Documente Academic

Documente Profesional

Documente Cultură

Materials Selection and Temperature

Încărcat de

panbuuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Materials Selection and Temperature

Încărcat de

panbuuDrepturi de autor:

Formate disponibile

9/8/2016

MaterialsSelectionandTemperature

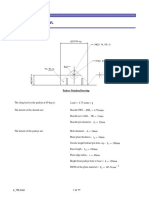

Solution

Thisquestionillustratessomeaspectsofmaterialselectioninthedesignofapressurevessel,whichexperiencesarangeof

operatingtemperatures.Hencematerialtoughness,asafunctionoftemperature,formsanimportantpartofthefracturesafedesign

process.Thisisdemonstratedgraphicallyinthequestion.

Itshouldtakearound15minutestocomplete.

p)of40MPaandattemperaturesfrom0Cto300C.Theproposedwallthickness(t)is100mmandthediameter(D)is2m.Two

candidatesteelalloyshavebeensuggested:

SteelA:Forthissteel,KC=(150+0.05T)MPamwhereTisoperatingtemperatureindegreescentigrade,andtheyieldstrength

variesinalinearfashionfrom549MPaat0Cto300MPaat300C.

SteelB:HereKC=(100+0.25T)MPam,andtheyieldstrengthvarieslinearlyfrom650MPaat0Cto500MPaat300C.

Graphicallydetermine,byinspection,therangeoftemperaturesoverwhicheachofthesealloyswouldhavethehighestsafety

factorwithrespecttofastfracture.

Throughthicknesscrackscanbeassumedtobecriticalandthestressintensityfactorforsuchcracksinthisgeometryisgivenby:

ThemembranestressinthepressurevesselwallmaybetakenaspD/4t.

ScientificCalculator|RPNCalculator|Theory

Answer:SteelAisbestbelowapproximately212C,SteelBisbetterabovethistemperature.

SolvingthisquestionissimplyamatterofcalculatingtherequiredvaluesoffracturetoughnessKCtoavoidfractureatvarious

temperaturesintheoperatingrange,say0C,100C,200Cand300Cforbothsteels.Thesecanbeplottedagainsttheactual

valuesofalloytoughnessatthesametemperatures,andthealloywiththehighesttoughness,andthehighestmarginbetween

actualandrequiredtoughnessvalues,assessedvisually.Graphicalpresentationofengineeringdataisoftenmoreuseful,and

accessible,thanpresentingthesameinformationanalytically,orinatable.Theproblemcouldbesolvedanalyticallyforthecross

overtemperaturebutatthelossofeasyvisualisationofsafetymarginsinfractureperformance.

Themembranestressissimplyfoundfrom:

Althoughthedesigncaseisbasedonleakbeforebreak,theamountofpressurereliefcausedbyathroughthicknesscrackis

unknown.Itisthereforeconservativetoassumethattheinternalpressurewillloadthecracksurfaces,hencethetotalstress

intensityfactorwillbecalculatedusingthesumofthemembranestressandtheinternalpressure,i.e.240MPa.Leakbeforebreak

designrequiresthepressurevesseltotolerateathroughthicknesscrackoftotallength2a=thesurfacelength(2c)ofthepre

cursorsemiellipticcrack.Aswehavenoinformationregardingcrackellipticity,wewillhavetoassumethatitwassemicircularand

hence2a=2t,wheretisthewallthickness.Thereforetherequiredvaluesoftoughnessarefoundfrom:

Thetablebelowgivesrequiredandavailabletoughnessvaluesforthetwoalloys.

