Documente Academic

Documente Profesional

Documente Cultură

Post Installed Anchor

Încărcat de

cadetpalang0 evaluări0% au considerat acest document util (0 voturi)

12 vizualizări2 paginiAnchor Calc

Drepturi de autor

© © All Rights Reserved

Formate disponibile

TXT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAnchor Calc

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

12 vizualizări2 paginiPost Installed Anchor

Încărcat de

cadetpalangAnchor Calc

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

A reinforced concrete mat foundation is a common type of

foundation system used in many buildings. They are a specific

type of shallow foundation that uses bearing capacity of the

soil at or near the building base to transmit the loads to the soil.

Compared to individual spread footings, a mat foundation may

encompass all or part of the building s footprint. Compared to

an ordinary slab on grade, a reinforced concrete mat is much

thicker and is subjected to more substantial loads from the

building.

A mat foundation is often used where soil and load conditions

could cause substantial differential settlement between

individual spread footings but where conditions are not so

poor as to require a deep foundation system. For buildings

with significant overturning moments, which can occur in

regions of high seismicity or because of irregularities of

the superstructure, a mat foundation is commonly used to

distribute the bearing pressure over a large footprint and/or

to resist significant uplift forces that can develop. Another

frequent application for a mat foundation is where individual

spread footings would be large and close together. Similarly,

where many grade beam ties between footings are required, it

may not be economical to excavate and form individual spread

footings as compared to building a single mat foundation. For

a basement that is below the water table, a mat foundation is

often used to create a bathtub system to keep the basement

dry and to use the weight of the mat to resist hydrostatic uplift

forces. Where a mat is supported on deep foundation elements,

the mat also functions as the pile cap.

The behavior of a mat foundation can be correlated to a twoway

slab system turned upside down. The distributed soil

pressure applied to the bottom of the mat is analogous to a

distributed slab load, and the columns and walls above the mat

become the supports for the mat foundation. Therefore, it is

common to apply analysis and design methods from two-way

slabs to a mat foundation.

The design forces, load combinations, and some analysis

requirements for a mat foundation are in ASCE7, which has

been adopted into the IBC. In adopting ASCE7 provisions,

IBC includes some modifications and additions that will be

discussed later. As noted in the sidebar on the previous page,

IBC 2012 is the current version of this code but may not yet

be adopted by all jurisdictions; therefore, the governing code

should be confirmed for each particular project jurisdiction

as appropriate. The design and detailing requirements for

a reinforced concrete mat foundation are presented in ACI

318, which has been adopted by the IBC as an incorporated

standard.

For concrete design, structural engineers predominately

consider ultimate strength design methods where the ultimate/

factored loading is compared to the member s nominal strength.

This method has been incorporated into ACI 318 since the

1960s. However, geotechnical engineers predominately

consider allowable stress design, comparing service loads to

allowable stresses and soil bearing pressures. This fundamental

difference must be understood and addressed when designing

a mat foundation. There is on-going development in building

code committees to codify ultimate strength design for

geotechnical engineers, but its use is not yet commonplace.

This issue of coordination between the structural engineer

and geotechnical engineer will be addressed in greater detail

throughout this Technical Brief.

Mat foundations were originally envisaged as a floating

foundation with distinct advantages where the soil was poor or

unacceptable differential settlements were likely to occur. Early

work showed that mats on sand (loose compacted, medium,

or dense) posed few problems. The factor of safety assumed

for such mats was twice that for an individual spread footing

and therefore no strength difficulties were to be expected if

the loading imposed on the mat by the superstructure was

effectively uniform. The allowable soil pressure was governed

by settlement and differential settlements between the walls

and columns supported by a mat. Typically, these allowable

soil bearing pressures were less than those for isolated footings

subject to the same loading.

By contrast, mats on clays had factors of safety against bearing

failures that were the same as those for footings and were

dependent on the length-to-width ratio of the mat or footing.

Otherwise the bearing strength was practically independent of

the area loaded by the mat or footing. Many of the initial uses

of mats were for large grain elevators and their performance

demonstrated those findings.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- ch05 PDFDocument44 paginich05 PDFNizar Pratama PutraÎncă nu există evaluări

- Cellular RaftDocument6 paginiCellular Raftaminjoles100% (1)

- Chapter 5 SolutionDocument10 paginiChapter 5 SolutionËmêrson SîntujÎncă nu există evaluări

- Plasticity LectureDocument17 paginiPlasticity LectureOptimMart InternationaleÎncă nu există evaluări

- AISC Steel Construction Manual ASD 7th Edition 1st Impression 1973Document1.066 paginiAISC Steel Construction Manual ASD 7th Edition 1st Impression 1973Eric WilkinsÎncă nu există evaluări

