Documente Academic

Documente Profesional

Documente Cultură

Bonded

Încărcat de

Aravind Phoenix0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări1 paginăBonded

Drepturi de autor

© © All Rights Reserved

Formate disponibile

TXT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentBonded

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări1 paginăBonded

Încărcat de

Aravind PhoenixBonded

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

BONDED NON-METALLIC GAUGES.

**A strain gauge using direct bonding of a non-metallic resistor element to a ma

terial in which the strain is so to be measured was reported by Bloach in 1935.

In this gauge a carbon coating is applied directly to the surface of the struct

ure in which strain is to be measured. For metallic structures the surface is f

irst coated with a non-conducting material.

**If the underlying surface of such a coating is stretched, the carbon particle

would move apart, and the under-coating is compressed, the particles would move

closer together, and the resistance will change. This resistance change can be

interpreted in terms of strain.

Generally these type of gauges are made by impregnating carbon particles in plas

tic sheets. These sheets are then cut into strips about 6 mm wide and 25 mm lon

g. On each end of the strip a silver band is plated so that lead wires may be a

ttached (fig). The gauge is bonded directly to the surface to be strained with

a common glue.

These sensitivity and resistance of the gauge are affected by temperature and hu

midity. This gauge is of rugged construction and can withstand rough handling.

However, the cross-sensitivity of the gauge is quite high

BONDED METALLIC GAUGES.

**The bonded metallic type of strain gauge consists of a length of a strain-sens

itive conductor mounted on a small piece of paper or plastic backing. In use th

is gauge is cemented to the surface of the structural member to be tested.

**These gauges may be either of the wire or foil type. In the case of wire stra

in gauges, the filament consists of a long length of wire in the form of a grid

fixed in place with a suitable cement. The wire grid may be either of the flat

type (fig. a) or wrap-around type (Fig. b).

**After attaching the lead wires to the two ends of the grid, a second piece of

paper is cemented over the wire as a cover. In the wrap around type of wire gau

ges, the strain-sensitive wire is wound around a cylindrical core in the form of

a close-wound helix. This core is then flattened and cemented between layers o

f paper for purpose of protection and insulation. Fig.(c) shows a flat wire gri

d free filament construction.

The foil type of gauges have the following advantages over the wire type gauges.

1.The width of the foil at the end of each loop can be greatly increased to redu

ce the sensitivity of the sensitivity of the gauge to transverse strains.

2.The cross-section of the gauge conductor is rectangular, resulting in the high

ratio of surface area to cross-section area. This increases heat dissipation a

nd avoids adhesion between the grid and the backing material.

3.The gauge factor is higher by 4 to 10 per cent that other gauges.

4.These gauges are easier to manufacture.

5.These gauges can be used to measure strain on curved surfaces.

6.These gauges are suitable for static and dynamic strain measurements.

7.They have very good fatigue properties.

8.Stress relaxation and hysterisis is very less in these gauges

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Ce 2 Marks UpdatedDocument10 paginiCe 2 Marks UpdatedAravind PhoenixÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Career Air Force-India (Candidate Section)Document1 paginăCareer Air Force-India (Candidate Section)Aravind PhoenixÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- SM Model Exam QuestionDocument5 paginiSM Model Exam QuestionAravind PhoenixÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- GE2022 2 Marks PDFDocument23 paginiGE2022 2 Marks PDFsudharsonkumarÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Tracking TipsDocument8 paginiTracking TipsAravind PhoenixÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Experimental Stress Analysis - AN 010 702Document2 paginiExperimental Stress Analysis - AN 010 702Aravind PhoenixÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Mon Slow Learners TTDocument2 paginiMon Slow Learners TTAravind PhoenixÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- AE6505 CE Nov Dec 2016 IMP QuestionDocument2 paginiAE6505 CE Nov Dec 2016 IMP QuestionAravind PhoenixÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- What Is The Load Factor? Explain The V-N Diagram in Detail With Neat Sketch. ADocument2 paginiWhat Is The Load Factor? Explain The V-N Diagram in Detail With Neat Sketch. AAravind PhoenixÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- Answer ALL Questions PART A - (10 X 2 10 Marks)Document1 paginăAnswer ALL Questions PART A - (10 X 2 10 Marks)Aravind PhoenixÎncă nu există evaluări

