Documente Academic

Documente Profesional

Documente Cultură

DLSKL c802c2 Manual

Încărcat de

Nguyễn Văn ChứcTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DLSKL c802c2 Manual

Încărcat de

Nguyễn Văn ChứcDrepturi de autor:

Formate disponibile

Dolang Technology Equipment Co., Ltd.

Dolang Technology Equipment Co., Ltd.

Content

Warnings and Precautions......................................................................................... 1

Chapter One System Using Introduction ................................................................. 3

Chapter Two Training, Assessment Content.......................................................... 14

Trining 1 Milling Hardware Connection ............................................................... 25

Training 2 System Boot Electricity ........................................................................ 47

Training 3 Basic Operation of CNC Machine Tools ............................................. 49

Training 4 System Debugging Preliminary Knowledge....................................... 51

Training 5 System Basic Parameters Settings ....................................................... 53

Training 6 Inverter Application .............................................................................. 57

Training 7 Basic Operation..................................................................................... 95

Dolang Technology Equipment Co., Ltd.

Warnings and Precautions

In order to avoid injury and damage to the product and its related products, operate the following

safety warnings and cautions before using. In order to avoid potential hazards, use the specified

operation.

1. Specified operation by the guide book, otherwise the protection provided by the equipment

may be impaired and damage.

2. Install the unit in a clean, dry and flat environment is properly connected and removal.

3. Please use the rule voltage and a grounded to prevent electric shock and other accidents.

4. No special fault, remove the electromagnetic substances to ensure that around the controller do

not have electromagnetic field, do not operate if there is an error in hidden, if you are not sure

whether that damage the device or not, please let the professionals check to make sure before

operation.

5. Do not operate in explosive air.

6. Do not open the casing of the controller or module parts.

Safety Precautions

Correct and safe use of the product, to prevent accidents, please read the "Safety Precautions".

Note "WARNING" and "CAUTION" and other content, appropriate details, please refer to the

following "logo Description Table".

Before using the product, please be sure to carefully read the "Safety Precautions".

Warning signs

[Danger]

"Danger High Voltage" signs, high-voltage electric shock hazard, if

failure to follow instructions may result in serious injuryor even

death.

[Warning]

Potentially dangerous, if failure to follow instructions may result in

serious injury or even death.

[Caution]

Unpredictable potential hazards, if failure to follow instructions may

result in minor injury or product damaged phenomenon.

Web: www.didactic.cn

1

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

[Note]

Useful information and annotated

Web: www.didactic.cn

2

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Chapter One System Using Introduction

I Overview

1.1 Brief introduction

DLSKL-C802C2 CNC milling skills training assessment system (including semi-kind) for each

class of vocational and social electrician electrical assessment, and cities, counties and other

units maintenance electrician teaching, training, practice, assessment and technical evaluation

and research and development physical appraisal system. Physical examination of the electrical

system of the machine parts and mechanical parts of the machine are connected together

organically, using 808D numerical control system, frequency spindle and the machine

semi-physical simulation models combine all the movements of the machine all displayed. Able

to complete CNC system installation, parameter setting, PMC programming, fault diagnosis and

repair, CNC machine assembly debugging, CNC programming and machining operations and

many other teaching training. The system appearance, easy to operate, intuitive and strong,

teaching more vivid and closer to the industrial field of suitable maintenance electrician

(beginning, middle, high) level skills identified in the electrical part of the machine training and

Web: www.didactic.cn

3

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

examination. Mainly covers the CNC milling machine and CNC milling machine two functions

training device.

1.2 Feature

(1) Small size, beautiful appearance.

(2) Intuitive and strong, through the operation of the electrical machine can become familiar with

the principles and the appearance of the machine structure. The electrical control system

operating the machine can achieve a variety of motion control, which includes: Spindle forward /

reverse rotation start / stop, X / Z-axis table movement, return to the reference point, the limit

position of the soft / hard limit protection and cooling simulated movements.

(3) Electrical control circuit components are used in practical industrial applications on the

machine electrical components are mounted on the bench electrical cabinet, at a glance, and has

a corresponding test points for easy wiring and testing circuit operation.

(4) Modular design, each module can be installed independently, independently removable,

failure is low and easy maintenance.

(5) Semi-physical simulation model of the machine is the machine with reference to the normal

size scaled according to a certain design; give a true reproduction of the mechanical motion of

CNC machine tools, CNC machine tools demonstrate a variety of actions, but do not have the

processing capacity.

(6) Electrical control circuit design thoughtful, with all lines of circuit protection and overload,

short circuit protection.

(7) Equipment repeated use, the students completed each training can be restored to normal, to

facilitate future students to receive training without conflict in the Taiwan body can practice

wiring.

II Basic composition

2.1 Platform body part

(1) Table is steel spray, color RAL7035.

(2) Workbench is divided into two parts: the above is a numerical system modules, spindle

module, feed module; following are input and output modules, DC motor module, control

module, power module.

(3) On each side of workbench upper part has a tin socket; see from the front left side of the

Web: www.didactic.cn

4

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

lower part of the table there are three air plugs, whose role is to connect the-loop limit switch

signal, and frequency spindle motor power line and Z-axis servo motor the brake power cord;

right to have a four-pole circuit breaker, total control as the system power supply.

Spindle motor

Limit switch

4) The lower part of the body is a double door structure, experimental Zhuodi also has four

direction wheel;

(5) Behind the body followed by a double-door structure, easy to install various components;

(6) The overall design meets each school to do CNC training requirements, elegant appearance,

seen from the front upper edge down tilt.

2.2 Coordinate milling

Web: www.didactic.cn

5

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

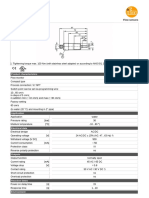

Semi-kind milling technical parameters:

X axis stroke

110mm

Y axis stroke

170mm

Z axis stroke

150mm

X/Y/Z Rapid traverse

8000mm/min

Spindle power

25W

Maximum spindle speed

1400r/min

Timing belt gear ratio

12

Coordinate Dimensions

575790840mm

Screw pitch

5mm

Here to introduce each axis limit switch adjustment method

1, X-axis to adjust the position of the switch

1) X-axis negative limit switch adjustment method

Web: www.didactic.cn

6

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Stroke

switch

Install holder

Adjustable mounting holes

X-axis touch panel

Figure 3 X-axis negative limit switch and touch panels

The picture above shows the X-axis negative limit, when the X-axis in the negative direction

during the operation, touch the plate collision normal limit switch, and you will hear the sound of

pressing the switch, and the CNC control system can collect signals and commands X axis stops

running, issue overrun alarm information, which means that the switch installed properly, failing

that, will have to adjust the limit switch mounting bracket upward or downward adjustments to

normal until the touch plate collision X-axis negative limit switch.

2X-axis reference point adjustment method

Figure 4, adjust the direction of ditto

Web: www.didactic.cn

7

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

X-axis

reference point

X-axis limit

Figure 4 X-axis positive limit reference points and schematic

3) X-axis limit switch adjustment method

Figure 4, adjusted as above

2, Z-axis position adjustment of the limit switches

Z-axis limit

Z-axis

negative

direction limit

Z-axis

reference point

Web: www.didactic.cn

8

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Figure 5 Z-axis each switch location map

Adjustment same with the X-axis

3, The limit switch outlet

All qualifying travel switch have reached a TB1512-type terminal blocks on the right side,

according to the line number corresponding seat on the other side through a 12-pin cable

soldered to the aviation plug (male), the line number is 201202 203 204 205 206 207 210 211 3L

+

4, The spindle motor outlet

Three-phase asynchronous motors to power line line number U5 V5 W5 all terminals connected

to left of TB1512 , pictured as above

5, X-axis / Y axis / Z axis servo motor terminal

Power lines are an orange Military Connector (4-pin female) as follows, Siemens standard

configuration, open the dust cover when connecting to the servo motor side is also true method

of operation.

