Seismic

Response of Mid-Rise Buildings Subjected to Strong Earthquakes .................. 117

Quoc Van Nguyen, Behzad Fatahi, and Aslan S. Hokmabadi

Characterization of Freezing Fresh Concrete by Multiple Non-Destructive

Methods ................................................................................................................... 125

Yan Liu, Junliang Tao, Xinbao Yu, Zhen Liu, and Xiong (Bill) Yu

The Influence of Pile Cap to p-y Curves under Lateral Loads .......................... 136

Shen-Kun Yu, Zhi Zhang, and Honghua Zhao

Multi-Scale Analysis of Deformation Modes in Granular Material Using a

Dynamic Hybrid Polygonal Finite Element-Discrete Element Formulation .... 144

Brandon Karchewski, Peijun Guo, and Dieter Stolle

A Novel Model to Simulate the Behaviour of Cement-Treated Clay under

Compression and Shear ......................................................................................... 152

Lam Nguyen, Behzad Fatahi, and Hadi Khabbaz

Chemo-Mechanical Approach to Modelling the Expansive Behavior of

Sulfate Bearing Soils: The Role of Crystallization Pressure in

Ettringite Formation .............................................................................................. 159

Pawan Sigdel and Liang Bo Hu

Analysis of the Effect of Stiffening at the Top of a Single Granular Pile

with a Stress-Dependent Deformation Modulus .................................................. 167

K. S. Grover and J. K. Sharma

ASCE

Geo-China 2016 GSP 259

Finite Element Analysis of Laterally Loaded Piles in Clays ............................... 175

Fath Elrahman E. Nur Eldayem and Yahia E.-A. Mohamedzein

Analysis of Ring Foundation Systems Resting on an Anisotropic Elastic Soil

Medium Subjected to Working Compressive and Tensile Loads ...................... 183

Avishek Nath, V. Srinivasan, and Priyanka Ghosh

3-D Analysis of a Piled-Raft Foundation Subjected to Vertical and Lateral

Loads ........................................................................................................................ 193

Nasr E. Nasr and Tamer M. Sorour

Research on a Calculation Method and Three-Dimensional Simulation of a

High-Filled Embankment Rheological Settlement .............................................. 201

Zhi-Chao Wang, Du-Min Kuang, Tao Zhao, Ying-She Luo, and Wei-guo Wang

Dynamic Characteristics Study of Geosynthetic-Reinforced Soil under

Cyclic Loading ........................................................................................................ 210

Wei Shi, Tao Lu, Longlong Zhang, and Yue Pan

Transitional Plasticity Compression Model for Clays ........................................ 217

Gyan Vikash

Numerical Behavior of Reinforced Soil by Rigid Inclusion ................................ 225

Samia Boussetta, Mounir Bouassida, and Mondher Zouabi

Study of the Behavior of Tunis Soft Clay ............................................................. 233

Mnaouar Klai and Mounir Bouassida

ASCE

vi

Geo-China 2016 GSP 259

Offshore Foundations Applied to Renewable Energy Infrastructure (RES)

Luisa N. Equihua-Anguiano1; Marcos Orozco-Caldern2; Carlos Chavez-Negrete1;

and Jos Roberto Prez-Cruz1,3

1

Professor, Civil Engineering, UMSNH Univ., Felicitas del Ro, Morelia, Mich. Mexico. E-mail:

nicteea@yahoo.com.mx; cachavez@umich.mx

2

Specialist Engineer, Cd. del Carmen, Campeche, Mexico. E-mail: marcos.orozco.c@outlook.com

3

Conacyt Research Fellow. E-mail: jrperezcr@conacyt.mx

Abstract: New sources of energy are necessary today to totally avoid the oil

dependence. People around the world are researching on renewable energy systems

(RES). In this sense, we present an overview of the current status of the energy

production, based on RES technologies, in Mexico. In addition, a typical yield failure

envelope obtained with RS3 in 3D is included. The main objective is to present this

envelope, which has the special soil characteristics, found in sea sediments.

Additionally, we present a response spectrum, since earthquakes are events that

frequently impact the infrastructure, making the design always dependant on transient

events The time histories of acceleration, used to obtain the spectrum, correspond to

earthquakes localized in the area of the Gulf of Mexico.

INTRODUCTION

Worldwide oil dependence involves high economic and environmental costs due to

rising use of fuels and derivative and the declining global reserves. One of the main

disadvantages for oil exploration is the greater water depth, which is reflected in

difficulties to achieve special infrastructure. Renewable energies (RES) are a

challenge for economics and clean energy sources in the world. Countries like Mexico

require future developments of this kind of energy to support the demand growth. For

this, it is necessary to consider the offshore wave and wind potential besides to its

onshore potential. Developing RES require of many engineering disciplines and

Geotechnics is closely linked to the development of these. Suction caissons are an

excellent alternative for offshore wind turbines. These foundations are widely used for

oil and gas industry. There are many studies of the suction caisson used in deep

waters, nevertheless, few studies have been developed for wind turbines.

RENEWABLE ENERGY

Renewable energies are defined as those practically limitless sources respect to the

human lifetime and whose use is technically feasible. General RES classification can

be divided in two types: tidal and wind energies.

ASCE

Geo-China 2016 GSP 259

Types of wind turbines

There are two main systems of wind turbines (WT), based on axes structures:

horizontal (HAWTs) and vertical (VAWTs), being HAWTs the most frequently used.

From the point of view of Civil Engineering, the WT design needs a study of soilfoundation interaction, by using the environmental forces. Figure 1a depicts the typical

loads used in the design.

Foundations for offshore wind turbines

Offshore turbines require special foundations for stability. Worldwide, the monopile

foundations have dominated offshore wind structures (Fig 1b), followed only by the

gravity bases (Fig 1e). Monopod or tripod/tetrapod are used as shown in Figures 1c

and 1d, with piles as a foundation system. Suction caissons may be used as a

foundation for offshore wind turbines due to its simple installation procedure and

other advantages. They have been mainly used in clays for oil/gas industry, whose

efficiency in offshore areas is widely known.

Mexico Production

Power generation in Mexico is dominated by thermoelectric, using fossil fuels. Up

today, the power generation based in renewable energy covers only 2.3% of the total

electricity generation capacity (SENER, 2011) with an installed electrical capacity of

18,716 MW, while the wind potential is estimated at 71,000 MW (Economy, SD,

2012).

GEOTECHNICAL AND STRUCTURAL CONSIDERATIONS

Soil parameters

Geotechnical parameters were obtained from a shear strength profile su=1.6z that

matches a CPT profile (Fig 2a), where z is the vertical depth. To obtain effective

parameters c and s, numerical simulations were done by varying both parameters,

until the real shear strength profile was reproduced, using Plaxis 2D. Shear profile is

considered for a linear increase and the elastic modulus E is constant with depth (z).

A linear perfect plastic Mohr-Coulomb model was used by considering a plastic

behavior and the water table in the surface of the numeric model. The geotechnical

parameters are showed in Table 1.

Anchor characteristics

Anchor's geometry is a cylinder, top closed-bottom opened, with a relationship

L/d=0.5 (Fig. 2b). The walls and the top anchor were simulated using liner elements

according to RS3, by considering a high stiffness to guarantee a rigid behavior. The

shaft friction and the stiffeners, inside the anchor, were not modeled. Points A and B

were taken as the references to obtain results of stresses and displacements.

ASCE

Geo-China 2016 GSP 259

(a)

(b)

(c)

(d)

(e)

FIG. 1. (a) Typical loads and dimensions for a 3.5 MW turbine (Villalobos-Jara,

2006) and Typical foundations for wind offshore turbines (b) monopod (c)

tripod/tetrapod (d) piled jacket tower and (e) gravity base as reported by

Theengineer (2015).

