Documente Academic

Documente Profesional

Documente Cultură

Fisher V Ball

Încărcat de

JeEJyZaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fisher V Ball

Încărcat de

JeEJyZaDrepturi de autor:

Formate disponibile

Product Bulletin

Vee-Ball Attenuator

51.3:Vee-Ball(S2)

January 2013

D101843X012

Fisherr Vee-Ball V150, V200, and V300

Noise Attenuator

Fisher Vee-Ball Series valves (V150, V200, and V300)

with the severe service Attenuator combine the

efficiency of a rotary valve with the energy absorbing

capability of a special trim to provide improved

performance for demanding applications. The Fisher

attenuator design can be utilized in both liquid and gas

service to reduce cavitation and noise effects that

cause pipeline vibration. See table 1 for a competitive

comparison.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

W6116-1

Features

Fisher Vee-Ball Series Noise Attenuator Ball

Trim VersatilityTrim components are

interchangeable for Fisher V150, V200, and V300

valves. This feature allows you to reduce your spare

parts inventory and maintenance procedures.

Attenuator-Ball FabricationThe ball-attenuator

construction provides structural integrity because

of its rugged fabrication weld.

Excellent Flow CharacteristicPrecise contouring of

the V-notch ball provides an approximately equal

percentage flow characteristic.

Sour Service CapabilityOptional materials are

available that comply with NACE MR0175-2002.

Improved Environmental CapabilitiesThe optional

ENVIRO-SEAL packing system is designed with very

smooth stem surfaces and live-loading provides

improved sealing, guiding, and loading force

transmission. The seal of the ENVIRO-SEAL system

can control emissions to below the EPA

(Environmental Protection Agency) limit of 100

ppm (parts per million) for valves.

Quick and Easy MaintenanceThe Vee-Ball valve ball

seals can be inspected simply by removing two

screws on the valve body inlet. There is no need to

remove the actuator or disassemble the valve. No

special tools are required for valve maintenance

procedures, such as removing the packing, ball seal,

and shafts.

Attenuator PerformanceUp to -10 dBA acoustical

attenuation, and a Kc=1.0 for hydrodynamics are

achievable depending on service conditions.

Application VersatilityThe Vee-Ball valves are

available as standard with ISA S75.04 face-to-face

dimensions as well as ASME B16.10-short

face-to-face dimensions for CL150 valves. IEC

60534-3-2 face-to-face dimensions are also available

(60534-3-2 face-to-face dimensions are equivalent

to S75.04 face-to-face dimensions).

Long Service LifeSolid HD metal seal construction

(figure 1) provides long service life in demanding

applications. The constant wiping action of the seal

across the ball's sealing surface prevents scale and

sludge buildup, and provides excellent service on

www.Fisher.com

steam, gases, slurries, and various liquid

applications.

Product Bulletin

Vee-Ball Attenuator

51.3:Vee-Ball(S2)

January 2013

D101843X012

Specifications for Vee-Ball Valves and Noise Attenuator

Valve Sizes and End Connection Styles

NPS J 4, J 6, J 8, J 10, J 12, J 14, J 16, or J 20

valves that mate with CL150 or 300 raised-face

flanges. Valves sizes also mate with DN 50 through

DN 300 and DIN PN10 or PN16 flanges

Maximum Inlet Pressures(1)

Consistent with applicable pressure-temperature

ratings, but do not exceed the material temperature

capabilities and pressure drop limitations listed in

Bulletin 51.3:Vee-Ball

Maximum Shutoff Pressure/Temperature Ratings(1)

Composition (TCM Plus or TCM Ultra) Seals, Flat

Metal, HD (Heavy-Duty) and High Temperature HD

Metal Ball Seals: See Bulletin 51.3:Vee-Ball

Flow Ring Constructions: Contact your Emerson

Process Management sales office for more

information

Shutoff Classification

See Bulletin 51.3:Vee-Ball

Attenuator Ball Material

J Standard attenuator ball material is CG8M.

J Other attenuator ball materials are available upon

request. For other valve parts, refer to the

appropriate valve bulletin

Temperature Capabilities(1)

Fisher TCM Plus or Ultra Seals: -46 to 232_C (-50 to

450_F)

HD Metal Seals: -46 to 288_C (-50 to 550_F)

High Temperature HD Metal Seal: 288 to 427_C (550

to 800_F). Contact your Emerson Process

Management sales office if higher temperatures are

required.

