Documente Academic

Documente Profesional

Documente Cultură

API 510 QUIZ No.3

Încărcat de

Hatem RagabTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

API 510 QUIZ No.3

Încărcat de

Hatem RagabDrepturi de autor:

Formate disponibile

C

E

(

C

C

T

I

I

C

O

)

Quiz No. 3

1. External inspections are normally performed by

a. The examiner

b. The inspector

c.The owner/user

d. Any of the above

2. Buried

vessels

shall

be

their external surface condition

obtained from

inspected

to

determine

,the corrosion rate information

a.During maintenance activity on similar vessel

b.From the interval examination of similarly buried vessel

c.

From representative portions of the actual vessel

d. All of the above

3. When the short term corrosion rate changes significantly from the previous

identified rate

a.The inspector should consult with the corrosion Engineer

b.

The inspector should analyze the cause

c. The inspector should report to the owner

d. None of the above

4. Inspection

for

CUI

shall

be

considered

for

externally-insulated vessels and those that are in intermittent service or

operate between

a.10C and 350C for carbon and low alloy steels

b.140C and 350C for austenitic stainless steels

c.A and B

d.None of the above

5. it is not necessary to remove the insulation for inspection of the vessel

a.If external coverings are in good condition

b.If no evidence of fluid leakage.

c.

If Equipment is not in intermittent service

d.All of the above

6. The minimum hydro test temperature for in-service vessel of 2 thickness is:

a. MDMT+10 F

b. MDMT+30F

c.

MDMT+ 0C

d. MDMT+ 15C

7. When the service is changed from highly corrosive medium to clean non

corrosive hydrocarbon service

El Serag Mall Towers, Tower No. 2, Entrance No. 3, Flat No.81, Nasr city, Cairo, Egypt

E-mail:i.desoky@cic-egypt.com

E-mail: admin@cic-egypt.com

Web:

www.cic-egypt.com

Mob. 0121 47464749 Mob. 011 484 14 904

Fax: +2 02 26707979

Tel: +2 0226702161

E

(

C

C

T

I

I

C

O

)

a.CMLs may be eliminated or the number significantly reduced

b.The inspector should consult with the engineer

c.

A and B

d.None of the above

8. When the owner/user requires the detection of interior surface (ID) breaking

flaws when inspecting from the external surface (OD); .

a.

b.

c.

d.

The

The

The

The

Inspector shall specify industry-qualified UT shear wave examiners

owner/user shall specify industry-qualified UT angle beam examiners

owner/user shall specify industry-qualified UT angle beam examination procedure

examiner shall be qualified and certified

9. Possible sources of UT measurement inaccuracies

a. Improper instrument calibration

b. Excessive rocking of the probe

c. Subsurface material flaws

d. Any of the above

10. after an alteration

a. A pressure test is normally required

b. a pressure test shall be applied if the inspector believes that one is necessary

c. An engineer should be consulted

d. All of the above

11. Before applying a hydrostatic test

a. the supporting structures and foundation design should be reviewed to assure they

are suitable for the hydrostatic load

b. The Engineer should be consulted

c. The Owner/user shall be informed

d. The repair organization shall provide the water for the test

12. Appropriate NDE shall be specified and conducted when a pressure test is not

performed after a major repair

a. only after the engineer has approved

b. only after the inspector has approved

c. only after the Owner/user has approved

d. a and b

13.Calculate estimated inspection period for external and internal inspection for a

vessel whose remaining life is estimated as 12 years.

a. Internal = 6 years, external = 10 years

b. Internal = 6 years, external = 5 years

c. Internal = 5 years, external = 10 years

d. None of the above

14.A 2.0 inch thick vessel data-sheet shows MDMT= 50 deg. F. The minimum

pressure-test temperature for Hydro test to be carried out after alteration shall

be:

a. 70 deg F

b. 80 deg. F

c. 60 deg. F

El Serag Mall Towers, Tower No. 2, Entrance No. 3, Flat No.81, Nasr city, Cairo, Egypt

E-mail:i.desoky@cic-egypt.com

E-mail: admin@cic-egypt.com

Web:

www.cic-egypt.com

Mob. 0121 47464749 Mob. 011 484 14 904

Fax: +2 02 26707979

Tel: +2 0226702161

d.