Web: www.didactic.cn

9

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Encoder signal line is a grass green Military Connector (15-pin female), as shown below,

Siemens standard configuration, open the dust cover when connecting to the servo motor side is

also true method of operation.

III The main technical parameters of equipment

(1) Input power: three-phase five-wire 380V 10% 50HZ

(2) Working environment: Temperature -10 - +40 , relative humidity <85% (25 ), altitude

<4000mm

(3) System Capacity: <2kVA

(4) Leakage protection action current: 30 mA; leakage protection time: 0.1s

(5) Physical Assessment System Dimensions: length width height

Training sets: 1477 606 1700 mm (excluding three-color lights height)

Three color lights Height: 350mm

Semi-physical training tables: 800 1000 760 mm

Coordinate demonstration units: 575 790 840

Web: www.didactic.cn

10

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

(6) Coordinate main parameters:

X-axis screw length: 275mm Z-axis screw length: 300mm Y-axis screw length: 345mm

Workbench Mobile Travel: X to 110 mm, Z to 150mm, Y-axis 170

Table Maximum speed: 8000 mm / min

Maximum spindle speed: 1400r/min, 25W.

IV System main configuration

Name

Mode

Qty

Uni

t

Remark

Includes

Training bench

With nameplate,

certificate

the

1

Set

following

eight

modules

CNC system

DLSK-808D2

Pc

DLSK-S1616

Pc

DLSK-ZDJ01

Pc

Spindle module

DLSK-SBPQ3

Pc

Servo feed

DLSK-3Servo

Pc

DLSK-KZ01

Pc

module

Input and output

modules

DC motor

module

module

Control module

(the same

configuration,

wiring different

Web: www.didactic.cn

11

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

DC Power

Module

DC Power

DLSK-DY83B

Pc

DLSK-DYX03

Pc

Set

Pc

Pc

Pc

Pc

Pc

8A

Pc

5A

Pc

3A

Pc

Pc

Pc

13

Pc

13

Pc

Module

Including spindle

Coordinate

training bench

motor, nameplate, a

4-pin male one airline, a

12-core cable limit

switch, etc.

CNC power

Two end is the 2-pin

cable

header 1 meter needle

aviation

X4 Cable

Two 3-pin header 1

meter needle aviation

One is the DP25 pin

(female) one is DP25

DP25 cable

(Male) Cable 1 m

DP25 Male to Female

Two is DP25 cable 1

meter needle

Insurance Core

Red 1.0 m head to head

K2 test line

Blue 1.0 m head to head

Red 1.0 m head to head

K3 test line

Blue 1.0 m head to head

Web: www.didactic.cn

12

E-mail: didactic@dolang.cn

On for

OP520

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Black 1.0 m head to

head

Yellow 1.0 m head to

head

K4 test line

Green 1.0 m head to

35

Pc

Pc

Pc

Pc

head

Red 1.0 m head to head

Milling(3-1)

Operation

Boo

k

Milling(3-2)

Programming(Sie

mens

instructions)

Programming(IS

Diagnostics

Manual

Manual

SINUMER

IK 808D

O dialects)

Stroke switch

6FC5398-4DP10-0BA0

Milling(3-3)

Allen wrench

boo

Boo

k

Boo

k

Boo

k

9 sets

Set

KW15

Siemens

V. Main Training Project

Project One milling hardware connection

Project Two system power on

Project Three basic operation of CNC machine tools

Project Four rudimentary knowledge of system debugging

Project Five basic system parameter setting

Project The use of inverter

Web: www.didactic.cn

13

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Projectseven Basic operation training system

Chapter Two Training, Assessment Content

IThe training 's nature and mission

"CNC machine fault analysis and maintenance training." CNC technology professional

(vocational) compulsory training session. This is in line with the task of training materials,

through the typical faults of CNC machine tools and comprehensive systems analysis and

diagnosis, fault location and troubleshooting, theory and practice to master CNC machine fault

diagnosis and maintenance of the basic ideas, judgment rule, the basic approach and the specific

implementation steps.

II Training Objectives and Requirements

1, to develop serious attention to safety, ease. Rigorous, meticulous work style.

2, to establish CNC machine fault detection and diagnosis of the basic ideas and principles of

judgment.

3, learn to have full access to the technical information of CNC machine tools, machine tools,

electrical control system to master the composition and the basic principles. Learn phenomena

and background investigation and analysis are summarized on the basis of some typical faults

fault feature large fault type and fault localization. Work out the associated system block diagram

related to the operation of FIG. To problems flowchart to determine the diagnosis and repair of

concrete steps.

4, learn to use CNC machine self-diagnosis. Preliminary master examination and diagnosis tools

Web: www.didactic.cn

14

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

and methods that can initially locate the fault. Learn how to establish fault file.

5, to understand basic principles of operation of CNC machine tools, CNC 808D familiar

methods of operation, to fully understand the control panel of the switch functions and operation

methods.

5, to understand basic principles of operation of CNC machine tools, CNC 808D familiar

methods of operation, to fully understand the control panel of the switch functions and operation

methods.

6, master CNC equipment input system, learn the input processing procedures and methods, and

the master program edit, modify, debug, and run approach.

7, the training contents of the report: This paper describes the requirements for each training

program and content; book by training required to answer the question, fill out the training

obtained or calculated data, draw the required drawings; finish each after project experience, the

experience gained and lessons learned; project on the training to improve and enhance its own

proposals.

8, submitted a report on training session, the final submission of CNC machine fault diagnosis

and maintenance of the summary report.

9, with all the real news reports and comprehensive assessment of the respondent's scores as

training to the evaluation results.

III Recognize seven kinds of separate modules hanging box

3.1 CNC system modules (DLSK-808D1)

SINUMERIK 808D base lineCNC system panel LCD area, keyboard, operating area of organic

together, user-friendly operation and use.

Web: www.didactic.cn

15

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Benefits:

Easy to learn

Thanks to the multimedia training materials, SINUMERIK 808D on PC software and CNC

system integrated online help systems, different operating

As staff are able to easily learn SINUMERIK 808D Operation and Programming. And all the

training materials are free of charge!

Easy to maintain

Service plan features can help you track and manage your machine lubricants, filters and other

accessories replacement and maintenance.

Easy to operate

SINUMERIK 808D supports DIN ISO language programming language and can be adapted to

different user programming habits.

Powerful contour

Calculator can also be complex contours do not need any CAD / CAM software and

programming directly on the CNC system. Many technology cycles for turning, drilling of the

many technology cycles can help you easily write your processing program

Web: www.didactic.cn

16

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Handwheel Control

System Start System Stop CNC Power

Input

X21

Output

CW

CCW

www.dolang.cn

3L-

1L+

L-

3L+

CNC system modules

808D is CNC systems, CNC operator panel

Web: www.didactic.cn

17

E-mail: didactic@dolang.cn

Tel+86-531-87586199

3L-

Dolang Technology Equipment Co., Ltd.

