Documente Academic

Documente Profesional

Documente Cultură

Exercise 5 Combined Cycle

Încărcat de

Nho Nha TranDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Exercise 5 Combined Cycle

Încărcat de

Nho Nha TranDrepturi de autor:

Formate disponibile

SPG course MJ2405

Exercise 5: Combined Cycle detailed calculations

An old steam power plant is refurbished (repowered) by scrapping the steam boiler

and adding a gas turbine as a topping cycle, thus converting it into a combined cycle.

The gas turbine has the following characteristics:

Gas Turbine

Electrical

Power Output

(MW)

Electrical

Efficiency (%)

Alstom

115

33.1

GT11N2

The gas content in the exhaust gas flow is x ~ 30%.

Exhaust Gas

flow (kg/s)

Exhaust gas

temperature

(C)

399

531

The old steam turbine already exists and would use a single-pressure HRSG, without

supplementary firing. Steam needs to be produced at 50 bar, superheated to 510 C.

The isentropic efficiency of the steam turbine is 88%. The mechanical and electrical

efficiencies of the steam turbine are together 98%. The electrical power output from

the steam turbine is 56 MW. The pressure in the condenser is 0.05 bar.

The steam cycle will be simplified and all feedwater preheaters demolished. For the

sake of clarity the feedwater tank can also be neglected for this calculation.

Main Tasks:

1. Calculate the necessary steam mass flow for the existing steam turbine.

2. Calculate the pinch point temperature difference in the HRSG.

3. Calculate the combined cycle electrical efficiency.

4. Calculate the flue gas temperature at the end of the HRSG (in the stack).

Additional Tasks:

5. Find the exact gas content if the fuel is pure methane with LHV = 50 MJ/kg.

6. If supplementary firing is added in the HRSG to raise the gas temperature to

600 oC how much would be the new combined cycle electrical efficiency?

7. Convert the HRSG into a double-pressure system by changing the steam

turbine with a new one demanding HP steam input at 90 bar and LP steam at

10 bar, where the HP and LP steam mass flows are equal. Recalculate for

finding the new overall electrical efficiency value.

S-ar putea să vă placă și

- Tugas 2 MS2230 Sem II 18-19 PDFDocument1 paginăTugas 2 MS2230 Sem II 18-19 PDFHanif MuhammadÎncă nu există evaluări

- MPD 2012 - Sheet 3 - Binary and Combined CyclesDocument3 paginiMPD 2012 - Sheet 3 - Binary and Combined CyclesPeter Raouf100% (1)

- Assignment and Its Solution - Airstandardcycle and VapourcycleDocument24 paginiAssignment and Its Solution - Airstandardcycle and VapourcycleMatthias100% (1)

- Power Plants SheetsDocument8 paginiPower Plants Sheetsmkk0% (2)

- Performance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat RecuperationDocument6 paginiPerformance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat Recuperationwgxiang100% (4)

- Hybrid Combined Cycle Power Plant: Károly VeszelyDocument8 paginiHybrid Combined Cycle Power Plant: Károly Veszelyankit407Încă nu există evaluări

- 0 S PP Chap6Document57 pagini0 S PP Chap6Adib Nawawi100% (1)

- Thermo-2 Worked Examples and Worksheet On Vapor Power CycleDocument11 paginiThermo-2 Worked Examples and Worksheet On Vapor Power CycleÇãłl Mê MęlkãÎncă nu există evaluări

- Electric CarsDocument48 paginiElectric Carsabdokhamis000Încă nu există evaluări

- Contoh Penyelesain Soal Termo DuaDocument44 paginiContoh Penyelesain Soal Termo DuaNuisma MaharaniÎncă nu există evaluări

- Tutorial Vapor and Combined Power CyclesDocument3 paginiTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- Ppe Activity 9Document3 paginiPpe Activity 9Marycris Bautista RosarioÎncă nu există evaluări

- Problemario MFCDocument31 paginiProblemario MFCPonce MrlnÎncă nu există evaluări

