Documente Academic

Documente Profesional

Documente Cultură

1 PDF

Încărcat de

anon_789699787Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 PDF

Încărcat de

anon_789699787Drepturi de autor:

Formate disponibile

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Volume 2, Issue 2, 2016, PP 1-10

ISSN 2454-8693 (Online)

www.arcjournals.org

Analysis and Design of Prestressed Box Girder Bridge by

IRC: 112-2011

Phani Kumar.Ch

Student of final year M.Tech Structural Engineering,

Mandava Institute of Engineering and Technology, Andhra Pradesh

S.V.V.K.Babu, M.Tech

Assistant Profeessor, Civil Engg. Department,

Sri Vasavi Institute of Engineering and Technology, Andhra Pradesh

D.Aditya Sai Ram, M.Tech

Assistant Professor, Civil Engg. Department,

Mandava Institute of Engineering and Technology, Andhra Pradesh

Abstract: Bridge construction today has achieved a worldwide level of importance. Bridges are the key

elements in any road network and use of prestress girder type bridges gaining popularity in bridge engineering

fraternity because of its better stability, serviceability, economy, aesthetic appearance and structural efficiency.

In this thesis analysis and design of prestressed concrete bridges (Deck Slab, T-Girder and Box Girder) are

carried out using IRC:112-2011. The unified concrete code (IRC:112) published by the Indian Road Congress

in November 2011 combining the code for reinforced concrete and prestressed concrete structures represents a

new generation code, which is significantly different as compared to previous codes (i.e. IRC:21 for RCC

structures and IRC:18 for PSC structures). IRC:21 and IRC:18 stands withdrawn, with the publication of

IRC:112. The fundamental difference between IRC:112 and old codes is that IRC:112 based on limit state

theory while the previous codes were based on working stress design philosophy.

Keywords: prestress, Deck slab, T-slab, Box Girder, IRC:112.

1. INTRODUCTION

Bridges are defined as structures which are provided a passage over a gap without closing way

beneath. They may be needed for a passage of railway, roadway, footpath and even for carriage of

fluid, bridge site should be so chosen that it gives maximum commercial and social benefits,

efficiency, effectiveness and equality. Bridges are nations lifelines and backbones in the event of

war. Bridges symbolize ideals and aspirations of humanity. They span barriers that divide, bring

people, communities and nations into closer proximity. They shorten distances, speed transportation

and facilitate commerce. Bridges are symbols of humanitys heroic struggle towards mastery of forces

of nature and these are silent monuments of mankinds indomitable will to attain it. Bridge

construction constitutes an importance element in communication and is an important factor in

progress of civilization, bridges stand as tributes to the work of civil engineers.

Classification of Bridges:

Bridges are classified based on different criteria as follows

According to function as aqueduct (canal over a river), viaduct (road or railways valley, pedestrian,

highway, railway, road-cum-rail or pipe line bridge.

According to material of construction of super structure as timber, masonry, iron, steel, reinforced

concrete, prestress concrete, composite or aluminum bridge.

According to form or type of super structure as slab, beam, truss, arch, suspension bridge.

According to inter span relation as simple, continuous and cantilever bridge.

According to position of bridge floor relative to superstructure as a deck, trough, half-trough or

suspension bridge.

According to span length as culvert (less than 8m), minor bridge (8m to 30m) or long span bridge.

ARC

Page | 1

Phani Kumar.Ch et al.

2. BASIC CONCEPT OF PRESTRESSING

Prestressing is the application of an initial load on a structure, to enable it to counteract the stresses

arising from subsequent loads during its service period. prestressing has been practiced from ancient

times the behaviour of spokes of the bicycle when it is loaded, is also example of prestressing.

Prestressed concrete is basically a concrete in which internal stresses of a suitable magnitude and

distribution are introduced so that the stresses resulting from external loads are counteracted to

desired degree. In reinforced concrete members, the prestress is commonly the steel reinforcement.

The minimum grade of concrete in prestressing technique is M40 for pre tensioning and M35 for post

tensioning. The tensile strength of concrete is only 8-14% of its compressive strength of concrete.

