Documente Academic

Documente Profesional

Documente Cultură

Pressure Transient and Production Data Analysis of Horizontal Well in Unconsolidated Formation in Frade, Brazil

Încărcat de

NguyễnBìnhPhươngTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pressure Transient and Production Data Analysis of Horizontal Well in Unconsolidated Formation in Frade, Brazil

Încărcat de

NguyễnBìnhPhươngDrepturi de autor:

Formate disponibile

SPE 147506

Pressure Transient and Production Data Analysis of Horizontal Well in

Unconsolidated Formation in Frade, Brazil

Yan Pan1, Russ Ewy1, Don Ringe2, Medhat M. Kamal1, Ralph Affinito2 and Oluwole Sotunde1

1

Chevron Energy Technology Company, 2Chevron Global Upstream & Gas

Copyright 2011, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE Annual Technical Conference and Exhibition held in Denver, Colorado, USA, 30 October2 November 2011.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Frade Asset is a medium-heavy-oil field located in the Northern Campos Basin, approximately 75 miles offshore from Rio de

Janeiro, Brazil in 3500 ft water depth. The structure is a low relief anticline with two main fault blocks consisting of four

stacked unconsolidated reservoirs. First production started in June 2009, and field development target peak production is

80,000 barrels of crude oil per day. Currently, the field is producing from 9 horizontal oil wells with 3 vertical water injection

wells to maintain reservoir pressure. Continuous well monitoring and reservoir characterization is the key to cost-efficient

development in this deep-water subsea field. Therefore, most wells in Frade are equipped with permanent down-hole gauges

for reservoir surveillance.

In this paper, we discuss the impact of three efforts on field performance: 1) monitoring the pressure and production data

from horizontal wells since first production, 2) the real-time pressure transient analysis (PTA) of a series of buildup tests, and

3) the transient study combined with long-term production data analysis (PDA). The study results provide insight into

formation quality and the change of well conditions with time. The estimations of current drainage area, average reservoir

pressure, and original oil in place help to optimize the field development plan. The impacts of pressure-dependent oil

properties and rock compaction were also studied, and the first quantitative evaluation of pressure-dependent

permeability/porosity reduction was performed using both long-term dynamic well data and laboratory core experiment

results. The applications of PTA and PDA in Frade showed that using current advanced technologies properly can yield

valuable well and reservoir information from well pressure and rate data.

The positive impact of focused efforts to measure and analyze pressure transient and production data, and to use pressuredependent permeability and porosity values in managing a large asset, demonstrated best practices that may be followed in

other oil and gas fields.

Introduction

Frade is a medium-heavy-oil field offshore from Rio de Janeiro, Brazil, which consists of stacked unconsolidated reservoirs

(Fig. 1). The development strategy includes horizontal production wells and deviated injection wells for water flooding to

maintain reservoir pressure. At the very beginning of the field development, the asset management team realized the

challenges of this particular field in this offshore environment and made the decision to install permanent down-hole gauges

at every production and injection well drilled with a reservoir surveillance plan in place to monitor well and reservoir

performance.

The active reservoir surveillance enabled engineers to make sound and quick operation decisions, such as shutting in wells,

changing chokes, or planning well intervention, etc., based on the dynamic data collected at wells continuously. It also

provided real-time information for improved reservoir characterization, model forecasts, and optimized future development

plans. As the data streams in continuously, the cycle from data collection, to updating reservoir models, to field performance

forecast, to development optimization, can be shortened.

SPE 147506

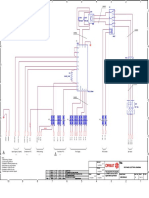

Fig. 1 Frade reservoirs and well information.

Because the reservoirs in Frade consist of unconsolidated sands, capturing the changes of formation properties with time is

important for field management. The availability of continuous pressure measurements made it possible to utilize the

transient data collected during all shut-in periods including scheduled buildup tests, operation required shut-ins, and

unplanned shut-ins. Permanent downhole gauges also allowed real-time analysis of buildup tests to obtain valuable well and

reservoir information earlier and to optimize the shut-in duration while testing to minimize the production loss without

sacrificing data quality.

Example Well: Producer #2

Horizontal well Producer #2 is located in the up-thrown fault block (Fig. 2) which has an original reservoir pressure of 3079

psia and reservoir temperature of 110 deg F. The net pay is approximately 42 m, and the horizontal well was drilled 30 m

above the sealing bottom of the reservoir. The well trajectory is parallel to the fault in the southwest and the axial fairway

edge in the north east. The well is completed with an open-hole gravel pack, and the total completion length is 507 m. The

permanent downhole gauge is installed above the top of the gravel pack completion.

N

N570 Axial

Fairway Edge

Toe

Heel

Prod #2

Fault

OWC

OWC

Km

Fig. 2 Frade reservoir top structure map.

Production history and observations

Producer #2 has been producing since July 2009. The oil gravity is about 19 deg API and oil viscosity is around 14 cp.