- Power Plant New QuestionDocument2 paginiPower Plant New QuestionRishav niroulaÎncă nu există evaluări

- Comparison Concerning To The Cogeneration Systems DevelopmentDocument6 paginiComparison Concerning To The Cogeneration Systems DevelopmentMarianoÎncă nu există evaluări

- Home Assignment: 2 Power Plant Engineering: ME 413TLPDocument1 paginăHome Assignment: 2 Power Plant Engineering: ME 413TLPBIPIN SHARMAÎncă nu există evaluări

- Heat Engines Mechanical Energy Make ElectricityDocument5 paginiHeat Engines Mechanical Energy Make ElectricityAbdelrhman AboodaÎncă nu există evaluări

- CHP 17 - Web GicquelDocument10 paginiCHP 17 - Web GicquelEr Sathyaprakash RamasamyÎncă nu există evaluări

- Assingment 2Document2 paginiAssingment 2habtish100% (1)

- HW 5 Problem SetDocument3 paginiHW 5 Problem SetJustinTimeÎncă nu există evaluări

- Combined Gas (Turbine) and Steam (Turbine) : (COGAS)Document28 paginiCombined Gas (Turbine) and Steam (Turbine) : (COGAS)scribdhas2006100% (1)

- Problemario MFCDocument80 paginiProblemario MFCBassaldua AlfreedÎncă nu există evaluări

- Lecture No.3 The Ideal Reheat Rankine CycleDocument12 paginiLecture No.3 The Ideal Reheat Rankine Cycledanielalejandro133Încă nu există evaluări

- 01-Sheet 01Document9 pagini01-Sheet 01samir mohamedÎncă nu există evaluări

- ASME90 GT 335 BollandDocument9 paginiASME90 GT 335 Bollandank_mehraÎncă nu există evaluări

- MPE112s - Sheet - 05 - Applications On 1st Law of ThermodynamicsDocument2 paginiMPE112s - Sheet - 05 - Applications On 1st Law of Thermodynamicsb5fc94cdd3Încă nu există evaluări

- Mini Project ThermoDocument3 paginiMini Project Thermoady joffriyÎncă nu există evaluări

- Air FanDocument6 paginiAir FanDevi PurnamasariÎncă nu există evaluări

- Tutorial 1Document4 paginiTutorial 1Anonymous lV8E5mEOÎncă nu există evaluări

- Tutorial2 Sheet For Combined Power PlantsDocument2 paginiTutorial2 Sheet For Combined Power PlantsEngMohammed AhmedÎncă nu există evaluări

- Numerical Problems: Power Plant Equipment (Electrical IV/I)Document3 paginiNumerical Problems: Power Plant Equipment (Electrical IV/I)Rishav niroulaÎncă nu există evaluări

- EGR 334 Lecture 32 Superheating and RegenerationDocument29 paginiEGR 334 Lecture 32 Superheating and RegenerationChris HockubaÎncă nu există evaluări

- Assignment 1Document1 paginăAssignment 1Billy LimÎncă nu există evaluări

- MHD GeneratorDocument5 paginiMHD GeneratorAmit KumarÎncă nu există evaluări

- Combined CycleDocument8 paginiCombined CycleAnonymous mNQq7oj100% (1)

- Tutorial - Gas Turbine CyclesDocument3 paginiTutorial - Gas Turbine CyclesSuchi Suchi SuchiÎncă nu există evaluări

- Assignment 1 MEPPEDocument5 paginiAssignment 1 MEPPEFrancis Paulo CruzÎncă nu există evaluări

- Vapour MathDocument2 paginiVapour MathMD.OSMAN ALIÎncă nu există evaluări

- Thermo Thaqif (Rewritten)Document9 paginiThermo Thaqif (Rewritten)AmirulAminÎncă nu există evaluări

- Vapor CycleDocument4 paginiVapor CycleImie CamachoÎncă nu există evaluări

- Vapour Power Cycle - Part 2Document18 paginiVapour Power Cycle - Part 2Shwe Wen LimÎncă nu există evaluări

