Documente Academic

Documente Profesional

Documente Cultură

03

Încărcat de

gokilavanireveendranDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

03

Încărcat de

gokilavanireveendranDrepturi de autor:

Formate disponibile

Case study: high capacity spiral

concentrators

J

o

u

r

n

a

l

by P. Ramsaywok*, M.K.G. Vermaak*, and R. Viljoen*

Spiral concentrators are compact, cost-effective and generally

efficient gravity concentration separators for a wide range of

applications (for example: coal, beach sands, iron ore, chromite and

tantalite). Large mineral processing plants consist of thousands of

spiral concentrators resulting in large plant footprints (capital

intensive) and the adjustment of splitters is time consuming,

impractical and is in many cases neglectedhigh capacity (HC)

spiral concentrators aim to address these shortcomings. As a result

Exxaro Namakwa Sands is currently investigating high capacity

spiral technology for the spiral circuit upgrade at the primary

concentrator plants (PCPs). This article summarizes the rougher

spiral performance evaluation that was conducted on different types

of spiral concentrators (the traditional MG4 spiral concentrator and

the high capacity (HC) spiral concentrator) under different feed

conditions. In addition, the effect of slimes on the spiral concentrator performance was also investigated. Slimes rheology was

linked to the poor concentrator performance at the higher slimes

concentrations. The test campaign shows a sacrifice in recovery

under design-feed conditions can be expected when using high

capacity spiral concentrators in the rougher stage when compared

to traditional spiral technology currently in use. Both spiral concentrators show a detrimental impact of slimes on the performance, but

the high capacity spiral concentrator is more sensitive to the higher

slimes conditions.

Keywords

Spiral concentrators, high capacity spirals, slimes, heavy minerals.

Introduction

Spiral concentrators are gravity separators

usually separating particle sizes between 0.1

and 2 mm in a water carrier medium1,2. The

capacities of the spiral concentrators range

between 1 and 3 t/h dry solids and recently in

excess of 7 t/h in the case of high capacity

spiral concentrators when treating typical

heavy mineral beach sands deposits3. The

spiral concentrators are usually configured in 5

to 7 turns and can accommodate up to four

starts per column.

Spiral concentrators have been part of the

minerals processing industry for the past 50

years4. The technology is fairly simple,

relatively inexpensive and well established for

pre-concentration application in mineral sands

The Journal of The Southern African Institute of Mining and Metallurgy

VOLUME 110

* Exxaro Resources.

The Southern African Institute of Mining and

Metallurgy, 2010. SA ISSN 0038223X/3.00 +

0.00. This paper was first presented at the SAIMM

Conference, Physical Beneficiation 2010, 46 May

2010.

NOVEMBER 2010

637

Synopsis

and coal industries for treating fine ore.

Developments over the years include;

improved feed box and splitter designs, trough

design, wash water addition, capacity

improvements, re-pulpers and product boxes1.

Some disadvantages of spiral concentrators

are: low throughput per unit (requiring large

banks of spiral concentrators and large

footprint, resulting in high capital processing

plants); operation difficulties (especially

cleaning the troughs and setting the splitters);

sensitivity to feed fluctuations (the splitters

need to be adjusted as feed conditions

change); and large recycles due to inefficiencies. Recent trends are looking at high

capacity units and automated splitter

adjustments.5,6

As heavy mineral producers move into

treating more difficult-to-treat low grade ores,

concentrator plant capital cost and separation

efficiencies become critical to the viability of

processing the mineral deposit. Multistage

processing and high recirculation loads are

required to maintain high mineral recoveries of

above 90% at mineral grades usually above

90%typically 4 to 5 stages being the norm

for the Exxaro and Richards Bay Minerals

operations3. Concentrator plants are usually

sized to a predetermined output and grade of

mineral concentrate. Thus, the feed grade,

determines the size of concentrator plants

Traditional spiral concentrators such as the

MG4 can operate in the range of 1.6 to 2.6 t/h

(solids) at 35% solids by mass in slurry feed.