Fig1.1. Behavior of RC member with and without prestressing

Types of Prestress Girders and its Purposes:

One of the most commonly used forms of superstructure in concrete bridges is precast girders with

cast-in-situ slab. This type of superstructure is generally used for spans between 20 to 40 m. Majority

of prestress concrete bridges, constructed in India are post tension type. The span to depth ratio is

usually kept as 20 for simply supported spans and 25 for continuous spans. The girder spacing of 2 to

3 m. The deck slab overhang should be provided as required to provide the desirable aesthetic effect

and to reduce transfer moments. Different types of girder bridges as shown in Figure 2.1

a. Cross section of T-Girder with cast in situ deck

b. I-Girder with cast in situ deck

c. Box girder with cast in situ deck

Fig2.1. Different types of girder sections

3. FINITE ELEMENT METHOD

The finite element method is a technique for analyzing complicated structure by nationality cutting up

the continuum of the prototype into a number of small elements which are connected at discrete joints

called nodes. For each element, approximate stiffness equation are derived relating the displacements

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 2

Analysis and Design of Prestressed Box Girder Bridge by IRC: 112-2011

of the nodes to the node forces between elements and, in the same way that slope defection equations

can be solved for joints in a continuous beam, an electronic computer is used to solved the very large

number of simultaneous equations that relate node forces and displacements.

a) 3 Noded Triangle, 4 Noded Quadrilateral, 6 Noded Triangle, 8 Noded Quadrilateral

b) 9 Noded Hexahedron, 10 Noded tetrahedron, 20 Noded Curved solid

4. IRC RECOMMENDATIONS ON DESIGN OF BRIDGES

The first and major step in any bridge analysis is selection of type of loading, they are dead load, live

load, impact effect, wind load, longitudinal force due to tractive effort of vehicles, longitudinal force

due to braking of vehicle, seismic effects, earth pressure, vehicle collision forces etc. Out of these

loads live load plays a major role.

Vehicle Live Loads:

Vehicle live loads are categorized based on their configuration and intensity as IRC Class 70R, IRC

Class AA (tracked and wheeled type), IRC Class A and IRC Class B loading.

Load Combinations:

All critical loading stages shall be investigated. The stages stated below

At the stage of prestressing

construction stages including temporary loading, transport, handling and erection or any occasional

loads that may occur during launching of girders

design loads according to IRC:6 that includes service dead load, prestress with full losses and

service dead load, live load and prestress with full losses

For the combination of loads with differential temperature gradient effects, maximum 50 per cent

live load shall be considered

Ultimate strength: A prestressed concrete members checked for failure conditions at an ultimate

load of

a.1.25 G + 2 SG + 2.5 Q---under moderate conditions

b.1.5 G + 2 SG + 2.5 Q--- under severe exposure conditions.

For sections, where the dead load causes effects opposite to those of live loads shall be checked

for G + SG + 2.5 Q.

Calculation of Ultimate Strength:

There are two conditions of failure at which strength should be calculated and minimum of these shall

be considered for design. They are

a) Failure by yield of steel

Mult = 0.9 db As fp

(2.1)

b) Failure by crushing of concrete

Mult = 0.176 b db2 fck

International Journal of Constructive Research in Civil Engineering (IJCRCE)

(2.2)

Page | 3

Phani Kumar.Ch et al.

5. ANALYSIS OF BOX GIRDER BRIDGES

The methods for the analysis of box girder bridges are as follows

Simple line analysis or beam analysis

Grillage analysis

BEF Analysis (Beams on elastic foundation)

Space frame analysis

Finite element method

For study of box girder bridges finite element method is more accurate method.

5.1. Description of Model

Loading on Box Girder Bridge:

The various type of loads, forces and stresses to be considered in the analysis and design of the

various components of the bridges are given in IRC 6.

Thickness of Web:

The thickness of the web shall not be less than d/36 plus twice the clear cover to the reinforcement

plus diameter of the duct hole whered is the overall depth of the box girder measured from the top of

the deck slab to the bottom of the soffit or 200 mm plus the diameter of duct holes, whichever is

greater.

Thickness of Bottom Flange:

The thickness of the bottom flange of box girder shall be not less than 1/20 th of the clear web spacing

at the junction with bottom flange or 200 mm whichever is more.