(a)

(b)

FIG. 2. (a) CPT profile (Colliat, 1999) and (b) scheme of suction caisson

(M=moment load, V=vertical load, H=horizontal load).

Table 1. Geotechnical effective parameters using Mohr Coulomb criterion

c (kN/m2) E (kN/m2)

OCR

Soil

s ()

sat (kN/m3)

Clay

17

27

1.6

9049

0.35

1.0

NUMERICAL MODELING

Mesh

Figure 3a shows the mesh used in all calculations, where it is observed a more

refinement in the anchor area to ensure a good accuracy. Boundaries conditions are

zero-displacement in the vertical plane (z axis), while the base of the mesh is fixed in

three coordinates (x, y and z). The mesh has an extension of 66 m in depth and has

150m x 150m. Figure 3b shows the Major principal strain-Sigma xz effective curve

obtained at the point A (Fig 5a), using H=5.9 MN, M=0 MN and V=0 MN.

ASCE

Geo-China 2016 GSP 259

(a)

(b)

FIG. 3. (a) RS3 mesh for L/d=0.5 (10951 elements) and (b) Major principal

strain - xz curve, H=5.9 MN, M=0 MN, L/d=0.5.

Yield failure envelope

The yield points obtained of numerical simulations were plotted in a plane and fitted

using equation (1) (Villalobos-Jara, 2006).

2

H M

H M

y=

1 = 0

+

2e

hV

i 0

i 0

i 0 dmV

i 0

hV

dmV

(1)

Where hi and mi represent the intersection of each ellipse (with the axis H/Vo and

M/dVo respectively); e is the eccentricity of the ellipse; H is the horizontal load; M is

the momentum; V0 corresponds to the maximum vertical load; and d is caisson

diameter.

FIG. 4. Numerical points and analytical yield failures envelope.

ASCE

Geo-China 2016 GSP 259

The yield envelope, obtained under different horizontal (H) and moment (M) loads,

was normalized respect to the maximum vertical load (Vo) and the caisson diameter (d)

as shown in Figure 4. The filled points are the numerical results obtained for different

H-M combinations and V=0 MN. The plot of the yield surface, using Eq. (1),

corresponds to the solid line. There is a good agreement between the two results.

Figure 5b shows the failure kinematics obtained in RS3, with load H and with H-M

loads combination.

(a)

(b)

Fig. 5. (a)Failure kinematics in 2D of a horizontal (H) loaded suction caisson load

applied at A and B points and (b) total suction caisson displacement.

GROUND SHAKING RESPONSE

Seismic performance of civil structures should be reviewed carefully. Recent

research in full scale models of monopiles in granular marine soils, subjected to a

lateral load (Hokmabady, et al., 2012), show results that may be applied in the design

practice. In the same way, effects of the seismic soil-pile-structure interaction in clays,

shown by Hokmabady, et al., 2014, determine the seismic response at a pile group

foundation, tested in a shaking table of superstructures fixed on the base. To obtain a

response spectrum, we performed an analysis by using the computer program EERA

(Bardet et al., 2000).

Soil properties of site

For our purpose, we use the shear strength profile su=1.6z. The best estimated profile

of shear wave velocity (Vs) was obtained by using an empirical correlation between su

and in-situ shear modulus Gmax (Taboada et al., 2012). The lower and upper limits Vs

profiles were determined by applying a factor scale of 0.85 and 1.15 respectively. We

note that the histories of accelerations, applied to the depth (where Vs = 750 m/s),

were required to extrapolate the properties of the soil below the bottom of the survey,

considering a linear variation with depth. Modulus reduction curves of G/Gmax and

variation of damping ratio , used in this study, correspond to the proposed by Vucetic

and Dobry (1991).

Accelerograms

For this work, we used the history accelerations control movements of the horizontal

components given by the earthquake recorded at Minatitlan station in 1971/10/31 (see

Fig. 6), with epicenter coordinates lat 15.27, long 93.9, and magnitude of 4.7 on the

Richter scale (BMDSF, 1997). Scale factors were applied to the component

accelerations to obtain earthquakes motions of a return period of 100 to 500 years.

ASCE

Geo-China 2016 GSP 259

Table 2 includes the six combinations analysis, the combination number can be

increased depending of seismic sources signals.

Site response results

Throughout the depth, we calculated the results of profiles variation of normalized

stiffness modulus (G/Gmax), shear strain (), the maximum deformation of the land and

the maximum acceleration (amax) were calculated throughout the depth. The transfer

functions, the history of accelerations and response spectrum were calculated at

different depths.

Figure 7 presents accelerations results, obtained from the analysis of seismic

response of offshore site. Specifically the histories of accelerations, calculated on the

surface of the seabed and at 120 m depth, correspond to the bottom of the soil profile

on the site. Figure 7a depicts the condition of the lower bound estimated soil

properties (0.85Vs) and a maximum acceleration of 0.025g (combination 4) in the

bedrock. It can be seen that the movement of the seabed level are amplified with

respect to the calculated at 120 m depth. Figures 7b and 7c show the combinations,

considered as the central and upper limit (factor of 1.0 and 1.15 for Vs), with

maximum acceleration in the bedrock of 0.03g and 0.025g; respectively.

(a)

(b)

FIG. 6. Acceleration time histories recorded ad Minatitlan station, 1971/10/31.

Table 2. Combinations for ground surface response

Acceleration

Earthquake

Combination

maximal (g)

Direction

Vs profile

motion

No.

bedrock

0.025

LB (0.85Vs)

4

0.030

Central (Vs)

Longitudinal

8

0.025

UB (1.15Vs)

6

MINA7110311

LB (0.85Vs)

0.025

13

0.030

Central (Vs)

Transversal

17

0.025

UB (1.15Vs)

15

We compared the calculated response spectrum with the response spectrum included

at the reference NRF-003-PEMEX-2007, that considers the design spectrum for a

return period of 200 years and a damping =5% for Bay of Campeche and Northern

Region of Gulf of Mexico. Figure 8 presents that the maximum spectral accelerations

are close to 0.29 s, and in some cases the spectral accelerations exceed the plateau

ASCE

Geo-China 2016 GSP 259

spectrum of reference NRF for the Bay of Campeche, hence the importance of

calculating the design spectrum.

(a)

(b)

(c)

FIG. 7. Acceleration time histories calculated at 120 m depth and sea bed. (a)

Combination 4, (b) Combination 8 and (c) Combination 6.

Spectral acceleration, g

Respose spectra computed

1

Bay of Campeche, NRF-003-2007

0.1

0.01

0.01

0.1

10

Period, sec

FIG. 8. Response spectra computed and comparison with NRF-003.

CONCLUSIONS

In this paper, a typical yield failure envelope obtained with RS3, considering special

soil characteristics of sea sediments has been presented. The failure points obtained

using RS3 has a good agreement with the ellipse obtained from equation (1).

Adhesion factor is not possible to simulate in RS3, so that the responses shown in

this article have a higher load capacity. It is necessary obtain envelopes that take into

ASCE

Geo-China 2016 GSP 259

account adhesion factor. Laboratory tests and full scale models are a necessary to

complement the seismic response of civil structures.

A study of the seismic response of an offshore site, taking into account both the

seismic and geotechnical site was made. The program used to calculate the seismic

response takes into account dimensional equivalent linear model. Three sets of soil

properties were studied through varying the profile of Vs and using two components of

acceleration in order to calculate the response spectra at the seafloor.

Mexico has great potential to develop renewable energy systems (RES), however it

requires more research on all the related fields.