In contrast high capacity spiral concentrators

(HC) can operate between 4 and 7 t/h at

similar feed densities (% solids)3,6. Four MG4

spiral concentrators have a footprint of

approximately 1.5 m x 1.5 m whereas four HC

P

a

p

e

r

Case study: high capacity spiral concentrators

spirals have a footprint approximately 2 m x 2 mtherefore,

by employing high capacity spiral concentrators, concentrator

plants may be able to reduce plant footprints. But at what

cost?

Plant design and spiral selection may also be influenced

by the mining methods. For example, if you have an

excavator or monitor gun, a smaller footprint lower capital

plant would be ideal. However, if your mining method is by

dredging, then it is easier to accommodate a wide, flat

structure.

The aim of the study was to compare performance of the

MG4 spiral concentrator with a high capacity spiral concentrator (HC) for various feed conditions and to evaluate the

effect of slimes on the recovery of zircon when using these

spiral concentrators in a rougher duty.

Experimental

concentration of slimes in the water. For this purpose a

250 ml volumetric flask was calibrated with water at a RD

of 1. Slime slurry was screened by employing a 45 m

laboratory screen. The -45 m fraction was thoroughly mixed

and the density measured using the calibrated 250 ml

volumetric flask. The flask was weighed in grams to the

nearest second decimal. Individual data validation tests were

conducted by drying the solids after density measurements to

determine the % solids in the slurrythis was compared to

the calculated values. The relationship shown in Figure 1 was

developed for ease of measurement during a campaignthe

relationship shows the mass % slimes in the spiral feed by

measuring the density of the water containing slime (at 35%

solids in feed to the spiral). The relationship in Figure 1 is

applicable only at the feed conditions specified. At different

feed conditions, the relationship would have to be

recalculated using the volumetric flows.

Feed sample properties

X-ray diffraction analysis

A test sample of 500 kg was sourced from the rougher spiral

feed from Exxaro Namakwa Sands operations. The sample

was deslimed (slime defined as the -45 m fraction), dried at

120C for 8 hours and screened at 1 mmthe mineralized

portion of the ore is below 1 mm. The -1 mm fraction was

then split using rotary dividers into representative subsamples of 15 kg each. This was to ensure that representative

samples were available during make-up for the individual

spiral concentrator tests. A head sample was also taken

during the feed preparation process. Slime was sourced from

thickener underflow stream during the desliming process

the slimes were added when the influence of slime concentration on separation was evaluated.

Samples were pulverized in a tungsten carbide milling vessel.

X-ray diffraction analysis was conducted using a PANalytical

XPert pro powder diffractometer with XCelerator detector

and variable divergence and receiving slits with Fe filtered

Co-K radiation. Semi-quantification was done using

Panalytical XPert Highscore analytical software.

Analytical methods

Sink-float analysis

Sink-float analyses were conducted in glass separating flasks

using tetrabromoethane (TBE) as a medium with a relative

density of 2.9. Up to 500 g of sample was added to 500 ml of

TBE, thoroughly mixed and allowed to stand, allowing

material heavier than 2.9 g/cm3 to sink. This was repeated

three times and then the material heavier than 2.9 g/cm3

(sinks) was removed through a valve at the bottom of the

separating flask. The floats and sinks were washed with

acetone to remove any residual TBE. These samples were

then dried and the percentage sinks and floats quantified.

Experimental set-up

Experiments were carried out on a closed-circuit test rig

comprising a pump, variable speed drive (VSD), mouth-organ

splitter, a chinese-hat distribution box and the spiral concentrator. There are two exit streams from the distribution box

one feeds the spiral concentrator and the other is a return line

to the sump. The return is positioned in such a way that it

agitates the material in the sump.

The current primary concentration plant (PCP plant) at

Exxaro Namakwa Sands is fitted with MG4 spirals in the

rougher circuit. A HC test unit was available at Exxaro R&D

for test work. Both spirals are supplied by Downer EDI. The

two test spiral concentrators (MG4 and HC) were fitted with a

mouth-organ splitter and swing sampler (see Figure 2) that

were able to divide the cross-profile of the spiral into seven

splits. Seven cuts were sufficient to produce a representative

and continuous release curve. Water and feed material were

added to the sump to achieve the desired feed density

Qemscan analysis

Qemscan particle mineralogical analyses (PMA) were

performed on the sink fractions to quantify the mineral

species. The Exxaro developed sip (species identification

protocol) file was utilized for the identification and quantification of the mineral species. 2000 grains on a 5 m grid

spacing were analysed per sample.