Continuous pressure measurements are available from permanent down-hole gauges. The production rates used in the

analysis are allocated daily rates based on well test data. In addition, the rate data was further calibrated (rate changes and

shut-in) according to pressure behavior and the cumulative production for each period. Figure 3 shows the pressure and rate

history since first production. Figure 4 shows the overlay of pressure and pressure derivative curves of a series of buildup

SPE 147506

periods (marked by arrows with dates in the corresponding color in Fig. 3) in the log-log plot. Some of the buildup periods

were scheduled transient tests, such as the one conducted in October 2009 for reservoir characterization purpose. Some of the

shut-ins were unplanned due to operational or other reasons. Nevertheless, all data collected could be used to obtain well and

reservoir information.

The first real-time analysis for this well was performed for the October 2009 buildup test. One of the test objectives was to

estimate the reservoir size. From geological information and 3D seismic mapping, the general shape of the reservoir was

known (Fig. 2), but the distances to boundaries still needed to be validated. After about 100 hours of shut-in, the real-time

analysis indicated that the transient response to the two boundaries closer to the well in the northeast and southwest had been

observed, but the expected duration to detect the two far away boundaries in the east and west would require more than onemonth of shut-in time. With the knowledge that combining the buildup test analysis and long-term production data analysis

later on (which does not require shutting in the well) would help us estimate the reservoir size, the decision was made at that

point to terminate the buildup test and put the well back into production. This further reduced production loss, and the

remaining test objectives were later fulfilled by subsequent production data analysis.

As Fig. 4 shows, the pressure transient behavior of buildups at different times was consistent. From the pressure derivative

(lower curves in Fig. 4), it was observed that the effective oil permeability was decreasing with time. The pressure change

(upper curves) indicated that the well total skin (if assuming constant kh value) was increasing with time. The well bottomhole pressure had dropped below bubble point (2842 psi); however, there was no apparent increase in the Producing gas oil

ratio. Its possible that some gas had come out of solution in the formation, and the reduction of formation effective

permeability might be partially due to multiphase effects.

Oct 2009 Dec 2009 Feb 2010 Mar Apr

Jul 2010

Oil rate

(STB/D)

Pressure (psi)

Jul 2009

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

Mar

Apr

May

Jun

Jul

2010

Pressure and pressure

derivative (psi)

Fig. 3 Frade Well Producer #2 production history.

1000

Skin increased

Koeff decreased

100

10

1E-3

0.01

0.1

10

100

Time (hr)

Fig. 4 Frade Well Producer #2 buildup test overlay in log-log plot.

When the effective oil permeability estimated from pressure transient analysis of different buildup periods using constant oil

PVT properties was normalized (Fig. 5), it clearly shows the formation permeability as a function of downhole pressure after

removing the data points with high uncertainty in rate measurements. As the reservoir was depleted, the formation pressure

decreased, and the absolute permeability of the unconsolidated sand was reduced. Figure 6 shows the skin estimation

changed with time when a constant kh value (from July 2009 buildup) was assumed. These calculated total skin factors

include possible mechanical damage, the effects of rock compaction, and possible multiphase flow.

SPE 147506

11

1.1

Effectiveskinfactor

Normalizedeffectivekh

0.9

0.7

0.5

Rate uncertain

0.3

0

200

400

600

pi pwf psi

800

1000

1200

Fig. 5 Producer #2 normalized kh estimation as

a function of pressure.

9

7

5

3

1

1

Jul09 Sep09 Nov09 Jan10 Mar10 May10 Jul10

Fig. 6 Producer #2 skin estimation from buildup periods

at different time assuming constant kh.

Pressure transient analysis of horizontal well

The development strategy of Frade is to produce from horizontal wells. Monitoring the well performance and analyzing the

pressure and rate data collected at wells requires the understanding of the transient behavior of a horizontal well. Figure 7

shows a typical buildup pressure response from Producer #2. At the early time, the flow is dominated by wellbore storage

effects where the pressure curve (green) and pressure derivative curve (red) are aligned at unit-slope straight line. Then

reservoir response follows, which starts with the vertical radial flow around the horizontal well, and the product of the

contributing well length (usually smaller than the total drilled length) and the average permeability in the plane perpendicular

to the horizontal well trajectory, Lw*sqrt( kv*kr ), and well skin factor could be estimated. After that, the flow reaches

pseudoradial flow (the flat portion of pressure derivative curve) where the flow capacity kh and hence the horizontal

permeability kr, could be calculated. The late-time behavior is affected by boundaries. For Producer #2, the two no-flow

boundaries close to the well (Fig. 2) were observed during buildup tests that were longer than two days. The distances to the

far end boundaries, and hence the reservoir size, were determined by analyzing the entire 14-month pressure and production

data while honoring the initial pressure.

Pressure and pressure derivative -psi

Applying pressure transient analysis techniques assuming constant fluid and rock properties, the well and reservoir properties

were obtained with an uncertainty range from the buildup data at Producer #2. The estimation of initial (July 2009) formation

effective kh value was 112,000 mD-m and 40,000 mD-m in July 2010. The effective skin factor changed from -0.3 in July

2009 to 10.5 in July 2010. The minimum connected reservoir size was between 2.1~3.7 km2. An estimation of average

reservoir pressure is also possible from this analysis. The calculated pressure (red curve) and pressure derivative (black

curve) match the data (green cross and red circle) reasonably well as shown in diagnosis loglog plot Fig. 7 and Cartesian

history plot Fig. 8. Since the well skin was changing with time, time-dependent skin was used to match the data (Fig. 8). The

match using the same consistent model for different buildup tests is also shown in Fig. 9.