REFERENCES

Bardet, J.P., Ichii, K. and Lin, C.H. (2000). EERA A computer program for

equivalent-linear earthquake site response analyses of layered soil deposits.

University of Southern California. Department of Civil Engineering.

BMDSF (1997). Base Mexicana de Datos de Sismos Fuertes, Sociedad Mexicana de

Ingeniera Ssmica, A.C.; Instituto de Ingeniera, UNAM; CFE; Fundacin ICA;

CIRES, A.C.; CENAPRED, Volumen II, Mxico.

Colliat, J.L. (1999). Caissons succion pour lancrage de structures ptrolires en

mer profonde. Revue Francaise de Gotechnique, 88:11-19.

Economa, S.D. (2012). "Informe anual de la Secretaria de Economa." Mxico;

Secretaria de Economa, PROMXICO.

Hokmabadi, A.S., Fatahi, B. and Samali, B. (2014). Phisical Modeling of Seismic

Soil-Pile- Structure Interaction for Buildings on Soft Soils, International Journal

of Geomecanics ASCE, ISSN 1532-3641/04014046(18), Vol. 15, april.

Hokmabadi, A.S., Fakher, A. and Fatahi, B. (2012). Full scale lateral behavior of

monopoles in granular marine soils, Journal of the Marine Structures, Elsevier,

Vol. 29, december, 198-210.

NRF-003-PEMEX.2007. Diseo y evaluacin de plataformas marinas fijas en el Golfo

de Mxico. Comit de Normalizacin de Petrleos Mexicanos y Organismos

Subsidiarios, enero 2007.

Plaxis 2D Version 8, Edited by R.B.J. Brinkgreve, Delf University of Technology &

Plaxis b.v., the Netherlands.

RS3 Version 1.017 64-bit, Copyright 2013-2015 Rocscience Inc., Toronto, Ontario,

Canada.

SENER, (2012). National Energy Balance 2011. Secretary of Energy Planning and

Technological Development, Mexico.

SSN (2013). Servicio Sismolgico Nacional, catlogo de sismos. UNAM, Instituto de

Geofsica, http://www.ssn.unam.mx/.

Taboada, V.M., Gan, K.C., Cruz, D., Barrera, P., Espinosa, E., and Carrasco, D.

(2012). Field Gmax relationships for Bay of Campeche clay. Memorias XXVI

Reunin Nacional de Mecnica de Suelos e Ingeniera Geotcnica, Sociedad

Mexicana de Ingeniera Geotcnica, A.C., Cancn, Quintana Roo, Mxico.

Villalobos-Jara, F.A. (2006). Model Testing of Foundations for Offshore Wind

Turbines. Thesis for the degree of Doctor of Philosophy, Oxford University, UK.

Vucetic, M. and Dobry, R. (1991). Effect of soil plasticity on cyclic response.

Journal of the Geotechnical Eng. Div., ASCE, Vol. 111, No. 1, January, 89-107.

ASCE

Geo-China 2016 GSP 259

Study on the Property and Analysis of DX Pile Bearing Capacity

Po Lin Chen1; Da-Wei Jian2; De-Xin He3; and Dave Ta-Teh Chang4

1

Assistant Professor, Dept. of Civil Engineering, Chung Yuan Univ., 200 Chung Pei Rd., Taoyuan 32023,

Taiwan, R.O.C. E-mail: hauer45680@yahoo.com.tw

2

Ph.D. Candidate, Dept. of Civil Engineering, Chung Yuan Univ., 200 Chung Pei Rd., Taoyuan 32023,

Taiwan, R.O.C. E-mail: davidjian520@yahoo.com.tw

3

The Inventor of DX Pile Technology, Beijing ZhongKuo Foundation Technology CO., LTD. E-mail:

dx-13@sohu.com

4

Professor, Dept. of Civil Engineering, Chung Yuan Univ., 200 Chung Pei Rd., Taoyuan 32023, Taiwan,

R.O.C. E-mail: ttc514ttc@yahoo.com.tw

Abstract: In this study, three sets of vertical static loading test for the performance of

DX piles (=600 mm) are implemented in Fangcheng Port Steel Plant Construction

Project (in Guangdong Province, PRC). Test results showed that three sets of DX pile

(600 mm), that were even though not to be plugged into the Moderately weathered

rock bed, but their ultimate bearing capacity are greater than or equal to () 9,800 kN

and tested settlements ranged in 21~24.54 mm, are better than the requirements of

original design of straight hole embedded Pile (800, plug-into-rock). Through the

Stress - Strain Gauge installed along the pile and pile bottom, we found that the major

bearing capacity of DX pile came from the bearing plate at highly weathered rock layer;

while the shared bearing capacity of pile bottom is less than 25% of total capacity.

Therefore, by using the DX pile, the piles are no longer need to be plugged into deeper

rock stratum. Through the above results, we can also infer that the impact of pile bottom

sediments of DX pile is less than cast-in-place pile.

INTRODUCTION

DX pile is a new type of variable cross-section pile technology, which is a multi-nodal

rotary drilling, squeezing and expanding cast-in-situ pile invented by the Chairman Mr.

He De-Xin of Beijing Zhongkuo Foundation Technology Co., Ltd. (named after the

inventor Mr. He De-Xin, hereinafter referred to as DX pile). Based on the traditional

hole-drilling cast-in-situ pile technique, DX pile forms its bearing mechanism by using

a dedicated rotary drilling equipment to squeeze and expand pile near the bottom into a

bearing plate shape then pour concrete, so as to be jointly supported by its pile body,

bearing plate and pile toe. Since the bearing plate increases effective bearing area of pile,

meanwhile the squeezing and expanding equipment compact the surrounding soil to

dense, thus the bearing capacity of DX pile can be greatly improved.

ASCE

Geo-China 2016 GSP 259

10

In comparison with the traditional squeezing and expanding pile technologies, this

rotary drilling, squeezing and expanding device has significant advantages, such as:

providing bilateral relative displacement and Dual hydraulic cylinders to drive the three

pairs of rotary drilling squeezing and expanding arms, always in contact with the

surrounding earth, to cut, roll and squeeze soil with little disturbance and relatively less

sediment; furthermore the bearing stratum of bearing plate can be selected depending on

ground conditions, with the advantages of high flexibility, adaptability, fast and safety

construction.

What is important is that DX pile is a new type of pile jointly supported by

multi-section side resistance (skin friction) and multi-layer-end resistance (end bearing).

Currently, its stress mechanism and calculation method are still in the exploratory phase.

With an increasingly wide application, the DX pile can greatly shorten the demand pile

length, reduce the consumption of concrete and save the construction period, thus it

appears a very broad application prospects. Due to competitive advantages, the DX pile

has been used in various fields of pile foundation projects and created great effects and

economic benefits. This case study will focus on the bearing features of DX pile, with

its application in the highly and moderately weathered rock layer. Chen F. and Chen L.

(2012)Chen L., Zhang Q. and Yuan X. (2012)Wang M., He D. and Tang S.(2012)

Geological Conditions of the Test Site

The test site is situated in the sea-filling area of cofferdam and Reclaimed sand.

Initially, the stretch of beaches and shallow sea had been filled, the soil layers are

described in a descending way as follows: (as shown in Table 1):

Table 1. Soil Parameter on Site

Soil

No

Classification

Clayey fill earth

Silty fine sand

Clayey soil

Loose

Moderately

compacted

Fluid plastic

and soft plastic

Completely

weathered

Strongly

weathered

Moderately

weathered

Completely weathered

muddy sandstone

highly weathered

muddy sandstone

Moderately weathered

muddy sandstone

11

12

13

Thickn

ess (m)

2.4-2.7

Max tested

skin friction

(kPa)

59

6.3-8.1

83

0.3-2.8

100

0.5-2.5

102

6.2-9.9

114

134

Max tested

bottom

friction (kPa)

12973

(1) Clayey fill earth: Purple-brown-gray, with plant roots, slightly wet, loose state with

a thickness of 2.7m.