E

(

C

C

T

I

I

C

O

)

None of above

15. Calculate the remaining life of a vessel given the following data: Actual

thickness = 0.955 inch. Minimum thickness required = 0.787 inch Thickness at

pervious inspection 5 years prior to present inspection = 1.015 inch

a.

b.

c.

d.

20 years

14 years

28 years

None of the above

16. A pressure vessel constructed according to ASME Sec VIII Div 1 with shell

thickness 7/8 (Material of Construction SA 387 gr 11 cl.1) is to be repaired by

using insert plates. The requirement of radiography to be incorporated in repair

procedure shall be:.

a.

b.

c.

d.

Full radiography

Spot radiography

May be a, or b depending on joint efficiency

Data is not adequate

17. For non-continuous corrosive service with remaining life 25 years, external

inspection shall be performed not later than:

a.

b.

c.

d.

10 years

12.5 years

5 years

None of above

18. A pressure vessel has been in service for 12 years and has a history of

corrosion over its service life. The original thickness was 1.9375 inches; the

current thickness is 1.405 inches. What is the corrosion rate for this vessel?

a.

b.

c.

d.

0.044

0.089

0.266

0.532

inch

inch

inch

inch

per

per

per

per

year

year

year

year

19. What will be total thinning (metal loss) up to next inspection due after 10

more years if Corrosion rate is 6 mills per year (mpy).

a.

b.

c.

d.

0.05 inch

0.06 inch

0.006 inch

0.6 inch

20. After an inspection interval is completed and if calculations indicate that an

inaccurate rate of corrosion has been assumed initially, how do you determine

the corrosion rate for the next inspection period?

a.

Check the original calculations to find out what the error is in the original

assumption.

b. Unless the corrosion rate is changed by Jurisdiction, the initial rates shall be used.

c. The corrosion rate shall be adjusted to agree with the actual rate found.

El Serag Mall Towers, Tower No. 2, Entrance No. 3, Flat No.81, Nasr city, Cairo, Egypt

E-mail:i.desoky@cic-egypt.com

E-mail: admin@cic-egypt.com

Web:

www.cic-egypt.com

Mob. 0121 47464749 Mob. 011 484 14 904

Fax: +2 02 26707979

Tel: +2 0226702161

d.

E

(

C

C

T

I

I

C

O

)

Call in a corrosion specialist

21. Materials used for making repair by welding in carbon steel vessels shall have

the following limitations?

a.

b.

c.

d.

They shall meet the requirements stipulated in NACE Standard.

The carbon content shall not be over 0.35%

Welding repair shall be done by using only the GTAW process

All of the above

22. For non-continuous corrosive service with remaining life 25 years, internal

inspection shall be performed not later than:

a.

b.

c.

d.

10 years

12.5 years

5 years

None of above

23. Calculate the remaining life and external insp. interval of a vessel given the

following data:

Actual thickness = 0.955 inch

Minimum thickness required = 0.755 inch

Thickness at previous inspection 5 years prior to present inspection = 1.025 inch

a.

b.

c.

d.

20 years, 10 years

14 years, 5years

28 years, 10 years

None of the above

24. A vessel which was inspected six years ago and had shell thickness = 0.870.

As on today the thickness as reported by filed inspection is 0.786. What was

the corrosion rate over last six years?

a.

b.

c.

d.

10 mpy

12 mpy

14 mpy

none of above

25. Which of the following are commonly preferred to know the process side

degradation of pressure vessels?

a.

b.

c.

d.

On stream inspection.

Internal inspection

External inspection as alternative to internal inspection

Any of above is OK

El Serag Mall Towers, Tower No. 2, Entrance No. 3, Flat No.81, Nasr city, Cairo, Egypt

E-mail:i.desoky@cic-egypt.com

E-mail: admin@cic-egypt.com

Web:

www.cic-egypt.com

Mob. 0121 47464749 Mob. 011 484 14 904

Fax: +2 02 26707979

Tel: +2 0226702161

E

(

C

C

T

I

I

C

O

)

26. Before carrying out an internal service inspection on a vessel put in-service

for quite some time what the inspector should do first

a.

b.

c.

d.

