Documente Academic

Documente Profesional

Documente Cultură

Ethanol Animal Fat Emulsions As A Diesel Engine Fuel - Part 2 PDF

Încărcat de

Ramnarayan MeenaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ethanol Animal Fat Emulsions As A Diesel Engine Fuel - Part 2 PDF

Încărcat de

Ramnarayan MeenaDrepturi de autor:

Formate disponibile

Fuel 85 (2006) 26462652

www.fuelrst.com

Ethanol animal fat emulsions as a diesel engine fuel Part 2:

Engine test analysis

M. Senthil Kumar, A. Kerihuel, J. Bellettre *, M. Tazerout

Departement Syste`mes Energetiques et Environnement, Ecole des Mines de Nantes, 4 rue Alfred Kastler,

BP 20722, 44307 Nantes, Cedex 03, France

Received 9 March 2005; received in revised form 22 May 2006; accepted 23 May 2006

Available online 23 June 2006

Abstract

This work aims on the ecient use of animal fat in a diesel engine by making its stable emulsions with ethanol and water. A single

cylinder direct injection diesel engine is tested using neat diesel, neat animal fat and animal fat emulsion (optimal emulsion) as fuels under

variable load operating conditions. Results show increased peak pressure and ignition delay with ethanol animal fat emulsion as compared to neat fat. Heat release pattern shows improvement in the premixed combustion phase with animal fat emulsion as compared to

neat animal fat. Drastic reduction in smoke, nitric oxide, hydrocarbon and carbon monoxide emissions are observed with the emulsion as

compared to neat fat and neat diesel mainly at high power outputs. Only, hydrocarbon and carbon monoxide emissions are found as high

with the emulsion at light loads. In general, animal fat emulsion shows considerable reduction in all emissions and improvement in engine

performance as compared to neat fat.

2006 Elsevier Ltd. All rights reserved.

Keywords: Diesel engine; Ethanol; Animal fat emulsion

1. Introduction

Diesel engines are mainly used in industrial, transport

and agricultural applications due to their high eciency

and reliability. However, they suer from high smoke and

nitric oxide emissions [13]. The increase in prices of diesel

fuel, reduced availability, more stringent governmental regulations on exhaust emissions and the fast depletion of

world-wide petroleum reserves provide a strong encouragement to the search for alternative fuels. It is commonly

accepted that clean combustion in diesel engines can be

achieved only if engine development with fuel reformulation and the use alternative fuels are implemented [46].

In the name of energy security, regional air quality and

greenhouse gas emissions reduction, use of oxygenated

alternative fuels are advocated to reduce emissions in diesel

Corresponding author. Tel.: +33 251858296.

E-mail address: Jerome.Bellettre@emn.fr (J. Bellettre).

0016-2361/$ - see front matter 2006 Elsevier Ltd. All rights reserved.

doi:10.1016/j.fuel.2006.05.023

engines. In this regard, animal fats have come across good

choice to use as fuel in diesel engines [7,8]. As a compression

ignition engine fuel animal fats have cetane number and caloric value very close to diesel. The added advantage is that

animal fats have xed oxygen present in it [9]. Hence they

can increase the local oxygen concentration in the fuel mixture when used as fuel in diesel engines. Contrary to fossil

fuels animal fats are free from sulfur. However, the high viscosity and poor vaporization characteristics of animal fats

indicate that they need modications before using them in

diesel engines.

Animal fats oer the advantage of freely mixing with

alcohols (both methanol and ethanol) and these blends

can be used in the existing diesel engines without modications. This is a simple process. The major advantages of the

blending are the absence of technical modications and the

ease of implementation. Blending of animal fats with alcohols results in signicant improvement in physical properties [10]. Viscosity and density are considerably reduced.

Volatility is also improved. Although both methanol and

M.S. Kumar et al. / Fuel 85 (2006) 26462652

ethanol reduce emissions in diesel engines, ethanol has the

advantage of having higher miscibility with diesel, vegetable oils and animal fats. Besides being a biomass-based

renewable fuel, ethanol has cleaner burning characteristics

and a high cetane rating than methanol [11,12]. It has been

reported that the application of ethanol as a supplementary

compressionignition fuel can reduce environmental pollution, strengthen the agricultural economy and reduce diesel

fuel requirements [1316]. Therefore, the use of ethanol in

compression ignition engines has received considerable

attention in recent years.

Though several research projects have been carried out

on a number of alternative fuels in diesel engines, not much

data is available on the performance of constant speed stationary diesel engine fuelled with animal fat. Moreover,

study of ethanol animal fat emulsions on diesel engines

seems to be not done anywhere in the past. In Europe,

the production of animal fat is very high. Hence it nds

attraction to use as fuel in diesel engines. Since low horsepower stationary diesel engines are commonly used in agricultural and transport sectors, there is a need to study their

performance using alternative fuels. This can be further

extended to high power output multi cylinder engines also.

