Documente Academic

Documente Profesional

Documente Cultură

491

Încărcat de

Miguel RojasDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

491

Încărcat de

Miguel RojasDrepturi de autor:

Formate disponibile

NO: 491R2

DATE:

November

30,1995

SUPERSEDES:

LIMITED

DISTRIBUTION

SUBJECT:

DS TRANSFER

Publications

DS Transfer

References:

Pump

GENERAL

PUMP

Bulletin

dated 4/l/95

and

MOTORS

REGULATOR

Service

Regulator

S.B. 491Rl

CHANGES

230

Bushings

As previously outlined in Service Bulletin 485, it is necessary to prevent

pressure from building up between the vehicle fuel supply pump and the

injection pump inlet during hot soak conditions on GM 6.5L DS-equipped

applications. This pressure build-up, under certain conditions could prevent

the electrical shutoff solenoid plunger from lifting off its seat when the

solenoidis energized.

To address this condition a flatted transfier pump regulator piston stop

bushing was released (Type 2 below in Figure 1) as replacement for the

original, plain Type 1 (P/N 21262) bushing. The flat prevents pressure

build-up by allowing fuel to escape past the bushing into the transfer pump

B

TV;

@I

\; 2P$a2in

@Ore

Type;j,:;ed

Type 3 - Notched

FIGURE 1

pressure gallery of the pump.

Recently it was found that venting could also be accomplished by simply

placing notches on the face of bushing resulting in the Type 3 bushing

pictured above in Figure 1. Consequently, in production, a plain 21262

bushing is now pressed into the regulator using special mandrels which

stamp a V-notch in the side which faces the piston.

Diesel Systems Division, Stanadyne

Automotive Corp.

CJ~Deerfield ~~~~~ VVindsor, CT 06095, USA

Tel: (203) 525-0821;

Telex:

99218;

TekCoPY:

(203)

525-4215

S.B. 491RZ

4%

As a result, the flatted 31348 bushing has now been discontinued and venting

of DS transfer pump regulator piston stop bushings will be accomplished

during servicing through the use of a transfer pump regulator venting

mandrel, P/N 32505, shown below in Figure 2.

Transfer Pump Regulator Venting

Mandrel, P/N 32505

FIGURE 2

When servicing DS pumps, it is necessary to determine whether the regulator

contains a vented type bushing or not. All DS pumps with serial numbers

greater than 7,742,324 should have a vented bushing (type 2 or 3), but

Service Dealers are requested to be sure that one or the other is present in all

DS pumps during the rebuilding process.

To do this, disassemble the adjusting screw, spring and regulating piston

from the regulator. Do not press the bushing out of the regulate?. Clean

and dry the regulator assembly and examine the bushing to determine

whether it is either flatted or has vent grooves on the face that the piston

rests on by looking down the regulator bore with the aid of a light. If it has a

flatted type bushing (Type 2) or has a groove or grooves on the face (Type 3),

then it should be left as is. If it is a plain bushing (Type l), then it should be

modified as outlined below.

Bushing

Modification

1) Grind the small diameter end of a transfer pump regulator bushing

installation tool, P/N 27985 to a maximum length of 0.135(3.43mm) so it

will not protrude through the regulator bushing. See Figure 3.

3) Clamp the modified bushing installation tool in a vise with the stepped

end up. Place the regulator over the installation tool as is shown in

Final Max. Length

.135 (3.43mm)

II!

P/N 27985

Remove

Material

FIGURE 3

L.

S.B. 491RZ

-3-

Figure 4 and insert the 32505 venting mandrel into the regulator. Tap

the 32505 tool with a hammer to form the venting grooveson the face of

the bushing.

i%=-

ansfer Pump

Regulator

Assembly

Modified Bushing

Installation Tool

27985

FIGURE 4

Once the a DS pump is equipped with a vented bushing (type 2 or 3) the

pump can utilize either the original 30934 electric shutoff solenoid (steel tip)

or the current 31146 solenoid (rubber tip) without concern over pressure

build-up in the fuel supply system as long as the pump meets all specification

checkpoints - and in particular, the fuel shutoff checkpoint.