ASCE

Geo-China 2016 GSP 259

11

(2) Silty fine sand: Yellow gray-gray-brownish gray, mechanical reclaimed seabed

sand, partly containing round gravel, coarse sand with shells, shell fragments;

rendering saturated, loose-slightly tight state, and with a thickness of 6.3m.

(3) Reclaimed clayey soil: Gray- brownish gray, mechanical reclaimed seabed formed

mud deposits, partly containing silty fine sand with shells, shell fragments;

rendering saturated, plastic flow-soft plastic state, and with a thickness of 2.8m.

(4) Completely weathered muddy sandstone: purple-grey purple and partially light grey

and grey black; folded with silty mudstone, shale, the main mineral components

including quartz, feldspar, clay minerals and sericite etc.; Cementation of iron and

mud; rock core rendered a soil-like state, and with a thickness of 2.5m.

(5) Highly weathered muddy sandstone: Purple-purple gray-partial light gray-dark

gray; folded with silty mudstone, shale, the main mineral components including

quartz, feldspar, clay minerals and sericite etc.; Cementation of iron and mud;

sand-like and moderately thick layered structure; rock core rendered earth-like and

clastic state, dehydration easy to crack into a chunky, and with a thickness of 9.9m;

(6) Moderately weathered muddy sandstone: Purple-purple gray-partial light gray;

folded with silty mudstone, shale, the main mineral components including quartz,

feldspar, clay minerals and sericite etc.; Cementation of iron and mud; sand-like

and moderately thick layered structure; rock core rendered long, short columnar or

block state (broken-intact state); dehydration easy to crack into a chunky; not

drilled through.

Allocation of Test Piles and Matters Concerned

As a reference, the Maximum Test Load of DX pile testing was scheduled not to

exceed 10000 kN; and the bearing capacity calculation and type design of DX pile is

conducted on the basis of geological exploration data to select a highly weathered rock

layer to act as bearing stratum of bearing plate and ensure that pile bottom is embedded

in the moderately weathered rock, and area from the bottom of bearing plate to the pile

toe should be embedded in the highly weathered rock at least 2.0 m (as shown in Figure

1). There were Six DX test piles to be set up on site, numbered #9-1, #9-2, #9-3 and

#9-7, #9-8, #9-9, to carry out this ultimate bearing capacity test of axially loaded

vertical pile, its relevant dimensions are as detailed in Table 2.

Table 2. Details of DX test pile

No.

#9-1

#9-2

#9-3

#9-7

#9-8

#9-9

ASCE

Pile

length(m)

29.1

29.1

23.0

36.6

31.0

25.3

Pile

diameter(m)

0.6

0.6

0.6

0.8

0.8

0.8

Bulbs

depth(m)

19

18

19

16

16

18

Bulbs

diameter(m)

1.4

1.4

1.4

2

2

2

Maximum test

load (kN)

pile failure or not

exceed 10000kN

not exceed

10000kN

Geo-China 2016 GSP 259

12

Precautions for the layout of test pile are as follows:

Name of soil layer

(1) The horizontal interval between two neighboring piles in x

& y direction are 20m and 8m. The pile top use stirrup

(10mm) with 150mm spacing (i.e. @ 150mm) and Fragmented stone filling soil

welded with wire fabrics and filled with concrete to make

smooth flat at the top of the pile.

Bowing and filling

powdered fine sand

(2) Attention should be paid to hole cleaning. Before hole

filling cohesive

cleaning the pump must be turned off to grind to smash Blowing andsoil

mud masses for 10 minutes, and then pumped it out of the

Powdered fine sand

ground surface.

Strongly weathered

(3) When the head of rotary drilling squeezing and expanding

sandstone

machine is laid down, it shall not be allowed to apply force

Moderately

if there is any obstacle. Instead, the head should be pulled

weathered sandstone

out, and inspect the causes for a solution to avoid the

hole to collapse and being buried.

FIG. 1. Layout of DX pile

(4) After each step of rotary drilling, squeezing and

bearing plate and pile toe

expanding, slurry should be added to maintain the

water head pressure in the hole.

(5) Filling factor for measuring pouring concrete quantity of DX pile should be greater

than 1.

(6) In each test pile, rebar stress gauges were installed with layers of 2m spacing (two

sets put in a layer); then a Load Cell was also installed at bottom of the pile.

(7) Construction quality should be controlled in accordance with the procedures,

regulations and technical requirements. (Refer to Table3)

(8) The pile testing adopted heaped load to provide reaction force.

(9) The 800 test piles are loaded according to the 1,000kN grade standard; the 600

test piles loaded according to the 700kN grade standard; twice of the grade load

was used in the first-level loading.

(10) Terminate test loading in case one of the following situations occurs:

a. If there is a steep decline segment of the decidable limit bearing force on the

Q-S Curve and the amount of settlement exceeds 40mm;

b. The amount of pile settlement is over twice of the condition of previous-level

load, and it cannot keep relatively stable after 24 hours;

c. When it has not reached the ultimate load but has reached the maximum test

load, also the settlement rate of the pile top has achieved the relatively stable

criteria (convergence).

d. Estimated ultimate bearing capacity has been reached.

Table 3. Quality control standards

Item

Number

1

2

3

ASCE

Item

Quality Control Standards

Hole location deviation

d/6-d/4 mm (d referring to pile diameter)

and not over 100mm

Hole diameter

deviation

Hole depth deviation

50mm

+300mm

Geo-China 2016 GSP 259

Plate diameter

deviation

Hole deviation

Slurry proportion

Slurry viscosity

8

9

Sand content of Slurry

Settlement thickness

13

-4%

<1%

<1.25g/cm3 (Within 500mm to bottom of

hole)

Funnel viscosity 28s (Within 500mm to

bottom of hole); Marsh funnel 30-45s

8% (Within 500mm to bottom of hole)

100mm

Analysis of Pile Testing Results

As shown in FIG. 2., FIG. 3. and FIG. 4., the testing results of three trial piles

(diameter 0.6 m, numbered # 9-1, # 9-2 and # 9-3) were plotted into axial force and

depth relationship diagram. It can be observed that pile axial force appeared plunged at

the location near the bearing plate, that bearing plate share a great part of the load, while

the bottom of the pile withstand only about 25% to 38% of load which can be speculated

that a small amount of displacement in pile bottom incurred. While observed from the

average pile skin friction and depth relationship diagram (as shown in FIG. 5, FIG. 6

and FIG. 7) it was found that nearby area of bearing plate provided more than 40% of

the pile skin friction resistance, but the friction resistance of the remaining area was

developed less than 60%.

ASCE

FIG. 2. Relationship between the pile

axial force and depth of DX pile

#9-1(600)

FIG. 5. Relationship between the

average pile skin friction and depth of

DX pile #9-1(600)

FIG. 3. Relationship between the pile

axial force and depth of DX pile

#9-2(600)

FIG. 6. Relationship between the

average pile skin friction and depth of

DX Pile #9-2 (600)

Geo-China 2016 GSP 259

FIG. 4. Relationship between the Pile

Axial Force and Depth of DX Pile #9-3

(600)

14

FIG. 7. Relationship between the

Average Pile Skin Friction and Depth

of DX Pile #9-3 (600)

Since the measured settlement of all the three piles was lower than 24.5mm, far lower

than the damage limit 40mm, and reached the piles bearing of 9,800kN, extremely close

to the maximum test load (10,000kN), the pile testing was suspended. And based on the

test results, the bearing of the test pile had reached 9,800kN, thus the axial

stress-resistance bearing value of the DX pile can be set as over 4,900kN. Accordingly,

the bearing plate installed in the highly weathered rock layer can effectively enhance the

bearing of the DX piles and reduce settlement.