Therefore, a study is undertaken with the objective of nding out the performance of a diesel engine operated on the

fuels completely obtained from renewable energy sources

such as animal fat and ethanol. The chemical composition

and the dierent properties of the tested fat and its

emulsion have been measured in the rst part of this work

[17].

2. Experimental setup and experimental procedure

2.1. Engine test cell

A single cylinder air cooled Lister Petter diesel engine

developing a power output of 2.8 kW at 1500 rev/min is

used for the work. The Schematic of the experimental set

up is shown in Fig. 1. An electrical dynamometer is used

for loading the engine. An orice meter connected to a

large tank is attached to the engine to make air ow measurements. The fuel ow rate is measured on the volumetric

basis using a burette. Chromel alumel thermocouples in

conjunction with a slow speed digital data acquisition system is used for measuring the exhaust gas temperature.

2.2. Combustion data acquisition

A high-speed digital data acquisition system (AVLIndiwin) in conjunction with two AVL piezoelectric transducers is used for the measurement of cylinder pressure and

fuel line pressure histories. An optical shaft position encoder is used to give signals at TDC. Engine in cylinder pressure and crank angle are sampled for 100 consecutive cycles

at increments of 0.1 crank angle and averaged to obtain

combustion parameters.

13

7

20

16

15

10

Diesel

Tank

3

10

5

Diesel

Tank

4

14

12

19

2647

11

17

2

18

1. Test Engine

2. Dynamometer

3. Animal Fat Tank

4. Diesel Tank

5. A/D Card for Pressure

6. A/D Card for Analyser

7. Air Tank

8. Burette for diesel

9. Burette for Animal Fat

10. Charge Amplifier

11. Fast Data Acquisition Sysytem

12. Slow Data Acquisition system

13. Cylinder Pressure Sensor

14. Injection Pressure Sensor

15. Diesel Filter

16. Animal fat Filter

17. TDC Encoder

18. Speed Sensor

19 Exhaust gas Analyser

20. Smoke Meter

Fig. 1. Schematic of experimental setup.

2648

M.S. Kumar et al. / Fuel 85 (2006) 26462652

2.3. Emission instrumentation

90

Peak Pressure (bar)

An infrared (COSMA) exhaust analyzer is used for measuring hydrocarbon (HC) and carbon monoxide (CO)

emissions. NO in the exhaust is measured by using a Beckman chemiluminescence NOx analyzer. Smoke levels are

measured using a standard HARTRIDGE smoke meter

which works on light absorption technique (passing a light

beam through the exhaust sample and the fraction of light

is absorbed by the exhaust gas). Light extinction coecient

K is used as the measure of smoke density.

100

80

70

60

Neat Diesel

50

2.4. Experimental procedure

Speed : 1500 rpm

Inj. Timing : 20 BTDC

3.1. Combustion parameters

The variation of maximum cylinder gas pressure at dierent power outputs for neat diesel, neat animal fat and its ethanol emulsion is shown in Fig. 2. Neat animal fat results in

lower peak pressure as compared to neat diesel. The maximum cylinder pressure is found as 92 bar with neat diesel

and 80.7 bar with neat fat at peak power output. However,

except at lightest loads the maximum cylinder pressure

increases with the animal fat emulsion. It is found as

87 bar with animal fat emulsion at peak power output.

The increase in peak pressure with the emulsion of animal

fat can be explained by the higher premixed burning rate

of emulsion due to the long ignition delay (will be seen later).

The low cetane number and high latent heat of vaporization

of ethanol in the emulsion results in increased ignition delay.

The increase in ignition delay results in a strong premixed

combustion phase and gives rise to the cylinder gas pressure

with the emulsion. This behavior becomes more obvious at

high engine loads. The increase in the ignition delay with

the ethanol animal fat emulsion increases the amount of fuel

burned within the premixed burning phase. At high engine

loads more fuel is burned in the premixed burning phase,

causing high value of peak pressure and rate of pressure rise.

700

1100

1500

1900

2300

2700

3100

Power (watts)

Fig. 2. Variation of cylinder pressure with animal fatethanol emulsion.