- L3-Vapor Power SystemsDocument18 paginiL3-Vapor Power SystemsTarun MalviyaÎncă nu există evaluări

- Problem Sheet-07 ME201 Power CyclesDocument1 paginăProblem Sheet-07 ME201 Power CyclesKavitha KandulaÎncă nu există evaluări

- Assignment I (Analysis of Steam Cycle)Document2 paginiAssignment I (Analysis of Steam Cycle)SR SuryaÎncă nu există evaluări

- Thermodynamics Rankine ExamplesDocument8 paginiThermodynamics Rankine ExamplesSre VinodÎncă nu există evaluări

- Rumus Perhitungan Turbin UapDocument17 paginiRumus Perhitungan Turbin Uapricki yusufÎncă nu există evaluări

- Motor Bakar Minggu-11Document45 paginiMotor Bakar Minggu-11setoÎncă nu există evaluări

- Vapour and Combine Power CyclesDocument4 paginiVapour and Combine Power CyclesKishore KrishÎncă nu există evaluări

- 8 Combined Cycle and CogenerationDocument19 pagini8 Combined Cycle and CogenerationMuffin Everydays100% (1)

- Combined Cycle Power PlantDocument2 paginiCombined Cycle Power Plantiman562Încă nu există evaluări

- Thermo of MechDocument2 paginiThermo of MecheyobÎncă nu există evaluări

- ME LAB 3 ReportDocument37 paginiME LAB 3 ReportwijawijaÎncă nu există evaluări

- Module 3 - Regenerative Rankine Cycle: Answers: (A) 1016.5 KJ/KG (B) 37.8 %Document1 paginăModule 3 - Regenerative Rankine Cycle: Answers: (A) 1016.5 KJ/KG (B) 37.8 %subyÎncă nu există evaluări

- 3.1 Regenerative Rankine Cycle PDFDocument1 pagină3.1 Regenerative Rankine Cycle PDFsubyÎncă nu există evaluări

- Part One Introduction of N600-16.7/538/538 Steam TurbineDocument10 paginiPart One Introduction of N600-16.7/538/538 Steam TurbinetoxxkÎncă nu există evaluări

- Slides - What Is ProgrammingDocument13 paginiSlides - What Is ProgrammingNho Nha TranÎncă nu există evaluări

- Shortcut Keys For Windows 10Document3 paginiShortcut Keys For Windows 10Dan Gusarenco100% (1)

- S? D?NG Serial Key: DTU-D43E-835C-EF9C-4C52-B279-DAC8Document1 paginăS? D?NG Serial Key: DTU-D43E-835C-EF9C-4C52-B279-DAC8Nho Nha TranÎncă nu există evaluări

- WORKINGINTEAMS CreatingEffectiveTeamsDocument16 paginiWORKINGINTEAMS CreatingEffectiveTeamsNho Nha TranÎncă nu există evaluări

- Calmet Company Portrait EN 2023-01Document4 paginiCalmet Company Portrait EN 2023-01shailesh shaileshÎncă nu există evaluări

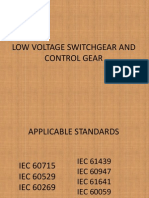

- Low Voltage Switchgear and Control GearDocument9 paginiLow Voltage Switchgear and Control Gearshanmars007Încă nu există evaluări

- Laser Pulses Power Energy EquationsDocument9 paginiLaser Pulses Power Energy EquationsViệt TrầnÎncă nu există evaluări

- Updated Register of Licensed Electrical ContractorsDocument63 paginiUpdated Register of Licensed Electrical ContractorsmachariakaruriÎncă nu există evaluări

- Spad 346 C Stabilized Differential Relay: User S Manual and Technical DescriptionDocument178 paginiSpad 346 C Stabilized Differential Relay: User S Manual and Technical DescriptionMohd SalehÎncă nu există evaluări

- Welcome To My Presentation: Topic Name: Socio-Economic Impact of Solar Home System in BangladeshDocument28 paginiWelcome To My Presentation: Topic Name: Socio-Economic Impact of Solar Home System in BangladeshNaeem AhmadÎncă nu există evaluări