DS Transfer

Pump Regulating

Spring

(P/N 30669)

DS Transfer Pump Regulating Spring, P/N 30669, has been redesigned and

now is 0.100 inches (2.5mm) longer in free length in order to increase the

range of transfer pressure adjustment. The previous 30669 spring and the

new 30669 spring are depicted below in Figure 5.

Red Stripe Length

Of Spring For

Identification

Both Ends

Red

Original 30669 Spring

Current 30669 Spring

Free Length:

Free Length:

0.640 inches (16.3mm)

0.740 inches (18.8mm)

FIGURE 5

-4-

S.B. 491RZ

Stanadyne is not recalling stocks of the original design 30669 springs,

therefore dealers should continue to use their existing stocks of old 30669

springs until depletion. However, should you encounter a DS pump where the

adjusting plug bottoms out before the desired pressure is obtained during

pump calibration, the longer version of spring 30669 should be tried.

DS Transfer Pump Regulator and Inlet Fitting

The DS pump fuel inlet fitting, P/N 30493, and transfer pump regulator

assembly 30495 recently underwent minor design changes.

The thread length on both the inlet fitting and the regulator have both been

shortened slightly as shown below in Figure 6.

Inlet Fitting

31326

Inlet Fitting

30493

Note difference

in thread depth

Regulator Assembly

30495

-

Original Design

Current Design

FIGURE 6

Please note that the 30495 regulator assembly did not receive a part number

change as a result of the design change, but inlet fitting 30493 has been

superseded by the new, shorter fitting, P/N 31326. Fitting 31326 is sold

separately and may be used interchangeably with both old and new regulator

assemblies.

However, since longer 30493 fittings should not be used with the latest 30495

regulator design, the 31326 fitting has now been added to the current design

30495 regulator packaging to ensure that the correct parts are used together.

Transfer

Pump

Regulator

Screen

(P/N

32228)

To prevent the possibility of debris entering the bottom of the DS transfer

pump regulator and blocking the regulating slot or causing the regulating

FIGURE 7

S.B. 4i91R2

-5-

piston to become stuck, a screen, P/N 32228, has been added to the DS Pump

Transfer Pump Regulator Sleeve (Reference Figure 7).

When DS pumps are overhauled, the 32228 screen should be added whenever

the regulator does not already have one fitted and, if the pump is within the

warranty period the screen should be added to the list of replaced parts on the

warranty claim. If the screen is already present, it should be left in place

during servicing. Should a 32228 screen ever need to be removed from a

regulator sleeve during servicing, a new screen should be installed. Removed

screens should not be reused.

Transfer Pump

Regul$fxween

Transfer Pump

Regula~;4$sembly

Transfer Puqp

Regulaa;iprmg

FIGURE 8

1) Place the screen on the end of a 30669 Transfer Pump Regulator Spring.

2) Push the regulator sleeve down onto the screen and apply enough force

to seat the screen against the Transfer Pump Regulator Bushing. See

Figure 8.

3) Remove the 30669 regulating spring witlh a counterclockwise twist to

prevent tearing the screen.

Technical Support Group

Product Support Department

S-ar putea să vă placă și

- TOYOTA 1CD-FTV D4D Engine FuelDocument27 paginiTOYOTA 1CD-FTV D4D Engine FuelLuis Daniel Cortes100% (16)

- Diesel Fuel Receiving and Issuance ProcedureDocument4 paginiDiesel Fuel Receiving and Issuance Proceduresukarno amin100% (1)

- 454 GD & HS Fuel Pump Timing & CalibrationsDocument15 pagini454 GD & HS Fuel Pump Timing & Calibrationsslipsittin75% (4)

- SS1 Dellorto Carburetor Technical ManualDocument10 paginiSS1 Dellorto Carburetor Technical ManualLSÎncă nu există evaluări

- Operating Book For Mud Pump 2Document57 paginiOperating Book For Mud Pump 2Kaleem Ullah100% (3)