Fig. 3 illustrates the heat release pattern with neat diesel,

neat animal fat and its ethanol emulsion at maximum

power output. Neat animal fat and its emulsion follow

the trend similar to diesel. It can be seen that the combustion is more pronounced at the diusion phase rather than

premixed phase with neat fat. However, ethanol animal fat

emulsion indicates improvement in heat release rate at

the premixed combustion period. It clearly shows a delay

at the starting position of heat release as compared to that

of the diesel fuel and neat animal fat. The presence of ethanol and water fraction in the emulsion decreases the

cetane number of the emulsion and increases the ignition

delay period. This results in increased amount of combustible fuel to be prepared within the period of ignition delay

and increases the heat release rate. It is important to note

that although more fuel is needed for the emulsion to

obtain the same power as compared to diesel, the increase

in fraction of the premixed burning phase and shortening

in diusive burning phase could be still achieved with the

emulsions. At low engine loads (not shown), the heat

release curve revealed a sharp and short premixed burning

100

Neat Fat

Heat Release Rate (kJ/m3 deg)

3. Results and discussion

Ethanol Emulsion

40

300

Experiments are initially carried out on the engine using

diesel and neat fat as fuels. The injection timing is set at 20

before TDC for all the tested fuels. The engine is stabilized

before making all measurements. Readings for engine

speed, fuel ow, air ow, exhaust gas temperature etc.

are recorded for obtaining performance parameters.

Exhaust gas analyzers are calibrated before making measurements. Observations are made for smoke, NO, HC

and CO to analyze the emission characteristics. In all cases

pressure crank angle data are recorded and processed to get

combustion parameters. Optimum animal fat emulsion

obtained, based on viscosity, stability and micro-structure

is nally tested in the same engine at the same operating

conditions. Performance, emission and combustion characteristics of the optimum emulsion are analyzed and compared with neat fat and neat diesel.

Neat Fat

Ethanol Emulsion

80

Neat Diesel

60

Speed : 1500 rpm

Inj.Timing : 20 BTDC

Load : 100 %

40

20

-20

15

25

35

45

55

65

75

Crank Angle (CA)

Fig. 3. Variation of heat release rate with animal fatethanol emulsion.

M.S. Kumar et al. / Fuel 85 (2006) 26462652

18

60

Speed : 1500 rpm

Inj. Timing : 20 BTDC

Combustion Duration (CA)

16

14

Ignition delay (CA)

2649

12

10

8

6

Neat Diesel

Neat Fat

50

40

30

20

Neat Diesel

10

Neat Animal Fat

Speed : 1500 rpm

Inj. Timing : 20 BTDC

Ethanol Emulsion

Ethanol Emulsion

2

300

700

1100

1500

1900

2300

2700

300

3100

700

1100

Power (watts)

pattern. This can also be explained by the inuence of the

ignition delay as long ignition delay will make the combustion to postpone to a late stage. At low power outputs the

combustion becomes inferior with the emulsions due to

very low temperature of the cylinder. Hence the heat

release becomes very weak at low power outputs.

Fig. 4 shows the ignition delay for neat diesel, neat animal fat and its emulsion with ethanol and water at all

power outputs. As expected, ignition delay decreases with

increase in power outputs for all the tested fuels. The

decrease in ignition delay with the increase in engine load

is due to the inuence of cylinder gas temperature within

the ignition delay period. The gas temperature is higher

at high engine loads than that at low engine loads. It is seen

that the ignition delay is more with the emulsions as compared to neat fat and diesel at all power outputs. It is found

as 8 CA with neat fat, 6 CA with neat diesel and 10 CA

with ethanol animal fat emulsion at peak power output.

The increase in ignition delay with the emulsion can be

explained by the vaporization of ethanol and water in the

emulsion which causes the injected fuel spray into a relatively low gas temperature environment and increases the

period of ignition delay. It can be further explained by

the low cetane number of ethanol emulsion.

The total combustion duration decreases with the animal fat emulsion as compared to neat fat as seen in

Fig. 5. This is mainly due to the increase in rapid burning

rate of the emulsion. The addition of ethanol with the animal fat emulsion promotes combustion and shortens the

combustion duration. As being explained in the above section of heat release analysis, the faster combustion rate in

the premixed burning phase and shorter diusive burning

phase decrease the total combustion duration of the animal

fat ethanol emulsion.

3.2. Performance parameters

1900

2300

2700

3100

Fig. 5. Variation of combustion duration with animal fatethanol

emulsion.

emulsion is shown in Fig. 6. The specic energy consumption decreases with the increase in engine load. After a certain percentage of maximum load, any further increase in

brake load causes only a small increase in brake horsepower. This results in increased specic energy consumption at very high power outputs. It is seen that neat

animal fat results in higher SEC as compared to neat diesel.