Electronic hand wheel

System start button

System stop button

CNC Power Interface

X21 Interface

CNC system input interface DP25 seat (female)

CNC system output interface DP25 seat (male)

K3 banana jack

K2 banana jack

3.2 Input Output Module (DLSK-S1616)

Web: www.didactic.cn

18

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

OUTPUT

Q0.0

Q0.1

Q0.2

Q0.3

Q0.4

Q0.5

Q0.6

Q0.7

Q1.0

Q1.1

Q1.2

Q1.3

Q1.4

Q1.5

Q1.6

Q1.7

INPUT

I0.0

I0.1

I1.1

www.dolang.cn

I1.0

I0.2

I1.2

Input

I0.3

I0.4

I0.5

I1.3

I1.4

3L-

I0.6

I1.5

I0.7

I1.6

I1.7

Output

Module consists of:

Status Indicator

K3 banana jack

Input Interface DP25 seat (female)

Output Interface DP25 seat (male)

Features:

Display signal status;

Exercise wiring;

Convenient troubleshooting;

Detection and judgment:

When the three sliding table limit switch connected, the input status indicator will be lit each, so

you can judge the trip switch and the PLC signal corresponding to the correct, if not properly be

improved until it is correct.

When the system sends each axis movement command, there will be a corresponding output

signal output point, the corresponding indicator light is lit.

Web: www.didactic.cn

19

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

This module can detect and determine the external wiring, as well as programming situations.

3.3 DC motor moduleDLSK-ZDJ01

Knife library

1

Knife library signal

Knife library motor

3L+

3L-

Cooling motor

Lubrication motor

www.dolang.cn

Modules:

Three DC motors

6 Inductive sensors

LED indicator

K3 banana jack

Benefits:

Achieve turret simulation;

Pump simulation;

Lubrication simulation;

Exercise wiring;

Signal detection and adjustment turret

Knife-election once every tool number, tool motor rotation to the corresponding tool number to

stop, such as choosing T1 knife, the motor forward rotation to stop at the 1st place, this time on

the 1st lights lit, if not bright, adjust the two places: one would be rotating in a proximity switch

or screwed into the second mounting plate to the center of the screw fastening position, these two

Web: www.didactic.cn

20

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

methods is to make the signal detection points can be better proximity to the switch position, to

facilitate the signal acquisition.

Promixity

switch

Signal

point

testing

3.4 Splinder moduleDLSK-SBPQ3

DI

AC380V

DIN1

L1

DIN2

L2

www.dolang.cn

DIN3

+24V

L3

Modules:

Drive M420 AC380V 0.75KW

K3 banana jack

Web: www.didactic.cn

21

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

K4 banana jack power connector

Benefits:

Spindle inverter control;

With Siemens 808D simulated voltage control;

Wiring is simple, easy to control.

3.5 Servo drive module (DLSK-3Servo)

X axis

Y axis

Z axis

www.dolang.cn

-X4

Web: www.didactic.cn

22

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Modules

V60 servo drive module 6SL3210-5CC14-0UA0

Three-phase AC220V power supply

Benefits:

Implementation and 808D CNC system connections.

Exercise wiring.

3.6 Control moduleDLSK-KZ01

X + limit

X - limit

X axis origin

Z + limit

Z - limit

Z axis origin

Y + limit

Y - limit

Y axis origin

3L+

KA1

KA4

KA2

KA5

KA3

KA8

KA6

www.dolang.cn

KA7

KA9

3L-

Modules:

9 intermediate relay

9 signal interface board

K3 banana jack

Benefits:

Train students wiring connections;

Training students to the principles set;

Web: www.didactic.cn

23

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Can be reused.

3.7 Power moduleDLSK-YD83B

CNC Power

CNC Power

I/O Power

1L+

3L+

1L+

3L+

L-

3L-

L-

3L-

Work lamp

Red

-X4

FU2 5A

FU3 8A

www. dolang.cn

FU1 3A

3L-

Modules:

3A switching power supply 1

Switching power supply 8.3A 1

2 Pin Receptacle 1

3 Pin Receptacle 1

OP520 fuse holder 3, with fuse is the different

K3 banana jack

Benefits:

Power control applications;

DC24V DC power supply for the system;

True representation of the industrial control loop disk layout;

4, Power Box

The right part of the electrical operating area is the intelligent assessment and a power supply

unit is equipped with fault appraisal system (LCD and keypad unit); start, stop, emergency stop

button.

Web: www.didactic.cn

24

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

www.dolang.cn

L3

Inverter

L1

L2

AC380V

CNC

Control

Power Zone

ERGEN

M

S TO P

Drive

Power Switch

Power indicator

Control Zone

VU

Voltage Indicator

CY

VW

WU

Modules:

DIP switch 3 files two segments

Voltmeter 85L17 AC 500V

Power indicator

Power with the key switch

Emergency stop switch

Control section: three-pole circuit breaker, two pole circuit breaker, single-pole circuit breakers

K4 banana jack

Trining 1 Milling Hardware Connection

I Training purpose

Learn 808D CNC system structure; grasp CNC milling machines (cross slide) integrated training

system components and cabling.

II Training device

Hardware connections necessary equipment:

Item

1

Web: www.didactic.cn

Device

CNC system module

Input and output modules

25

E-mail: didactic@dolang.cn

Model

Qt

DLSK-808D2

DLSK-S1616

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

3

4

8

9

DC motor module

Spindle module

Servo feed module

Control module

DC Power Module

Power Box

Test line

DLSK-ZDJ01

DLSK-SBPQ3

DLSK-2Servo

DLSK-KZ01

DLSK-DY83B

DLSK-DYX03

K3

Including spindle

motor, nameplate, a

10

Coordinate training bench

4-pin male one

airline, a 12-core

cable limit switch,

etc.

Two is the 2-pin

11

CNC poer cable

header 1 meter

needle aviation

Two is the 3-pin

12

X4 cable

header 1 meter

needle aviation

Head is DP25pin

femaleHead is

13

DP25cable

Female

15

Web: www.didactic.cn

DP25cable 1m

DP25 Male to

14

Two is the DP25

26

E-mail: didactic@dolang.cn

1

1

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

needle (male to

male) cable 1 m

III Training steps

3.1

Milling machine I/O allocation table

Input

I0.0

Remark

Emergency stop

signal

Output

Remark

Q0.0

Machine alarm lights

I0.1

X axis + To limit

Q0.1

Machine arunning lights

I0.2

X axis + To limit

Q0.2

Machine ready light

I0.3

Y axis + To limit

I0.4

Y axis + To limit

Q0.4

Cooling pump

I0.5

Z axis + To limit

Q0.5

I0.6

axis + To limit

Q1.0

I0.7

Lubrication pump

Turret motor

X-axis reference

point

I1.0

Y-axis reference

I1.1

Z-axis reference

I1.2

T1

I1.3

T2

I1.4

T3

I1.5

T4

I1.6

T5

I1.7

T6

3.2 X-axis reference point

Web: www.didactic.cn

27

E-mail: didactic@dolang.cn

Tel+86-531-87586199

L1 L2 L3

Black

Black

Black

PE N

Blue

Bicolor

Dolang Technology Equipment Co., Ltd.