Wellbore

storage

100

skin

kh

10

Two far away

Boundaries

Lw and

kv/kr

1

1E-3

First two

Boundaries

0.01

0.1

1

10

100

Time - hr

Fig. 7 Producer #2 horizontal well transient behavior and analysis results in log-log plot.

SPE 147506

skin6

< skin7

Oil rate

Pressure

skin1 < skin2 < skin3 < skin4 < skin5 <

0

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

Mar

Apr

May

Jun

Jul

2010

Fig. 8 Producer #2 pressure transient analysis results in Cartesian history plot.

Feb. 2010

100

10

1

1E-3

Pressure and pressure derivative -psi

Pressure and pressure derivative -psi

100

July 2009

10

1E-3

0.01

0.1

100

0.01

Oct. 2009

0.1

Time [hr]

100

10

1E-3

Dec. 0.01

2009

0.1

10

100

Time [hr]

100

10

1E-3

0.01

0.1

1

Time [hr]

0.01

0.1

10

100

10

Apr. 2010

100

10

1E-3

0.01

0.1

10

Jul. 2010

Time [hr]

10

1E-3

10

Mar. 2010

Time [hr]

100

Time - hr

10

1E-3

0.01

0.1

10

Time - hr

Fig. 9 Producer #2 transient analysis results in log-log plots of different buildup tests.

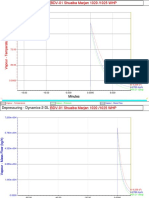

Production data analysis

The availability of long-term continuous measurements of pressure at wells enabled the application of production data

analysis to obtain reservoir information that a buildup test with limited duration could not achieve. The advantage of

production data analysis is that by using rate-normalized pressure integral and equivalent time (cumulative production / rate)

it converts the pressure response to long-term production with various rates to a format that is similar to an equivalent

drawdown test with constant rate. Conventional pressure transient analysis techniques can then be used to diagnose different

flow regimes and estimate well and reservoir properties. Figure 10 shows the normalized pressure versus equivalent time

from Producer #2 in log-log plot. The early time was noisy due to the normal variation of rates during production. However,

the late-time data clearly indicated the forming of a unit-slope straight-line trend, which implied the detection of multiple noflow boundaries. Therefore, the minimum connected reservoir volume could be estimated. Combining pressure transient

analysis of the buildup periods and production data analysis of the entire history, the well and formation properties as well as

the minimum reservoir size were obtained for Producer #2. The calculated rates, pressure, and cumulative production (red

curves) match the rate measurements (brown), pressure data (green), and cumulative volume (orange) reasonably well as

shown in Fig. 11.

SPE 147506

Rate-normalized

pressure integral -psi

100

10

1

1

10

100

1000

10000

Pressure [psia]

Liquid rate [STB/D]

Equivalent time - hr

Fig. 10 Producer #2 production data analysis results in log-log plot.

Jul

Aug

Sep

Oct

Nov

Dec

Jan

2010

Feb

Mar

Apr

May

Jun

Jul

Aug

Fig. 11 Producer #2 production data analysis results in Cartesian history plot.

Uncertainty of contributing well length

One of the uncertainty factors in horizontal well transient analysis is the unknown effective well length. Due to reservoir

heterogeneity (different permeability distribution along the well trajectory) or possible plugging, usually the fraction of the

well that contributes to flow is less than the total drilled length. Because of the complex deployment method and associated

high cost and risk, production logging is seldom run in horizontal wells, and direct measurement of the effective well length

is usually unavailable. The well contributing length is directly correlated with the ratio of formation vertical permeability to

horizontal permeability and the well skin factor (Kamal et al. 1993, Yildiz and Ozkan 1998, and Ozkan 2001). Hence,

different combinations of parameters could provide similar results. Table 1 shows three sets of solutions with different

assumptions of the contributing well length, and the calculated corresponding pressures overlap each other with all matching

the data reasonably well as shown in Fig. 12. This poses an additional challenge for horizontal well transient analysis that

does not exist in vertical well transient analysis. However, using all available data from well logs, core analysis, and analogs,

the uncertainty ranges were narrowed allowing for acceptable solution ranges.

TABLE 1 UNCERTAINTY OF CONTRIBUTING WELL LENGTH

Lw , m

500

310

100

kv/kr

0.005

0.011

0.088

Skin 1

2.46

1.70

0.19

Skin 2

4.80

4.00

2.50

Rate (STB/D) Pressure (psia)

SPE 147506

Lw310k2107

Lw500k2107

Lw100k2107

8/5/2009

8/24/2009

9/12/2009

10/1/2009

10/20/2009

time

Fig. 12 Producer #2 pressure transient analysis results with different contributing length.