- HL2-90 Compressor Instr ManualDocument12 paginiHL2-90 Compressor Instr ManualCosmin Iulian100% (3)

- Wartsila Fuel Pump - MaintenanceDocument15 paginiWartsila Fuel Pump - MaintenanceAbhishek Singh Chauhan0% (1)

- SM60129 1Document12 paginiSM60129 1HENKO7659100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Baby Roller-3 PDFDocument7 paginiBaby Roller-3 PDFaris setiawanÎncă nu există evaluări

- Mechanical Technology Lab ReportDocument16 paginiMechanical Technology Lab ReportBilal Akhundzada100% (2)

- Parts and Technical Service Guide Guía de Servicio Técnico y Recambio Guide D'instructions Et Pièces de Rechange Technische BedienungsanleitungDocument14 paginiParts and Technical Service Guide Guía de Servicio Técnico y Recambio Guide D'instructions Et Pièces de Rechange Technische BedienungsanleitungAlex Molina100% (2)

- 3042 G Tag Axle R12 Brake Valve RetrofitDocument6 pagini3042 G Tag Axle R12 Brake Valve RetrofitHamiltonÎncă nu există evaluări

- Service InformationDocument2 paginiService InformationMarcelo GiussaniÎncă nu există evaluări

- DElphi InjectorsDocument3 paginiDElphi InjectorsАмурдеталь БлаговещенскÎncă nu există evaluări

- viewpdfMSV 30MAX PDFDocument2 paginiviewpdfMSV 30MAX PDFcarlos76Încă nu există evaluări

- Modular Feeder PSG 2Document22 paginiModular Feeder PSG 2LLÎncă nu există evaluări

- LOCOPUMP S2 User ManualDocument9 paginiLOCOPUMP S2 User ManualAngelica DragulescuÎncă nu există evaluări

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDocument4 paginiCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemÎncă nu există evaluări

- lt3 00032 2 A p24 p30sDocument67 paginilt3 00032 2 A p24 p30sBruno SamaeianÎncă nu există evaluări

- Yukenmodularvalves Yuken CatDocument140 paginiYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- Instruction Manual AND Parts List For: SRM00032 Rev. 01 (13-0218) July 2013Document17 paginiInstruction Manual AND Parts List For: SRM00032 Rev. 01 (13-0218) July 2013royert80Încă nu există evaluări

- OILPUMP CadillacDocument47 paginiOILPUMP CadillacHugoÎncă nu există evaluări

- SM 64349Document32 paginiSM 64349HENKO7659Încă nu există evaluări

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Document8 paginiVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliÎncă nu există evaluări

- Microfilter FinalDocument6 paginiMicrofilter FinalRobs BankÎncă nu există evaluări

- CSL 1007Document11 paginiCSL 1007oscar horacio flores100% (1)

- SAMSUNG SEM-3074E - Piping Design Manual (Pump Piping)Document21 paginiSAMSUNG SEM-3074E - Piping Design Manual (Pump Piping)Tanveer Ahmad100% (2)

- PUMP PIPING DESIGN MANUALDocument21 paginiPUMP PIPING DESIGN MANUALSlobodan AnticÎncă nu există evaluări

- Presion de Gas de Etntrada MotorDocument24 paginiPresion de Gas de Etntrada MotorSERTECC SASÎncă nu există evaluări

- SB 09-2916a Reg. MooneyDocument16 paginiSB 09-2916a Reg. MooneyJavier Leonidas0% (1)

- En Scroll Replacement Guidelines 0Document10 paginiEn Scroll Replacement Guidelines 0Ferdie FernandezÎncă nu există evaluări

- TM 5-5065 Le Roi Compressor, 1954Document356 paginiTM 5-5065 Le Roi Compressor, 1954Advocate100% (1)

- Holley Contender Intake ManifoldDocument4 paginiHolley Contender Intake Manifoldpaul_a_rodriguezÎncă nu există evaluări

- Phased Out Products: Gear Pumps and Motors General ProductsDocument18 paginiPhased Out Products: Gear Pumps and Motors General ProductsAndrei VladÎncă nu există evaluări