Equipment limits

BVR2.5mm 2

U0

QF0

V0

Emergency Stop

SB3

KM 1

3

Black

W0

Key Switch

SA 1

KM 1

PE

1N

1L 1 1L 2 1L 3

HL0

Black

BVR1.0mm 2

9 11

10 12

SA2

KM1

PE

Ground Screw

V

N1

Light Blue

1L1

Red

Left Six-Hole Socket

Right Six-Hole Socket

QF1

17

18

19

BVR2.5mm 2

Splinder

Inverter

Black

U0 V0 W0

AC380V

TC

AC220V

U01

QF2

Black

Black v04

W01

Black w04

20

21

Web: www.didactic.cn

U04

V01

28

E-mail: didactic@dolang.cn

XS1

XS2

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

BVR0.3 mm2

23

Web: www.didactic.cn

25

29

E-mail: didactic@dolang.cn

26

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Web: www.didactic.cn

30

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

PPU

X1

24VDC

V60

Servo Motor

Z axisX53

V60

Servo Motor

Spindle

X54

Spindle Analog

X axisX51

Yaxis X52

Spindle encoder

X60

Spindle encoder

interface

Electronic hand

wheel

Signal 1 to 10

Handwheel

X10

IN

Quick Input Output

X21

I0.0~I0.7 X100

Same

I1.0~I1.7 X101

Same

IN

I2.0~I2.7 X102

Q0.0~Q0.7X200

Q1.0~Q1.7X201

IP24

OUT

M

Signal 1 to 24

Load 1 to 16

X30

USB interface

3L-

3L+

L-

2L+

X10 MCP

Web: www.didactic.cn

31

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Web: www.didactic.cn

32

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

P

P

P

P

P

P

Web: www.didactic.cn

33

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Web: www.didactic.cn

34

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Web: www.didactic.cn

35

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

60

61

3.3Machine connections

3.3.1Connection to prepare

Name

K2

test

line

Web: www.didactic.cn

Model

Red 1.0M head to

head

Blue1.0M head to

head

Qty

Unit

Pc

Pc

36

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Red1.0M head to

K3

test

line

head

Blue 1.0M head to

head

Black 1.0M head to

head

Red1.0M head to

head

K4tes

Blue 1.0M head to

t line

head

Double color 1.0M

head to head

13

Pc

13

Pc

35

Pc

Pc

Pc

Pc

3.3.2 Weak power connections

K3 control loop with a black test leads, 24V power supply circuit test line with a red K3, 0V test

line with a blue K3. According to I / O allocation table and electrical schematic connect the line

Each interface devices are used military aviation plug for secure connection devices when

connecting caution label, not even by mistake.

The first step in the demonstration stage coordinate find a 4-pin black cable (with 4-pin male

connector of military regulations), direct access to the training bench body left inside the four

small pinholes seat (label affixed SPIND), as shown in

The second step

in the demonstration stage to find a coordinate 12-core black cable (with 12-pin male connector

of military regulations), direct access to the training bench body on the left inside the 12

small pinhole seat (label affixed LIMIT), as shown in picture

Web: www.didactic.cn

37

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

The third step will be labeled X-axis motor power cables and encoder cables (green for the

encoder line and orange as the power supply cord) connected to the corresponds X-axis.

as shown in picture

Step Four: Similarly the Y-axis / Z axis motor power cable and encoder cable access Y axis / Z

axis motor, as shown below

Step Five: The three-phase five-wire platform body leads to a cable connected to the user side of

the power switch of the air terminal, where three black wires were three-phase line of fire, L1 L2

L3, blue zero line N, yellow and green color is the ground wire PE (this line must be connected

to prevent electrical interference).

Web: www.didactic.cn

38

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

3.4 Milling line connection

3.4.1 Semi-physical and abutment connection between the servo motor

1) sets the body control the servo motor drive, labeled X-axis motor power line and the X-axis

encoder line with the semi-physical side X-axis servo motor relative access; likewise labeled

Z-axis motor power line and Z-axis encoder line and semi-solid special end Z-axis servo motor

relative access.

2) spindle motor cable as four-pin plug and Taiwan aviation aviation plug is connected to the

side of the body

3) Limit switch cable connection: Connect the 12-pin connector cable with aviation platform

body is connected to the side of the air outlet

3.4.2 Connection diagram between the various modules

1) CNC system modules (DLSK-808D) with input and output modules (DLSK-S1616)

drawing connections between

Equipment ready:

DP25-pin cable is two male 1;

DP25-pin cable one is a male, one is female;

DP25 Adapter (Female to Female)

K3 blue test line 1

Input/output Module

DL SK -16I16O

OUTPUT

Q0.0

Q0.1

Q0.2

Q0.3

Q0.4

Q0.5

Q 0.6

Q0.7

Handwheel Control

Q1.0

Q1.1

Q1.2

Q1.3

Q1.4

Q1.5

Q 1.6

Q1.7

INPUT

System Start System Stop CNC Power

Input

X21

Output

CW

I0.0

I0.1

I0.2

I0.3

I0.4

I0.5

I0.6

I0.7

I1.0

I1.1

I1.2

I1.3

I1.4

I1.5

I1.6

I1.7

CCW

1L +

L-

3L+

3L-

WWW.DOLANG.CN

www.dolang.cn

3L-

2) CNC system modules (DLSK-C808D) and Power Module (DLSK-DY83B) wiring diagram

Web: www.didactic.cn

39

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

CNC Power

Handwheel Control

CNC Power

I/O Power

1L+

3L+

1L+

3L+

L-

3L-

L-

3L-

Work lamp

Red

-X4

+

3L-

System Start System Stop CNC Power

Input

X21

Output

CW

CCW

3L-

L-

3L+

FU2 5A

www.dolang.cn

www.dolang.cn

FU1 3A

1L+

3L-

Equipment ready:

CNC cable (two for the 2-pin header 1 meter needle aviation) 1

K2 test line 1 meter red and blue each one

K3 test line 1 m, red and blue each one

3) CNC system modules (DLSK-C808D) and control module (DLSK-KZ01) wiring diagram

X + limit

Handwheel Control

Z axis origin

X - limit

X axis origin

Z + limit

Y + limit

Y - limit

Y axis origin

KA1

-

KA4

Z - limit

3L+

KA7

KA2

System Start System Stop CNC Power

Input

X21

KA5

KA8

Output

CW

KA3

KA6

KA9

CCW

1L+

4)

Equipment ready:

L-

3L+

3L-

www.dolang.cn

www.dolang.cn

3L-

3L-

K3 test line 1 meter: Black and Blue 2

4.4 Control Module (DLSK-KZ01) with input and output modules (DLSK-S1616) wiring

diagram

Web: www.didactic.cn

40

E-mail: didactic@dolang.cn

Tel+86-531-87586199

FU3 8A

Dolang Technology Equipment Co., Ltd.