Uncertainty of total compressibility

Frade reservoirs are all unconsolidated sand. There is uncertainty of the total compressibility, which includes the

compressibility of fluids and rocks in the reservoir. Because the estimation of distance to boundary is directly correlated to

the square root of total compressibility, the uncertainty of compressibility is carried over to the estimation of reservoir size.

For the Producer #2 well, the total compressibility ranges from 5.6E-5 psi-1 to 8.6E-5 psi-1 for clean axial sand based on rock

mechanics testing done on Frade core samples. This implies that the reservoir size calculation has 54% uncertainty due to the

uncertainty in total compressibility. As more data are collected and more reliable lab analysis results are available, the

uncertainty in total compressibility could be reduced. At that stage, all transient analysis results need to be updated

accordingly to provide more accurate reserve estimation.

55

1.15

Viscosity [cp]

Reservoir to SC liquid volume ratio [B/STB]

Impact of pressure-dependent fluid properties

In classic pressure transient analysis of oil wells, the oil is assumed as a slightly compressible fluid and the PVT properties

are constant throughout the test period. In Frade, the oil properties, especially viscosity, are strong functions of pressure. The

oil viscosity in the near-wellbore region increased 38% from 13 cp to 18 cp during the 14-month production period of

Producer #2. As Fig. 13 shows, the oil formation volume factor is a linear function of pressure. Fig. 14 shows the oil

viscosity decreases with pressure. When pressure drops below 2000 psia (as is the case for Producer #2 starting in August

2010), non-linear behavior dominates the fluid flow. When that occurs, the assumptions of the linearity and constant PVT

properties are not valid any more. To study the impact of pressure-dependent fluid properties, the pressure and rate data were

analyzed again using pseudopressure functions (Evinger and Muskat 1942) to take into account the change of oil formation

volume factor and oil viscosity due to pressure drawdown in the reservoir. Even though the total compressibility is also a

function of pressure due to software limitation, it was not investigated in this study. The pseudopressure function is defined

as,

p dp

.

(1)

m ( p ) = ( Bo o ) ref

0 B

o o

1.1

Non-linear

behavior

35

1.05

15

1

0

1000

2000

3000

Pressure [psia]

Fig. 13 Frade oil formation volume factor.

1000

2000

Pressure [psia]

3000

Fig. 14 Frade oil viscosity.

Pressure transient analysis was performed assuming oil formation volume factor and viscosity as functions of pressure. The

change of the average reservoir pressure over the 14-month period was around 150 psi (Fig. 15). This indicated that the

change of the ratio of oil formation volume factor and viscosity (Bo/o) due to the reservoir average pressure decline was

about 6%. If using constant PVT properties to estimate the average flow capacity kh in the reservoir, this would result in 6%

SPE 147506

3100

101%

100%

3050

99%

98%

97%

96%

95%

Bo/ o

pavg

3000

2950

2900

94%

93%

2850

Average reservoir pressure -psia

Change of oil FVF/viscosity

lower calculated kh values. However, there was additional pressure drawdown (about 900 psi) in the reservoir near Producer

#2, and hence bigger oil property changes, and the non-linearity of oil viscosity at low pressure (Fig. 14) also caused a

significant transient behavior difference. The end results of using pseudopressure functions to take into account of the oil

FVF and viscosity changes were that the kh estimation was 21% higher and the drainage area was 23% larger than the

original analysis assuming constant oil properties.

Jul09

Oct09

Jan10

Apr10

Jul10

Fig. 15 Frade oil property FVF/viscosity and average reservoir pressure versus time.

Impact of rock compaction

The Frade reservoirs consist of unconsolidated sand. Understanding the rock compaction effect helps to obtain more accurate

reservoir characterization. Like most unconsolidated sands, the porosity and permeability of the formation changes with the

reservoir pressure condition. A change in fluid pressure causes a change in effective stress, and the sand responds to this

change in effective stress. Reservoir pressure depletion results in an effective stress increase, which in turn causes a

reduction in porosity. Because permeability is directly tied to porosity and to pore-space connectivity via pore throats, this

porosity reduction is associated with a reduction in permeability. These changes in porosity and permeability can be directly

measured in laboratory tests. To quantify these changes, tests were performed on samples from recently-cored Frade wells.

Laboratory experiments

Two types of laboratory tests were performed to assess the impact of pressure depletion. The first test is a pore volume

compressibility, or compaction, test. The second is permeability versus stress test. Both tests were performed in Chevrons

in-house rock mechanics laboratory. Both tests were custom-designed for the in-situ stress conditions at Frade. For each

reservoir tested, values of initial effective vertical stress and effective horizontal stress were calculated. As seen in Fig. 1, the

Frade reservoirs cover a significant depth range. Coupled with the relatively shallow burial depth below sea-bottom, this

means that the initial (pre-depletion) effective stresses are quite different in the different reservoirs.