Thickness of Top Flange:

The minimum thickness of the deck slab including that at cantilever tips be 200 mm. For top and

bottom flange having prestressing cables, the thickness of such flange shall not be less than 150 mm

plus diameter of duct hole.

Losses in Prestress:

While assessing the stresses in concrete and steel during tensioning operations and later in service,

due regard shall be paid to all losses and variations in stress resulting from creep of concrete,

shrinkage of concrete, relaxation of steel, the shortening (elastic deformation) of concrete at transfer,

and friction and slip of anchorage.

Calculation of Ultimate Strength:

Ultimate moment resistance of sections, under these two alternative conditions of failure shall be

calculated by the following formulae and the smaller of the two values shall be taken as the ultimate

moment of resistance for design.

Failure by Yield of Steel

Mult = 0.9 db As Fp

Failure by Crushing of Concrete

Mult = 0.176 b db2 fck

(5.1)

6. ANALYSIS AND DESIGN OF POST TENSIONED DECK TYPE BOX GIRDER BRIDGE

A post tensioned deck type box girder bridge of clear span 30 m and width of roadway is 7.5 m is

considered for the analysis. Live loads are taken as per IRC:6. Cross section of box girder is shown in

Figure 6.1 and mathematical modeling is done using SAP2000 and is shown in Figure 5.3. The

overhang face of the girder is 1.2 m and deck slab thickness is 0.25 m. Bottom slab thickness is 0.25

m and girder thickness is 0.35 m. Material properties used are M50 grade of concrete and Fe415 grade

steel. The tendon profile considered is parabolic in nature. The Bridge analysis for different span to

depth ratios (L/d) ratio starting from 15 to 19 and different span to depth ratios (L/d) are considered as

follows.

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 4

Analysis and Design of Prestressed Box Girder Bridge by IRC: 112-2011

Case1 L/d= 15, d= 2.0

Case2 L/d=16, d= 1.9

Case3 L/d=17, d= 1.8

Case4 L/d= 18, d= 1.7

Case5 L/d= 19, d= 1.6

(5.2)

6.1Cross Section of Box-Girder

6.1. Mathematical Modeling

The mathematical model of a box girder bridge having a span of 30 m is shown in Figure6.2

Fig6.2. Modeling of box girder bridge

The tendon profile considered for the design of post tensioned box girder bridge is parabolic and

mathematical model is shown in Figure 6.3

Fig6.3. Tendon profile

6.2. Validation of Results

The bending moment, shear force and deflection results are obtained by using SAP2000. The bending

moment and shear force are obtained by considering different loading conditions consisting of dead

load, super imposed dead load and live load. The results are shown below for case 1. The variation of

bending moment and shear force along the length up to mid span is shown in Tables 6.1 and 6.2.

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 5

Phani Kumar.Ch et al.

Table 6.1. Bending moment variation along span (tm)

Span (m)

DL

LL

SIDL

Total

0L

0

0

0

0

0.1L

526

218

62

806

0.2L

934

381

110

1425

0.3L

1226

495

145

1866

0.4L

1400

565

165

2130

0.5L

1459

588

172

2219

0.4L

39

23

5

67

0.5L

0

0

0

0

Table 6.2. Shear variation along span (kN)

Span (m)

DL

LL

SIDL

Total

0L

194

80

23

297

0.1L

156

72

18

246

0.2L

117

57

14

188

0.3L

78

41

9

128

Moment due to DL+SIDL (Mg) = 1631 tm

Total Maximum moment (Mt) = 2219 tm

Initial Stresses:

fck = 50 MPa

fci= 40 MPa

fct= 20 MPa

fcw = 16.5 MPa

ftt= 2 MPa

ftw = 0 MPa

fbr= 16 MPa

Loss ratio= 0.8

The variation of prestress force, eccentricity and number of cables with respect to span to depth ratios

are summarized in Table6.3

Table 6.3. Calculation of prestress force and eccentricity

L/d

15

16

17

18

19

fsup (MPa)

1.57

1.59

1.6

1.62

1.64

finf (MPa)

0.81

0.78

0.76

0.73

0.7

Prestressing Force P (kN)

5428

5370

5309

5251

5194

e (mm)

850

800

750

700

650

using the freyssinet system, anchorage type 7K-15 in 65mm cable ducts (IS:6006-1983)

No of Cables

4

4

4

4

4

The following checks are performed for the above mentioned case1.