Input/output Module

DLSK -16I16O

OUTPUT

Q0.0

Q0.1

Q0.2

Q0.3

Q0.4

Q0.5

Q0.6

Q0.7

Q1.0

Q1.1

Q1.2

Q1.3

Q1.4

Q1.5

Q1.6

Q1.7

X + limit

X - limit

X axis origin

Z + limit

Z - limit

Z axis origin

Y + limit

Y - limit

Y axis origin

3L+

KA1

KA4

KA7

INPUT

KA2

I0.0

I0.1

I0.2

I0.3

I0.4

I0.5

I0.6

I0.7

I1.0

I1.1

I1.2

I1.3

I1.4

I1.5

I1.6

I1.7

KA5

KA3

www.dolang.cn

WWW.DOLANG.CN

KA6

KA8

KA9

3L-

Equipment ready:

K3 test line red \ blue \ black 1.0 m certain

4.5 Control Module (DLSK-KZ01) and Power Module (DLSK-DY83B) wiring diagram

Equipment ready:

K3 test line red \ blue \ black 1.0 m certain

Web: www.didactic.cn

41

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

CNC Power

CNC Power

Work lamp

I/O Power

1L+

3L+

1L+

3L+

L-

3L-

L-

3L-

X + limit

X - limit

X axis origin

Z + limit

Z - limit

Z axis origin

Y + limit

Y - limit

Y axis origin

3L+

Red

-X4

KA1

KA4

KA7

3L-

KA2

KA5

KA3

KA9

www.dolang.cn

FU3 8A

www.dolang.cn

FU2 5A

KA8

KA6

FU1 3A

3L-

4.6 Control Module (DLSK-KZ01) and spindle module (DLSK-SBPQ1) wiring diagram

X + limit

X - limit

X axis origin

Z + limit

Z - limit

Z axis origin

Y + limit

Y - limit

Y axis origin

3L+

KA1

KA4

KA7

KA5

KA2

KA8

DI

KA3

KA6

AC220V

KA9

DIN1

L

DIN2

www.dolang.cn

www.dolang.cn

DIN3

3L-

+24V

PE

K3 test line red \ blue \ black 1.0 m certain

4.7 Control Module (DLSK-KZ01) and DC motor module (DLSK-ZDJ01) connection

diagrams

Equipment ready:

Web: www.didactic.cn

42

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

K3 test line red \ blue \ black 1.0 m certain

DLSK- ZDJ01

DC Motor Module

Knife library

6

X + limit

X - limit

X axis origin Z + limit

Z axis origin

Y + limit

Y - limit

KA1

KA7

Knife library motor

KA2

1

3L+

3L-

KA5

Cooling motor

KA8

M

+

Lubrication motor

KA3

KA6

KA9

WWW.DOLANG.CN

WWW.DOLANG.CN

3L+

Knife library signal

Z - limit

Y axis origin

KA4

DLSK-KZ01

Control Module

3L-

4.8DC motor module (DLSK-ZDJ01) with input and output modules (DLSK-S1616) wiring

diagram

Equipment ready:

K3 test line red \ blue \ black 1.0 m certain

Web: www.didactic.cn

43

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

DLSK-16I16O

Input/output Module

DLSK-ZDJ01

DC Motor Module

OUTPUT

Knife library

6

R

Q0.0

Q0.1

Q0.2

Q0.3

Q0.4

Q0.5

Q0.6

Q0.7

Q1.0

Q1.1

Q1.2

Q1.3

Q1.4

Q1.5

Q1.6

Q1.7

Knife library motor

3L+

3L-

Cooling motor

INPUT

M

R

I0.0

I0.1

I0.2

I0.3

I0.4

I0.5

I0.6

I0.7

I1.0

I1.1

I1.2

I1.3

I1.4

I1.5

I1.6

I1.7

Lubrication motor

WWW.DOLANG.CN

Knife library signal

WWW.DOLANG.CN

4.9 Inverter module (DLSK-SBPQ1) with power box modules (DLSK-DYX02) connection

diagrams

Equipment ready:

K4 test line red \ blue \ color 1.0 meters each one

Power Zone

CNC

Control

Drive

AC380V

DI

AC380V

L1

DIN1

L2

L1

DIN2

Inverter

L2

L3

www.dolang.cn

DIN3

+24V

L3

www.dolang.cn

Web: www.didactic.cn

44

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

NOTE: The power box module is the local chart

4.10Power Module (DLSK-DY83B) and the feed axis module (DLSK-3Servo) connection

diagrams

Equipment preparation:

two 3-pin header aviation needle 1 meter cable 1

X axis

Y axis

Z axis

CNC Power

CNC Power

I/O Power

1L+

3L+

1L+

3L+

L-

3L-

L-

3L-

Work lamp

Red

-X4

FU1 3A

3L-

FU2 5A

FU3 8A

www.dolang.cn

www.dolang.cn

-X4

3.4 Definition of MCP panel

Defined

K11 key as lubrication switch

Web: www.didactic.cn

45

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

is cooling switch

K10 is knife selection switch , JOG mode or handwheel mode operation

Note: Each module is connected to the connection between the finished, you should carefully

check, accurate test run before electricity

IV Training report

1. According to the chosen training program write wiring process

2. Write the connection process problems

3. Write the time spent when wring cable

Web: www.didactic.cn

46

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Training 2 System Boot Electricity

I Training purpose

Master check line method and energized steps.

II Training content

Check the hardware connections and wiring; switched training system power (according to the

schematic.

III Training Steps

3.1 Check electrical wiring meets electrical schematics, short circuit faults

33.2 All switches and circuit breakers will be disconnected, the system displays X1 (back)

Unplug

DC plug-in of each servo is unplug

3.3 The power switch on the client, and then measured with a multimeter, the multimeter to

750V AC file at start of each phase measured voltage is normal, such as whether the L1 phase

and L2 phase AC380V 10%, L2 and L3 phase whether AC380V 10%, L1 and L3 phase

whether AC380V 10%, and then measured between phases L1 and N whether AC220V power,

L2 whether between the N phase AC220V power, L3 and N phase AC220V power between

whether . Right into the measured value, and then the right side of the body training station 4P

circuit breaker switch, as shown below, after closing, measuring tin AC220V power outlet is

normal and then to the next step.

3.4 Release the emergency stop switch on the power box, so that spin out, then hit the key switch

to the ON position, I heard "dumb" is heard, the power supply AC contactor pull the power,

Web: www.didactic.cn

47

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

indicator is red, the voltage indicated is betweenAC380V ~ AC400V

3.5 Then measure the input voltage on the circuit breaker 3P whether AC220V, two 1P

circuit breaker on the input voltage is measured with the N phase whether AC220V, 2P breaker

power whether AC220V, normal data, respectively, for "CNC" breaker, "Control" circuit

breakers, "Drive" circuit breakers, "Inverter" circuit breaker switch power supply, as shown

below,

Then drive module DLSK-SBPQ2 has power, the inverter display frequency, measuring servo

drive

Whether the port is DC24V voltage terminal, and then press the CNC system

modules

button,the back middle relay, then use a multimeter to measure whether the

CNC system at the back of X1 is DC24V voltage. If you do not normally need to be carefully

detection circuit, and then retest until the correct date; If the servo DC power supply is normal

normal and CNC systems, measuring button

is pressed,Intermediate relay back of the

system is disconnected, the circuit will hit "OFF" state, confirm that the device does not power

up, and then plug

into the servo drive connection interface,Each circuit hit "OFF"

state, confirm that the device does not power up, and then plug into the servo drive servo

connected interface, the system plug

into the system X1 office, and then re-inserted

sequential transmission, CNC system startup is complete.

Web: www.didactic.cn

48

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Training 3 Basic Operation of CNC Machine Tools

I Training purpose

Familiar with the controller operation method , fully understand the function and operation

method of the controller switch .

II Training content

Master machine operator panel functions.

III Training steps

3.1Introduction of numerical control system panel

LCD display area

8 "LCD monochrome display, 640 320 pixels, VGA

display, CCFL backlight

35 numeric character keys, 8 soft keys, 8 vertical direction

Panel

NC Keyboard

Definition

of the software, 16 function keys 6 arrow keys and special

keys 6, 7 queries key

MCP Machine

Control Area

Web: www.didactic.cn

Double-bit digital tube, 35 function keys, four user-defined

keys, 30 LED display

Spindle override key points feedrate override key

49

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Operation and function of each key CNC concise introduction see operating manual.