With the results of three test piles (diameter 0.8 m, numbered # 9-7, # 9-8, # 9-9)

plotted as axial force and depth relationship diagram, their bearing capacity envelops

(as shown in FIG. 8, FIG. 9 and FIG. 10) are consistent with 0.6 m test pile (numbered #

9-1, # 9-2, # 9-3), thus pile axial force appeared plunged at the location near the bearing

plate, bearing plate shared a great part of the load, while the bottom of the pile bearing

further reduced to 18% ~ 25% of load which would cause a small amount of

displacement in pile bottom. While observed from the average Pile Skin Friction and

Depth relationship diagram (as shown in FIG. 11, FIG. 12 and FIG. 13), it can also be

found that the nearby area of bearing plate shared a great proportion of the Pile Skin

Friction which produces a small amount of displacement.

The settlement of all the these three piles were lower than 18.31mm, far lower than the

damage limit 40mm, and the piles had reached the maximum testing load of 10,000kN,

thus the tests were suspended. Whereas, according to these test results, the limit axial

stress-resistance bearing of the test pile can be estimated more than 10,000kN, and the

practice bearing capacity of the DX pile should be set as over 10,000kN.

The analysis of the soil layers of the piles testing showed that a bearing plate installed

on the strongly weathered rock layer can effectively enhance the bearing of pile and

reduce settlement. The reason is that the strongly weathered rock and the bearing plate

provide most of the bearing, which greatly reduces the skin friction development of the

pile body and thus suppress settlement.

ASCE

Geo-China 2016 GSP 259

15

FIG. 8. Relationship between the pile

axial force and depth of DX Pile

#9-7(800)

FIG. 11. Relationship between the

average pile skin friction and depth of

the DX Pile #9-7 (800)

FIG. 9. Relationship between the pile

axial force and depth of DX pile #

9-8(800)

FIG. 12. Relationship between the

average pile skin friction and depth of

DX pile #9-8 (800)

FIG. 10. Relationship between the Pile

Axial Force and Depth of DX Pile #9-9

(800)

FIG. 13. Relationship between the

Average Pile Skin Friction and Depth

of the Pile #9-9 (800)

CONCLUSIONS

1. According to the observed settlement and the axial force development, all the six test

piles did not really reach the limit bearing, so there was still large amount potential

ASCE

Geo-China 2016 GSP 259

bearing existed in the piles. However, the piles' bearing capacity based on the

theoretical calculation were lower than that of testing results, thus it is suggested that

the limit axial stress-resistance bearing of the test pile can be consistent with the pile

body strength based on the theoretical calculation.

2. Based on the comparison analysis between the two diameters of piles under the same

bearing condition, the bearing plate of 800mm pile provided stronger skin friction

force and had a smaller range of the bearing plate impact than the bearing plate of

600mm pile. It is speculated that the ratio between the diameter of the bearing plate

and the pile is related.

3. With the same bearing, it is possible to shorten the pile length or reduce pile diameter

by adopting DX pile, such as: using 600mm DX pile to meet the requirement of

10,000kN design load and replace the 800mm straight hole pile to achieve the

benefit of high-quality and low-cost construction.

4. The bearing plate installed in the highly weathered rock layer can significantly

enhance the bearing, and its pile end embedded on the moderately weathered rock

bed can meet the requirement of bearing and suppress settlement.

5. Based on the measurement of stress gauges installed in the pile body and the pile toe

of the DX pile, it is accounted that the bearing plate situated in the highly weathered

rock layer provided over 50% bearing, and contribution of the bearing at the pile toe

was less than 25% of the total bearing. Thus, there is no need to install large part of

DX pile in the moderately weathered rock bed. Meanwhile, the settlement of the pile

toe plays only little impact on the bearing of the DX pile, it is entirely different from

that of the straight-hole pile.

Acknowledgments

Thanks to President Mr. He De-Xin of Beijing Zhongkuo Foundation Technology Co.,

Ltd. for providing precious construction experience and professional advice.

References

Chen F. and Chen L. (2012), "Discussion on design method of DX pile." Engineering

sciences, vol. 14, No1, 60-64.

Chen L., Zhang Q. and Yuan X. (2012), "Numerical analysis on uplift bearing

characteristic of cast-in-situ DX pile." Engineering sciences, vol. 14, No1, 31-36.

Wang M., He D. and Tang S.(2012) "New pile foundation technology of 21 century:

DX pile." Engineering sciences, vol. 14, No1, 4-11.

ASCE

16

Geo-China 2016 GSP 259

17

Influence of Soft Soil Shear Strength on the Seismic Response of Concrete Buildings

Considering Soil-Structure Interaction

Ruoshi Xu1; Behzad Fatahi2; and Aslan S. Hokmabadi3

1

Ph.D. Candidate, School of Civil and Environmental Engineering, Univ. of Technology Sydney (UTS),

Sydney, Australia. E-mail: Ruoshi.Xu@student.uts.edu.au

2

Senior Lecturer, Geotechnical Engineering (Ph.D., CP.Eng.), School of Civil and Environmental

Engineering, Univ. of Technology Sydney (UTS), Sydney, Australia. E-mail: Behzad.fatahi@uts.edu.au

3

Geotechnical Engineer (Ph.D., CP.Eng.), Ove Arup & Partners, Hong Kong. E-mail: aslan.shokmabadi@arup.com

Abstract: Influences of undrained shear strength on seismic response of moment

resisting concrete building considering soil-structure interaction (SSI) have been studied.

A 15-storey building model resting on class Ee soil with different values of undrained

shear strength has been simulated through FLAC3D. Fully nonlinear dynamic analysis

under four different earthquakes including two far-field and two near-field recordings

has been conducted by direct method and results in terms of base shear, maximum

lateral displacement, inter-storey drift and spectral acceleration have been compared and

discussed. Results indicate that by increasing the undrained shear strength of the subsoil,

the superstructure experiences extra base shear under earthquake excitations due to SSI.

Furthermore, the maximum lateral displacements and inter-storey drifts of the

superstructure increase by adopting higher values for the undraied shear strength of the

subsoil. It is concluded that practicing engineers should treat soil properties gained from

field or laboratory tests with extreme care when dealing with numerical based seismic

design of the soil-structure systems.

INTRODUCTION

In recent decades, several studies have shown that superstructures resting on soft soil

are vulnerable to the effect of SSI (e.g. Hokmabadi et al. 2014; Fatahi et al. 2014). Also

fully nonlinear analysis of seismic soil-structure interaction (SSI) becomes feasible due

to the development of commercial computer analysis packages. During strong

earthquake excitations, significant soil damping is induced by both soil modulus

degradation and soil plastic flow, which influences the response of the superstructure.

Undrained shear strength is one of the essential soil properties and it is commonly

required when performing nonlinear numerical analysis as it governs soil plastic

behaviour. To obtain accurate undrained shear strength, either field or laboratory tests is

required. However, Kamei and Iwasaki (1995) pointed out that undrained shear strength

gained could be impacted by the mode of testing, boundary conditions, strain rate,

confining stress level, initial consolidation, state in-situ testing device and other

ASCE

Geo-China 2016 GSP 259

variables and therefore it is expected different test types produce different test results for

soil shear strength. This paper aims to investigate the influence of soft soils undrained

shear strength on the seismic response of moment resisting structures considering soilstructure interaction.