- TQM Dimensions and Quality PlanningDocument18 paginiTQM Dimensions and Quality PlanningAravind PhoenixÎncă nu există evaluări

- Investment Casting & Welding ProcessesDocument3 paginiInvestment Casting & Welding ProcessesAravind PhoenixÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Oct Nov Dec 16 and Jan 17 NotificationDocument1 paginăOct Nov Dec 16 and Jan 17 NotificationAravind PhoenixÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Quantitative AptitudeDocument2 paginiQuantitative AptitudeSivakumar MÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Forward Flight PerformanceDocument3 paginiForward Flight PerformanceAravind PhoenixÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- AD 2 Nov 2015Document3 paginiAD 2 Nov 2015Aravind PhoenixÎncă nu există evaluări

- Had May2016Document3 paginiHad May2016Aravind PhoenixÎncă nu există evaluări

- Aircraft Structures I Nov 2015Document4 paginiAircraft Structures I Nov 2015Aravind PhoenixÎncă nu există evaluări

- Assignment 1Document1 paginăAssignment 1Aravind PhoenixÎncă nu există evaluări

- Aircraft Design Project-1 Performance ReviewDocument2 paginiAircraft Design Project-1 Performance ReviewAravind PhoenixÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- INSTRUCCIONES V7.3 2017s English SpanishDocument15 paginiINSTRUCCIONES V7.3 2017s English Spanishjfernand81Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Testing Week 2 - August 2016Document4 paginiTesting Week 2 - August 2016Aravind PhoenixÎncă nu există evaluări

- Rajalakshmi Institutions - Eligible Database For Vulcan Tech - 2017 BatchDocument8 paginiRajalakshmi Institutions - Eligible Database For Vulcan Tech - 2017 BatchAravind PhoenixÎncă nu există evaluări

- Direct Voice Input Allows Pilots to Control Aircraft Systems Using Voice CommandsDocument29 paginiDirect Voice Input Allows Pilots to Control Aircraft Systems Using Voice CommandsAravind PhoenixÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Title of The Project: Guide and Student DetailsDocument13 paginiTitle of The Project: Guide and Student DetailsAravind PhoenixÎncă nu există evaluări

- Find Sum of Non-Edge Elements in Matrix (40Document28 paginiFind Sum of Non-Edge Elements in Matrix (40Aravind PhoenixÎncă nu există evaluări

- Investment CastingDocument1 paginăInvestment CastingAravind PhoenixÎncă nu există evaluări

- Retest Time Table For Unit Test-IDocument4 paginiRetest Time Table For Unit Test-IAravind PhoenixÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- University Registration and Roll Number DocumentDocument36 paginiUniversity Registration and Roll Number DocumentAravind PhoenixÎncă nu există evaluări

- MIDC UNITSDocument16 paginiMIDC UNITSSatej SatyanÎncă nu există evaluări

- Haematoxylin (Ehrlich) : Intended UseDocument3 paginiHaematoxylin (Ehrlich) : Intended Useyohanes e. gunawanÎncă nu există evaluări

- Literature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Document115 paginiLiterature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Patricia BrandÎncă nu există evaluări

- 3363 - Problem - 5-6 Material Balance High Press Gas Reservoir - Jun07Document2 pagini3363 - Problem - 5-6 Material Balance High Press Gas Reservoir - Jun07Charles PabaneÎncă nu există evaluări

- Schedule of Rates 2014Document10 paginiSchedule of Rates 2014A. S. M. Elias ShahÎncă nu există evaluări

- Wivacryl As 50: Styrene Acrylic Paint BinderDocument7 paginiWivacryl As 50: Styrene Acrylic Paint Bindermahesh.nakÎncă nu există evaluări

- Geotehnics of SoftsoilDocument44 paginiGeotehnics of SoftsoilVinna RinayaniÎncă nu există evaluări

- Sample Problem Mod 3 CPCDocument6 paginiSample Problem Mod 3 CPCAman PratikÎncă nu există evaluări