Flow Ring or Flat Metal Seal : -198 to 425_C (-325 to

800_F)

PEEK/PTFE Bearings: -198 to 260_C (-325 to 500_F)

Packing Constructions

PTFE V-ring: -198 to 232_C (-325 to 450_F)

Graphite: -198 to 538_C (-325 to 1000_F)

ENVIRO-SEALt Single PTFE V-ring: -46 to 232_C (-50

to 450_F)

ENVIRO-SEAL Graphite: -7 to 316_C (20 to 600_F)

Flow Coefficients

See Fisher Catalog 12

Flow Characteristic

Modified equal percentage (see figure 3)

Face-to-Face Dimensions

Consistent with J ISA S75.04 and IEC 60534-3-2

face-to-face dimensions

Option for CL150 J ASME B16.10-short

Standard Flow Direction

Forward flow direction is into the convex face of the

V-notch ball. The valve with the attenuator must be

placed in the forward flow direction for the

attenuator to be effective.

Actuator Mounting

J Right-hand or J left-hand as viewed from

upstream end of valve. Counter-clockwise to close for

both mounting styles.

Maximum Ball Rotation

90 degrees

Valve/Actuator Action

With diaphragm or piston rotary actuator,

field-reversible between

J push-down-to-close (extending actuator rod closes

valve) and

J push-down-to-open (extending actuator rod opens

valve)

ENVIRO-SEAL Packing

This optional packing system provides improved

sealing, guiding, and transmission of loading force to

control liquid and gas emissions.

Options

J Alloy construction materials, and other common

valve parts are available upon request, J Materials

that comply with NACE MR0175-2002 for sour

service. Refer to Bulletin 51.3:Vee-Ball, or contact

your Emerson Process Management sales office

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation for valve should not be exceeded.

Product Bulletin

Vee-Ball Attenuator

51.3:Vee-Ball(S2)

January 2013

D101843X012

Figure 1. Fisher Vee-Ball Series Rotary Attenuator Construction

V-NOTCH BALL

SEE VIEW A

TCM BALL SEAL

SEAL

PROTECTOR

RING

GASKET

FOLLOWER

SHAFT

SEAL

PROTECTOR

RING

BEARING

GROOVE PIN

BODY

TAPER KEY

COMPLETE VALVE WITH TCM BALL SEAL

W6129-1

SEAL PROTECTOR

RING

HD SEAL

RADIAL

SEAL

WAVE

SPRING

FLAT

METAL

BALL

SEAL

SPRING

SEAL

V-NOTCH BALL

W5704-2

V-NOTCH BALL

W5787-2

BODY

SHIMS

BODY

VIEW A

FLAT METAL BALL SEAL DETAIL

VIEW A

HD METAL BALL SEAL DETAIL

SEAL

PROTECTOR

RING

RETAINING

RINGS

PISTON

RING

HD

METAL

SEAL

WAVE

SPRING

RETAINING RING (USE ONLY

WHEN ATTENUATOR IS

USED)

W8479

NPS 4 THROUGH 8 & NPS 14 THROUGH 20

HD METAL BALL SEAL

NPS 10 AND 12

HD METAL BALL SEAL

VIEW A

HIGH-TEMPERATURE HD METAL BALL SEAL

Product Bulletin

Vee-Ball Attenuator

51.3:Vee-Ball(S2)

January 2013

D101843X012

Other Considerations

When a rotary noise attenuator is installed in a Vee-Ball

valve, the V-notch is no longer a point of high-velocity

erosion. As a result, the CoCr-A V-notch option is not

required when a rotary noise attenuator is used. The

rotary attenuator and CoCr-A V-notch options are not

available together.

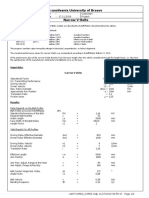

Table 1. Segmented Ball Benefits Analysis Comparison

Benefits

Typical Competitive

Device

Fisher Vee-Ball

Attenuator(1)

Predictable Performance

No

Yes

-10 dBA Aerodynamic Noise Attenuation

No

Yes

Superior Attenuation Effect at Critical Opening Position

No

Yes

Maximum Pressure Drop Capability

No

Yes

Heavy Duty, Integrally Welded Attenuator/Ball Assembly

No

Yes

Valve Splined Shaft Connects to Clamped Actuator Lever to Minimize Lost Motion

No

Yes

Superior Soft Seats for Tight Shutoff

No

Yes

Moderate Kc Improvement vs Unattenuated Device

Yes

Yes

Trunnion Mounted Ball for Superior Wear Resistance

Yes

Yes

Heavy Duty Metal Seats for Demanding Applications

Yes

Yes

1. See figure 3 for valve characteristics.

Figure 2. Typical Fisher ENVIRO-SEAL PTFE and

Graphite Packing Arrangements

PACKING

BOX STUD

Figure 3. Valve Characteristics

SPRINGS

ACTUATOR

MOUNTING

YOKE

VALVE

SHAFT

VALVE

BODY

ANTIEXTRUSION

RINGS

YOKE

BEARING

PACKING

FLANGE

PACKING

FOLLOWER

PACKING

BOX RING

PTFE

PACKING

V-RINGS

SHOWN

W5806-1

B2365-1

VALVE OPENING--DEGREES

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, Vee-Ball, and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E

4 1991, 2013 Fisher Controls International LLC. All rights reserved.