SteelA

YieldStrength

MPa

RequiredKC

MPam

0C

100C

200C

300C

540

460

380

300

141.7

144.7

150.3

163.1

https://www.fose1.plymouth.ac.uk/fatiguefracture/tutorials/FractureMechanics/StressIntensity/Solutions/Solution14.htm

1/2

9/8/2016

MaterialsSelectionandTemperature

ActualKC

150

155

160

165

650

600

550

500

139.4

140.2

141.4

143.0

100

125

150

175

MPam

SteelB

YieldStrength

MPa

RequiredKC

MPam

ActualKC

MPam

Thisdataisplottedinthegraphbelow.Byinspection,thetoughnessvaluesforSteelAarehighestandthereforethesafetymargin

greatest,uptoabout212C.Abovethattemperature,SteelBhasbecomethebestchoicebecauseofitsverysteepincreasein

toughnesswithtemperature.

TOP

CloseWindow

https://www.fose1.plymouth.ac.uk/fatiguefracture/tutorials/FractureMechanics/StressIntensity/Solutions/Solution14.htm

2/2

S-ar putea să vă placă și

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášÎncă nu există evaluări

- Temperature Field Calculation and Analysis Within Steel Tube Reinforced ColumnsDocument6 paginiTemperature Field Calculation and Analysis Within Steel Tube Reinforced ColumnsBatepola BacÎncă nu există evaluări

- Acom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFDocument16 paginiAcom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFpipedown456Încă nu există evaluări

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDe la EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysÎncă nu există evaluări

- Assignment 1Document3 paginiAssignment 1154 ahmed ehabÎncă nu există evaluări

- Fitting Curves and Impact Toughness Transition Temperature of Quenched and Tempered Steel WeldsDocument9 paginiFitting Curves and Impact Toughness Transition Temperature of Quenched and Tempered Steel WeldsSiangmalamÎncă nu există evaluări

- ME 352 - All Problem Class - 14-18 BatchDocument125 paginiME 352 - All Problem Class - 14-18 BatchEntertainment GamingÎncă nu există evaluări

- Numerical Simulation On Residual Stress Distribution of Hard-Face-Welded Steel Specimens With Martensite TransformationDocument5 paginiNumerical Simulation On Residual Stress Distribution of Hard-Face-Welded Steel Specimens With Martensite TransformationJR ZookÎncă nu există evaluări

- Detremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatDocument5 paginiDetremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatLjubica MilovicÎncă nu există evaluări

- Poletskov 2020 IOP Conf. Ser. Mater. Sci.Document8 paginiPoletskov 2020 IOP Conf. Ser. Mater. Sci.Александр ТиньгаевÎncă nu există evaluări

- Paper PublishedDocument7 paginiPaper PublishedNavlesh JamdarÎncă nu există evaluări

- Design of Penstock Pipe For A HydroelectDocument21 paginiDesign of Penstock Pipe For A Hydroelectjanardhana100% (1)

- Stretch - Angeability of A High-Strength TRIP Type Bainitic SheetDocument7 paginiStretch - Angeability of A High-Strength TRIP Type Bainitic SheetKhomasan JumpasriÎncă nu există evaluări

- Metallurgical Design and Performance of Erw Linepipe With High-Quality Weld Seam Suitable For Extra-Low-Temperature ServicesDocument8 paginiMetallurgical Design and Performance of Erw Linepipe With High-Quality Weld Seam Suitable For Extra-Low-Temperature ServicesMarcelo Varejão CasarinÎncă nu există evaluări

- 3 13Document8 pagini3 13pitoulabeteÎncă nu există evaluări

- Durability de MST 2014Document19 paginiDurability de MST 2014irfankohaaÎncă nu există evaluări

- Instructions: Write Neatly and Sketch Clearly Draw Diagram Where It Is NecessaryDocument2 paginiInstructions: Write Neatly and Sketch Clearly Draw Diagram Where It Is NecessaryEngrNisarAhmedÎncă nu există evaluări

- Fracture Behaviour of Dissimilar Metallic Welds: Specimens and Pipe Weld With CrackDocument9 paginiFracture Behaviour of Dissimilar Metallic Welds: Specimens and Pipe Weld With Crackmade dwi payanaÎncă nu există evaluări

- A10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsDocument9 paginiA10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsXÎncă nu există evaluări