For both test types, the samples were first brought to an effective stress condition that is similar to the initial stress in that

particular reservoir. Depletion was then simulated by increasing the values of effective stress on the samples. In doing such

tests, it is important to use a stress path that is similar to that which would happen in the reservoir due to depletion. For the

pore volume compressibility test, this is accomplished by applying uniaxial-strain boundary conditions. This means that as

the sample is compacted due to increasing vertical effective stress, the lateral dimensions are not allowed to change. This

closely simulates the boundary conditions in the reservoirs. These boundary conditions result in a changing effective

horizontal stress during the test, but with a different magnitude of change than the vertical effective stress. This measured

stress path was then used to design the stress loading for the permeability tests. For the permeability tests, unequal stresses

were applied to the samples, and the stress changes were made to closely mimic the expected effective stress changes in the

reservoir. Permeability was measured in the direction parallel to the least stress (the horizontal stress) for these tests.

It was found in these tests that all the Frade reservoirs are quite sensitive to stress. Even the more deeply buried reservoirs,

with initial porosities in the range 28% - 33%, were quite compactable and displayed significant permeability reduction due

to simulated pressure depletion. However, the more shallow reservoirs, with ambient porosities as high as 39%, were the

most stress-sensitive. The measured result on some of these shallower samples from a well at similar depth as the production

zone of Producer #2 in the same stratigraphic sand is shown in Fig. 16. In this plot, a zero value on the x-axis corresponds to

the initial reservoir stress condition, and negative values indicate the amount of simulated reservoir pressure change. These

data indicate that the reduction of porosity is 7.7% and the reduction of permeability is 38.3% due to pressure depletion over

the 14-month period. Multiple samples were tested from each reservoir, and consistent results were obtained.

Normalizedpermandporosity

SPE 147506

1.2

(core sample @ 2050.55 m)

1.0

0.8

August 2010

0.6

k (core sample @ 2053.93 m)

0.4

0.2

0

300

600

900

1200

1500

1800

2100

p pref (psi)

Fig. 16 Frade core lab results of pressure-dependent porosity and permeability.

Pressure transient analysis with rock compaction

Incorporating the pressure functions for formation permeability and porosity derived from core lab results, the permanent

downhole gauge pressure data were analyzed again. The derived initial formation flow capacity kh (July 2009) is 29% higher

and the drainage area estimation is 36% larger than the analysis results assuming constant porosity and permeability.

Comparison of different factors

Frade is a complex oil field with various challenging characteristics. To understand the impact of different factors on pressure

response, a sensitivity study was performed on pressure dependent fluid properties and rock properties using a synthetic 14month constant-rate production history with the same cumulative production from Producer #2.

Case 1. The base case assumed that the oil properties, formation porosity and permeability were constant through the entire

production history. The reservoir was set to have an area of 3.7 km2, net pay of 40 m, a kh value of 88500 mD-m, and well

skin value of 5.0.

Case 2. The oil formation volume factor and viscosity were treated as functions of pressure, and the formation permeability

and porosity were constant.

Case 3. The formation permeability and porosity were functions of pressure, and the oil FVF and viscosity were constant.

Case 4. The oil FVF, viscosity, and formation permeability and porosity were all pressure-dependent.

Base Case 1. constant B o, o, k,

Case 2. Bo(p), o(p), constant k,

Case 3. k(p), (p), constant Bo, o

Case 4. B o(p), o(p), k(p), (p)

production at constant-rate of 5700 STB/D

4

Jul

Aug Sep Oct Nov Dec Jan Feb Mar

2010

Apr May Jun

Jul

Aug

Pressure and pressure derivative -psi

Oil rate

quid

rate[STB/D]

[STB/D

Pressure [psia]

The pressure responses to the 14-month constant-rate production from different cases are shown in Cartesian plot (Fig. 17a)

and in the diagnosis log-log plot (Fig. 17b). The sensitivity study results indicated that:

After 14-month production, the pressure drawdown at the well caused by pressure-dependent oil FVF and viscosity (blue

curves) is 15% more than the base case (green).

Rock compaction alone (orange) induced an additional 20% pressure drawdown at the well compared to the base case

(green).

Pressure dependent oil properties and rock compaction (red) added 49% more pressure drawdown at the well in total

than the base case (green).

Case 1. constant B o, o, k,

Case 2. B o(p), o(p), constant k,

Case 3. k(p), (p), constant Bo, o

Case 4. B o(p), o(p), k(p), (p)

1000

100

Base case 1

10

0.01

0.1

10

Time - hr

100

1000

100

10000

(a) Pressure 14-month drawdown

(b) Log-log plot of drawdown period

Fig. 17 Producer #2 pressure transient analysis results considering different factors (a) rate and pressure history (b) log-log plot.

Another study was done to understand the impact of different factors to pressure transient analysis results. This investigation

used the same reservoir and well assumptions as Case 1 to generate the pressure response for the 14-month constant-rate

10

SPE 147506

production history. Then the pressures were considered as measurement data (green curve in Fig. 17a and Fig.17b), and

different pressure-dependent fluid and rock properties were used to match the same set of data. Table 2 listed the transient

analysis results.

Considering the pressure-dependent oil formation volume factor and viscosity, the estimation of formation kh value at

the beginning of production (July 2009) needed to increase 20.9%, well skin had to be increased 34%, and the reservoir

size estimation was also 23.3% bigger than the base solution with the assumption of constant fluid properties.