Web: www.didactic.cn

50

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Training 4 System Debugging Preliminary Knowledge

I Training purpose

Master the system boot steps.

II Training content

Understand the role and landing guidance system password

III Training steps

3.1 Boot procedure

Press the start button system, the system is powered on, start automatically.

3.2 After Power CNC system login password

System Password: SUNRISE

Manufacturers Password: Evening

3.3 Enter the parameter setting screen

Press "ALT + N" to enter the parameter setting screen.

3.4 Return reference point operate

3.5 Handwheel mode (current ratio is 10)

Web: www.didactic.cn

51

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

3.6 JOG operation mode

Web: www.didactic.cn

52

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Training 5 System Basic Parameters Settings

I Training purpose

Master the basic parameters of the system setup and modification method, a preliminary

understanding of the basic meaning of each parameter.

II Training content

Axis parameter setting, the servo parameter setting, spindle parameter settings.

III Training steps

3.1 PLC parameter settings overview

For instance in the use of more flexible procedures, DI16 and DO16 inputs and outputs of the

filtering process. As the examples of PLC programs, PLC machine parameters are defined in the

area reserved for the user.

3.2 X-axis parameter settings

31020 (ENC_RESOL)setting is 10000

31030 is set to 5 screw pitch

31050 is set to a load gearbox denominator

31060 is set to 1 Load gear numerator

31400 is set to 10000 steps per motor revolution number (semi servo)

32000 is set to maximum axis speed 5000mm/min

32010 Jog is set to fast speed 5000mm/min

32020 Jog speed is set to 2000mm/min

32060 default setting is 10000mm/min positioning axis

32100 axis direction is set to 1

32110 is set to a position feedback polarity

32260 is set to the rated motor speed 2000mm/min

32450 is set to 0mm backlash

32300 is set to 1

34000 is set to 1

34010 is set to 0 negative reference point

34020 set reference point speed 5000mm/min

34040 set reference point lookup speed 300mm/min

34060 is set to the reference point marker 20mm maximum distance

Web: www.didactic.cn

53

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

34,070 set to 5000mm/min reference point positioning speed

34,080 set-2mm distance reference point

34090 is set to 0mm reference point offset / absolute offset

36100 set-225mm negative software limit

36110 is set to 120mm Positive software limit

3.3 Z-axis parameter settings

31020 (ENC_RESOL) is set to 10000

31030 is set to 5 screw pitch

31050 is set to a load gearbox denominator

31060 is set to 1 Load gear numerator

31400 is set to 10000 steps per motor revolution number (semi servo)

32000 is set to maximum axis speed 4000mm/min

32010 Jog is set to fast speed 4000mm/min

32020 Jog speed is set to 2000mm/min

32060 default setting is 10000mm/min positioning axis

32100 axis direction is set to 1

32110 is set to a position feedback polarity

32260 is set to the rated motor speed 2000mm/min

32450 is set to 0mm backlash

32300 is set to 1

34000 is set to 1

34010 is set to a positive reference point

34020 set reference point speed 5000mm/min

34040 set reference point lookup speed 300mm/min

34060 is set to the reference point marker 20mm maximum distance

34,070 set to 5000mm/min reference point positioning speed

34,080 set-2mm distance reference point

34090 is set to 0mm reference point offset / absolute offset

36100 set-251mm negative software limit

36110 is set to 100mm Positive software limit

3.4 Spindle SP parameter settings

Web: www.didactic.cn

54

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

31020 is set to 2048

31030 is set to 10mm

31050 is set to 1

31060 is set to 2

Is set to 10000 31400

32000 set 100rev/min

32010 is set to 100 rev / min

32020 is set to 100 rev / min

32060 is set to 100 rev / min

32100 is set to 1

32110 is set to 1

32260 is set to 1400 rev / min

34060 is set to 720

34070 is set to 2 rev / min

34080 is set to -2

35100 is set to 1400 rev / min

35110 is set to 1400 rev / min

3.5 Y axis parameter settings

31020 (ENC_RESOL) is set to 10000

31030 is set to 5 screw pitch

31050 is set to a load gearbox denominator

31060 is set to 1 Load gear numerator

31400 is set to 10000 steps per motor revolution number (semi servo)

32000 is set to maximum axis speed 5000mm/min

32010 Jog is set to fast speed 5000mm/min

32020 Jog speed is set to 2000mm/min

32060 default setting is 10000mm/min positioning axis

32100 axis direction is set to 1

32110 is set to a position feedback polarity

32260 is set to the rated motor speed 2000mm/min

Web: www.didactic.cn

55

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

32450 is set to 0mm backlash

32300 is set to 1

34000 is set to 1

34010 is set to a positive reference point

34020 set reference point speed 5000mm/min

34040 set reference point lookup speed 300mm/min

34060 is set to the reference point marker 20mm maximum distance

34,070 set to 5000mm/min reference point positioning speed

34,080 set-2mm distance reference point

34090 is set to 0mm reference point offset / absolute offset

36100 is set to a negative software limit-300mm

36110 is set to 110mm Positive software limit

3.6 Machine parameters

14510 (20) is set to 6

14510 (24) is set to 60

14510 (25) is set to 500

Web: www.didactic.cn

56

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Training 6 Inverter Application

I Training Purpose

Master basic principle and control methods of inverter.

II Training content

Inverter connection and commissioning, the significance of parameters and modifications.

III Training steps

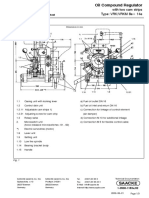

3.1 Familiar with the basic operation of the inverter

MICROMASTER 420 inverter in the standard mode of supply fashion have a status display

panel SDP (see Figure 1), for many users, the use of SDP and the factory default settings, you

can make the drive successfully put into operation. If the factory default setting value does not fit

on your device, you can use the Basic Operator Panel (BOP) (see Figure 1) or advanced control

panel (AOP) (see Figure 1) modify the parameters to match up. BOP and AOP is supplied as an

option. You can also use the PC IBN tool "Drive Monitor" or "STARTER" to adjust the factory

settings. Related software on the CD ROM supplied with the drive can be found.

SDP

State Dashboards

BOP

AOP

Basic Operate Panel

Advanced

operate panel

Figure 1 MICROMASTER 420 inverter operation panel

Web: www.didactic.cn

57

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

This article only for the Basic Operator Panel (BOP) to explain

Prompt

The default power frequency setting (factory setting) SDP can be changed under the DIP

switches; inverter delivery settings are as follows:

DIP switch 2:

Off position:

Europe Default

(50Hz, power unit: kW)

On Location

North America defaults

(60Hz, Power Unit: hp)

DIP switch 1

Not available to users.

Prerequisites:

Mechanical and electrical installation has been completed:

Web: www.didactic.cn

58

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Prompt

We recommend that you follow the above diagram for debugging

With the Basic Operator Panel (BOP) for debugging

Using the Basic Operator Panel (BOP) can change the various

parameters of the drive, in order to set the parameters with the BOP,

you must first remove the SDP, and install the BOP.

BOP has a five-digit 7-segment display, you can display the serial

number of parameters and values, alarm and fault information, and

set and actual values. Parameter information can not be stored using

the BOP.