- The Modulus of Elasticity of Steel Is It 200 GPaDocument8 paginiThe Modulus of Elasticity of Steel Is It 200 GPaPratik PatelÎncă nu există evaluări

- W.R.T Mechanical & Thermal Properties Preparation of W.P.S For Stainless Steel (Ni, CR, Mo, Nu) WeldingDocument3 paginiW.R.T Mechanical & Thermal Properties Preparation of W.P.S For Stainless Steel (Ni, CR, Mo, Nu) WeldingArun KumarÎncă nu există evaluări

- 01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeDocument6 pagini01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeŞarîngă George AlexandruÎncă nu există evaluări

- MOM Assignment IDocument3 paginiMOM Assignment IAll_regÎncă nu există evaluări

- Resistance WeldingDocument7 paginiResistance Weldingswaroop_exlncÎncă nu există evaluări

- Creep Properties of Grade S275JF Steel at High Temperature:, A B A B B B B C A A ADocument5 paginiCreep Properties of Grade S275JF Steel at High Temperature:, A B A B B B B C A A AViorel UngureanuÎncă nu există evaluări

- Homework3 s450 1Document2 paginiHomework3 s450 1cassandra_wittenÎncă nu există evaluări

- High-Cycle Fatigue Behavior of Type 316L Stainless SteelDocument9 paginiHigh-Cycle Fatigue Behavior of Type 316L Stainless SteelDeva RajÎncă nu există evaluări

- Kim 2018Document26 paginiKim 2018Muhammad Rizki Gorbyandi NadiÎncă nu există evaluări

- Effect of Ti On MA SteelsDocument10 paginiEffect of Ti On MA Steelslillyren2808Încă nu există evaluări

- Nominal Moment Capacity of Box Reinforced Concrete Beams Exposed To FireDocument14 paginiNominal Moment Capacity of Box Reinforced Concrete Beams Exposed To FireReivax50Încă nu există evaluări

- Zheng2012 PDFDocument5 paginiZheng2012 PDFanon_47684961Încă nu există evaluări

- The in Uence of Welding Parameters On The Joint Strength of Resistance Spot-Welded Titanium SheetsDocument8 paginiThe in Uence of Welding Parameters On The Joint Strength of Resistance Spot-Welded Titanium Sheetskaliappan45490100% (1)

- Study The Change of Current Weld On Mechanical Properties and Microstructure of Low Carbon Steel Welded by Electric Arc WeldingDocument8 paginiStudy The Change of Current Weld On Mechanical Properties and Microstructure of Low Carbon Steel Welded by Electric Arc WeldingBasim Al-bhadleÎncă nu există evaluări

- Microstructures and Fatigue Crack Growth of EH36 TMCP Steel WeldmentsDocument8 paginiMicrostructures and Fatigue Crack Growth of EH36 TMCP Steel WeldmentsJohan Esteban Garcia PuentesÎncă nu există evaluări

- MOM2Tutorial 10-1Document3 paginiMOM2Tutorial 10-1Ishola mujeebÎncă nu există evaluări

- CronfaDocument20 paginiCronfaKassya SchunkÎncă nu există evaluări

- BWRA and Séférian Model For Preheating Temperature Calculation in Case of Low Alloyed and Unalloyed SteelDocument6 paginiBWRA and Séférian Model For Preheating Temperature Calculation in Case of Low Alloyed and Unalloyed SteelChokri AtefÎncă nu există evaluări

- Materials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangDocument5 paginiMaterials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangAntonio Alonso Diaz ArriagaÎncă nu există evaluări

- (9 07) Design and Construction of Penstocks Using Ht100Document13 pagini(9 07) Design and Construction of Penstocks Using Ht100Alejandra Monserrat Pérez CanalesÎncă nu există evaluări

- Analysis of The Martensitic Transformation at Various Scales in TRIP SteelDocument4 paginiAnalysis of The Martensitic Transformation at Various Scales in TRIP SteelHarold Agudelo MÎncă nu există evaluări