DYNAMIC ANALYSIS OF SOIL-STRUCTURE SYSTEM

Byrne et al (2006) highlighted the advantages of the fully nonlinear analytical methods

in simulating the dynamic SSI problems. These methods are capable to precisely model

nonlinearity in dynamic analysis of soil-structure systems and can follow the prescribed

constitutive model. Structural nonlinearity can also be captured in the fully nonlinear

methods. Accordingly, fully nonlinear analytical methods have been adopted in this

study to investigate the influence of undrained shear strength on seismic response of a

moment resisting concrete building. During solution process, specified limiting plastic

moment is assigned to the structural elements to simulate the elastic-perfectly plastic

structural behaviour. In addition, the damping of the system in numerical simulation

should be able to reproduce energy losses in natural system subjected to dynamic

loading. Wegel and Walther (1935) mentioned that energy dissipation is largely

hysteretic in nature soil and rock; therefore, hysteretic damping algorithm is necessary to

enable strain-dependent modulus and damping functions to be incorporated directly into

the numerical simulation. Apart from above mentioned, damping in soil arising from

plastic flow, especially for soft soil medium subjected to large seismic loading, should

also be taken into account by employing appropriate constitutive model in numerical

simulation.

NUMERICAL MODELLING

In this study, seismic soil-structure interaction analysis is conducted adopting direct

method which evaluates the dynamic response in a single step and can capture more

realistic behaviour for the soil-structure system in comparison with the substructure

method. Furthermore, time domain analysis is utilised to consider the nonlinear dynamic

responses, as recommended by Chu (2006). A three dimensional explicit finite

difference based program FLAC3D (Fast Lagrangian Analysis of Continua) version 5.0

has been employed in this study.

Structure and Soil Medium Model

A fifteen-storey moment resisting concrete building which comprises beam and shell

structural elements has been adopted. SAP2000 V14 has been utilised for the structural

design purpose. The specified compressive strength of concrete and concrete unit weight

are assumed to be 40MPa and 23.5kN/m3, respectively. All the structural sections of the

model have been designed based on inelastic method assuming elastic-perfectly plastic

behaviour by specifying a limiting plastic moment of the structural element. According

to AS/NZS1170.1-2002 (Permanent, imposed and other actions), permanent and

imposed loads are determined and applied to the structure model. It should be noted that

referring to ACI318-08 (2008), cracked sections for the reinforced concrete sections are

taken into account through multiplying second moment of area of the uncracked sections

ASCE

18

Geo-China 2016 GSP 259

19

(Ig) by

b cracked section

s

coeffficients (0.35

5Ig for beam

ms, 0.70Ig for columns aand 0.25Ig foor

slabss). Designed

d foundation comprises solid

s

elemennts with 16 m

meters in botth length and

width

h, and 1 meeter in depth

h. Four real earthquake rrecords show

wed in FIG 3 have beenn

appliied at the baase of the fo

oundation to perform dyynamic analyysis for fixedd-base casess.

Finallly, the strructural meembers are designed iin accordannce with A

AS3600-2009

(Ausstralian Stand

dard for Con

ncrete Structtures) in a w

way that the performancee level of thhe

struccture stays in

n the life saffe zone by limiting

l

the maximum innelastic inteer-storey drifft

to 1.5%. FIG 1a shows the dimensions

d

of

o the structture adoptedd in this studdy possessingg

the fundamental

fu

natural perio

od of 1.28 seeconds.

FIG 1 (a) Fixed

d-base system; (b) Soil--structure in

nteraction ssystem

Intterface elem

ments were placed betw

ween the fo

foundation aand the soiil surface to

incorrporate the different

d

mecchanical chaaracteristics of them, andd to capture any possiblle

uplifft and slidin

ng of the foundation du

uring shakinng excitationn. The adoppted interface

elem

ments are rep

presented by

y normal (kn) and shearr (ks) springss between tw

wo planes inn

contaact, where the

t shear strrength of th

he interface elements arre defined bby the MohrrCoullomb failuree criterion. The

T relativee interface m

movement iss controlled by interfacce

Normal andd shear spring

stiffn

ness values in

i the normaal and tangen

ntial (shear) directions. N

stiffn

ness values for

f interfacee elements of the soil-strructure moddel are set too ten times oof

the equivalent

e

sttiffness of th

he neighbourring zone (E

Eq. 1) basedd on the recoommendationn

by Rayhani

R

and Naggar

N

(200

08).

k

10

(1)

wherre, K and G are the bulk

k and shear modulus

m

of the neighboouring zone, respectivelyy,

and z

min is the smallest wid

dth of an adjoining zone in normal ddirection.

Acccording to the

t classificaation of AS1

1170.4-2007 (Earthquakke actions in Australia), a

soft soil

s represen

nting subsoill class Ee haas been seleccted in this sstudy. During simulationn,

Moh

hr-Coulomb model

m

has been

b

adopted

d to simulatee plastic flow

w in the soill elements aas

used by many reesearchers fo

or SSI analy

ysis (e.g. Connniff and Kiiousis, 2007, Hokmabaddi

et al.. 2014; Fataahi et al. 201

14). FIG 1b shows the ccharacteristiccs and dimennsions of thhe

soil medium

m

ado

opted in this study. The undrained

u

shhear strengthh has been aapplied in thhe

ASCE

Geo-China 2016 GSP 259

20

way that the strength increases with the depth of soil medium at a rate of 2.3 kPa/m (e.g

50 kPa on the surface and 120 kPa at the bottom of the soil medium). Thus, the average

undrained shear strengths for the soil medium are 65, 75, 85, 95 and 105 kPa. In addition,

a benchmark case, in which only the hysteretic damping of the soil is modelled (i.e. no

plastic flow), has been considered for the comparison purposes.

Hysteretic damping has been adopted to capture the energy losses in the soil medium

during shaking excitations by reproducing the actual hysteretic behaviour of the soil

elements in the nonlinear dynamic analysis. The hysteretic damping in FLAC3D is based

on the defined secant modulus reduction curve (FIG 2) for primary loading and a

Masing rule assumption for loading/unloading (Itasca, 2014). The Mohr-Coulomb model

has a constant elastic shear modulus (Gmax) and a constant yield stress (Su). The

hysteretic damping model is used to provide energy dissipation in the elastic range of the

adopted constitutive model by reducing the shear modulus from the initial value of Gmax

and increase the damping ratio. Thus, when hysteretic damping is used with MohrCoulomb model in FLAC3D, the modulus-reduction technique is applied in elastic range,

and natural damping induced by constitutive model applies in the plastic range.

Free field boundaries have been employed at the side boundaries of the soil medium

generating one-dimensional free-field wave propagation in parallel with the main-grid

analysis (Itasca, 2014). Thus, plane waves propagating upward undergo no distortion at

the boundaries as the free-field grid supplies conditions identical to those in an infinite

model. In addition, a rigid boundary has been adopted at the bedrock level to simulate

the large dynamic impedance (e.g. low velocity sediments sitting on high velocity

bedrock).