- Arcovis 3000 - Chapter 8 - Electrical Drawings - RevCDocument53 paginiArcovis 3000 - Chapter 8 - Electrical Drawings - RevCEleanor LouÎncă nu există evaluări

- KW and KWH Explained: What Is Energy?Document8 paginiKW and KWH Explained: What Is Energy?Wai Ee YapÎncă nu există evaluări

- TS Synchronous CondenserDocument8 paginiTS Synchronous CondenserAndré LuizÎncă nu există evaluări

- Boiler (Steam Generator) : From Wikipedia, The Free EncyclopediaDocument20 paginiBoiler (Steam Generator) : From Wikipedia, The Free EncyclopediaCarlito PantalunanÎncă nu există evaluări

- Lab 1 Introduction To Power System ProtectionDocument11 paginiLab 1 Introduction To Power System Protectionsaud aliÎncă nu există evaluări

- Electricity Bill Duplicate Bill: Account No: 1973942840Document1 paginăElectricity Bill Duplicate Bill: Account No: 1973942840Gaurang GoelÎncă nu există evaluări

- Part 4 - Electrical and Electronic Systems Within Structures 5 - CompactDocument157 paginiPart 4 - Electrical and Electronic Systems Within Structures 5 - Compactneoph138Încă nu există evaluări

- Kamstrup 162 M - Brochure - EnglishDocument4 paginiKamstrup 162 M - Brochure - EnglishAnonymous TVdKmkÎncă nu există evaluări

- 30 kVA Specification SheetDocument2 pagini30 kVA Specification SheetAlex MohanÎncă nu există evaluări

- Split Phase AC Motor ReviewDocument1 paginăSplit Phase AC Motor ReviewJenny MaristelaÎncă nu există evaluări

- Add Info B-65285EN 03Document8 paginiAdd Info B-65285EN 03Denis Villanueva PerezÎncă nu există evaluări

- DIgSILENT Print PDFDocument3 paginiDIgSILENT Print PDFDanny A. AnchapuriÎncă nu există evaluări

- Electrical System Design For High Rise BuildingDocument12 paginiElectrical System Design For High Rise Buildingbookbok100% (5)

- Pre-Designed Steam Turbines enDocument8 paginiPre-Designed Steam Turbines enBoos Kanhaiya LalÎncă nu există evaluări

- Ground-Fault Circuit-Interrupters UL 943: 1 ScopeDocument1 paginăGround-Fault Circuit-Interrupters UL 943: 1 Scopedanielliram993Încă nu există evaluări

- 15 Power Converter Technologies for Photovoltaic Systems and Energy Storage - คุณณัฐนันท์Document24 pagini15 Power Converter Technologies for Photovoltaic Systems and Energy Storage - คุณณัฐนันท์chock channel 19Încă nu există evaluări

- Revo Series - II: Product SnapshotDocument2 paginiRevo Series - II: Product SnapshotStefan CorneaÎncă nu există evaluări

- Tesla Coil (2K19EE219) R1Document11 paginiTesla Coil (2K19EE219) R1Sanyam JainÎncă nu există evaluări

- Question Bank in TransformersDocument17 paginiQuestion Bank in TransformersMark Franz Templonuevo57% (7)

- Elctrical Machine 1 Final ExamDocument4 paginiElctrical Machine 1 Final ExamAbdullahi Mohamed IsakÎncă nu există evaluări

- PK Reverse Power Flow Protection of Generator PaperDocument4 paginiPK Reverse Power Flow Protection of Generator PaperTushar BehalpadeÎncă nu există evaluări

- 05512647Document9 pagini05512647rajia@cput.ac.zaÎncă nu există evaluări

- TurbochargerDocument24 paginiTurbochargerVulebg VukoicÎncă nu există evaluări

- Trihal TRI1250245297IP210Document2 paginiTrihal TRI1250245297IP210Aryo BayuÎncă nu există evaluări