Check for Section Modulus:

Required section modulus Zreq = 571 x 106 mm3

Provided section modulus Zpro =341 x 108 mm3

Zpro> Zreq, Hence the section provided is adequate.

Check for Stresses:

At transfer stage

Stress at top = 1.52 MPa < fct

Stress at bottom = 0.87 MPa < ftt

At working stage

Stress at top = 1.4 MPa < fcw

Stress at bottom = 0.48 MPa (As per IS1343:1980 there is no tensile stress)

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 6

Analysis and Design of Prestressed Box Girder Bridge by IRC: 112-2011

All the stresses at top and bottom fibers at transfer and service loads are well within the permissible

limits.

Check for Flexural Strength:

For the centre of span section

According to IRC: 18-2000,

Mu = 1.5 M(G)+ 2 M(SG)+ 2.5 M(Q)

Mu = 40025 kNm

The ultimate flexural strength is calculated as follows

Failure by Yielding of Steel

Mu = 0.9 db Ap fp

Mu = 118244 kNm

Failure by Crushing of Concrete

Mu = 0.176 bw d2fck + (2/3) 0.8 (b-bw) (d-0.5Df) Df fck

Mu = 234556 kNm

The ultimate flexural strength Mu = 118244 > 40025 kNm, Hence safe.

Deflection Check:

Table 6.4. Check for deflection

Span/Depth Prestressing Force (kN)

15

5428

Eccentricity (mm)

850

Deflection (mm)

DL+SIDL DL+SIDL+PRE DL+LL+PRE+SIDL

14

11

18

Maximum permissible deflection according to IS: 1343-1980, Deflection due to self weight +

prestress + live load = span / 350 or 20 mm, whichever is less Permissible deflection = minimum of

(86 or 20) =20 mm > 18 mm Hence safe.

6.3. Design of Reinforcement in Box Girder Bridge

Design of End Block

P=5428 kN

bw=350 mm

d=1800 mm

Assume 200 mm wide and 200 mm deep distribution plate, located concentrically at center.

Ypo/yo = 0.57

As per IRC18:2000, from table 8. Fbst/Pk = 0.149

Fbst = 404kN

Ast = 1119mm2

Provide 12 mm diameter bars @ 100 mm c/c in horizontal direction and in vertical direction also

same reinforcement provided up to 750 mm in longitudinal direction and same reinforcement to other

web also.

Side Face Reinforcement

Ast = 315 mm2

Provide 6-12 mm diameter on each face of web.

Design of Deck Slab

Bending moment = 2219 kNm

Depth required= 201 mm

Depth provided= 250 mm safe.

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 7

Phani Kumar.Ch et al.

Main Reinforcement

Ast = 4256 mm2

Providing 16 mm diameter bars 100 mm c/c

Design of Transverse Reinforcement

M = 0.3 ML + 0.2 (MDL + MSIDL) M = 503 kNm

Ast = 1235 mm2

Providing 12 mm diameter bars @ 160 mm c/c

The detailing of side face reinforcement as shown in Figure 6.4 and cross sectional detailing as shown

in Figure .6.5

Figure6.4. Side face reinforcement detailing

Figure6.5. Cross sectional view (all dimensions are in mm)

6.4. Comparison of Results for Various Span to Depth Ratio

The comparison of prestress force, deflection and stresses values are obtained for various span/depth

ratios for box girder bridge as shown in Table 6.5.

Table6.5. Comparison of prestress force and deflection for various span to depth ratio

Span/Depth

15

16

17

18

19

Prestressing Force

(kN)

5428

5370

5309

5251

5194

Eccentricity

(mm)

850

800

750

700

650

DL+SIDL

14

16

17

19

22

Deflection (mm)

DL+SIDL+PRE DL+LL+PRE+SIDL

11

18

12

20

13

23

16

26

18

29

The comparison of stresses at transfer and working stage for various span to depth ratios for box

girder bridge as shown in Table 6.6.