- A Review of Prestressed Concrete Pile With CirculaDocument10 paginiA Review of Prestressed Concrete Pile With CirculahasithrÎncă nu există evaluări

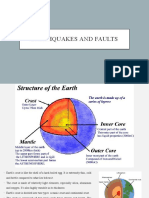

- Lesson 1 Earthquakes and FaultsDocument32 paginiLesson 1 Earthquakes and FaultsCJ SarsalejoÎncă nu există evaluări

- Assignment 1: Introduction To Aircraft StructuresDocument4 paginiAssignment 1: Introduction To Aircraft StructuresLv NanhengÎncă nu există evaluări

- Discussion Iso 12215-5Document21 paginiDiscussion Iso 12215-5erhan yuvacıÎncă nu există evaluări

- Pre Stressed PDFDocument36 paginiPre Stressed PDFmark dominicÎncă nu există evaluări

- Yield Curvature For Seismic Design of Circular Reinforced Concrete Columns PDFDocument9 paginiYield Curvature For Seismic Design of Circular Reinforced Concrete Columns PDFMohammad AshrafyÎncă nu există evaluări

- MR Chhabilal Timilsina - Sitapaila - SOil Test Report PDFDocument46 paginiMR Chhabilal Timilsina - Sitapaila - SOil Test Report PDFAnonymous GaaXAYYÎncă nu există evaluări

- 3331 ST7008 Prestressed Concrete QBDocument11 pagini3331 ST7008 Prestressed Concrete QBsundar100% (1)

- Earthquake Location: The Basic PrinciplesDocument40 paginiEarthquake Location: The Basic PrinciplesMohit JhalaniÎncă nu există evaluări

- Design of Machine Elements: Dr. M. SasikumarDocument11 paginiDesign of Machine Elements: Dr. M. SasikumarRajesh RJÎncă nu există evaluări

- Sizing of The SlabDocument5 paginiSizing of The Slabseljak_veseljak100% (1)

- ReinforcedDocument17 paginiReinforcedrishiÎncă nu există evaluări

- Design of ColumnDocument7 paginiDesign of ColumnD SRINIVASÎncă nu există evaluări

- GATE Civil Engineering Old Papers - Extract - ExtractDocument402 paginiGATE Civil Engineering Old Papers - Extract - Extractvimal bhojaniÎncă nu există evaluări

- Designing of Reinforce Concrete Deck Slab Bridge With Aashto (LRFD) Design SpecificationDocument54 paginiDesigning of Reinforce Concrete Deck Slab Bridge With Aashto (LRFD) Design SpecificationTharach JanesuapasaereeÎncă nu există evaluări

- 9 - RC U-Shaped Walls Subjected To In-Plane, Diagonal, and Torsional Loading NewDocument38 pagini9 - RC U-Shaped Walls Subjected To In-Plane, Diagonal, and Torsional Loading NewAshwin Muthuraman RamurathinamÎncă nu există evaluări

- Seismic Analysis of Horseshoe Tunnels Under Dynamic Loads Due To EarthquakesDocument8 paginiSeismic Analysis of Horseshoe Tunnels Under Dynamic Loads Due To EarthquakesPaloma CortizoÎncă nu există evaluări

- Assignment 3 Timber DesignDocument17 paginiAssignment 3 Timber Designkyle catarunganÎncă nu există evaluări

- Fema 450 2 Commentary Part 2Document110 paginiFema 450 2 Commentary Part 2Tariq AbdulsalamÎncă nu există evaluări

- Strenght of Materials Problem Set No. 4Document12 paginiStrenght of Materials Problem Set No. 4Ashner Novilla100% (1)

- Guideline For Design and Quality Control of Soil Improvement For Buildings - Deep and Shall PDFDocument31 paginiGuideline For Design and Quality Control of Soil Improvement For Buildings - Deep and Shall PDFMinhQuangDương100% (2)

- Shear Reinforcement Design of Beam Column JointsDocument35 paginiShear Reinforcement Design of Beam Column JointsAnggi Novi AndriÎncă nu există evaluări

- Engineering Fracture Mechanics: T. Ghidini, C. Dalle DonneDocument15 paginiEngineering Fracture Mechanics: T. Ghidini, C. Dalle DonnemnoghabiÎncă nu există evaluări

- 10 1 1 467 9558 PDFDocument23 pagini10 1 1 467 9558 PDFDiego Leonel Suárez VásquezÎncă nu există evaluări

- Finite Element Models For Rock Fracture Mechanics PDFDocument19 paginiFinite Element Models For Rock Fracture Mechanics PDFVictor J. PerniaÎncă nu există evaluări