This can be explained by the poor combustion of the

injected fat as a result of high viscosity and density. However, there is an improvement in SEC with the emulsions of

animal fat. Minimum value of SEC is found at 60% of the

maximum load with the emulsion. The improvement in

specic energy consumption with the emulsion is attributed

to the changes occurring in the combustion process. The

physical and chemical dierences in fuel structure of ethanol and fat lead to a combination of changes in the combustion process. The physical properties of animal fat are

changed when ethanol is added. The addition of ethanol

causes the viscosity of animal fat to decrease. Presence of

70000

Neat Diesel

60000

Neat fat

Ethanol Emulsion

50000

SEC (kJ/kW.hr)

Fig. 4. Variation of ignition delay with animal fatethanol emulsion.

1500

Power (watts)

40000

30000

20000

10000

0

300

Speed : 1500 rpm

Inj. Timing : 20 BTDC

700

1100

1500

1900

2300

2700

3100

Power (watts)

The relationship between power output and specic

energy consumption with neat animal fat and its ethanol

Fig. 6. Variation of specic energy consumption with animal fatethanol

emulsion.

2650

M.S. Kumar et al. / Fuel 85 (2006) 26462652

700

700

Speed : 1500 rpm

Inj. Timing : 20 BTDC

Neat Diesel

600

500

Hydrocarbon (ppm)

Exhaust gas temperature (C)

600

400

300

200

Neat Diesel

Neat Fat

Ethanol Emulsion

500

Speed : 1500 rpm

Inj . Timing : 20 BTDC

400

300

200

Neat fat

100

100

Ethanol Emulsion

0

0

700

1100

1500

1900

Power (watts)

2300

2700

3100

Fig. 7. Variation of exhaust gas temperature with animal fatethanol

emulsion.

water in the emulsion leads to secondary atomization

(micro-explosion) of the fuel and results in more complete

combustion and rapid energy release. All these factors

result in low specic energy consumption with the

emulsion.

The variation of exhaust gas temperature at dierent

power output conditions for neat diesel, neat animal fat

and its emulsion with ethanol and water is shown in

Fig. 7. It is clear from the gure that as the power

increases, the exhaust gas temperature increases with all

the fuels. The maximum exhaust gas temperatures of

540 C, 595 C and 480 C are observed at maximum

power output when the engine is running on diesel, neat

animal fat and ethanol animal fat emulsion respectively.

The variations in exhaust gas temperature indicate that

the type of fuel and engine brake load have a signicant

eect on exhaust gas temperature. It is seen that animal

fat emulsion has lowest exhaust gas temperature as compared to neat diesel and neat animal fat. This can be

explained by the high latent heat of vaporization of water

and ethanol which results in lower burning temperatures

with the emulsion. In addition to that, the shorter diusive

combustion reduces the late burning of fuel. Neat fat due

to its slow burning (late combustion) characteristics produces highest exhaust gas temperature.

3.3. Emission parameters

Hydrocarbon emissions emitted from neat diesel, neat

animal fat and its emulsions are shown in Fig. 8. Compared

to neat diesel, neat animal fat emits more hydrocarbon

emissions at all operating conditions. The maximum

hydrocarbon emission is found as 126 ppm with neat diesel

and 625 ppm with neat fat at peak power output. The main

reason for the higher hydrocarbon is the result of incomplete combustion of neat fat. Animal fat emulsion shows

lower hydrocarbon emissions (about 215 ppm) as compared to neat fat mainly at high power outputs. Improved

300

700

1100

1500

1900

2300

2700

3100

Power (watts)

Fig. 8. Variation of hydrocarbon emission with animal fatethanol

emulsion.

vaporization and atomization of the emulsions result in

better mixing with air and leads to complete combustion

of the fuel at high loads. However, at low power outputs

emulsion shows higher hydrocarbon emissions. The hydrocarbon emissions tend to increase because of the quench

layer of unburned ethanol present in the combustion chamber at low power outputs. In addition to that the high

latent heat of vaporization of water produces slow vaporization and mixing of fuel and air. In homogeneity of the air

fuel mixture may also contribute to leaner mixture in some

regions of combustion chamber and results in more

unburned fuels at low power outputs.

Neat animal fat results in higher carbon monoxide emissions as compared to neat diesel as shown in Fig. 9. Neat

animal fat results in fuel richness and leads to more carbon

monoxide emissions. It is observed that animal fat emulsion also results in higher carbon monoxide emission than

neat diesel and neat fat at low power outputs. The increase

3000

Neat Diesel

2500

Carbonmonoxide (ppm)

300

Neat fat

Ethanol Emulsion

2000

Speed : 1500 rpm

Inj. Timing : 20 BTDC

1500

1000

500

0

300

600

900

1200 1500

1800

2100 2400 2700

3000

Power (watts)

Fig. 9. Variation of carbon monoxide emission with animal fatethanol

emulsion.