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 8

Analysis and Design of Prestressed Box Girder Bridge by IRC: 112-2011

Table 6.6. Comparison of stresses for various span/ depth ratio

Span/Depth

15

Stress at Top

Stress at Bottom

1.52

0.87

Stress at Top

Stress at Bottom

1.41

0.48

16

17

At the Transfer Stage

1.51

1.5

0.87

0.87

At the Working Stage

0.43

0.43

-0.48

-0.47

18

19

units

1.49

0.87

1.48

0.88

Mpa

Mpa

0.42

-0.46

0.41

-0.45

Mpa

Mpa

7. CONCLUSIONS

From the analysis and design of post tensioned box girder bridge for various span to depth ratios the

following observations are made.

The various span to depth ratio are taken for the analysis of box girder bridges, and for all the

cases, deflection and stresses are within the permissible limits.

As the depth of box girder decreases, the prestressing force decreases and no of cables decreases.

Because of prestressing, more strength of concrete is utilized and also well governs serviceability.

New code (IRC:112) requires increased cover for pre tensioned strands as well as post tensioned

ducts, which will lead to increased thickness of webs and deck slab / soffit slabs for PSC girders /

PSC box girder bridges.

For the same cross section and same applied moment, steel difference is quite noticeable compare

to WSM, LSM consumes less steel than WSM and its better to change grade of steel rather

increasing grade of concrete for more %p steel difference.

REFERENCES

[1] Barr, P.J. (2008). Comparison of prestress losses for a prestress concrete bridge made with high

performance concrete, J. Bridge Eng., ASCE, 13 (5), 468-475.

[2] Byung Hwan Oh, In Hwan Yang (2001). Realistic long term prediction of prestress forces in

psc box girder bridges, J. Structural Eng., ASCE, 127 (9), 1109-1116.

[3] Chang-Su Shim, Pil-Goo Lee, Sung-Pil Chang (2001). Design of shear connection in composite

steel and concrete bridges with precast decks, J. Bridge Eng., ASCE, 15 (3), 725-733.

[4] Dereck J. Hodson, Paul J. Barr, and Marvin W. Halling (2012). Live-Load Analysis of Posttensioned Box-Girder Bridges, J. Bridge Eng., ASCE, 17(4), 644-651.

[5] Gonzalo R., Angel, C. A., Gonzalo R. and Juan R.C. (2000). Externally prestressed high

strength concrete viaduct, J. Bridge Eng., ASCE, 26 (4), 337-345.

[6] IRC: 18.(2000). Design criteria for prestressed concrete road bridges (post tensioned concrete),

IRC, New Delhi, India.

[7] IRC: 6. (2010). Loads and stresses, IRC, New Delhi, India.

[8] IRC:112. (2011). Code of practice for concrete bridges, IRC, New Delhi, India.

[9] IS1343.(1980). Indian Standard code of practice for prestressed concrete (First Revision), BIS,

New Delhi,India.

[10] Jarret Kasan, s. m., Kent, A. H. (2011). Redevelopment of prestressing force in severed

prestressed strands, J. Bridge Eng., ASCE,16 (3), 431-437.

[11] John B. Kennedy and Mohamed H. Soliman (1987). Temperature distribution in composite

bridges J. Structural Eng., ASCE, 113 (3), 475-482.

[12] Krishna Raju, N. (1995). Prestressed Concrete, Tata McGraw- Hill Publishing company

Limited, New Delhi.

[13] Leo E. Rodriguez, Paul J. Barr, Marv W. Halling (2013). Temperature effects on a box girder,

integral abutment bridge, journal of performance of constructed facilities, ASCE, 16(7), 548553.

[14] Raina, V.K. (1994). Concrete Bridge Practice-Analysis, Design and Economics, McGraw- Hill

Publishing Company Limited, New Delhi.

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 9

Phani Kumar.Ch et al.

[15] S. Maleki (2002). Effect of deck and support stiffness on seismic response of slab girder

bridges, Engineering Structures, 24, 219-226.

[16] Vikash Khatri, Pramod Kumar Singh and P.R.Maiti (2012). Comparative study of prestressed

steel concrete composite bridge of different span length and girder spacing, International

Journal of Modern Engineering Research, 2(5), 3917-3922.