Density determination of slime-containing water to predict

the slimes content of the water

In order to perform in-time adjustments of the slimes concentration in the spiral feed, a relationship had to be established

between the density of the slime-containing water and the

638

NOVEMBER 2010

VOLUME 110

Figure 1Experimental relationship of the density of slime-containing

water as a function of the % slimes (by mass) feeding the spiral

concentrator

The Journal of The Southern African Institute of Mining and Metallurgy

Case study: high capacity spiral concentrators

(a)

J

o

u

r

n

a

l

(b)

P

a

p

e

r

Figure 2Components of the equipment set-up are depicted in the mouth-organ splitter (a) and the pneumatic sampling point (b)

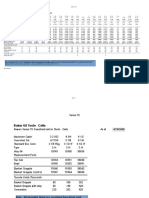

Table I

Test matrix detailing the range of tests conducted when comparing the selected spiral concentrators

Test conditions for MG4 spiral

Test no. Feed rate (t/h) Feed concentration (%solids) % slime in spiral feed Test no. Feed rate (t/h) Feed concentration (%solids) % slime in spiral feed

Feed rate variation (t/h)

Feed slimes variation (mass % slimes)

1.5

35

35

1.75

35

35

2.0

35

35

2.2

35

35

Feed grade variation (% THM)

Feed concentration variation (% solids)

35

13

37

10

35

14

40

11

35

15

42

12

35

Test conditions for HC spiral

Feed rate variation (t/h)

Feed slimes variation (mass % slimes)

16

4.5

35

20

35

17

5.0

35

21

35

18

5.5

35

22

35

19

6.0

35

23

35

During testing only a single parameter was changed, all other variables were kept constant as far as practical possible. The bold numbering indicate the

variations of the specific condition

(expressed as % solids by mass) and flow rate (t/h) required

per test. Once the desired parameters were obtained, two or

three samples were taken to investigate stability of the flow

conditions on the separation trough. This was done by

sampling the entire spiral profile at once. The slurry was

weighed and then the water was decanted. It was inferred

that when the water is decanted from the slurry sample, the

remaining solids contained 20% moisture (this value was

confirmed prior to the actual test by drying the solids after

decantation). The samples were subsequently returned to the

system and the procedure repeated two-more times. This was

to ensure that the system was stable and the desired

conditions reached. Once stable conditions had been obtained

a sample of 7 cuts was taken. Between 35 and 80 kg of feed

sample was required to the reach desired tonnages of 1.5 to 7

t/h for the various tests.

The spiral concentrator comparison was based on feedrate (t/h), slime content and feed grade (mineral content)

variation.

The Journal of The Southern African Institute of Mining and Metallurgy

VOLUME 110

Experimental test conditions

A test matrix detailing the conditions tested is provided in

Table I.

Slimes addition

NOVEMBER 2010

639

Slime content was increased by adding material originated

from the thickener underflow to the sump. It was assumed

that the recirculation of this material would break up any

flocculant in the thickener underflow. Slimes content of the

slurry stream was determined by the density measurement of

the slimes-containing water as described earlier.

Case study: high capacity spiral concentrators

Recovery calculations

Separation curves were developed for each of the valuable

minerals in every experimental run conductedsee earlier for

the detail on the Qemscan analysis. The separation curve is a

plot of cumulative mass % mineral recovered as a function of

the cumulative mass % recovered across the spiral profile

starting from the part of the mouth-organ splitter closest to

the centre column. Of all the valuable minerals only zircon is

used for illustrative purposes in this paper (as shown in

Figure 3). Zircon recoveries were determined by utilizing the

separation curves and used for comparative purposes as

discussed in the remainder of this studyonly the 30% mass

recovery value was used. The value of 30% was selected as

an arbitrary point. In the PCP up to 50% from the rougher

circuit can report to concentrate and middling. It is important

to reject as much mass as possible to tails in the rougher

circuit with little mineral lost to tails.