Check

Check

Check

Check

the

the

the

the

material in which it is constructed.

permanent file of the vessel.

progressive history file of the vessel.

original thickness report.

27. A pressure vessel of 60 has three pits within a circle of 7 diameter. The

nominal thickness of the shell is 0.75 and the CA is 0.125. The details and

dimensions of the pits are listed below. Your assessment is:

a.

b.

c.

d.

The

The

The

The

0.475 x 0.385 depth 0.21

1 diameter depth 0.35

0.375 x 0.385 depth 0.23

pit area is more than the acceptable

pit length is more than the acceptable

pit depth is more than the acceptable

pits are acceptable as they are meeting the requirement

28. For a new vessel the corrosion rate will be established based on:

a.

b.

c.

d.

Run the vessel for 3 or 6 weeks and establish the corrosion rate

Run the vessel for 3 or 6 months and establish the corrosion rate

Run the vessel for 18 weeks and establish the corrosion rate

After 1000 working hours

29. For MAWP calculations as per API 510, the thickness as determined by

inspection shall be used in these calculations after:

a.

b.

c.

d.

Deducting corrosion loss up to next inspection

Deducting twice the corrosion loss up to next inspection

Use the thickness as it is.

As regards thickness reduction due to corrosion, Code does not give specific

guidelines.

30. A vessel in service has different zones of corrosion. The next inspection

frequency will be decided by:

a.

b.

c.

d.

Zone with highest rate of corrosion

Zone with lowest remaining life

Average rate of corrosion shall be taken into consideration

To be established for each zone independently

31.

Each vessel above ground shall be given a visual external inspection

preferably while in operation at a frequency of:

a.

b.

c.

d.

At least once in every 5 years

Same as that required for internal or on stream inspection

The lesser of a or b

None of the above are applicable

El Serag Mall Towers, Tower No. 2, Entrance No. 3, Flat No.81, Nasr city, Cairo, Egypt

E-mail:i.desoky@cic-egypt.com

E-mail: admin@cic-egypt.com

Web:

www.cic-egypt.com

Mob. 0121 47464749 Mob. 011 484 14 904

Fax: +2 02 26707979

Tel: +2 0226702161

E

(

C

C

T

I

I

C

O

)

32. During Hydrostatic testing, risk of brittle fracture, which of the following

action may be taken

a.

b.

c.

d.

Replace Hydro testing by pneumatic testing

Recalculate test pressure based on material stress at MDMT

Carry out test at temperature more 300F above MDMT

None of the above

33. Which of the following are essential elements of a Quality Assurance system of

a repair organization of relive device?

a.

b.

c.

d.

Organizational authority and responsibility

Statements about Working (Inspection/repair)Procedures and

Statement of controls to ensure Quality conformance

All of the above

their documentation

34. Which of the following statements is true?

a.

b.

c.

d.

All defects are not discontinuities

All discontinuities are defects

Discontinuities are rejectable defects

Defects are rejectable discontinuities

El Serag Mall Towers, Tower No. 2, Entrance No. 3, Flat No.81, Nasr city, Cairo, Egypt

E-mail:i.desoky@cic-egypt.com

E-mail: admin@cic-egypt.com

Web:

www.cic-egypt.com

Mob. 0121 47464749 Mob. 011 484 14 904

Fax: +2 02 26707979

Tel: +2 0226702161

S-ar putea să vă placă și

- Mae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsDocument28 paginiMae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsmibarjanÎncă nu există evaluări

- API-510 Practice Exam QuestionsDocument18 paginiAPI-510 Practice Exam QuestionsAshish Patel100% (2)

- API 510 QUIZ No.1Document3 paginiAPI 510 QUIZ No.1Hatem RagabÎncă nu există evaluări

- API 510 Open Book Practice ExamDocument48 paginiAPI 510 Open Book Practice Examcorey jacobsÎncă nu există evaluări

- Welding Interview Question His Answers GuideDocument8 paginiWelding Interview Question His Answers GuideHatem RagabÎncă nu există evaluări

- Cyliani's Hermes UnveiledDocument31 paginiCyliani's Hermes UnveiledAndre Bambu100% (2)

- API 510 Closed Questions GuideDocument5 paginiAPI 510 Closed Questions GuideEinsteinw2Încă nu există evaluări