AUTHORS BIOGRAPHY

Phani Kumar.Ch, got bachelor of technology in civil engineering from JNTUKakinada University. I did the project on Analysis & Design Of Prestressed Box

Girder Bridge By Irc-112-2011 in M.Tech Structural engineering with my guide

D.aditya sai kumar at Mandava nstitute of engineering and technology, jaggaipeta,

Andhra Pradesh.

S.V.V.K.Babu, was born in Machilipatnam, India, in 1991. He received the B.Tech.

degree in civil engineering from the University of JNTU KAKINADA, Andhra

Pradesh in 2013, and the M.Tech. degree in structural engineering from the

University of JNTU KAKINADA in 2015. In 2015, he joined as a Assistant

Professor in the Department of Civil Engineering, College of Sri Vasavi Institute of

Engineering & Technology, Nandamuru, Andhra Pradesh.

International Journal of Constructive Research in Civil Engineering (IJCRCE)

Page | 10

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Experimental and Computational Fluid Dynamics (CFD) Analysis of Additively Manufactured WeirsDocument7 paginiExperimental and Computational Fluid Dynamics (CFD) Analysis of Additively Manufactured Weirsanon_789699787Încă nu există evaluări

- Physical Progress of 1ADocument1 paginăPhysical Progress of 1Aanon_789699787Încă nu există evaluări

- Performance Analysis of Fiber Reinforced Concrete Using Experimental Method, Etabs and Optimization by Taguchi MethodDocument8 paginiPerformance Analysis of Fiber Reinforced Concrete Using Experimental Method, Etabs and Optimization by Taguchi Methodanon_789699787Încă nu există evaluări

- HAM 2015.11.24 Hybrid Annuity Model Bid Excel SheetDocument5 paginiHAM 2015.11.24 Hybrid Annuity Model Bid Excel Sheetanon_789699787Încă nu există evaluări

- PDP & DRN DPR Qty 04.03.2021Document49 paginiPDP & DRN DPR Qty 04.03.2021anon_789699787Încă nu există evaluări

- Water Supply Pipeline LengthDocument1 paginăWater Supply Pipeline Lengthanon_789699787Încă nu există evaluări

- MSS-53 Design of Box Culvert of Size 3.0m X 3.0 Reg.Document103 paginiMSS-53 Design of Box Culvert of Size 3.0m X 3.0 Reg.anon_789699787Încă nu există evaluări

- Material Rate 4Document1 paginăMaterial Rate 4anon_789699787Încă nu există evaluări

- Marshall Stability TestDocument10 paginiMarshall Stability Testanon_789699787Încă nu există evaluări

- Basic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine OutputDocument3 paginiBasic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine Outputanon_789699787Încă nu există evaluări

- QuarryDocument1 paginăQuarryanon_789699787Încă nu există evaluări

- Basic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine OutputDocument4 paginiBasic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine Outputanon_789699787Încă nu există evaluări

- MSRDC PKG 11: Rates of LabourDocument1 paginăMSRDC PKG 11: Rates of Labouranon_789699787Încă nu există evaluări

- Rate (As Per 2017-18) (B) Labour Description of LabourDocument2 paginiRate (As Per 2017-18) (B) Labour Description of Labouranon_789699787Încă nu există evaluări

- Qt. 20128101Document2 paginiQt. 20128101anon_789699787Încă nu există evaluări

- Honda Activa 125 Vs Yamaha Fascino 125 - Compare Prices, Specs, Features at ZigWheelsDocument12 paginiHonda Activa 125 Vs Yamaha Fascino 125 - Compare Prices, Specs, Features at ZigWheelsanon_789699787Încă nu există evaluări

- Marshall Stability TestDocument22 paginiMarshall Stability Testanon_789699787Încă nu există evaluări

- Machinery Rate AnalayisiDocument10 paginiMachinery Rate Analayisianon_789699787Încă nu există evaluări

- Nashik Material - Rates - 2016-2017 - 22Document46 paginiNashik Material - Rates - 2016-2017 - 22anon_789699787100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Lighting System DesignDocument2 paginiLighting System DesignReybin AlvarezÎncă nu există evaluări

- Application Testing Suite: Openscript Functional Testing IntroductionDocument36 paginiApplication Testing Suite: Openscript Functional Testing IntroductionRaul OlveraÎncă nu există evaluări