If oil FVF and viscosity were assumed constant, and only permeability and porosity were treated as pressure-dependent,

the initial permeability estimation was 28.8% higher, the skin was 44.4% bigger, and the drainage area was 36.4% larger.

When both pressure-dependent oil FVF and viscosity, and rock compaction effects were taken into account, the initial

permeability estimation was 48.0% higher, the skin was 60.0% bigger, and the drainage area was 76.7% larger.

TABLE 2 ANALYSIS RESULTS CONSIDERING DIFFERENT FACTORS

Cases

khinJuly2009

khratio

skin

skinratio

drainagearea

arearatio

4.

1.constant

2.

3.

B(p),(p),

B,,k, B(p),(p) k(p), (p)

k(p), (p)

mDm

88,500 107,000

114,000

131,000

1.000

1.209

1.288

1.480

5.0

6.7

7.2

8.0

1.000

1.340

1.440

1.600

2

km

3.735

1.000

4.606

1.233

5.096

1.364

6.600

1.767

Conclusion

1. Frade is a complex oil field with challenging characteristics. Efforts are being made to continuously measure and analyze

pressure transient and production data to monitor the performance of wells and characterize the reservoirs, which is key

to effective reservoir management.

2. Continuous well monitoring and real-time pressure transient analysis of scheduled and unplanned buildup tests made it

possible to obtain well and reservoir properties promptly with the minimum required shut-in time, and hence the least

production loss, and to provide important information for optimizing the operation decisions and development strategies.

3. Pressure transient study combined with long-term production data analysis provided insight into formation quality and

the change of well conditions with time. The estimations of current drainage area and average reservoir pressure helped

to optimize the field development plan.

4. The transient behavior of horizontal wells is complex, and the analysis results involve higher uncertainty than those of

vertical wells due to the large number of unknown parameters associated with horizontal wells, such as the contributing

well length and the ratio of vertical to horizontal permeabilities. However, information from other sources of data, such

as well logs, cores and analogs from similar wells and reservoirs, allows for a set of solutions within an acceptable

uncertainty range to be obtained.

5. When the oil properties (especially viscosity) are strong functions of pressure, as the case in Frade, the impacts on

transient analysis results should be investigated. The analysis on the Frade well example indicated that the formation

flow capacity kh could be underestimated by 21% if constant oil formation value factor and viscosity were used. The

uncertainty of drainage area estimation due to the uncertainty in total compressibility was also assessed.

6. The impact of rock compaction of unconsolidated sand in Frade was evaluated quantitatively using both long-term

dynamic well data and laboratory core experiment results of pressure-dependent permeability and porosity reduction. Its

impact was significant on reservoir property estimations and reserve calculation.

SPE 147506

11

Nomenclature

B

= formation volume factor, RB/STB

h

= formation net thickness, ft

k

= permeability, mD

= vertical permeability, mD

kv

= horizontal permeability, mD

kr

= effective well length, m

Lw

p

= pressure, psi

q

= flow rate, STB/D

s

= well skin factor

= viscosity, cp

= porosity

Subscripts

i

= initial

ref

= reference

wf

= flowing well

Acknowledgments

The authors thank Chevron, Petrobras, and Frade Japao Petroleo Limitada for permission to publish this work.

References

Davies, J.P. and Davies, D.K. 2001. Stress-Dependent Permeability: Characterization and Modeling. SPE Journal 6 (2): 224235. DOI:

10.2118/71750-PA.

Evinger, H.H. and Muskat M. 1942. Calculation of Productivity Factors for Oil-gas-water Systems in the Steady State. AIME 146: 194-203.

SPE-942194-G.

Franquet. M., Ibrahim, M., Wattenbarger, R.A. and Maggard, J.B. 2004. Effect of Pressure-Dependent Permeability in Tight Gas

Reservoirs, Transient Radial Flow. Paper PETSOC 2004-089 presented at Canadian International Petroleum Conference, Jun 8 - 10,

Calgary, Alberta, Canada. DOI: 10.2118/2004-089.

Kasap, E. 2003. Estimating a Relationship between Pore Pressure and Natural Fracture Permeability for Highly Stressed Reservoirs. Paper

SPE 84410 presented at SPE Annual Technical Conference and Exhibition, 5-8 October 2003, Denver, Colorado. DOI: 10.2118/84410-MS.

Kamal, M.M. 2009. Transient Well Testing. Monograph Series No.23, SPE, Dallas TX. Chapter 14 by Ozkan, E, 407-445.

Kamal, M.M., Buhidma, I.M., Smith, S.A. and Jones, W.R. 1993. Pressure-Transient Analysis for a Well with Multiple Horizontal

Sections. Paper SPE 26444 presented at SPE Annual Technical Conference and Exhibition, 3-6 October, Houston, Texas. DOI:

10.2118/26444-MS

Kuchuk, F.J. 1995. Well Testing and Interpretation for Horizontal Wells, J. Pet Tech. 47 (1): 36-41. DOI: 10.2118/25232-PA.