- WPS PQR Checklist 2014Document2 paginiWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- ASME V QuestionsDocument25 paginiASME V QuestionsAshish PatelÎncă nu există evaluări

- Api 510 Questions & Answers (Closed 1)Document12 paginiApi 510 Questions & Answers (Closed 1)Mohammed Shakil100% (3)

- 510 Final CBDocument14 pagini510 Final CBcsrajesh100% (1)

- Daily Points To Recall (Day 3) : API 653 PreparatoryDocument2 paginiDaily Points To Recall (Day 3) : API 653 PreparatoryMohammed ShakilÎncă nu există evaluări

- Api 510 Q&aDocument13 paginiApi 510 Q&aShaikh Aftab100% (1)

- Bay.t-510 Close Prac Exam #3Document22 paginiBay.t-510 Close Prac Exam #3Karim Mamdouh50% (2)

- Wellhead Corrosion and Trim SelectionDocument34 paginiWellhead Corrosion and Trim SelectionGuillaume Boyer100% (3)

- API-510 Exam # 3 2008 Closed Book ExamDocument22 paginiAPI-510 Exam # 3 2008 Closed Book ExamDarwisyEzanee100% (1)

- Boost Your API-570 Piping Inspectors Exam ScoreDocument6 paginiBoost Your API-570 Piping Inspectors Exam Scorejaire esparzaÎncă nu există evaluări

- P91 Welding and PWHT ProcedureDocument4 paginiP91 Welding and PWHT ProcedureHatem Ragab100% (2)

- API 570 Final Exam Open Book Questions 24Document11 paginiAPI 570 Final Exam Open Book Questions 24Ravindra S. Jivani100% (5)

- API 510 Mid Session Closed0Document10 paginiAPI 510 Mid Session Closed0مبشر أحمد100% (2)

- API 572 (Question Answers)Document39 paginiAPI 572 (Question Answers)Muhammad Shoaib100% (1)

- API 510.jan 2022open ClosedDocument3 paginiAPI 510.jan 2022open ClosedChiheb KaanicheÎncă nu există evaluări

- API 510 PC 20 31 Aug05 Bench MarkDocument4 paginiAPI 510 PC 20 31 Aug05 Bench MarknikafiqÎncă nu există evaluări

- API 510 ClosedDocument15 paginiAPI 510 ClosedHarmish mewadaÎncă nu există evaluări

- API 510 Questions Amp Answers Closed Book 1 PDF FreeDocument12 paginiAPI 510 Questions Amp Answers Closed Book 1 PDF Freejakariya100% (2)

- API 510 - Open 2 & Open 8Document11 paginiAPI 510 - Open 2 & Open 8EswaranÎncă nu există evaluări

- Api 510 Preparatory ExamDocument13 paginiApi 510 Preparatory Exameldobie3100% (1)

- BAY.t - 510 Close Prac Exam #5Document18 paginiBAY.t - 510 Close Prac Exam #5Moustafa Fares100% (2)

- Api 510 Q&a-2Document32 paginiApi 510 Q&a-2Mohammed ShakilÎncă nu există evaluări

- API 570 Final Exam Close Book Questions 23Document10 paginiAPI 570 Final Exam Close Book Questions 23Ravindra S. Jivani100% (1)

- API-510 Exam Prep Course Practice Exam #3 SolutionsDocument14 paginiAPI-510 Exam Prep Course Practice Exam #3 SolutionsKarim MamdouhÎncă nu există evaluări

- API 510 Exam May 2016Document5 paginiAPI 510 Exam May 2016abdoÎncă nu există evaluări

- API 510 Exam Study GuideDocument6 paginiAPI 510 Exam Study GuidetayyabÎncă nu există evaluări

- Set-C API 510 Preparatory CourseDocument29 paginiSet-C API 510 Preparatory CourseptssoftÎncă nu există evaluări

- Examination Question 510Document12 paginiExamination Question 510ohengjkt100% (1)

- API 510 Closed Book QuestionsDocument16 paginiAPI 510 Closed Book QuestionsRavindra S. Jivani100% (1)

- Api 510 Study Guide Practice Questions PDFDocument2 paginiApi 510 Study Guide Practice Questions PDFPrashant KumarÎncă nu există evaluări