Results and discussion

economic minerals. Recalculating mineral content as mass%

in feed gives zircon content of 0.81 mass% and ilmenite

content of 2.55%.

Figure 3Separation curve showing mass percent zircon recovered as

a function of mass recovered. Mass recovery was accumulated from

the inside of the spiral (next to the centre column). This figure illustrates

the MG4 performance at 1.8t/h and 35% solids in feed

Feed sample characterization

Table II is a summary of the spiral feed that was tested.

Zircon, rutile and ilmenite made up only 32% of the sinks.

This shows that there is a large amount of uneconomical

heavy minerals present in the feed. The RDs of ilmenite,

rutile and zircon are between 3.9 and 4.5 and that of quartz

(is approximately 2.6). Table II is a summary of the spiral

feed that was tested. Zircon, rutile and ilmenite made up only

32% of the sinks.

The feed material was sized between 1.0 mm and 0.05

mmthus the feed was suitable for spiral separation (correct

size range and adequate density differences: G > 1)2.

Zircon and ilmenite were fairly well liberated grains (see

Figure 4). Quartz particles were generally coarser than the

Table II

Head sample characterization of the test sample

Slime

Sink-float analyses @ RD 2.9

Mineral content in sinks

Fraction

Mass %

-45 m

Sink

Float

Zircon

Rutile

Ilmenite

0.75

12.68

86.58

6.35

5.66

20.11

Figure 4Qemscan particle map sorted by zircon particles (purple) on the top followed by ilmenite particles (green)

640

NOVEMBER 2010

VOLUME 110

The Journal of The Southern African Institute of Mining and Metallurgy

Case study: high capacity spiral concentrators

Effect of feed density at varying slimes concentrations on the performance of the MG4 spiral

concentrator

As indicated from the test matrix (Table I), the feed rate for

these experimental runs was kept constant at 2 t/h. The

effect of feed density at varying slimes concentrations on the

performance of the MG4 spiral is shown in Figure 5. For this

ore type, the MG4 was able to maintain high zircon

recoveries at a 30% mass recovery to concentrate when the

slimes concentration by mass in the spiral concentrator feed

was below 5%. However, if a slimes concentration of 6% is

exceeded the zircon recovery decreases sharply with an

increase in the feed solids concentration. The reason for the

sharp decrease in the zircon recovery is a result of the slimes

affecting the viscosity of the fluid. With a higher feed density

the slimes exacerbates the effect on the zircon recovery since

the total volumetric flow on the spiral concentrator decreases.

Effect of feed grade at varying slimes concentrations

on the performance of the MG4 spiral concentrator

As indicated in the experimental section the feed rate for

these experimental runs were kept constant at 2 t/h and the

feed density was maintained between 34 and 37 mass%

solids. The effect of feed grade (in mass % THM) at varying

slimes concentrations on the performance of the MG4 spiral

is shown in Figure 6. A constant 30% mass recovery to

concentrate was used to calculate zircon recovery. High

zircon recoveries at above 96% were achieved with low slime

in spiral feed irrespective of feed grade changes from 7% to

15% THM. At higher slime content in spiral feed (> 6% by

mass) zircon recovery losses were observed.

It is unfortunate that no data were available between 9

and 11% THM in the feed for the high slime trend in

Figure 6.

Effect of feed rate at varying slimes concentrations

on the performance of the MG4 and HC spiral

concentrators

Both spiral concentrators were evaluated for effect of feed

rate on performancefor this campaign the feed solids

concentration was kept constant. Figure 7 clearly indicates

that the performance of the spiral concentrator (measured as

the zircon recovery) decrease with an increase in the feed

rate. The break-away point for the slime discussed earlier is

clearly evident in Figure 7. For the MG 4 spiral concentrator

about a 7% zircon recovery is sacrificed if the slime concentration is allowed to exceed 5%. Approximately a 5% zircon

loss is experienced on the HC spiral concentrator due to the

same effect. In addition the HC spiral concentrator was less

sensitive for changes in feed rate provided that slimes

content was below 4%. Recoveries at low slime conditions on

the HC spiral concentrator were similar (recoveries around

85% of zircon) to the MG4 spiral concentrator performance at

high slime conditions. Similar trends in losses due to effect of

increase in feed rate were also observed by other

authors1,45.