- Mats 3 Sol 3Document7 paginiMats 3 Sol 3Devansh GargÎncă nu există evaluări

- Limits and State of The Art of The New Creep Resistant SteelsDocument64 paginiLimits and State of The Art of The New Creep Resistant SteelsRené Galbraith BerraÎncă nu există evaluări

- Effect of Plasma Carbonitriding On The High Temperature Tribological Properties of A TiAlCrN Coating On 300M Steel by Multi Arc Ion PlatingDocument15 paginiEffect of Plasma Carbonitriding On The High Temperature Tribological Properties of A TiAlCrN Coating On 300M Steel by Multi Arc Ion PlatingAbdelkarim GhanemÎncă nu există evaluări

- SS400-AMM34-High Strength Dual Phase Steels and Flow Curve Modeling ApproachDocument11 paginiSS400-AMM34-High Strength Dual Phase Steels and Flow Curve Modeling ApproachAgustine SetiawanÎncă nu există evaluări

- Tutorial 2 Metal WorkingDocument2 paginiTutorial 2 Metal WorkingSawai PariharÎncă nu există evaluări

- IAETSD-PREPARATION OF W.P.S FOR STAINLESS STEEL (Ni, CR, Mo, Nu) WELDING PDFDocument3 paginiIAETSD-PREPARATION OF W.P.S FOR STAINLESS STEEL (Ni, CR, Mo, Nu) WELDING PDFiaetsdiaetsd100% (1)

- Annales de Chimie: Science Des Materiaux: Received: 13 January 2019 Accepted: 2 April 2019Document4 paginiAnnales de Chimie: Science Des Materiaux: Received: 13 January 2019 Accepted: 2 April 2019purnashisÎncă nu există evaluări

- EMAT04C01/EAX - S - 210 2015-2016 S2: Q (1) (15 Marks, Divided Equally)Document4 paginiEMAT04C01/EAX - S - 210 2015-2016 S2: Q (1) (15 Marks, Divided Equally)sherif115040 BueÎncă nu există evaluări

- EMM7241-Advanced Machine Design Examination June 2016Document8 paginiEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiÎncă nu există evaluări

- Continuous Cooling Transformations in Nuclear Pressure Vessel SteelsDocument10 paginiContinuous Cooling Transformations in Nuclear Pressure Vessel SteelsVanina GiselaÎncă nu există evaluări

- 382 385 PDFDocument4 pagini382 385 PDFSinhrooÎncă nu există evaluări

- Iiw 1693 05Document19 paginiIiw 1693 05Pradip Goswami100% (1)

- Statically Indeterminate MembersDocument7 paginiStatically Indeterminate MembersKhan ToothÎncă nu există evaluări

- Tugas Metalurgi Las - Heat Flow in WeldingDocument4 paginiTugas Metalurgi Las - Heat Flow in WeldingRhidiyan Waroko100% (4)

- Strength and Fracture Toughness of Aluminum/alumina Composites With Interpenetrating NetworksDocument12 paginiStrength and Fracture Toughness of Aluminum/alumina Composites With Interpenetrating NetworksMuhd ZackuanÎncă nu există evaluări

- Assignment 6 SolutionsDocument8 paginiAssignment 6 SolutionsTalitha AdhyaksantiÎncă nu există evaluări

- Nitronic 30 BrochureDocument24 paginiNitronic 30 BrochuremkozinÎncă nu există evaluări

- Welding TMCP SteelsDocument7 paginiWelding TMCP SteelsElias Kapa100% (1)

- Analysis of Microstructure in Soft Zone and Precipitation Zone of Dissimilar Cr-Mo Steels WeldmentDocument8 paginiAnalysis of Microstructure in Soft Zone and Precipitation Zone of Dissimilar Cr-Mo Steels WeldmentMahsaÎncă nu există evaluări

- Calculator For Stiffness and Compliance of Lamina 90Document3 paginiCalculator For Stiffness and Compliance of Lamina 90panbuuÎncă nu există evaluări

- Failure Assessment DiagramsDocument1 paginăFailure Assessment DiagramspanbuuÎncă nu există evaluări