Prompt

In the default setting, use the BOP motor control functions are disabled. If you want the

BOP control, parameter P0700 should be set to 1, the parameter P1000 should be set to 1.

When coupled with the power inverter can also be fitted to the drive of the BOP, BOP or

removed from the inverter will.

If the BOP has been set to I / O control (P0700 = 1) when removing the BOP inverter

drive unit will automatically stop.

Table 1 using the BOP default settings when operating

Web: www.didactic.cn

59

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Parameter

Explanation

Defaults, European (or North

American) region

P0100

Run, Europe / North America

50Hz,kW(60Hz,hp)

P0307

Power (motor rated)

kW(Hp)

P0310

The rated power of the motor

50Hz(60Hz)

P0311

1395(1680)rpm[Decision variables]

The rated speed of the motor

P1082

Maximum motor frequency

50Hz(60Hz)

Basic Operation Panel (BOP) button

Display/button

Function

Status Display

Function explanation

LCD display inverter current setting

Press this button to start the drive. The default

Start Drive

value for this key is the run-time blocked. In order

to make effective operation of this key should be

set P0700 = 2

OFF1: Press this button, the drive will be selected

ramp down rate parking, the default value for this

key is blocked runtime; operation in order to allow

Stop the drive

this key should be set P0700 = 2.

OFF2: Pressing the button twice (or once long)

causes the motor to coast to a stop. This function is

always to "Enable" in.

Changing the

direction of

Web: www.didactic.cn

Press this button to change the direction of rotation

of the motor reverse motor with a minus sign or a

60

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

rotation of the

motor

flashing decimal point indicates the default value

for this key is the run-time blocked in order to

make effective operation of this key should be set

P0700 = 2

In the case of the inverter has no output this

button, the motor starts, the pre-set jog frequency

Jog motor

operation. When the key is released, the inverter

stop. If the inverter / motor is running, pressing

this key will be inactive.

This button is used to view additional information.

During inverter operation, any one parameter in

the display, press this button and hold for 2

seconds, the following parameter values (in the

inverter running start from any one parameter):

1 DC link voltage (indicated by d - units: V)

(2) Output Current A

3 Output frequency (Hz)

4 Output voltage (indicated by o - units V)

5 from the value selected in P0005 (P0005 choose

to show if any of the above parameters (4 or 5),

this will not be displayed).

Press this button repeatedly to cycle through the

above parameters.

Jump Function

From any parameter (rXXXX or PXXXX) a short

press of this button will immediately jump to

r0000, if necessary, you can then change another

parameter. After the jump to r0000, pressing this

key will return to your starting point.

Access

Parameters

Web: www.didactic.cn

Press to access parameters..

61

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Increase value

Press to increase the value of the parameter

displayed on the panel.

Decrease the

Pressing this button decreases the displayed

value

parameter values.

Figure 2 Basic Operator Panel (BOP) buttons

With the Basic Operator Panel (BOP) to change parameter values

The chart below shows how to change the value of parameter P0004. Modify the parameter

values under standard steps listed below see P0719 case diagram. According to this chart in a

similar manner as described, you can use 'BOP' to set any parameters.

Change P0004-parameter filtering

Procedure

1Press

Display results

Access Parameters

2push

3push

Web: www.didactic.cn

Until the P0004 show up

Access level to enter parameter values

62

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

push

Or

Push

Press to confirm and store the value

reach the required value

Users can only see the command parameters

Modify subscript parameter P0719 (Here we must note that the parameters must be set P0003 3,

P0004 is set to 0 or 7 before they can access to)

Select the command / setpoint source

Procedure

1push

2push

Display results

Access Parameters

Until the P0719 show up

3 push Enter parameter values access level

Web: www.didactic.cn

63

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

4push

push

Or

Displays the current settings

choose to run the required

maximum frequency

6 Press to confirm settings and storage P0719

Push Until display r0000

push Return to the standard drive display (defined by the user)

Description - busy information

When modify the parameter values, BOP sometimes display:

Indicates that the drive is busy

Web: www.didactic.cn

64

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

with higher priority tasks.

Changing a number of parameter values

In order to quickly modify the parameter values, you can modify the display one by one

to separate out each number, follow these steps:

Convinced that a certain parameter values already in access level (see "modify

parameters using the BOP").

Push

Function keys rightmost digit flashes.

Push

Push

Modifying the numerical value.

(Function keys) adjacent to the next digit flashes.

4 Perform steps 2 through 4 until the required value displayed.

5 Press to exit the access level of the parameter values .

Prompt

Function keys can also be used to confirm the occurrence of failure.

Quick commissioning flowchart (only applies to the first one access level)

Web: www.didactic.cn

65

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Start quick commissioning P0010

0 Ready to run

A quick commissioning

30 factory default settings

Explanation

Before the motor is in operation, P0010, must return to '0 '.

However, if selected after commissioning P3900 = 1, then,

P0010 zero return operation is automatic

P0100 Select work area is Europe / North America

0 power unit KM: f defaults to 50Hz

A power unit hp: f defaults to 60Hz

Two power units of KW: f defaults to 60Hz

Explanation

P0100 set values 0 and 1 should be used to change the DIP

related to the set value is fixed.

P0700 Select the command source 2)

On / off / reverse (on / off / reverse)

Factory settings

1 Basic Operator Panel (BOP)

2 inputs / digital inputs

P1000 Select requency setpoint 2)

0 No frequency setting

1. BOP control frequency with lifting

2 analog setpoint

P1080 Minimum motor frequency

This parameter sets the minimum motor frequency

(0-650Hz); reach this frequency when the motor

speed will be independent of the frequency

setpoint.

The value set here the motor forward and reverse

P1082 Maximum motor frequency

P0304 Motor rated voltage 1)

This parameter sets the maximum motor frequency

(0-650Hz); reach this frequency when the motor

speed will be independent of the frequency

setpoint.

The value set here the motor forward and reverse

10V-2000V

Type the nameplate rated motor voltage (V)

P0305 Motor rated current 1)

0-2 times inverter rated current (A)

Type the nameplate rated motor current (A)

P1120 Ramp-up time

0s-650s

Motor accelerate from standstill up to maximum

motor frequency required time.

P0307 Motor rated power 1)

0KW-2000KW

Type the nameplate rated motor power (KW)

If P0100 = 1, hp power unit should be

P1121 Ramp-down time

0s-650s

Reduced from the maximum frequency motor

standstill time required.

P0310 Motor rated frequency 1)

12Hz-650Hz

Type the nameplate rated motor frequency (Hz)

P3900 The end of the quick commissioning

P0311 Motor rated frequency 1)

0-40000 1/min

Typed according to the nameplate rated motor speed (rpm)

0 End quick commissioning, no motor calculations

or reset to factory default settings.

One end of the quick commissioning, the motor

calculation and reset to factory default settings

(the recommended way).

2 End quick commissioning, the motor

computation and I / O reset.

3 end of the quick commissioning, the motor

calculations, but not for I / O reset.

1With motor-related parameters - see motor nameplate.

Web: www.didactic.cn

66

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

2

Indicates that the parameter contains a more detailed setting value table can be used for specific

applications. See on the CD, "Reference Manual" and "Operating

Instructions"

Figure 3 A typical example of a nameplate motor

Prompt

If P00032, parameter P0308 or P0309. Is the only view you can see exactly which of

a parameter that determines the set value in P0100.

P0307 displayed in kW or HP, depending on P0100 settings. Detailed information

see parameter table.