Effect of varying slime in feed on the performance of

MG4 and HC spiral concentrators.

Figure 5Effect of feed density at varying slimes concentration on the

performance of the MG4 spiral concentration. Experimental runs were

performed at a constant feed rate of 2 t/h

Figure 8 illustrates that irrespective of feed rate similar losses

can be experienced with increase of slime on the spiral

concentrator. Significant zircon losses are observed as slime

content in the feed is increased. Poor desliming upfront can

severely negatively affect spiral concentrator performance.

Typically 6% slime can report to the spirals after desliming

with cyclones at Exxaros operations. The slime portion for

Exxaros mines contains typically 20 to 40% clay minerals

hence the significant zircon losses are observed during the

test work. The clay minerals have major impact on the

viscosity of the carrying fluid in the spiral.

Figure 7Effect of feed rate (t/h) at varying slimes concentration on the

performance of the MG4 and HC spiral concentrator. Experimental runs

were performed at constant feed density of 34 and 37 mass % solids

The Journal of The Southern African Institute of Mining and Metallurgy

VOLUME 110

NOVEMBER 2010

641

Figure 6Effect of feed grade (% THM) at varying slimes concentration

on the performance of the MG4 spiral concentration. Experimental runs

were performed at a constant feed rate of 2 t/h and the feed density

was maintained between 34 and 37 mass % solids

J

o

u

r

n

a

l

P

a

p

e

r

Case study: high capacity spiral concentrators

Figure 8Effect of slime at a constant feed rate at 35% solids showing zircon recovery as a function of slime in feed to the spiral

When comparing all the data obtained during the test

work campaign, it was evident that for both the spiral

concentrators employed, a break-away point could be

identified for the amount of slimes on the spiral concentrator

this break-away point indicated the point where the

zircon recovery was drastically affected. For the MG spiral

this point was at approximately 5% slimes by mass of the dry

solids or alternatively where the relative density (RD) of the

slime-containing water was 1.014 (see Figure 1). For the HC

spiral the same phenomenon was evident albeit at 4% slimes

by mass (RD of slime-containing water was 1.011). In order

to establish the relationship between the viscosity and the

density of the slime-containing water, viscosity

measurements were subsequently performed. It is known that

the high levels of slime adversely affect the performance of

spiral concentrators7,8. In addition, it is known that the

slimes can contain clay minerals. Some clay mineralsfor

example smectiteswell in the presence of water resulting in

the formation of fine particle which affect the rheological

behaviour of the slurry9. It is also known that the heavy

mineral slimes can contain up to 60% smectite clays9.

Literature shows that the slimes content of the spiral concentrator feed should be reduced to around 10% to ensure good

separation8. However, this work indicates a negative effect

even at lower slimes content. This shows that spiral

performance is dependent on the mineral deposit properties

a recent investigation at Richards Bay Minerals showed high

performance of the HC1 spiral.3

Acknowledgements

The authors would like to thank Exxaro Namakwa Sands for

the opportunity to publish the data present in this article.

References

1. HOLLAND-BATT, A.B. Some design considerations for spiral separators,

Minerals Engineering Lake Tahoe, 1995.

2. WILLS, B.A. Wills Mineral Processing Technology, Seventh Edition,

Oxford, 2007.

3. GRACIE, S. Redesigning the industry standarda new look at the wet

concentrator circuit. The 7th International Heavy Minerals Conference

What next, The Southern African Institute of Mining and Metallurgy,

2009. pp. 107108, 110

4. Separation solutions, Outokumpu Technology Physical Separation

Newsletter, issue 1, 2005.

5. RICHARDS, R.G. and PALMER, M.K. High Capacity gravity separators; a

review of current status. Minerals Engineering, vol. 10, no. 9 1997.

pp. 973982.

6. ERASMUS, W. Personal communications, 2010.

7. ABELA, R. The effect of the slimes content on the rougher spiral circuit in a

heavy mineral sands operation, Proceedings of the Heavy Mineral

Conference 2003, 2003.