- Models A & B Automatic Pressure Maintenance DevicesDocument4 paginiModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASÎncă nu există evaluări

- 1/3 HP Pump Technical SpecsDocument14 pagini1/3 HP Pump Technical SpecsBruno Pacheco100% (1)

- Toyo 1-55Document435 paginiToyo 1-55Yuda Satria100% (1)

- Manual de Servicio/partes/operacion Compresor Quincy Modelo 350 - 350 Quincy Compressor Manual Operation/service/spare PartsDocument20 paginiManual de Servicio/partes/operacion Compresor Quincy Modelo 350 - 350 Quincy Compressor Manual Operation/service/spare PartsTalleres Lilo100% (2)

- PerkinsDocument12 paginiPerkinsDalibor Sopina Duc100% (2)

- 1991 Ford Technical Service BulletinsDocument147 pagini1991 Ford Technical Service Bulletinsalexander pintoÎncă nu există evaluări

- KRAL Pump Stations Catalog for DKC/DMC SeriesDocument46 paginiKRAL Pump Stations Catalog for DKC/DMC Seriesmarine_dieselÎncă nu există evaluări

- Plant Layout-CompressorsDocument19 paginiPlant Layout-Compressorshalder_kalyan9216Încă nu există evaluări

- REXROTH Service Manual PVC PSSFDocument6 paginiREXROTH Service Manual PVC PSSFRaghavendra DeshpandeÎncă nu există evaluări

- 09-2916 Regulador Series Four WaukeshaDocument14 pagini09-2916 Regulador Series Four WaukeshaMaria Fernanda Bonilla SalasÎncă nu există evaluări

- DP1 Pump: 1:1, Air-Operated, OilDocument6 paginiDP1 Pump: 1:1, Air-Operated, OilSaravanan MathiÎncă nu există evaluări

- Pump Repair ManualDocument17 paginiPump Repair ManualSergiSerrano100% (1)

- 2RZ 3RZ SCDocument21 pagini2RZ 3RZ SCDiego Pillco0% (1)

- Improve 120G Motor Grader ControlDocument2 paginiImprove 120G Motor Grader ControlLeandro SalÎncă nu există evaluări

- A10v0 Variable Displacement Piston PumpDocument23 paginiA10v0 Variable Displacement Piston PumpVanadia Nohan100% (1)

- Manual Bomba Cat 05183Document4 paginiManual Bomba Cat 05183Angel SandovalÎncă nu există evaluări

- Vis YorkDocument56 paginiVis Yorkkulilin1100% (1)

- TF 500 Compressor ServiceDocument18 paginiTF 500 Compressor ServiceDaniel MalaveÎncă nu există evaluări

- Group 2 Hydraulic Pump: 1. GeneralDocument8 paginiGroup 2 Hydraulic Pump: 1. GeneralJet AcostaÎncă nu există evaluări

- SM47013 PDFDocument8 paginiSM47013 PDFHENKO7659Încă nu există evaluări

- ServiceManuals/LG/Fridge/GR151SW/GR-151SW Service ManualDocument13 paginiServiceManuals/LG/Fridge/GR151SW/GR-151SW Service Manualcolo-desÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- The Weir Direct-Acting Feed Pump - Working InstructionsDe la EverandThe Weir Direct-Acting Feed Pump - Working InstructionsÎncă nu există evaluări

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversDe la EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversEvaluare: 5 din 5 stele5/5 (2)

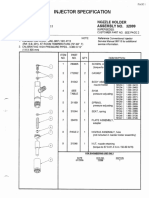

- Injector Specification: Assembly No: 32144Document1 paginăInjector Specification: Assembly No: 32144Miguel RojasÎncă nu există evaluări

- Stamping Reference GuideDocument170 paginiStamping Reference GuideMiguel Rojas100% (2)