S-ar putea să vă placă și

- Full Text 01Document295 paginiFull Text 01JeEJyZaÎncă nu există evaluări

- Reduce FoulingDocument6 paginiReduce FoulingJeEJyZaÎncă nu există evaluări

- BR 1899Document20 paginiBR 1899vb_pol@yahooÎncă nu există evaluări

- Grassy Point LNG Terminal Comprehensive Study ReportDocument528 paginiGrassy Point LNG Terminal Comprehensive Study ReportJeEJyZaÎncă nu există evaluări

- Guide For Insepction For Installed Fired HeatersDocument35 paginiGuide For Insepction For Installed Fired HeatersColoLatino100% (7)

- ThesisChapter2Part1A PMMADocument15 paginiThesisChapter2Part1A PMMAJeEJyZaÎncă nu există evaluări

- HysysDocument36 paginiHysysRamiro ArcentalesÎncă nu există evaluări

- Boil Off Gas 2Document6 paginiBoil Off Gas 2JeEJyZaÎncă nu există evaluări

- 07 SekiDocument10 pagini07 SekiJeEJyZaÎncă nu există evaluări

- A Practical Guide To Rotary Valves PDFDocument26 paginiA Practical Guide To Rotary Valves PDFjaime001254Încă nu există evaluări

- Advanced Combustion FunacesDocument4 paginiAdvanced Combustion FunacesJeEJyZaÎncă nu există evaluări

- 12 Dust - Explosion - Protection PDFDocument34 pagini12 Dust - Explosion - Protection PDFRafael Rodriguez SÎncă nu există evaluări

- Polybed PSADocument2 paginiPolybed PSAJeEJyZaÎncă nu există evaluări

- Technical Training ManualDocument225 paginiTechnical Training ManualJeEJyZaÎncă nu există evaluări

- Coalescer PallDocument16 paginiCoalescer PallJeEJyZaÎncă nu există evaluări

- UOP Advanced Mercury Removal Technologies Tech PaperDocument6 paginiUOP Advanced Mercury Removal Technologies Tech PaperrbajuadiÎncă nu există evaluări

- Thesis Chapter 1Document12 paginiThesis Chapter 1JeEJyZaÎncă nu există evaluări

- Methyl Methacrylate MSDSDocument81 paginiMethyl Methacrylate MSDSJeEJyZaÎncă nu există evaluări

- Methacrylate Esters Safe Handling Manual (2008Document34 paginiMethacrylate Esters Safe Handling Manual (2008JeEJyZaÎncă nu există evaluări

- Methyl Methacrylate MSDSDocument81 paginiMethyl Methacrylate MSDSJeEJyZaÎncă nu există evaluări

- 2006 03 Beacon Thai SDocument1 pagină2006 03 Beacon Thai SJeEJyZaÎncă nu există evaluări

- Stormwater Tanks LowresDocument27 paginiStormwater Tanks LowresGrundfosEgypt50% (2)

- A Practical Guide To Rotary ValvesDocument26 paginiA Practical Guide To Rotary ValvesJeEJyZaÎncă nu există evaluări

- Plant Design Lecture PDFDocument10 paginiPlant Design Lecture PDFmehrdad_k_rÎncă nu există evaluări

- Critical Flow Restricting Orifices: D-Zero Engineering Note: 3740.S10-EN-173 C.H. Kurita August 9, 1988Document6 paginiCritical Flow Restricting Orifices: D-Zero Engineering Note: 3740.S10-EN-173 C.H. Kurita August 9, 1988JeEJyZaÎncă nu există evaluări

- AFT CE Gasflow ReprintDocument8 paginiAFT CE Gasflow ReprintNacho.pÎncă nu există evaluări

- Pressure Drop Calculation FactDocument6 paginiPressure Drop Calculation FactadehriyaÎncă nu există evaluări

- Donaldson Indust Water Process ChillersDocument6 paginiDonaldson Indust Water Process ChillersJeEJyZaÎncă nu există evaluări

- Advance Boiler Control SystemDocument44 paginiAdvance Boiler Control SystemJeEJyZaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- List RukmanDocument46 paginiList RukmanDimas MaulanaÎncă nu există evaluări

- Standard Style Stuffing BoxDocument4 paginiStandard Style Stuffing BoxAdelzon KinteroÎncă nu există evaluări

- 00 - IntroductionDocument89 pagini00 - IntroductionMuhammad Amru YazidÎncă nu există evaluări