8. BROWN, R. Slimes Effect on Spiral Efficiency, Report on the Cooljarloo

North Mine, 2001,

Conclusions

Mineral recovery on the HC spiral was inferior to the MG4

spiral for this type of ore. Higher recoveries were attained at

lower tonnages, making the MG4 spiral concentrator more

suitable for treating this type of ore. The HC spiral concentrator also showed more sensitivity to the slime content of the

deposit. For every % increase in slime in feed, a 5% zircon

recovery loss was observed for both spirals. The MG4 spiral

was able to maintain good performance as long as the slime

concentration was kept below 5%. Significant mineral losses

were observed when slime in excess of 6% was encountered.

The same observations were made for the HC spiral but the

break-away slime point was only at 4%. The effect of feed

rate increase related to mineral recovery loss is well published

642

and similar trends were observedsome literature shows that

for some ores a low slimes content in feed benefits

separation. Spiral concentrator selection is dependent on ore

characteristics.

NOVEMBER 2010

VOLUME 110

9. MORKEL, J. and VERMAAK, M.K.G. The role of swelling clay in kimberlite

weathering, Mineral. Processing and Extractive Metallurgy (Trans. Inst.

Min. Metall. C), 2006, vol. 115, no. 3, pp. 150154.

Bibliography

1. MATTHEWS, W.B., FLEYCHER, C.A.J., and PARTRIDGE, T.C. Particle flow

modelling on spiral concentrators: Benefits of dense media for coal

processing? Second International Conference on CFD in the Minerals and

Process Industries, CSIRO, Melbourne, Australia, 1999.

2. MARCOS, S.P. and GILMAN, K.S. Old tricks for new dogs Areas for focus in

mineral sand processing. The 6th International Heavy Minerals

Conference Back to Basics, The South African Institute of Mining and

Metallurgy, 2007, pp. 5561.

The Journal of The Southern African Institute of Mining and Metallurgy

S-ar putea să vă placă și

- Hanson Malaysia - Hanson Malaysia039s ProductsDocument2 paginiHanson Malaysia - Hanson Malaysia039s ProductsgokilavanireveendranÎncă nu există evaluări

- New Illu KalkDocument1 paginăNew Illu Kalkripper_oopsÎncă nu există evaluări

- Harvard Referencing GuideDocument40 paginiHarvard Referencing GuideSteven MartinÎncă nu există evaluări

- PhytoremediationDocument43 paginiPhytoremediationHo DungÎncă nu există evaluări

- 131 Examination Instructions To CandidatesDocument2 pagini131 Examination Instructions To CandidatesNorhadi MohamadÎncă nu există evaluări

- 03Document6 pagini03gokilavanireveendranÎncă nu există evaluări

- EScholarship UC Item 6m743258Document35 paginiEScholarship UC Item 6m743258gokilavanireveendranÎncă nu există evaluări

- EScholarship UC Item 6m743258Document35 paginiEScholarship UC Item 6m743258gokilavanireveendranÎncă nu există evaluări

- Innisai Paadivarum Ilam Kaatruku Uruvam IllaiDocument1 paginăInnisai Paadivarum Ilam Kaatruku Uruvam IllaigokilavanireveendranÎncă nu există evaluări

- Heidelbergcement Sustainability Report 2013-2014Document54 paginiHeidelbergcement Sustainability Report 2013-2014gokilavanireveendranÎncă nu există evaluări

- Harvard Referencing GuideDocument40 paginiHarvard Referencing GuideSteven MartinÎncă nu există evaluări

- ALS Metallurgy - Mineral Sands Process DevelopmentDocument8 paginiALS Metallurgy - Mineral Sands Process DevelopmentaghilifÎncă nu există evaluări

- New Illu KalkDocument1 paginăNew Illu Kalkripper_oopsÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Common Causes of Tire Coupling FailuresDocument8 paginiCommon Causes of Tire Coupling FailuresIgor San Martín PeñalozaÎncă nu există evaluări

- HA12 26m MM - GB E0611 PDFDocument218 paginiHA12 26m MM - GB E0611 PDFFauziahÎncă nu există evaluări

- All OvershotsDocument25 paginiAll OvershotsnjileoÎncă nu există evaluări

- Sample Problem PetrochemDocument4 paginiSample Problem PetrochemElixir Azile0% (4)