- Windows Server 2012 R2 NIC Teaming (LBFO) Deployment and ManagementDocument52 paginiWindows Server 2012 R2 NIC Teaming (LBFO) Deployment and Managementkarthikri7693Încă nu există evaluări

- Understanding Passivhaus 2nd Edition SampleDocument31 paginiUnderstanding Passivhaus 2nd Edition Sampleeneejeh01Încă nu există evaluări

- Evidence Describing Cities and Places PaolaDocument5 paginiEvidence Describing Cities and Places PaolaCatalina g. gÎncă nu există evaluări

- Lectures32606 31061 SixDocument60 paginiLectures32606 31061 SixSucharita SahaÎncă nu există evaluări

- BalanceNG V3 ManualDocument146 paginiBalanceNG V3 ManualHuynh NangÎncă nu există evaluări

- Crecent BrochureDocument15 paginiCrecent Brochureफेक खातेÎncă nu există evaluări

- Fair Flowers Fair Plants PDFDocument2 paginiFair Flowers Fair Plants PDFJeffÎncă nu există evaluări

- Zend Guard Release Notes v6 0Document3 paginiZend Guard Release Notes v6 0Marcos Vinícius GuardaÎncă nu există evaluări

- BT4 SpecsDocument65 paginiBT4 SpecsDiether MiclaÎncă nu există evaluări

- Types of Kitchen Layout Grade 7Document12 paginiTypes of Kitchen Layout Grade 7nelmae100% (1)

- Air ConditionDocument15 paginiAir Conditionarch powerÎncă nu există evaluări

- Brick Pavers Price ListDocument4 paginiBrick Pavers Price ListmohitÎncă nu există evaluări

- S1200 MKII: Instruction Manual Gebruiksaanwijzing BedienungsanleitungDocument12 paginiS1200 MKII: Instruction Manual Gebruiksaanwijzing BedienungsanleitungtinomutendaÎncă nu există evaluări

- Report Bka PDFDocument20 paginiReport Bka PDFFatin Nadia DieyaÎncă nu există evaluări

- Bluetooth SecurityDocument42 paginiBluetooth Securitysandeepsharma707Încă nu există evaluări

- Rizal As A Inventor, Discover and An ArchitectDocument11 paginiRizal As A Inventor, Discover and An ArchitectCarlo CanalesÎncă nu există evaluări

- Rust in S Web Brochure May 2014Document27 paginiRust in S Web Brochure May 2014video12Încă nu există evaluări

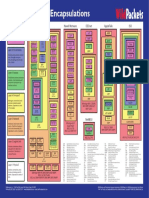

- Protocol Family Encapsulations ChartDocument1 paginăProtocol Family Encapsulations ChartbhzÎncă nu există evaluări

- Designs Guide To en 1994-2, Eurocode 4Document184 paginiDesigns Guide To en 1994-2, Eurocode 4Viet Duc Dang100% (3)

- PWC Design Guidelines For Sub-Development Rev3Document32 paginiPWC Design Guidelines For Sub-Development Rev3Dinesh GuptaÎncă nu există evaluări

- Royal Albert Hall Technical SpecificationDocument30 paginiRoyal Albert Hall Technical SpecificationtearamisueÎncă nu există evaluări

- Carrier - Rooftop Units Training ModuleDocument28 paginiCarrier - Rooftop Units Training Modulecalvin.bloodaxe4478Încă nu există evaluări

- Installation and User Manual: IP-Based Video Surveillance Management SystemDocument56 paginiInstallation and User Manual: IP-Based Video Surveillance Management Systemangelo_marananÎncă nu există evaluări

- Zome HildebrandtDocument8 paginiZome HildebrandtWes KlineÎncă nu există evaluări

- Tutorial Mikrotik KompletDocument284 paginiTutorial Mikrotik KompletDze AttharizzÎncă nu există evaluări

- Can BusDocument32 paginiCan BusSiddharth Chaudhury100% (3)

- Scenemaster3 ManualDocument79 paginiScenemaster3 ManualSeba Gomez LÎncă nu există evaluări

- Gangway Tower Dead WeightDocument71 paginiGangway Tower Dead Weight김남균Încă nu există evaluări