- Lessons in Radiography Using X-Ray SimulationDocument59 paginiLessons in Radiography Using X-Ray SimulationWilliam Pinto HernándezÎncă nu există evaluări

- Lessons in Radiography Using X-Ray SimulationDocument59 paginiLessons in Radiography Using X-Ray SimulationWilliam Pinto HernándezÎncă nu există evaluări

- Api 510 Practice Exam B (150 Questions) : Design Temp Test TempDocument45 paginiApi 510 Practice Exam B (150 Questions) : Design Temp Test Temperagorn100% (2)

- Milk, Butter, Cheese, Creams, Coloured Gems, Boot Polish, Rubber, Ink EtcDocument18 paginiMilk, Butter, Cheese, Creams, Coloured Gems, Boot Polish, Rubber, Ink EtcSaikat Ranjan PaulÎncă nu există evaluări

- API 510 CB Mockup 3 R0 26112010Document18 paginiAPI 510 CB Mockup 3 R0 26112010essnelsonÎncă nu există evaluări

- Final Exam With AnswersDocument7 paginiFinal Exam With AnswersHatem RagabÎncă nu există evaluări

- API 577 Key Points - Chapter 5Document4 paginiAPI 577 Key Points - Chapter 5muhammadazharÎncă nu există evaluări

- API 578 Sample QuestionsDocument8 paginiAPI 578 Sample Questionshenjisu100% (1)

- API Recert QuestionsDocument8 paginiAPI Recert Questionsrama77Încă nu există evaluări

- API 510 Preparatory Training Exam QuestionsDocument13 paginiAPI 510 Preparatory Training Exam QuestionsCss SfaxienÎncă nu există evaluări

- API 570 Open Book (26-02-18)Document5 paginiAPI 570 Open Book (26-02-18)Mahmoud Alwasif100% (1)

- 510 Closed Exam ADocument24 pagini510 Closed Exam AAPIÎncă nu există evaluări

- API 510 Questions June 02 2004 1Document10 paginiAPI 510 Questions June 02 2004 1Ariq FauzanÎncă nu există evaluări

- API 510 Exam 5 ClosedDocument4 paginiAPI 510 Exam 5 ClosedweerasinghekÎncă nu există evaluări

- Api 510 Close Book (Sec Viii & 510) - 17Document12 paginiApi 510 Close Book (Sec Viii & 510) - 17walid walid100% (1)

- Equilibrium Calculation For DMEDocument8 paginiEquilibrium Calculation For DMEAbhishek KumarÎncă nu există evaluări

- Open Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedDocument16 paginiOpen Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedBeantickÎncă nu există evaluări

- Api 653 Preparatory Course: Exam 4 - Closed BookDocument4 paginiApi 653 Preparatory Course: Exam 4 - Closed BookNuwan Ranaweera100% (1)

- M20Document54 paginiM20Mijail Pérez Miranda100% (1)

- 510 IRS Pune Open Book Questions FinalDocument6 pagini510 IRS Pune Open Book Questions Finaljaheer1Încă nu există evaluări

- Api 510 Preparatory Bench Mark Quiz: AppropriateDocument120 paginiApi 510 Preparatory Bench Mark Quiz: AppropriateCss Sfaxien100% (1)

- Daily Points To Recall (Day 8) : Page 1 of 3Document3 paginiDaily Points To Recall (Day 8) : Page 1 of 3chowhkÎncă nu există evaluări

- API 510.jan 2022 (Open & Closed)Document79 paginiAPI 510.jan 2022 (Open & Closed)Ali BEN YESAADÎncă nu există evaluări

- API 510 QUIZ No.4Document5 paginiAPI 510 QUIZ No.4Hatem RagabÎncă nu există evaluări

- API 572 Study Guide: Practice QuestionsDocument10 paginiAPI 572 Study Guide: Practice QuestionsRizwan Nazir100% (1)

- API 570 Preparatory Course Exam QuestionsDocument9 paginiAPI 570 Preparatory Course Exam QuestionsbananaÎncă nu există evaluări

- API 570 Open BookDocument9 paginiAPI 570 Open BookMusa ÇelikÎncă nu există evaluări

- API 510 QuestionsDocument17 paginiAPI 510 Questionsyesuplus2Încă nu există evaluări