McCulloch, B. 2010. Transitioning Safely From Greenfield to Operations: Case Study of a Major Capital Project. Paper SPE 127028

presented at SPE International Conference on Health Safety and Environment in Oil and Gas Exploration and Production, Rio de Janeiro,

Brazil, 12-14 April. DOI: 10.2118/127028-MS.

Ozkan, E. 2001. Analysis of Horizontal Well-Responses: Contemporary vs. Conventional. SPEREE 4 (4): 260-269. DOI: 10.2118/72494PA.

Raghavan R. and Chin, L.Y. 2004. Productivity changes in reservoirs with stress-dependent permeability, SPE Res Eval & Eng 7 (4): 308315. DOI: 10.2118/88870-PA.

Yildiz, T. and Ozkan, E. 1994. Transient Pressure Behavior of Selectively Completed Horizontal Wells. Paper SPE 28388 presented at the

SPE Annual Technical Conference and Exhibition, New Orleans, 25-28 September. DOI: 10.2118/28388-MS.

Zhang, M.Y. and Ambastha, A.K. 1994. New Insights in Pressure-Transient Analysis for Stress-Sensitive Reservoirs. Paper SPE 28420

presented at SPE Annual Technical Conference and Exhibition, 25-28 September 1994, New Orleans, Louisiana. DOI: 10.2118/28420-MS.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Rollins 1998Document10 paginiRollins 1998sharvan10Încă nu există evaluări

- Compressors (Sample Problems)Document3 paginiCompressors (Sample Problems)allovid0% (2)

- Helicopter OperationDocument15 paginiHelicopter OperationNguyễnBìnhPhương100% (1)

- Fuel Oil Line Connected To Filter HeaderDocument3 paginiFuel Oil Line Connected To Filter HeaderNguyễnBìnhPhươngÎncă nu există evaluări

- BDG Cold Startup at 15h30 Today AfternoonDocument1 paginăBDG Cold Startup at 15h30 Today AfternoonNguyễnBìnhPhươngÎncă nu există evaluări

- Chocke CC30 & CC40 Outline Drawings-C-2Document8 paginiChocke CC30 & CC40 Outline Drawings-C-2NguyễnBìnhPhươngÎncă nu există evaluări

- Seal & LubricatingDocument2 paginiSeal & LubricatingNguyễnBìnhPhươngÎncă nu există evaluări

- PR 24Document1 paginăPR 24NguyễnBìnhPhươngÎncă nu există evaluări

- VFD - 0.505.95.624.0Document1 paginăVFD - 0.505.95.624.0NguyễnBìnhPhươngÎncă nu există evaluări

- CP - 0.505.95.635.0Document3 paginiCP - 0.505.95.635.0NguyễnBìnhPhươngÎncă nu există evaluări

- Gas - Detection - 0.505.95.637.0Document1 paginăGas - Detection - 0.505.95.637.0NguyễnBìnhPhươngÎncă nu există evaluări

- Transformer - 0.505.95.621.0-1Document1 paginăTransformer - 0.505.95.621.0-1NguyễnBìnhPhươngÎncă nu există evaluări

- WATEQ4F Read MeDocument10 paginiWATEQ4F Read MeNguyễnBìnhPhươngÎncă nu există evaluări

- Clean - Air - Inverter - 6.505.30.617.0Document1 paginăClean - Air - Inverter - 6.505.30.617.0NguyễnBìnhPhươngÎncă nu există evaluări

- MCB - 0.505.95.646.0-2Document1 paginăMCB - 0.505.95.646.0-2NguyễnBìnhPhươngÎncă nu există evaluări

- Emergency Brake DatasheetDocument7 paginiEmergency Brake DatasheetNguyễnBìnhPhươngÎncă nu există evaluări

- Vacuum Pump - Ga - 140140 - enDocument64 paginiVacuum Pump - Ga - 140140 - enNguyễnBìnhPhươngÎncă nu există evaluări

- Chon - HST-Grayloc Products Catalog GLOC-105 1-06Document1 paginăChon - HST-Grayloc Products Catalog GLOC-105 1-06NguyễnBìnhPhươngÎncă nu există evaluări

- D01-001-GA DrawingDocument4 paginiD01-001-GA DrawingNguyễnBìnhPhươngÎncă nu există evaluări

- Y99ab Test Kit Application NoteDocument8 paginiY99ab Test Kit Application NoteNguyễnBìnhPhươngÎncă nu există evaluări

- C03-001-Structural Steel CalculationsDocument166 paginiC03-001-Structural Steel CalculationsNguyễnBìnhPhươngÎncă nu există evaluări

- Cad Cam Cad StandardDocument24 paginiCad Cam Cad StandardNguyễnBìnhPhươngÎncă nu există evaluări

- Capillary Pressure: Reservoir Seal Capillary Pressure / Saturation Relationship (S Model)Document12 paginiCapillary Pressure: Reservoir Seal Capillary Pressure / Saturation Relationship (S Model)NguyễnBìnhPhươngÎncă nu există evaluări

- C03-001-Structural Steel CalculationsDocument86 paginiC03-001-Structural Steel CalculationsNguyễnBìnhPhươngÎncă nu există evaluări