20

G\Gmax

Damping Ratio (%)

1

0.8

(a)

0.6

0.4

0.2

0

0.001

After Vucetic and Dobry (1991)

Applied Modulus reduction curves in this study

0.01

0.1

Cyclic Shear Strain, c (%)

15

After Vucetic and Dobry (1991)

Applied damping curves in this study

(b)

10

0

0.001

0.01

0.1

Cyclic Shear Strain, c (%)

FIG 2 (a) Relations between G/Gmax versus cyclic shear strain; (b) Relations

between damping ratio versus cyclic shear strain

Earthquake Ground Motions

In order to perform a comprehensive study on the seismic response of the structural

models, two near field seismic accelerations including Northridge earthquake, 1994

(FIG 3a) and Kobe earthquake, 1995 (FIG 3b), and two far field seismic accelerations

including El-Centro earthquake, 1940 (FIG 3c), and Hachinohe earthquake, 1968 (FIG

3d), are utilised for the dynamic time-history analysis in this study,which are selected by

the International Association for Structural control and Monitoring for benchmark

seismic studies (Karamodin and Kazemi 2008). Also it is well known that near field

earthquakes contain significant forward directivity pulse.

ASCE

Geo-China 2016 GSP 259

21

Name: Northridge

PGA: 0.887 g

Mw (R): 6.7

Dominant frequency: 0.4-0.63 Hz

0.5

Acceleration (g)

Acceleration (g)

-0.5

(a)

Name: Kobe

PGA: 0.833 g

Mw (R): 6.8

Dominant frequency: 1.0-1.5 Hz

0.5

-0.5

-1

(b)

-1

10

15

20

25

30

10

20

Time (Sec)

0.2

Acceleration (g)

Acceleration (g)

0.4

Name: El Centro

PGA: 0.349 g

Mw (R): 6.9

Dominant frequency: 1.0-2 .0Hz

0.4

0

-0.2

(c)

5

10

15

40

50

20

Time (Sec)

25

Name: Hachinohe

PGA: 0.229 g

Mw (R): 7.5

Dominant frequency: 0.3-2.1 Hz

0.2

-0.2

(d)

-0.4

-0.4

0

30

Time (Sec)

30

10

20

30

40

Time (Sec)

FIG 3 (a) Northridge Earthquake 1994; (b) Kobe Earthquake 1995; (c) El Centro

Earthquake 1940; (d) Hachinohe Earthquake 1968

NUMERICAL ANALYSIS

Dynamic analysis is carried out for a 15-storey model in conjunction with class Ee soil

possessing geotechnical characteristics (Vs = 150 m/s and density = 1470 kg/m3)

presented in FIG 1 for two different systems: fixed-base system (structure without soil

medium) and SSI system (structure resting on soil medium considering the interaction

between foundation and soil). For modelling fixed-base system, the four mentioned

earthquakes are applied at the structural foundation; while for SSI system, the

earthquakes are applied at the bedrock level directly. The Australian seismic code

evaluates local site effects based on the properties of the top 30 meters of the soil profile,

due to the fact that the main part of the amplification and attenuation occurs within the

first 30 meters of the soil profile. Therefore, a 30-meter soil medium has been

considered in this study.

RESULTS AND DISCUSSION

The results of the dynamic analyses for a 15-storey model in terms of base shear,

maximum lateral displacement, inter-storey drift and spectral acceleration under the

influence of four earthquake records for fixed-base system and SSI system with different

average undrained shear strength are derived from FLAC3D history records and are

presented and discussed in this section. According to Table 1, the base shear of the

structure accounting for SSI is always less than the base shear of the fixed-base cases

under the corresponding earthquake excitation. For SSI system, it is evident that with the

increase in the average undrained shear strength the structural system experiences

excessive base shear. Take the Northridge earthquake as an example, for average

undrained shear strength of 65 and 105 kPa and the case considering hysteretic damping

only, the maximum base shear were 11200 kN, 18000 kN and 25000 kN, respectively.

ASCE

Geo-China 2016 GSP 259

22

This means that the structure sitting on the soil with undrained shear strength of 105 kPa

experiences up to 60% more base shear in comparison with structure sitting on the soil

with undrained shear strength of 65 kPa. The reason is that less plastic flow occurs

during the excitation of the cases with higher undrained shear strength resulting in less

soil damping. Consequently, more energy transfers through the subsoil to the

superstructure and eventually leaded to the increase in the base shear of the structure

resting on the soft soil medium.

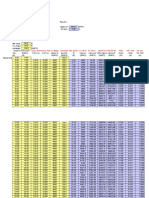

Table 1 Maximum base shear of the structure for different cases

Earthquake

Northridge

Kobe

El-Centro

Hachinohe

Su=65 kPa

11200

14400

10100

9450

Su=75 kPa

13000

15800

11800

11300

Su=85 kPa

14900

17700

12700

12500

Base Shear (kN)

Su=95 kPa Su=105 kPa

16200

18000

19600

21000

13000

13100

13200

13600

Excluding Su

25000

23000

13700

13600

Fixed-base

36653

36127

14345

13727

Table 2 and Figure 4 present the maximum inter-storey drifts and lateral displacements

of the superstructure under the applied earthquakes, respectively. This data was based on

the lateral deformation of each storey when maximum defection at the top level occurs

because, as Hokmabadi et al. (2012) stated, this approach gives a more reasonable

pattern of structural deformation compared to the approach where maximum absolute

storey deformation irrespective of the time they occurred were recorded. Accordingly,

the seismic response of the SSI system amplifies in comparison with the fixed-based

structure, in terms of maximum lateral displacements and inter-storey drifts due to the

rocking in the soil-structure system. Take the Northridge earthquake as an example, for

average undrained shear strength of 65 and 105 kPa and the case considering hysteretic

damping only, the maximum inter-storey drifts were 1.43%, 2.06% and 2.84%,

respectively. This means that the structures sitting on the soil with undrained shear

strength of 105 kPa experiences almost one and half times of inter-storey drifts in

comparison with structure sitting on the same soil with less undrained shear strength.

Although the shear wave velocity (or Gmax) is constant, the performance of soil is

significantly impacted by the average undrained shear strength due to the additional

amount of natural damping triggered by the plastic flow.

Table 2 Maximum inter-storey drift reported for different cases

Earthquake

Northridge

Kobe

El-Centro

Hachinohe

Su=65 kPa

1.43

1.46

0.83

0.77

Su=75 kPa

1.67

1.57

0.84

0.81

Maximum Inter-storey Drift (%)

Su=85 kPa Su=95 kPa Su=105 kPa

1.84

1.94

2.06

1.65

1.83

1.84

0.84

0.89

0.92

0.83

0.84

0.84

Excluding Su

2.84

2.00

0.92

0.85

Fixed-base

1.10

1.42

0.48

0.36

The acceleration response spectrum of Kobe earthquake presented in FIG 5, as an

example. It should be noted that all the other three earthquakes present similar pattern.

According to FIG 5, by increasing the average undrained shear strength, the maximum

spectral acceleration has been shifted to the longer period range. Moreover, in the range

beyond period of 1 second, it is clear that the spectral accelerations for all cases

ASCE

Geo-China 2016 GSP 259

23

considering SSI have been amplified, which further indicates that structures having

relatively long natural periods are vulnerable to the effect of SSI. This can be explained

referring to the conservation of energy concept. Accordingly, in relatively strong soil

medium (i.e. high Su value), soil experiences less plastic deformation and eventually less

natural damping has been created. Therefore, more energy transfers into the foundation

of the superstructure resulting in the amplification of the developed base shear and in

turn the foundation rocking and structural lateral displacements.