M.S. Kumar et al. / Fuel 85 (2006) 26462652

in the carbon monoxide levels with ethanol emulsions is the

result of incomplete combustion of the ethanolair mixture

at light loads. Factors causing combustion deterioration

such as high latent heats of vaporization can be responsible

for the poor oxidation reaction rate of carbon monoxide

and increased CO production. As mentioned earlier, a

thickened quench layer created by the cooling eect of

vaporizing alcohol can play a major role on CO production

at part loads. Although the CO level is higher at light loads

for the ethanol animal fat emulsion, the CO level is fairly

lower than that of neat animal fat and neat diesel at high

power outputs. Since ethanol has less carbon than diesel

fuel and its oxygen content increases the oxygen to fuel

ratio in the fuel rich regions. The increased airfuel ratio

due to the increased volumetric eciency leads to more

complete combustion of the fuel. The presence of atomic

bound oxygen in the fuel satises positive chemical control

over CO formation.

The black smoke emission resulting from combustion of

diesel, neat animal fat and its emulsions is plotted in

Fig. 10. Smoke levels are high at high power outputs with

diesel and neat animal fat. This is due to the presence of

fuel rich core at high loads. The maximum smoke level is

found as 7.7 K with neat diesel and 3.6 K with neat fat.

It is seen that the smoke level is lower with neat animal

fat than neat diesel. The result of low smoke emission with

neat animal fat is due to the presence of low carbon content

in the fat. In addition to that the oxygen present in the fat

helps in smoke reduction. Smoke emission is further

reduced with animal fat emulsion. The trend shows drastic

reduction (about 0.3 K) in smoke emissions with ethanol

animal fat emulsion. The reduced smoke at high loads

can be explained by the reasons that the use of ethanol,

an oxidizer is eectively introduced to the fuel-rich regions

and suppress soot formation in combustion chamber. Ethanol does not provide the initial radicals for the formation

of aromatic rings. The charge cooling increases ignition

delay and thus, enhances the mixing of fuel with air which

in turn makes better air utilization. The high oxygen content of the emulsion combined with low C/H ratio and aromatic fractions contributes to the reduction of smoke. High

level of oxygen atoms present in the fuel also results in

overall leaner mixture. All these factors result in overall

reduction in smoke emission.

The NO emission of the engine operating on diesel,

neat animal fat and ethanolanimal fat emulsions is given

in Fig. 11. It shows that the NO emission is reduced with

neat fat as compared to neat diesel. The maximum NO

emission is found as 1480 ppm with neat diesel and

965 ppm with neat animal fat. The reduction in NO emission with neat fat is due to the reduced premixed combustion as a result of slow burning. The NO emission is

further reduced with the emulsions of animal fat as compared to neat diesel and neat fat. The minimum value of

246 ppm at maximum power output is found with the animal fat emulsion. The main reason for the drastic reduction in NO emissions is again due to the high latent heat

of vaporization of water. In the absence of nitrogen in the

tested fuels, the formation of NO mainly depends on thermal NO and prompt NO. The kinetics formation of thermal NO are governed by the extended Zeltovitch

mechanisms. Since the latent heat of vaporization of

water is high, the charge temperature becomes low when

the fuel is injected into the combustion chamber. As a

result the peak combustion temperature becomes low

and leads NO to diminish. Presence of ethanol in the

emulsions also helps to suppress the formation of thermal

NO. The formation of prompt NO is initiated by the reaction between hydrocarbon radicals and molecular nitrogen. This kind of NO is principally formed in fuel rich

conditions. As the appearance of micro-explosion results

in a better air/fuel mixture, it prevents rich pockets.

Indeed, with animal fat emulsions the formation of

prompt NO is reduced to.

1800

Neat Diesel

Neat Diesel

Neat fat

1500

Neat fat

Ethanol Emulsion

Ethanol Emulsion

6

Nitric Oxide (ppm)

Smoke No. (m-1)

2651

Speed : 1500 rpm

Inj. Timing : 20 BTDC

5

4

3

2

1

1200

Speed : 1500 rpm

Inj. Timing : 20 BTDC

900

600

300

0

-1

300

700

1100

1500

1900

2300

2700

3100

Power (watts)

Fig. 10. Variation of smoke density with animal fatethanol emulsion.

300

700

1100

1500

1900

2300

2700

3100

Power (watts)

Fig. 11. Variation of nitric oxide with animal fatethanol emulsion.