Unless P0010 = 1 otherwise it is not change the motor parameters.

Ensure that the inverter according to the motor nameplate data has been correctly

Web: www.didactic.cn

67

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

configured, that in the above example, the motor is -shaped terminal voltage wiring

should be connected to 230V.

The inverter is reset to factory default settings

In order to reset all the parameters of the drive to the factory default settings should be in

accordance with the following values set parameters (with BOP, AOP or necessary

communication option):

1 Set P0010 = 30

2 Set P0970 = 1

Explanation

Complete the reset process for at least 3 minutes.

Normal operation

For the inverter standard parameters and extended parameters of a comprehensive description,

see parameter table.

Prompt

Drive is not the main power switch, so when the supply voltage is switched inverter

already charged. In the press run (RUN) key or digital input 5 appears in the "ON" signal

(forward rotation) before the inverter output has been blocked in a wait state.

If equipped with a BOP or AOP and has been selected to display the output frequency

(P0005 = 21), then slow down and stop the drive, the corresponding setpoint display

about once every second.

The same frequency at the factory Siemens rated power a conventional four-pole standard

motors application object to be programmed. If the user uses other types of motors, you

must enter the specifications on the motor nameplate data. About how to read the details

of the motor nameplate data, see Figure 3.

Unless P0010 = 1, otherwise it is not to modify the motor parameters.

For the motor is running, must be P0010 returns "0" value.

With BOP / AOP for the basic operation

Prerequisites

P0010 = 0 (in order to run the command correctly initialized).

P0700 = 1 (enable BOP operator panel start / stop button).

Web: www.didactic.cn

68

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

P1000 = 1 (enables the motor potentiometer setpoint).

Push green

button,

Starter motor. Press the "

Value Add" button, the motor rotational speed is

gradually increased .Add to 50Hz. When the inverter output frequency reaches 50Hz,

press the

"lower values" button and motor speed, Can change the direction of

rotation of the motor. Press the red button, electricity

External motor thermal overload protection

Below rated speed, the motor is running,

press the fan mounted on the motor shaft

of the cooling effect is reduced.

Therefore, if you want to run continuously

for long periods at low frequencies,

most motor must be rated lower power usage.

In order to protect the motor in this case

will not overheat and damage the motor PTC

sensor should be installed and connected to

its output signal corresponding to

the inverter control terminals, while enabling P0601.

Web: www.didactic.cn

69

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Figure 4 motor overload protection PTC wiring

MICROMASTER 420

Inverter system parameter profile

"Parameter description" formatted as follows:

1 Parameter NO.

2 Name

12 User

Access

9 Min

Level

[Subscript] 3 CStat: 5 Data Type: 7 Unit: 10 Default:

Four parameter groups: 6 Enable Effective: 8 Quick commissioning:

11 Maximum 13 Description:

1 parameter number

Refers to the parameter number. Parameter No. 0000-9999 with the four-digit number preceded

by the parameter a lowercase letter "r" , indicates that the parameter is " read-only" parameter,

which shows the specific parameter values , and can not be used with different values of the

parameter to change its value ( in some cases , " parameter Description " in the title bar of the

"Unit ", " Min ", " default " and "maximum " place to insert a dash " - " ) . All other parameters

are preceded by a number in front of the capital letter "P". Parameter settings directly in the title

bar of the " minimum" and "maximum" range to be modified.

[ Subscript ] indicates that the parameter is an indexing parameter and specify the subject of the

next valid number.

2 Parameter Name

Refers to the name of the parameter . Some parameter names preceded by the following initials :

BI, BO, CI , and CO, and is followed by a colon ": ." The meaning of the letters abbreviations

are as follows:

BI = Binector input , that is, you can select and define the parameters of the binary input signal

Web: www.didactic.cn

70

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

source .

BO = Binector output , that is, the parameter can select the output binary function , or as a

user-defined binary signal output.

CI = connector input , that is, you can select and define the parameters of the analog input signal

source.

CO = connector output , that is, the parameter can be selected analog output function , or as a

user-defined analog signal output.

CO / BO = analog / binary outputs interconnected , that is , the parameter can be used as analog

signals and / or binary signal output or defined by the user .

To take advantage of BiCo feature, you must understand the whole parameter table , the access

level , there may be many new BiCo parameter settings. BiCo function is associated with the

specified settings are not the same function , you can input and output functions are combined , it

is a more flexible way . In most cases, this function can be simply setting the second access level

together.

BiCo system allows complex functions to be programmed. In accordance with the needs of users,

Boolean algebra and mathematical expressions can be entered in a variety of ( digital, analog,

serial communications , etc. ) and outputs ( inverter current, frequency , analog output, relay

output, etc. ) between the configurations and combinations .

3.Cstat

Refers to the parameter debug state may have three states:

Debugging: C

Run: U

Ready to run: T

This indicates that the parameter is permitted to be modified at any time. A parameter can be

specified for one, two or all three states. If the three states are specified, it means the value of the

parameter setting of the three state inverter can be modified.

4.Parameter group

Refers to a specific feature set of parameters.

Explanation

Web: www.didactic.cn

71

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

Parameter P0004 (parameter filter)'s role is based on a selected group of function, the

parameters to filter (or filters), and focus on a set of parameters to filter out access.

5.Data Type

The valid data types are listed below.

NO.

Explanation

U16

16 Bit

unsigned

U32

32

Unsigned

I16

16

Integer

I32

32

Integer

Float

Float

6 Enable effective

Indicates that the parameter is:

Now the value of this parameter can be modified immediately (enter new parameter values in the

future).

Confirmation panel (BOP or AOP) on the "P" key has been pressed, before the new value

entered effectively modify the parameters of the original value.

7 units

Refers to the measurement of the parameter values used in the unit

8 quick commissioning

Refers to whether the parameter (yes or no) can only be modified in quick commissioning, is to

say, whether the parameter can only P0010 (select different parameter sets the debug mode) is

set to 1 (quick commissioning selection) when modifications.

9 min

Means that the parameter may be set to the minimum value.

10 Default

Means that the parameter default values, that is, if the user does not specify parameter values, the

Web: www.didactic.cn

72

E-mail: didactic@dolang.cn

Tel+86-531-87586199

Dolang Technology Equipment Co., Ltd.

drive uses this value as the factory set value of the parameter.

11 max.

Means that the parameter may be set to the maximum value.

12 User access level

Is to allow users to access the parameter level. Drive a total of four levels of access: Standard,

Extended, Expert and maintenance stages. Each function group contains the parameter number,

depending on the parameter P0003 (user access level) to set access levels.

13 Explanation

Description of the parameters set by a number of paragraphs, as its contents are listed below.

Some passages and content have a choice, if not used, they will be omitted.

Description: A brief explanation on the parameter functions.

Illustrations: Illustrations and when necessary characteristic curves to illustrate the role of

parameters.

Settings: You can specify a list of values and the use of the set. These values include the possible

settings, the most commonly used settings, subscript, and bit address bits.

Example: Select the appropriate examples of parameter settings for a particular role.

Relevance: This parameter must satisfy. That is, the parameters on the other (s) have a particular

role parameter, or other parameters of the parameters for a particular effect.

Report / Note / Tips / Help

To avoid injury to personnel or equipment / specific information damage must draw the user's

attention to important information such information to the user

Information to solve problems and understand there may be a state aid of

Details: For more detailed parameters of a particular data source.

Reset to factory default settings