- DBGVC231 6BMDocument3 paginiDBGVC231 6BMMiguel RojasÎncă nu există evaluări

- DBGVC231 7BMDocument3 paginiDBGVC231 7BMMiguel RojasÎncă nu există evaluări

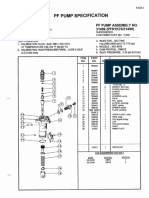

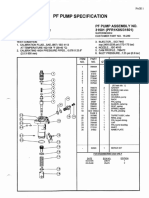

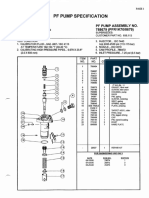

- PF Pump Specification: Stanadyne"Document2 paginiPF Pump Specification: Stanadyne"Miguel RojasÎncă nu există evaluări

- PF Pump Specification: Stanadyne"Document2 paginiPF Pump Specification: Stanadyne"Miguel RojasÎncă nu există evaluări

- DBGV (X429 - 3cli: ModelDocument2 paginiDBGV (X429 - 3cli: ModelMiguel RojasÎncă nu există evaluări

- Injector Specification: Stanadyne"Document2 paginiInjector Specification: Stanadyne"Miguel RojasÎncă nu există evaluări

- Injection Pump Specification for Ford 172 Cu. In. Industrial EngineDocument3 paginiInjection Pump Specification for Ford 172 Cu. In. Industrial EngineMiguel RojasÎncă nu există evaluări

- PF Pump Specification: Stanadyne"Document2 paginiPF Pump Specification: Stanadyne"Miguel RojasÎncă nu există evaluări

- Model DBGVCC42!3-8AJ: - Customer Part NoDocument2 paginiModel DBGVCC42!3-8AJ: - Customer Part NoMiguel RojasÎncă nu există evaluări

- PF Pump Specification: Stanadyne"Document2 paginiPF Pump Specification: Stanadyne"Miguel RojasÎncă nu există evaluări

- Cmi+9/643-H: Descrlptlon AMTDocument2 paginiCmi+9/643-H: Descrlptlon AMTMiguel RojasÎncă nu există evaluări

- PF Pump Specification: Stmdyne"Document2 paginiPF Pump Specification: Stmdyne"Miguel RojasÎncă nu există evaluări

- Injector Specification: Nozzle Holder Assembly No. 30163Document2 paginiInjector Specification: Nozzle Holder Assembly No. 30163Miguel RojasÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration DataMiguel RojasÎncă nu există evaluări

- 160 300isuzu1Document20 pagini160 300isuzu1Miguel RojasÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument3 paginiDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- MODEL DBGFC 637-n AF: Qtilog - Page NO GDocument2 paginiMODEL DBGFC 637-n AF: Qtilog - Page NO GMiguel RojasÎncă nu există evaluări

- PF Pump Specification SheetDocument2 paginiPF Pump Specification SheetMiguel RojasÎncă nu există evaluări

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 paginiInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsMiguel RojasÎncă nu există evaluări

- PF Pump Specification: Stanadyne"Document2 paginiPF Pump Specification: Stanadyne"Miguel RojasÎncă nu există evaluări

- C Program Files Documents and Settings All Users Gerencia Dieselmotor Mis Documentos GERENCIA TESTSPEC TESTSPEC 01EJ0081 PDFDocument3 paginiC Program Files Documents and Settings All Users Gerencia Dieselmotor Mis Documentos GERENCIA TESTSPEC TESTSPEC 01EJ0081 PDFMiguel RojasÎncă nu există evaluări

- Stanadyne Corporation: OEM To Fuel Manager Brand Cross Reference P/Ns For Filter Elements 99642 - August 2002Document3 paginiStanadyne Corporation: OEM To Fuel Manager Brand Cross Reference P/Ns For Filter Elements 99642 - August 2002Miguel RojasÎncă nu există evaluări

- Injection pump specification sheetDocument2 paginiInjection pump specification sheetMiguel RojasÎncă nu există evaluări

- User's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemDocument5 paginiUser's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemMiguel RojasÎncă nu există evaluări

- OEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Document6 paginiOEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Miguel RojasÎncă nu există evaluări