2652

M.S. Kumar et al. / Fuel 85 (2006) 26462652

4. Conclusions

Inuence of ethanol on engine performance, emissions

and combustion characteristics of a diesel engine fuelled

with the optimum animal fat emulsion (explained in Part

1) is studied experimentally. Ethanol animal fat emulsion

shows increased cylinder peak pressure and ignition delay.

Higher premixed combustion and lower combustion duration are found with the emulsions as compared to neat fat.

Further, improvement in performance and signicant

reduction in smoke, nitric oxide emissions, hydrocarbon

and carbon monoxide emissions are achieved mainly at

high power outputs.

Emulsication of animal fat with ethanol and water can

be a promising technique for using animal fat eciently in

diesel engines without any modications in the engine.

Simultaneous reduction in nitric oxide and smoke can be

achieved with the use of animal fat emulsions. However,

poor part load performance needs attention. Techniques

like exhaust gas recirculation, cetane improvers etc. can

further improve the emulsion performance at part loads.

References

[1] Larsen Chris, Oey Frederick, Levendis YA. An optimization study on

the control of NOx and particulate emissions from diesel engines.

Society of automotive engineers 1996, Paper No. 960473.

[2] Summers JC, Houtte SV, Psaras Dimitrios. Simultaneous control of

particulate and NOx emissions from diesel engines. Appl Catal B:

Environ 1996;10(13):13956.

[3] Ladommatos N, Abdelhalim S, Zhao H. Control of oxides of

nitrogen from diesel engines using diluents while minimizing the

impact on particulate pollutants. Appl Thermal Eng 1998;18(1):

96380.

[4] Xing-cai Lu, Jian-guang Yang, Wu-gao Zhang, Zhen Huang. Eect

of cetane number improver on heat release rate and emissions of high

speed diesel engine fueled with ethanoldiesel blend fuel. Fuel

2004;83(1415):201320.

[5] Satge de Caro P, Mouloungui Z, Vaitilingom G, Berge JC. Interest of

combining an additive with dieselethanol blends for use in diesel

engines. Fuel 2001;80(4):56574.

[6] Canakci M, Van Gerpen JH. Comparison of engine performance and

emissions for petroleum diesel fuel, yellow grease biodiesel and

soybean oil bio diesel. American society of agricultural engineers

2001, Paper No. 016050.

[7] Ali Yusuf, Eskridge KM, Hanna MA. Testing of alternative diesel

fuel from tallow and soybean oil in Cummins N14-410 diesel engine.

Bioresour Technol 1995;53(3):24354.

[8] Ali Yusuf, Hanna MA, Borg JE. Optimization of diesel, methyl

tallowate and ethanol blend for reducing emissions from diesel

engine. Bioresour Technol 1995;52(3):23743.

[9] Senthil Kumar M, Kerihuel A, Bellettre J, Tazerout M. Investigations

on the use of preheated animal fat as fuel in a diesel engine.

Renewable Energy 2005;30:144356.

[10] Kerihuel A, Senthil Kumar M, Bellettre J, Tazerout M. Use of animal

fats as CI engine fuel by making stable emulsions with water and

methanol. Fuel 2005;84:17136.

[11] Hansen AC, Zhang Q, Lyne PWL. Ethanoldiesel fuel blends a

review. Bioresour Technol 2005;96:27785.

[12] He BQ, Shuai Shi-Jin, Wang Jian-Xin, He Hong. The eect of ethanol

blended diesel fuels on emissions from a diesel engine. Atmos Environ

2003;37(35):496571.

[13] Irshad A. Oxygenated diesel: emissions and performance characteristics of ethanol- diesel blends in CI engines. Society of automotive

engineers 2001, Paper No. 2001-01-2475.

[14] Czerwinski J. Performance of HD-DI diesel engine with addition of

ethanol and rapeseed oil. Society of automotive engineers 1994, Paper

No. 940545.

[15] Ajav EA, Singh Bachchan, Bhattacharya TK. Experimental study of

some performance parameters of a constant speed stationary diesel

engine using ethanoldiesel blends as fuel. Biomass Bioenergy

1999;17(4):35765.

[16] Ajav EA, Singh Bachchan, Bhattacharya TK. Thermal balance of a

single cylinder diesel engine operating on alternative fuels. Energy

Conversion Manage 2000;41(14):153341.