- Jigs and Fixtures JoshiDocument252 paginiJigs and Fixtures JoshiVikram Govindarajan83% (6)

- Instructor: Dr. Bui Trong Vinh Presente R:: Pham Minh Khanh Nguyen Binh PhuongDocument37 paginiInstructor: Dr. Bui Trong Vinh Presente R:: Pham Minh Khanh Nguyen Binh PhuongNguyễnBìnhPhươngÎncă nu există evaluări

- Analysis of Gas Production Data Using Flowing Material Balance MethodDocument22 paginiAnalysis of Gas Production Data Using Flowing Material Balance MethodNguyễnBìnhPhươngÎncă nu există evaluări

- Underbalance Perforations - SLBDocument14 paginiUnderbalance Perforations - SLBNguyễnBìnhPhươngÎncă nu există evaluări

- Fluid Flow Mean Velocity and Pipe Diameter For Known Flow RateDocument10 paginiFluid Flow Mean Velocity and Pipe Diameter For Known Flow Ratefaisal mahmood azamÎncă nu există evaluări

- Thermal Energy Storage and Sensibile Energy StorageDocument30 paginiThermal Energy Storage and Sensibile Energy StoragesayoojÎncă nu există evaluări

- Design and Analysis of Shell and Tube Heat ExchangerDocument8 paginiDesign and Analysis of Shell and Tube Heat ExchangerawusomÎncă nu există evaluări

- Solution - Shape FactorDocument6 paginiSolution - Shape FactorVenkata DineshÎncă nu există evaluări

- C - Fluid Mechanics - PP - AnsDocument4 paginiC - Fluid Mechanics - PP - Anszyx xyzÎncă nu există evaluări

- Seismic Analysis of Multistoreyed RCC Building With Shear WallDocument10 paginiSeismic Analysis of Multistoreyed RCC Building With Shear WallParth SoniÎncă nu există evaluări

- Heat Loss and Gain CalculationDocument84 paginiHeat Loss and Gain CalculationMuhammad ZubairÎncă nu există evaluări

- Constitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Document12 paginiConstitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Jose ManuelÎncă nu există evaluări

- Fracture Analysis of Pressure Vessel Under Dynamic Loading and Thermal Effect PDFDocument108 paginiFracture Analysis of Pressure Vessel Under Dynamic Loading and Thermal Effect PDFsandeeppandey0789Încă nu există evaluări

- Steam TrapsDocument6 paginiSteam TrapssaurabhÎncă nu există evaluări

- Design Guide DSM GuideDocument0 paginiDesign Guide DSM GuideDavid García SalvatierraÎncă nu există evaluări

- Various Type of Steam TrapsDocument46 paginiVarious Type of Steam TrapsRamesh VenugopalÎncă nu există evaluări

- Time Dependent Deformations in Squeezing Tunnels: G. Barla, M. Bonini and D. DebernardiDocument11 paginiTime Dependent Deformations in Squeezing Tunnels: G. Barla, M. Bonini and D. DebernardiAlket DhamiÎncă nu există evaluări

- Strut Tie Model RC BeamDocument9 paginiStrut Tie Model RC BeamGnabBangÎncă nu există evaluări

- Canal DesignDocument34 paginiCanal Designniranjan100% (2)

- Class 7 Fos Theory o FailureDocument5 paginiClass 7 Fos Theory o FailureARUN KUMARÎncă nu există evaluări

- Hysys CurvesDocument32 paginiHysys CurvespradheepÎncă nu există evaluări

- 4.1.2 - 6695-PRC-000-FB-0101 - 0105 - 03 - Legend Sheets - P - IDDocument5 pagini4.1.2 - 6695-PRC-000-FB-0101 - 0105 - 03 - Legend Sheets - P - IDKiran KumarÎncă nu există evaluări

- On The Impact Toughness of Gradient-Structured MetalsDocument13 paginiOn The Impact Toughness of Gradient-Structured MetalsYlinÎncă nu există evaluări

- W2manual42 Part2 Theory Rev1Document256 paginiW2manual42 Part2 Theory Rev1Maria Camila Valencia CárdenasÎncă nu există evaluări

- CRUIDE OIL Tank Foundation - Design - REVDocument16 paginiCRUIDE OIL Tank Foundation - Design - REVchakrapanithotaÎncă nu există evaluări

- Nesa. Set 3Document10 paginiNesa. Set 3Leonesa Ananias LausÎncă nu există evaluări

- 2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaDocument20 pagini2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaefackopaÎncă nu există evaluări

- Cut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForDocument1 paginăCut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForKaterin HernandezÎncă nu există evaluări

- Model Question Paper 13.406 TURBO MACHINERY (S) : Part A Answer All QuestionsDocument3 paginiModel Question Paper 13.406 TURBO MACHINERY (S) : Part A Answer All Questionssk sanketÎncă nu există evaluări

- Hues 0303Document167 paginiHues 0303Anonymous nbozs80lygÎncă nu există evaluări

- Solved Examples - Heat Transfer - 1ET1010501 - CompressedDocument69 paginiSolved Examples - Heat Transfer - 1ET1010501 - CompressedPatel SarkarÎncă nu există evaluări