- Diesel Fuel Filter Systems GuideDocument6 paginiDiesel Fuel Filter Systems GuideMiguel RojasÎncă nu există evaluări

- DBGVC 433-1DW: ModelDocument2 paginiDBGVC 433-1DW: ModelMiguel RojasÎncă nu există evaluări

- Indica EV2 Manual PDFDocument164 paginiIndica EV2 Manual PDFKarthikPrakash100% (1)

- Lect-1 Intro 2014 Web 000Document45 paginiLect-1 Intro 2014 Web 000Junayed Khan100% (1)

- Mitsubishi Diesel Engine - S6B3-PTADocument2 paginiMitsubishi Diesel Engine - S6B3-PTAShe C.B100% (1)

- Brochure of EDC-220ASDocument8 paginiBrochure of EDC-220ASLMN ArchitectÎncă nu există evaluări

- Governors America CorpDocument20 paginiGovernors America CorpSamir Conrado Iguaran100% (1)

- Operation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsDocument38 paginiOperation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsJorge Perez DzulÎncă nu există evaluări

- Ice CH4 2019-2020 PDFDocument28 paginiIce CH4 2019-2020 PDFMohamad AhmadÎncă nu există evaluări

- Elf RangeDocument2 paginiElf RangeAnGBalÎncă nu există evaluări

- Johnston C201 Specification SheetDocument2 paginiJohnston C201 Specification SheetAdel SalamaÎncă nu există evaluări

- ECR28 ECR38 BrochureDocument12 paginiECR28 ECR38 Brochuredalibor_bogdanÎncă nu există evaluări

- Lehx4380 (1380-1944 Kva Engine) 25zDocument4 paginiLehx4380 (1380-1944 Kva Engine) 25zbambang ismailÎncă nu există evaluări

- Product Brochure Volvo A45GFSDocument12 paginiProduct Brochure Volvo A45GFSmnowaqÎncă nu există evaluări

- Personal Record Book: Automotive Service TechnicianDocument26 paginiPersonal Record Book: Automotive Service TechnicianCertified Rabbits LoverÎncă nu există evaluări

- Grove RT700E: Product GuideDocument20 paginiGrove RT700E: Product GuideDaniel Cáceres TrujilloÎncă nu există evaluări

- Specification Sheet: Standby Generator SetDocument2 paginiSpecification Sheet: Standby Generator SetAdrian MoratayaÎncă nu există evaluări

- DR Naushad Forbes & MR Satyadeo Purohit, Forbes MarshallDocument16 paginiDR Naushad Forbes & MR Satyadeo Purohit, Forbes MarshallGaurav DahakeÎncă nu există evaluări

- PIPE by Capote - TermsDocument109 paginiPIPE by Capote - TermsRochelle May CatbaganÎncă nu există evaluări

- 5093 - GPU Hobart 140CU20 - 180CU20 PDFDocument2 pagini5093 - GPU Hobart 140CU20 - 180CU20 PDFDario GuerraÎncă nu există evaluări

- Me6016 TeDocument44 paginiMe6016 TeKALIMUTHU KÎncă nu există evaluări

- MM 3144 UsDocument4 paginiMM 3144 UsGabriel AmorimÎncă nu există evaluări

- Genset Engine Specifications for TAD 1630 GEDocument2 paginiGenset Engine Specifications for TAD 1630 GEPakito-sanÎncă nu există evaluări

- FUEL CONSUMPTION INSTALLATION GUIDEDocument32 paginiFUEL CONSUMPTION INSTALLATION GUIDEadÎncă nu există evaluări

- Ch-7-W-13-14-VCR and Hyperbar EnginesDocument27 paginiCh-7-W-13-14-VCR and Hyperbar EnginesArkew Bogale100% (3)

- Liebherr R9400Document22 paginiLiebherr R9400Rohman FashihinÎncă nu există evaluări

- MAN InstrumentationDocument260 paginiMAN InstrumentationAntnhe Bayu80% (5)

- FICE 1 KeyDocument4 paginiFICE 1 KeyK. Swaminathan Asst Prof - Automobile DeptÎncă nu există evaluări