- API 577 Questions Scope and DefinitionsDocument10 paginiAPI 577 Questions Scope and DefinitionsmaorealesÎncă nu există evaluări

- API 510 Data Sheets - QuizletDocument1 paginăAPI 510 Data Sheets - Quizletads_1203Încă nu există evaluări

- API 510 exam questionsDocument8 paginiAPI 510 exam questionsJeremy CoussouÎncă nu există evaluări

- Polyurea Resistance ChartDocument1 paginăPolyurea Resistance ChartTanmay GorÎncă nu există evaluări

- Api 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetDocument14 paginiApi 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetCss Sfaxien100% (1)

- 510 Closed Exam B, Rev8Document20 pagini510 Closed Exam B, Rev8yrdna nawaiteosÎncă nu există evaluări

- MSTS Mark's API 510 STUDY GUIDE.Document30 paginiMSTS Mark's API 510 STUDY GUIDE.Hares SlalÎncă nu există evaluări

- API RP 572 QuizDocument17 paginiAPI RP 572 Quizamalhaj2013Încă nu există evaluări

- Intumescent Method Statement - UGDC - R00 14Document1 paginăIntumescent Method Statement - UGDC - R00 14Hatem RagabÎncă nu există evaluări

- Intumescent Method Statement - UGDC - R00 13Document1 paginăIntumescent Method Statement - UGDC - R00 13Hatem RagabÎncă nu există evaluări

- Intumescent Method Statement - UGDC - R00 12Document1 paginăIntumescent Method Statement - UGDC - R00 12Hatem RagabÎncă nu există evaluări

- Welding Advanced Chromium Alloys for High-Temperature ServiceDocument5 paginiWelding Advanced Chromium Alloys for High-Temperature Servicesaji_t1984100% (1)

- Influence of Heat Input and Post-Weld Heat Treatment On Boiler Steel P91 (9Document10 paginiInfluence of Heat Input and Post-Weld Heat Treatment On Boiler Steel P91 (9Hatem RagabÎncă nu există evaluări

- Intumescent Method Statement - UGDC - R00 11Document1 paginăIntumescent Method Statement - UGDC - R00 11Hatem RagabÎncă nu există evaluări

- Intumescent Method Statement - UGDC - R00 15Document1 paginăIntumescent Method Statement - UGDC - R00 15Hatem RagabÎncă nu există evaluări

- Job DescribtionDocument2 paginiJob DescribtionHatem RagabÎncă nu există evaluări

- Dear SirDocument1 paginăDear SirHatem RagabÎncă nu există evaluări

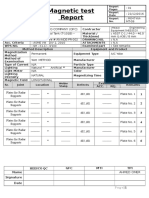

- Magnetic Test: Client: Gas Filling Company (GFC) ContractorDocument1 paginăMagnetic Test: Client: Gas Filling Company (GFC) ContractorHatem RagabÎncă nu există evaluări

- 7T04 CS Kma PR ND 0005Document12 pagini7T04 CS Kma PR ND 0005Hatem Ragab100% (1)

- Large GapDocument1 paginăLarge GapHatem RagabÎncă nu există evaluări

- Level III Responsibilities According To ASNTDocument1 paginăLevel III Responsibilities According To ASNTHatem RagabÎncă nu există evaluări

- PT General - Hellier No 2Document11 paginiPT General - Hellier No 2Hatem RagabÎncă nu există evaluări

- English Language CourseDocument216 paginiEnglish Language CourseHatem RagabÎncă nu există evaluări

- Real Time Radiography Course BookletDocument48 paginiReal Time Radiography Course BookletAnonymous gFcnQ4goÎncă nu există evaluări

- UT Report Data for Upper Part WeldsDocument3 paginiUT Report Data for Upper Part WeldsHatem RagabÎncă nu există evaluări

- Fu/ e ,'. C-.J Ef GK"-T, F SUDocument1 paginăFu/ e ,'. C-.J Ef GK"-T, F SUHatem RagabÎncă nu există evaluări

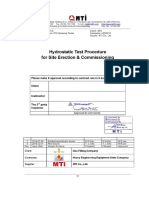

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1Document7 paginiHydrostatic Test Procedure For Site & Commissioning HT-031-R1Hatem Ragab100% (1)