- Available In:: 5 Mengel Court, Salisbury South, South Australia 5106 T: +618 8 8283 0222 F: +618 8 8283 4005Document2 paginiAvailable In:: 5 Mengel Court, Salisbury South, South Australia 5106 T: +618 8 8283 0222 F: +618 8 8283 4005Vadim ZorinÎncă nu există evaluări

- Location of Reboiler Return Inlet Nozzle in ColumnDocument10 paginiLocation of Reboiler Return Inlet Nozzle in Columnxaaabbb_550464353Încă nu există evaluări

- WPQ Template (Asme Ix) No LogoDocument4 paginiWPQ Template (Asme Ix) No LogorcpretoriusÎncă nu există evaluări

- VRV Condensing UnitDocument24 paginiVRV Condensing UnitLeo NgÎncă nu există evaluări

- Vor221184-Es1 2-131-132Document4 paginiVor221184-Es1 2-131-132Emanuel SotoÎncă nu există evaluări

- Owner/ Operator Manual: Professional Hot Water Extraction Cleaning SystemDocument20 paginiOwner/ Operator Manual: Professional Hot Water Extraction Cleaning SystemAngel Enrique Franco RiveraÎncă nu există evaluări

- Solar Panel Motor Driver - BOMDocument1 paginăSolar Panel Motor Driver - BOMmuhcemerÎncă nu există evaluări

- General Notes:: Straight Concrete Endwalls Single and Double 60" Pipe 430-031 1 3Document3 paginiGeneral Notes:: Straight Concrete Endwalls Single and Double 60" Pipe 430-031 1 3kingdbmÎncă nu există evaluări

- Steel Quantity by Thumb RuleDocument15 paginiSteel Quantity by Thumb RuleSheikh Nouman Mohsin RamziÎncă nu există evaluări

- Curtis Compressor Challenge Air PDFDocument44 paginiCurtis Compressor Challenge Air PDFSamy SamyÎncă nu există evaluări

- Sunflower-1434, Sunflower-1435, Sunflower-1544 Catalog AgcoDocument51 paginiSunflower-1434, Sunflower-1435, Sunflower-1544 Catalog AgcoПашик КотолевскийÎncă nu există evaluări

- Transilvania University Designs Narrow V-BeltsDocument2 paginiTransilvania University Designs Narrow V-BeltsDiana Maria CozmaÎncă nu există evaluări

- Record Physiological Changes with a KymographDocument42 paginiRecord Physiological Changes with a KymographSudhakar Lakavath100% (2)

- T ISS PX01 Instruction Manual Rev.01Document9 paginiT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Installation Manual: Manual 6687B Hydril I-P Series Pulsation DampenersDocument20 paginiInstallation Manual: Manual 6687B Hydril I-P Series Pulsation DampenersGerman VillalobosÎncă nu există evaluări

- Stryker TPS CORE - Cordless Drivers Accessories PDFDocument85 paginiStryker TPS CORE - Cordless Drivers Accessories PDFGeorge VlÎncă nu există evaluări

- Mechanical Design Calculation of FRP Tank: Project No. - Rev. 02 Document No. 1-074-9/DKP/18 Page 1 of 20Document25 paginiMechanical Design Calculation of FRP Tank: Project No. - Rev. 02 Document No. 1-074-9/DKP/18 Page 1 of 20muchamad yasinÎncă nu există evaluări

- Lathe and Mill Drill ManualDocument28 paginiLathe and Mill Drill Manual69x4Încă nu există evaluări

- ValvesDocument61 paginiValvesachari_swapnilÎncă nu există evaluări

- Work Inspection Request Form (WIR) APPROVEDDocument1 paginăWork Inspection Request Form (WIR) APPROVEDImran ZamanÎncă nu există evaluări

- GearsDocument51 paginiGearsKasi Visweswar Rao100% (1)

- Material Approval Request CWH DankosDocument4 paginiMaterial Approval Request CWH Dankosmelati puspitaÎncă nu există evaluări

- ISO 4427-5 2007 (E) - Character PDF Document PDFDocument12 paginiISO 4427-5 2007 (E) - Character PDF Document PDFgustavoÎncă nu există evaluări

- Atlas 65 RozdzielaczDocument23 paginiAtlas 65 RozdzielaczPawel TomwidlakÎncă nu există evaluări

- DS 5RB-CCDocument2 paginiDS 5RB-CCJOSE INESÎncă nu există evaluări

- MOS (Installation of Ceramic Tile) REV2Document3 paginiMOS (Installation of Ceramic Tile) REV2Don Roseller DumayaÎncă nu există evaluări

- Route Surveying: Horizontal CurvesDocument5 paginiRoute Surveying: Horizontal CurvesJacob SantosÎncă nu există evaluări