- Simovert Master Drives PDFDocument224 paginiSimovert Master Drives PDFRicardo GomesÎncă nu există evaluări

- Structural Analysis Is A: Science, Having Definite ValueDocument34 paginiStructural Analysis Is A: Science, Having Definite ValueRamanathan SenthilÎncă nu există evaluări

- An Overview of Thin Layer ChromatographyDocument12 paginiAn Overview of Thin Layer ChromatographyKristopher Glenn AltonÎncă nu există evaluări

- Rolas Pasa Cable de Fibra de VidrioDocument1 paginăRolas Pasa Cable de Fibra de Vidriogian marcoÎncă nu există evaluări

- Capsules Deduster: The PTGDocument2 paginiCapsules Deduster: The PTGRafael ZavalaÎncă nu există evaluări

- DoosanCARE Maintenance Inspection - Wheel LoaderDocument2 paginiDoosanCARE Maintenance Inspection - Wheel Loaderchady tanÎncă nu există evaluări

- Additives For High Solids and Water-Borne CoatingsDocument12 paginiAdditives For High Solids and Water-Borne CoatingsWIlliam CheungÎncă nu există evaluări

- Liquid Phase SinteringDocument242 paginiLiquid Phase SinteringAbir Roy100% (1)

- F1111 25156Document2 paginiF1111 25156johann tousÎncă nu există evaluări

- Technical Data Sheet For HIT HY 270 Injectable Anchor Mortar For Masonry Technical Information ASSET DOC 4098527Document33 paginiTechnical Data Sheet For HIT HY 270 Injectable Anchor Mortar For Masonry Technical Information ASSET DOC 4098527NGUYENÎncă nu există evaluări

- Case M4K Forklift Truck Service Repair Manual PDFDocument60 paginiCase M4K Forklift Truck Service Repair Manual PDFjfjksekdmeikÎncă nu există evaluări

- Labs Best Practices EnergyDocument107 paginiLabs Best Practices EnergynumeriqueÎncă nu există evaluări

- Facilities Solutions: Campus-WideDocument36 paginiFacilities Solutions: Campus-WideAmerican Hotel Register CompanyÎncă nu există evaluări

- Is 14735 Product ManualDocument9 paginiIs 14735 Product ManualNagarjuna NutakkiÎncă nu există evaluări

- CHAPTER I MaboloDocument18 paginiCHAPTER I MaboloZayn RauiÎncă nu există evaluări

- WORK PERMIT GAS TESTING GUIDEDocument39 paginiWORK PERMIT GAS TESTING GUIDEIbbad Ahmed MalikÎncă nu există evaluări

- Filtration of Apple Juice by Nylon Nanofibrous MembranesDocument7 paginiFiltration of Apple Juice by Nylon Nanofibrous MembranesDavid CamargoÎncă nu există evaluări

- Materials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFDocument50 paginiMaterials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFGOUAREF SAMIRÎncă nu există evaluări

- Pipeline Welding InspectionDocument4 paginiPipeline Welding InspectionRizky TrianandaÎncă nu există evaluări

- Food and Bio Process EngineeringDocument24 paginiFood and Bio Process EngineeringRosane Cavalcante100% (1)

- Plywood Used in So Many Different Ways: Eaturing Lywood in UildingsDocument23 paginiPlywood Used in So Many Different Ways: Eaturing Lywood in Uildingspilapil_jÎncă nu există evaluări

- Glazing TerminologyDocument4 paginiGlazing TerminologyDaliPotter100% (1)

- K7QO - QRP - Laboratory PDFDocument136 paginiK7QO - QRP - Laboratory PDFdetroit_me2553100% (1)

- HFD Catalog WPF PDFDocument16 paginiHFD Catalog WPF PDFPartsGopher.comÎncă nu există evaluări

- Ambient Accoustic Ceiling Systems - Brochure A4 PDFDocument16 paginiAmbient Accoustic Ceiling Systems - Brochure A4 PDFhuychungngÎncă nu există evaluări

- A Practical Guide For The Determination of Moisture Content of Woody BiomassDocument20 paginiA Practical Guide For The Determination of Moisture Content of Woody BiomassSaiRamÎncă nu există evaluări