- Paris Law TheoryDocument3 paginiParis Law TheorypanbuuÎncă nu există evaluări

- Crack Tip PlasticityDocument2 paginiCrack Tip PlasticitypanbuuÎncă nu există evaluări

- Exercise 6 - State-Space Models - SolutionsDocument13 paginiExercise 6 - State-Space Models - Solutionspanbuu100% (1)

- Chemical Reactor VesselDocument2 paginiChemical Reactor VesselpanbuuÎncă nu există evaluări

- Time-Domain Solution of LTI State Equations: 2.14 Analysis and Design of Feedback Control SystemsDocument32 paginiTime-Domain Solution of LTI State Equations: 2.14 Analysis and Design of Feedback Control SystemsGoodie SidÎncă nu există evaluări

- Converting To The State SpaceDocument29 paginiConverting To The State SpacepanbuuÎncă nu există evaluări

- Linear Transformation 1 PDFDocument14 paginiLinear Transformation 1 PDFpanbuuÎncă nu există evaluări

- FFF SolutionsDocument152 paginiFFF SolutionsMohammedAL-AthariÎncă nu există evaluări

- Introduction To Linear TransformationDocument7 paginiIntroduction To Linear TransformationpanbuuÎncă nu există evaluări

- Design: of Shell & Tube Heat ExchangerDocument27 paginiDesign: of Shell & Tube Heat ExchangerBalamurugan SakthivelÎncă nu există evaluări

- CIE IGCSE Forces Hookes Law OnlyDocument22 paginiCIE IGCSE Forces Hookes Law OnlyNaveed Ahmed100% (4)

- Drawing 4.Document1 paginăDrawing 4.tiyaniÎncă nu există evaluări

- MAQUINA PRODUCTORA DE HIELO HoweDocument76 paginiMAQUINA PRODUCTORA DE HIELO HoweWilder VilcaÎncă nu există evaluări

- Dimplex Bwp30hlw - Manual TécnicoDocument21 paginiDimplex Bwp30hlw - Manual Técnicohmgp1975Încă nu există evaluări

- Piping Maintenance and RepairDocument46 paginiPiping Maintenance and RepairJose Manjooran100% (4)

- Calculation Sheet of Slab Scaffolding: Middle East Scaffolding TR. L.L.CDocument8 paginiCalculation Sheet of Slab Scaffolding: Middle East Scaffolding TR. L.L.CissaÎncă nu există evaluări

- 03 - Thermostat & Accessories - EmailDocument24 pagini03 - Thermostat & Accessories - EmailTanveer AzizÎncă nu există evaluări

- Mathcad - 4 - 75tDocument4 paginiMathcad - 4 - 75tsereÎncă nu există evaluări

- LCP Users Manual v31 e PDFDocument87 paginiLCP Users Manual v31 e PDFwinowinoÎncă nu există evaluări

- SikaAustralia-Sika and Tricosal Waterstops-For The Waterproofing of Expansion and Construction JointsDocument27 paginiSikaAustralia-Sika and Tricosal Waterstops-For The Waterproofing of Expansion and Construction JointsfernandoÎncă nu există evaluări

- Unit 4 AssignmentsDocument5 paginiUnit 4 AssignmentsbattuarunÎncă nu există evaluări

- GravityVentilators CatalogDocument20 paginiGravityVentilators Catalogseccion3dÎncă nu există evaluări

- PVC Pipe Field Testing Maximum Test PressureDocument1 paginăPVC Pipe Field Testing Maximum Test Pressurebasim samehÎncă nu există evaluări

- General Material Selection Guidelines For Oil & Gas Industry PipelinesDocument3 paginiGeneral Material Selection Guidelines For Oil & Gas Industry PipelinesSajir ThiyamÎncă nu există evaluări

- Norsok MDS 51Document1 paginăNorsok MDS 51Leandro Luiz Dos SantosÎncă nu există evaluări