[17] Kerihuel A, Kumar MS, Bellettre J, Tazerout M. Ethanol animal

fat emulsions as a diesel engine fuel Part 1: Formulations and

inuential parameters. Fuel, in press. doi:10.1016/j.fuel.2006.05.002.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Advances in Medical Linear Accelerator TechnologyDocument22 paginiAdvances in Medical Linear Accelerator TechnologyNawel MorjanÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Solar D DryerDocument50 paginiSolar D DryerRamnarayan MeenaÎncă nu există evaluări

- APPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGDocument4 paginiAPPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGKyle LoveÎncă nu există evaluări

- WPS (AsmeDocument8 paginiWPS (AsmeMohammad Elhedaby100% (6)

- Sta. Lucia High School Science TestDocument3 paginiSta. Lucia High School Science TestEileen Joy Noceda86% (69)

- Centrifugal Pump TheoryDocument5 paginiCentrifugal Pump TheoryFungsam LimÎncă nu există evaluări

- Battery Bank Knowledge PDFDocument16 paginiBattery Bank Knowledge PDFamir uddinÎncă nu există evaluări

- Ampere Weber Electrodynamics HistoryDocument59 paginiAmpere Weber Electrodynamics Historyhanon90% (1)

- Solar Geometry ExplainedDocument13 paginiSolar Geometry ExplainedParimal BhambareÎncă nu există evaluări

- THE HIGH PRESSURE ROLLER PRESSDocument27 paginiTHE HIGH PRESSURE ROLLER PRESSThaigroup Cement100% (10)

- Session 12 Height and Distance, Odd Man Out and SeriesDocument22 paginiSession 12 Height and Distance, Odd Man Out and SeriesRamnarayan MeenaÎncă nu există evaluări

- Session 11 Clocks, Permutations and CombinationDocument13 paginiSession 11 Clocks, Permutations and CombinationRamnarayan MeenaÎncă nu există evaluări

- Session 9 Area Volume and SurfaceDocument12 paginiSession 9 Area Volume and SurfaceRamnarayan MeenaÎncă nu există evaluări

- Session 4 Percentage and AgesDocument14 paginiSession 4 Percentage and AgesRamnarayan MeenaÎncă nu există evaluări

- Session 7: Problems On Trains Boats and StreamsDocument11 paginiSession 7: Problems On Trains Boats and StreamsRamnarayan MeenaÎncă nu există evaluări

- Session 2 Decimal Fraction and SimplificiationDocument49 paginiSession 2 Decimal Fraction and SimplificiationRamnarayan MeenaÎncă nu există evaluări

- Session 8: Problems On Simple Interest and Compound InterestDocument11 paginiSession 8: Problems On Simple Interest and Compound InterestRamnarayan MeenaÎncă nu există evaluări

- Session 10: Problems On Races and Games of Skill and CalendarDocument9 paginiSession 10: Problems On Races and Games of Skill and CalendarRamnarayan MeenaÎncă nu există evaluări

- Session 3 Exponents Roots and AverageDocument17 paginiSession 3 Exponents Roots and AverageRamnarayan MeenaÎncă nu există evaluări

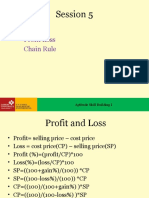

- Session 5 Profit Loss and Chain RuleDocument13 paginiSession 5 Profit Loss and Chain RuleRamnarayan MeenaÎncă nu există evaluări

- Session 6 Time and Work & Time and DistanceDocument20 paginiSession 6 Time and Work & Time and DistanceRamnarayan MeenaÎncă nu există evaluări

- Bridge Course On Aptitude Skill Building: Prepared By: Prof. Ravi Raval (701650137) Prof. Hitesh Rajput (9824474595)Document7 paginiBridge Course On Aptitude Skill Building: Prepared By: Prof. Ravi Raval (701650137) Prof. Hitesh Rajput (9824474595)Ramnarayan MeenaÎncă nu există evaluări

- Machine Design by S K MondalDocument81 paginiMachine Design by S K Mondalreyrey19Încă nu există evaluări

- Learning Psychrometric Chart and Measurement of T and RHDocument31 paginiLearning Psychrometric Chart and Measurement of T and RHRamnarayan MeenaÎncă nu există evaluări

- Psychrometry and Hvac: Psychrometry (Hygrometry) : Science of Moist Air HVAC: Heating, Ventilating, and Air-ConditioningDocument38 paginiPsychrometry and Hvac: Psychrometry (Hygrometry) : Science of Moist Air HVAC: Heating, Ventilating, and Air-Conditioningbenedict policarpioÎncă nu există evaluări

- 1 1 B Basic Solar GeometryDocument28 pagini1 1 B Basic Solar GeometryjhdmssÎncă nu există evaluări

- Review of Efficient High Productivity Solar StillsDocument24 paginiReview of Efficient High Productivity Solar StillsRamnarayan MeenaÎncă nu există evaluări

- Algae Derived Biodiesel Using Nanocatalytic 2017Document39 paginiAlgae Derived Biodiesel Using Nanocatalytic 2017Ramnarayan MeenaÎncă nu există evaluări