- DCTR : - Prhe Ah, M,,HBTZ T+WZDocument1 paginăDCTR : - Prhe Ah, M,,HBTZ T+WZHatem RagabÎncă nu există evaluări

- Site Consumable Part List For LPG Spherical TankDocument13 paginiSite Consumable Part List For LPG Spherical TankHatem RagabÎncă nu există evaluări

- UT Report Data For Equator 9-9-2016Document2 paginiUT Report Data For Equator 9-9-2016Hatem RagabÎncă nu există evaluări

- ARTICLE 4 Û Mandatory AppendixDocument10 paginiARTICLE 4 Û Mandatory AppendixHatem RagabÎncă nu există evaluări

- MSDS - Robond L-330 - ISS130910Document7 paginiMSDS - Robond L-330 - ISS130910Anonymous pXU4tefJÎncă nu există evaluări

- 17-Oil Centrifuge PDFDocument89 pagini17-Oil Centrifuge PDFUmangtarangÎncă nu există evaluări

- Pipe ForgeDocument6 paginiPipe ForgePierre799esÎncă nu există evaluări

- Concrete Repair and Protection System1 - CeresitDocument12 paginiConcrete Repair and Protection System1 - CeresitJill Jim LivestockÎncă nu există evaluări

- Motor Oil ENGDocument64 paginiMotor Oil ENGNicolai BelocosovÎncă nu există evaluări

- Factors of Safety for Cuttings in Normally Consolidated ClaysDocument5 paginiFactors of Safety for Cuttings in Normally Consolidated ClaysAnonymous GnfGTwÎncă nu există evaluări

- Ans No. 4-Conservation of Mass Equation-: + Known As Continuity EquationDocument4 paginiAns No. 4-Conservation of Mass Equation-: + Known As Continuity EquationHimanshu TrivediÎncă nu există evaluări

- K3 Skema Cemerlang Set 1Document4 paginiK3 Skema Cemerlang Set 1annurshah05Încă nu există evaluări

- Effect of Concentration in Rate of ReactionDocument3 paginiEffect of Concentration in Rate of ReactionblablaÎncă nu există evaluări

- A2 Biology Nerve Impulse ExamDocument16 paginiA2 Biology Nerve Impulse ExamDeborah HenniganÎncă nu există evaluări

- Clean Light-Colored Bricks SafelyDocument1 paginăClean Light-Colored Bricks SafelymutazsalihÎncă nu există evaluări

- 1400 10MDocument5 pagini1400 10MAngelia WileyÎncă nu există evaluări

- Sulfur and Nirogen IndustriesDocument58 paginiSulfur and Nirogen IndustriesSarah SanchezÎncă nu există evaluări

- Especificacion Tecnica Tanques FRP CANATUREDocument3 paginiEspecificacion Tecnica Tanques FRP CANATURETomasae1980Încă nu există evaluări

- DX 2010 0625 EngDocument12 paginiDX 2010 0625 EngguillermorettoÎncă nu există evaluări

- A-3 LM Sol (Pulley)Document28 paginiA-3 LM Sol (Pulley)rockingjoeÎncă nu există evaluări

- 1 02 Coco PDFDocument13 pagini1 02 Coco PDFsandeep lalÎncă nu există evaluări

- 128 Salicylic Rohdia MSDSDocument13 pagini128 Salicylic Rohdia MSDSWike Wingtias ArnesaÎncă nu există evaluări

- Bet Muestra 6Document7 paginiBet Muestra 6Eli GutierrezÎncă nu există evaluări

- LL0220AA Linear Low Density Polyethylene Film PropertiesDocument1 paginăLL0220AA Linear Low Density Polyethylene Film PropertiesXuân Giang NguyễnÎncă nu există evaluări

- NEET-2021 (Paper Analysis) FinalDocument32 paginiNEET-2021 (Paper Analysis) FinalMahasina BegumÎncă nu există evaluări

- Arora 2003 - VIPDocument6 paginiArora 2003 - VIPMaria Laura Viola AugustoÎncă nu există evaluări

- 13NO03 GN 60 001 Deliverable ListDocument4 pagini13NO03 GN 60 001 Deliverable Listbagus handokoÎncă nu există evaluări