- High Speed MachiningDocument7 paginiHigh Speed MachiningBob JonesÎncă nu există evaluări

- 2017 Winter Question Paper PDFDocument4 pagini2017 Winter Question Paper PDFJanardan JakhadÎncă nu există evaluări

- FRP GratingDocument5 paginiFRP GratingEsam Hamad100% (1)

- United States Patent: (45) Date of Patent: Aug - 21, 2018Document22 paginiUnited States Patent: (45) Date of Patent: Aug - 21, 2018RiskaÎncă nu există evaluări

- Conectores de 60 Pines 3400230Document4 paginiConectores de 60 Pines 3400230Rocky Escudero GonzalesÎncă nu există evaluări

- CE PROJECT 1 - 1st Semester SY 2019-2020Document1 paginăCE PROJECT 1 - 1st Semester SY 2019-2020Jose Mari RoldanÎncă nu există evaluări

- 01 Samss 012 2014Document10 pagini01 Samss 012 2014lhanx2Încă nu există evaluări

- Parts of The House and Furniture - 40028 PDFDocument1 paginăParts of The House and Furniture - 40028 PDFAndres Jesus Moreno AriasÎncă nu există evaluări

- Thermal Applicability of Two-Phase Thermosyphons in Cooking Chambers - Experimental and Theoretical AnalysisDocument17 paginiThermal Applicability of Two-Phase Thermosyphons in Cooking Chambers - Experimental and Theoretical Analysisabhishek992198Încă nu există evaluări

- SD 25 eDocument20 paginiSD 25 eseaqu3stÎncă nu există evaluări

- Experimental Development of The P-Y Relationship For Large Diameter Offshore Monopiles in Sand Centrifuge TestsDocument12 paginiExperimental Development of The P-Y Relationship For Large Diameter Offshore Monopiles in Sand Centrifuge TestsSunil Ranjan MohapatraÎncă nu există evaluări

- Liquid Recirculation System-2Document7 paginiLiquid Recirculation System-2Behnam AshouriÎncă nu există evaluări

- Electric Radiant Heating and WarmFlow Boilers BrochureDocument4 paginiElectric Radiant Heating and WarmFlow Boilers Brochuree-ComfortUSAÎncă nu există evaluări

- Composite Wrapping - A Challenging Solution For Deep-Water Repair ApplicationsDocument9 paginiComposite Wrapping - A Challenging Solution For Deep-Water Repair ApplicationsMubeenÎncă nu există evaluări

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDe la EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceÎncă nu există evaluări

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDe la EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceEvaluare: 4 din 5 stele4/5 (19)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDe la EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsDe la EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsEvaluare: 5 din 5 stele5/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDe la EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsÎncă nu există evaluări

- Laws of UX: Using Psychology to Design Better Products & ServicesDe la EverandLaws of UX: Using Psychology to Design Better Products & ServicesEvaluare: 5 din 5 stele5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneDe la EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneEvaluare: 4.5 din 5 stele4.5/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsDe la EverandDesign for How People Think: Using Brain Science to Build Better ProductsEvaluare: 4 din 5 stele4/5 (8)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsDe la EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsEvaluare: 4 din 5 stele4/5 (2)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDe la EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersEvaluare: 4 din 5 stele4/5 (13)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableDe la EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableÎncă nu există evaluări

- 507 Mechanical Movements: Mechanisms and DevicesDe la Everand507 Mechanical Movements: Mechanisms and DevicesEvaluare: 4 din 5 stele4/5 (28)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDe la EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsÎncă nu există evaluări

- Understanding Automotive Electronics: An Engineering PerspectiveDe la EverandUnderstanding Automotive Electronics: An Engineering PerspectiveEvaluare: 3.5 din 5 stele3.5/5 (16)

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesDe la EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesEvaluare: 3 din 5 stele3/5 (1)

- Design Recipes for FPGAs: Using Verilog and VHDLDe la EverandDesign Recipes for FPGAs: Using Verilog and VHDLEvaluare: 2 din 5 stele2/5 (1)