- AES L2 Solar Collectors 2017Document77 paginiAES L2 Solar Collectors 2017MuhammadÎncă nu există evaluări

- Reduction of No in Diesel EngineDocument43 paginiReduction of No in Diesel EngineDevesh RajputÎncă nu există evaluări

- Ec & Us Manual PDFDocument111 paginiEc & Us Manual PDFRamnarayan MeenaÎncă nu există evaluări

- Solar Radiation CalculationDocument49 paginiSolar Radiation CalculationOrlando DunstÎncă nu există evaluări

- Solar Collector ClassificationDocument6 paginiSolar Collector Classification06l01a0224Încă nu există evaluări

- Oxidation Stability of BiodieselDocument7 paginiOxidation Stability of BiodieselRamnarayan MeenaÎncă nu există evaluări

- Manual PDFDocument126 paginiManual PDFRamnarayan MeenaÎncă nu există evaluări

- 171P00480 PDFDocument3 pagini171P00480 PDFRamnarayan MeenaÎncă nu există evaluări

- Renewable Vs Nonrenewable ResourcesDocument13 paginiRenewable Vs Nonrenewable ResourcesRamnarayan MeenaÎncă nu există evaluări

- Millenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemDocument7 paginiMillenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemgimenÎncă nu există evaluări

- Motion Canada - Bearing CatalogDocument212 paginiMotion Canada - Bearing CatalogEric Lafrance100% (1)

- Russell J. Donnelly - Fifty-Five Years of Taylor - Couette FlowDocument35 paginiRussell J. Donnelly - Fifty-Five Years of Taylor - Couette FlowQMDhidnwÎncă nu există evaluări

- Specifyingstainlesssteelsurfacetreatments 10068 PDFDocument5 paginiSpecifyingstainlesssteelsurfacetreatments 10068 PDFshazia khanÎncă nu există evaluări

- ATSDR 2017 SPL Support DocumentDocument12 paginiATSDR 2017 SPL Support DocumentGela EcalÎncă nu există evaluări

- ABRASIVE JET MACHINING ModellingDocument3 paginiABRASIVE JET MACHINING ModellingAnkit OlaÎncă nu există evaluări

- Price 1998Document11 paginiPrice 1998LỢI NGUYỄN CÔNGÎncă nu există evaluări

- 9Document10 pagini9Laurentiu Chilibaru-Cristina OpritescuÎncă nu există evaluări

- PC1Document11 paginiPC1Allen Low100% (1)

- Specialized lubricants maximize steel industry productivityDocument16 paginiSpecialized lubricants maximize steel industry productivitySioney MonteiroÎncă nu există evaluări

- Haldia Institute of Technology Engineering Chemistry Laboratory (CH 191 &CH 291)Document29 paginiHaldia Institute of Technology Engineering Chemistry Laboratory (CH 191 &CH 291)Shresth Sanskar100% (1)

- Freeze-Drying of Acerola (Malpighia Glabra L.)Document7 paginiFreeze-Drying of Acerola (Malpighia Glabra L.)mÎncă nu există evaluări

- Feasibility of Using Lightweight Eps Based Partitions For Washrooms of ApartmentsDocument6 paginiFeasibility of Using Lightweight Eps Based Partitions For Washrooms of ApartmentsVishnuÎncă nu există evaluări

- NPTELDocument2 paginiNPTELMayur ArodaÎncă nu există evaluări

- 1 s2.0 S0020169309003971 MainDocument8 pagini1 s2.0 S0020169309003971 MainusmanÎncă nu există evaluări

- Black SandDocument2 paginiBlack SandMinato100% (1)

- Session 6 - Analytical Chem - Complexation and Precipitation Part 2Document22 paginiSession 6 - Analytical Chem - Complexation and Precipitation Part 2MehdiÎncă nu există evaluări

- Inorganic Chemistry Lab Synthesis and CharacterizationDocument6 paginiInorganic Chemistry Lab Synthesis and CharacterizationÖmer SaygılıÎncă nu există evaluări

- B.SC 2nd and 3rd Year Syllabus SVUDocument16 paginiB.SC 2nd and 3rd Year Syllabus SVUSrinivasulu Pudu100% (1)

- Caustic Potash SpecificationDocument1 paginăCaustic Potash SpecificationJayakumar AÎncă nu există evaluări

- Analysis of Hull ResistanceDocument6 paginiAnalysis of Hull ResistanceSahil JawaÎncă nu există evaluări

- Anomalous Diffusion ModelsDocument31 paginiAnomalous Diffusion ModelsAnanda SubramaniÎncă nu există evaluări