15

15

(b)

10

Fixed-base

65 kPa

75 kPa

85 kPa

95 kPa

105 kPa

Excluding Su

Northridge

0

0

200

400

600

Storey Level

Storey Level

(a)

800

1000

1200

10

Kobe

0

1400

200

Maximum Lateral Displacement (mm)

400

600

800

1000

Maximum Lateral Displacement (mm)

15

15

(d)

10

Fixed-base

65 kPa

75 kPa

85 kPa

95 kPa

105 kPa

Excluding Su

El Centro

0

0

50

100

150

200

Storey Level

(c)

Storey Level

Fixed-base

65 kPa

75 kPa

85 kPa

95 kPa

105 kPa

Excluding Su

250

300

350

10

Fixed-base

65 kPa

75 kPa

85 kPa

95 kPa

105 kPa

Excluding Su

Hachinohe

0

400

Maximum Lateral Displacement (mm)

50

100

150

200

250

300

350

Maximum Lateral Displacement (mm)

Spectral Acceleration (g)

FIG 4 Maximum lateral displacement: (a) Northridge Earthquake 1994; (b) Kobe

Earthquake 1995; (c) El Centro Earthquake 1940; (d) Hachinohe Earthquake 1968

3

65 kPa

75 kpa

85 kPa

95 kPa

105 kPa

Original

0

0

0.5

1.5

2.5

Period (s)

FIG 5 Spectral accelerations for Kobe earthquake 1995 with 5% damping ratio

under the influence of soil undrained shear strength variation

CONCLUSIONS

In this study, influence of the shear strength of soil on the seismic response of a

moment resisting concrete building has been numerically investigated. A three

dimensional numerical soil-structure model has been developed adopting direct method

of analysis. In order to capture realistic soil nonlinearities for different shear strength,

hysteretic damping has been implemented to simulate backbone curve of the shear

modulus and the damping ratio versus shear strain for soil. Numerical results show that

ASCE

Geo-China 2016 GSP 259

as the shear strength of subsoil increases, while other soil input properties are constant,

the base shear, the maximum lateral displacement and the inter-storey drift of the

structure amplifies by up to 60%, 100% and 44%, respectively. It can be concluded that

soil undrained shear strength has considerable effects on the seismic response of midrise building frames resting on soft soil deposits due to soil-structure interaction, and

considering unrealistic shear strength for the soil can considerably alters the predicted

response of the structure. Thus, in order to obtain a reliable numerical prediction, the soil

characteristics (undrained shear strength and plasticity) should be treated with extreme

care while conducting soil-structure interaction analysis.

REFERENCES

ACI318-08 (2008). Building code requirements for structural concrete and commentary

American Concrete Institute.

AS/NZS1170.1 (2002). Structural design actions - part 1: permanent, imposed and

other actions Standards Australia/Standards New Zealand, Sydney, Australia.

AS1170.4 (2007). Structural design actions - part 4: earthquake actions in Australia.

Standards Australian, Sydney, Australia.

AS3600 (2009). Concrete structures Standards Australia, Sydney, Australia.

Chu, D. (2006). Three-dimentional nonlinear dynamic analysis of soil-pile-structure

interaction PhD, Washington University.

Fatahi, B. and Tabatabaiefar, S. (2014). Fully nonlinear versus equivalent linear

computation method for seismic analysis of midrise buildings on soft soils

International Journal of Geomechanics, Vol. 14 (4): 1-15.

Hokmabadi, A.S. and Fatahi, B., 2015. Influence of foundation type on seismic

performance of buildings considering soilstructure interaction International

Journal of Structural Stability and Dynamics, p.1550043.

Hokmabadi, A.S., Fatahi, B. and Samali, B. (2014). Assessment of soil-pile-structure

interaction influencing seismic response of mid-rise buildings sitting on floating pile

foundations Computers and Geotechnics, Vol. 55: 172-186.

Hokmabadi, A.S., Fatahi, B. and Samali, B., 2015. Physical Modeling of Seismic SoilPile-Structure Interaction for Buildings on Soft Soils International Journal of

Geomechanics, 15(2), doi: 10.1061/(ASCE)GM.1943-5622.0000396.

ITASCA (2014). FLAC3D version 5.01 Fast Lagrangian Analysis of Continua in three

dimentions, User's Manual Minneapolis, Minnesota, USA: Itasca Consulting

Group, Inc.

Kamei, T. and Iwasaki, K. (1995). Evaluation of undrained shear strength of cohesive

soils using a flat dilatometer Soils Found, Vol. 35 (2): 111116.

Karamodin, A.K. and Kazemi, H.H. (2008). Semi-active control of structures using

neuro-predictive algorithm for MR dampers Structural Control and Health

Monitoring, Vol. 17 (3): 237253.

Vucetic, M. and Dobry, R. (1991). Effects of soil plasticity on cyclic response.

Journal of Geotechnical Engineering, ASCE, Vol. 117 (1): 89107.

Wegel, R. L. and Walther, H. (1935). Internal dissipation in solids for small cyclic

strains Physics, Vol. 6: 141157.

ASCE

24

Geo-China 2016 GSP 259

25

2D

Validation of the Structural Analysis by PLAXIS

Geotechnical Software

Mahbubeh Mortezaee1 and Ali Akhtarpour2

1

2

M.Sc. Student, Structural Engineering, Azad Islamic Univ., Shahroud.

Assistant Professor, Dept. of Engineering, Ferdowsi Univ. of Mashhad.

Abstract: In soil-structure interaction, modeling the soil and structure set is one of the

most important issues in geotechnical and structural field. In this regard, application of

soil mechanic software such as PLAXIS is of particular importance. In this paper, the

performance of PLAXIS in soil-structure interaction is addressed. Frist, beam analysis

results with different support condition were investigated by PLAXIS and compared

with classic structural analysis methods results. Then two building frames, a simple

one story frame and a 17-floor, 5 spans frame were modeled and analyzed by PLAXIS

and ETABS. Results of PLAXIS had good agreement with the results from classic

equations of structural analysis and ETABS software, suggesting the reliability of

PLAXIS in soil-structure interaction analysis.

Keywords: Soil-structure interaction; Building frame modeling; Validation;

PLAXIS2D; ETABS.

INTRODUCTION

In conventional analysis of structure dynamic, it is usually supposed that the

foundation soil is rigid and elasticity of soil is neglected. In this case, structure

response is under the influence of its own dynamic properties free from elasticity of

soil. This is true when the building is constructed on hard rock, but in cases where the

building is on soft soil, the response is totally different. In this case the structure has

some interaction with soil resulting in some changes in basis movements; this

interaction is mutual and known as soil-structure interaction. This interaction

significantly changes the structure response. Lamb investigated elastic vibrations in

1904 which is considered as a start for soil dynamics. Based on Lamb studies,

Reissner (1936) studied circular rigid foundation vibrations on elastic soil which is

known as the beginning for soil-structure interaction. Hokmabadi et al. (2014) studied

the effects of the seismic soil-pile-structure interaction (SSPSI) on the dynamic

response of buildings. it is observed that the SSPSI amplifies the maximum lateral

deflections and in turn interstory drifts of the structures supported by end-bearing pile

foundations in comparison with the fixed-base structures. Fatahi et al. (2014)

investigated the soil-pile interactive performance under lateral loads. In case of soft

ASCE

Geo-China 2016 GSP 259

26

clay, it has been observed that lateral loads on piles can initiate the formation of a gap,

soil heave and the tension crack in the vicinity of the soil surface and the interface,

whereas in medium dense sand, a semi-elliptical depression zone can develop.

The analysis of soil-structure interaction can be classified into two main categories,

including direct and multistep methods. In the direct method, the whole structurefoundation-soil system is analyzed in a single step. An example of it is finite element

method. The main advantages of this method are the capability of considering the

nonlinear behavior of materials of soil and structures, and modeling the complex

geometries (Wolf 1985).

Investigation of soil-structure interaction is an important issue which could not be

neglected; therefore soil-structure set modeling is a crucial item in geotechnical and