- Cat. IV Toughened Glass InsulatorDocument8 paginiCat. IV Toughened Glass InsulatorFernando GasparÎncă nu există evaluări

- Defense Technology 1082 - Riot Control Grenade CS MSDSDocument7 paginiDefense Technology 1082 - Riot Control Grenade CS MSDSCenangau DaunkariÎncă nu există evaluări

- 1 PDFDocument7 pagini1 PDFJose Luis Martinez SaavedraÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Angora Wool: Ultra-Soft Fiber From RabbitsDocument2 paginiAngora Wool: Ultra-Soft Fiber From RabbitsYogen Garbiyal100% (1)

- Steel I-Beam Calculation Design CheckDocument9 paginiSteel I-Beam Calculation Design CheckSuresh DevarajanÎncă nu există evaluări

- The Optical Properties of Magnesium Oxide ContainiDocument6 paginiThe Optical Properties of Magnesium Oxide ContainiAbdulbar kelilÎncă nu există evaluări

- General ChemistryDocument44 paginiGeneral ChemistrySUSANA, NIÑA FELIZ C.100% (1)

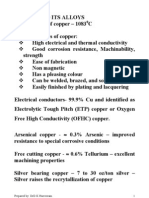

- Copper and It's AlloysDocument5 paginiCopper and It's AlloysReza MortazaviÎncă nu există evaluări

- CH 4034 Comprehensive Design Project II Interim Report 1: Production of Ammonia From NaphthaDocument21 paginiCH 4034 Comprehensive Design Project II Interim Report 1: Production of Ammonia From NaphthaAlfonso BlancoÎncă nu există evaluări

- Coal combustion calculationsDocument3 paginiCoal combustion calculationsShane PatulotÎncă nu există evaluări

- p608 PDFDocument8 paginip608 PDFMohamed TabetÎncă nu există evaluări

- WWW Visionalloys Com Stainless Steel Fasteners HTMLDocument4 paginiWWW Visionalloys Com Stainless Steel Fasteners HTMLNikhil JainÎncă nu există evaluări

- STMicroelectronics PCN NFME TO247Document9 paginiSTMicroelectronics PCN NFME TO247wilson sanchezÎncă nu există evaluări

- Method For Curing TyreDocument5 paginiMethod For Curing TyreNivantÎncă nu există evaluări

- Lintels and ArchesDocument49 paginiLintels and Arches18 Architects50% (2)

- Astm A560 A560m - 12Document3 paginiAstm A560 A560m - 12Leandro Dilkin ConsulÎncă nu există evaluări

- U-5 - 2022 - Tecnologías de Tratamientos - BDocument39 paginiU-5 - 2022 - Tecnologías de Tratamientos - BSimón OsésÎncă nu există evaluări

- Murashige and Skoog Basal Medium (M5519)Document1 paginăMurashige and Skoog Basal Medium (M5519)Dyo MandeÎncă nu există evaluări

- S2 RANGER Slag-Analyzer SolutionDocument30 paginiS2 RANGER Slag-Analyzer SolutionYassine ZamzamiÎncă nu există evaluări

- Sheet Pile WallDocument11 paginiSheet Pile WallKhandaker Khairul AlamÎncă nu există evaluări

- Advanced Lab Course 50: PhotovoltaicsDocument18 paginiAdvanced Lab Course 50: PhotovoltaicsHamza OuerfelliÎncă nu există evaluări

- 00-H-0008 Air-Cooled Water ChillersDocument14 pagini00-H-0008 Air-Cooled Water Chillershabibansari2010Încă nu există evaluări

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDe la EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseEvaluare: 3.5 din 5 stele3.5/5 (69)

- The Beauty of Falling: A Life in Pursuit of GravityDe la EverandThe Beauty of Falling: A Life in Pursuit of GravityÎncă nu există evaluări

- Quantum Physics: What Everyone Needs to KnowDe la EverandQuantum Physics: What Everyone Needs to KnowEvaluare: 4.5 din 5 stele4.5/5 (48)

- Summary and Interpretation of Reality TransurfingDe la EverandSummary and Interpretation of Reality TransurfingEvaluare: 5 din 5 stele5/5 (5)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessDe la EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessEvaluare: 4 din 5 stele4/5 (6)