Documente Academic

Documente Profesional

Documente Cultură

HR Blowers Positive Displacement Air Blowers Sizes 3&4 Specification

Încărcat de

relli10Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HR Blowers Positive Displacement Air Blowers Sizes 3&4 Specification

Încărcat de

relli10Drepturi de autor:

Formate disponibile

HR

ROTARY

BLOWERS

Positive Displacement

Air Blowers - Sizes 3& 4

Based on Success

HR Blowers are one of the worlds leading air blower

manufacturers and have a reputation for quality, innovation

and service.

Design Features

The conservative load carrying capacity of

the larger diameter rolling element bearings

ensures an extended operating life.

Timing gear life is also extended by

controlled lubrication systems.

The computer calculated impeller profiles

ensure maximum volumetric efficiency

with minimum absorbed power without

sacrificing torsional rigidity.

The high rigidity of the impeller / shafts

permits a higher pressure rise to be

obtained than with other machines of

comparable size.

The generous shaft diameter keeps drive

stresses low.

Gear and shaft strength is substantially

increased by the use of taper mounted gears

which do not need keyways for location.

Setting of the gear wheels to obtain correct

timing of the impellers is simplified, a

feature that facilitates field maintenance.

Precision ground and hardened steel

gears are used to ensure smooth, silent

running and accurate timing of the rotating

impellers. A controlled lubrication system

is provided to ensure efficient operation

without waste of energy in the gearcase.

Specially designed rotary oil seals are used

in the gearcase. This feature eliminates

maintenance associated with the use of

lip seals.

Design and manufacture is in accordance

with metric standards.

Use as an Exhauster

If used as an exhauster and dust or liquids

could be drawn into the machine due to

inadequate filtration, closed end rotors

should be specified. This will minimise risk

of loss of dynamic balance due to material

inside the rotors.

Specification

CASING: The cylinder and headplates are

manufactured from cast iron. The gearcase

is manufactured from aluminium.

IMPELLERS AND SHAFTS: The impellers are

made from SG iron, and cast with integral

shafts. (size 3) and from mehanite and have

pressed-in steel shafts (size 4). The shaft

diameter of machines in the HR Blowers

range is larger than that of earlier designs,

enabling increased operating pressures to

be achieved without increasing blower size.

GEARS: The precision ground and hardened

steel spur gears are taper mounted onto

the impeller shafts. The timing of the

impellers relative to each other is accurately

maintained at all times.

BEARINGS: The bearings are of generous

proportions to give long operational life.

Grease lubricated double row ball bearings

are used at the drive end of the size 3

Blower the size 4 blower has double angular

roller bearings at the drive end. In addition

to their normal duty of carrying radial loads

associated with the differential air pressure

on the rotating impellers, the ball bearings

provide axial location of the impellers.

Parallel roller bearings at the rear end

splash lubrication by oil from the gears.

LUBRICATION: An advanced design of

controlled gear wheel lubrication enables

the gears to operate at a high pitch line

velocity without the need for an oil pump.

Simple, maintenance free oil throwers fitted

behind each bearing in the gearcase prevent

leakage of oil.

DIRECTION OF ROTATION: Detachable

mounting feet enable the blower to be

positioned for either vertical or horizontal

air flow. Standard machines have a right

hand drive shaft for vertical air flow, and a

bottom drive shaft for horizontal air flow.

If machines are required with a left hand or

top drive shaft, all that needs to be done is

turn the gearcase and trough through 180.

Centre timing permits clockwise or

anti-clockwise drive shaft rotation.

BLOWER PROTECTION SYSTEM: (optional

extra). A number of insulated probes

projecting into the cylinder which are

electrically connected to one another and

to a junction box mounted on the blower

can be fitted. To operate this system a

control box is also required. The protection

system (UK and foreign patents granted)

detects excessive closure of the fine working

clearances within the blower which might be

caused by overload. Should this happen, the

prime mover is shut down automatically to

prevent seizure of the blower.

User Benefits

The delivered air is guaranteed

to be oil free because internal

lubrication is unnecessary, and

because all HR Blowers Positive

Displacement Air Blowers are

constructed with air gaps which

completely isolate bearing and gear

lubrication from the compression

chamber.

Noise levels are kept to a minimum.

Mechanical noise levels have been

reduced by the running accuracy of

the taper mounted gears. Air noise

is reduced by carefully designed air

ports and the elimination of

resonant unbraced surfaces.

The blower can be installed for

either vertical or horizontal air flow

simply by repositioning the

mounting feet. Installation costs

can be reduced by versatility of

mounting arrangement.

The generous diameter of the drive

shaft permits the use of V-belt drives

without the need for a double outer

bearing.

Air blowers can also be used as air

exhausters. Performance charts on

application.

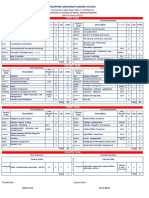

Dimensions

Horizontal

Flow

Vertical

Flow

All dimensions in millimetres

Size A B C D E FH HH E FV HV G J K L M N

S T U V W X Y

HR31

751 283

353

205 205 150 285 240

HR32

891 353

423

275 275 200

340 295

115

180 300 260 220 215 254 220

110 50.018/50.002 5.5/5.7 14.05/14.12 18 16 25 20 8 22

HR33

1005 410

480

333 333 200 340 295

HR41

954 353

456

260 260 200 340 8 295

HR42

1097 436

539

342.5

342.5 250

395

12 350

145

220 355

315 260 255 310 250

140 65.030/65.011 7.0/7.2

17.957/18.00 18 16 26 20

22

HR43

1252 513.5

616.5

420 420 300 440 12 395

Blower Performance

HR

Size

Speed

rpm

300 mbar

500 mbar

700 mbar

1000 mbar

m3/

kW

hour

m3/

kW

hour

m3/

kW

hour

m3/ kW

hour

2720 2360 24.4 2291 39.1 2236 53.8 2168 75.8

2500 2147 22.5 2078 35.9 2023 49.4 1955 69.6

2300 1953 20.7 1884 33.1 1829 45.5 1761 64.1

31 2100 1759 18.9 1690 30.2 1635 41.5 1567 58.5

1900 1566 17.0 1496 27.3 1441 37.6 1374 52.9

1700 1372 15.3 1303 24.4 1248 33.6 1180 47.3

1500 1178 13.5 1109 21.6 1054 29.6 986 41.8

1300 984 11.7 915 18.7 860 25.7 792 36.2

2720 3455 34.5 3356 55.9 3279 77.3

2500 3144 31.7 3045 51.4 2968 71.1

2300 2861 29.2 2763 47.3 2685 65.4

32 2100 2578 26.7 2480 43.2 2402 59.7

1900 2296 24.1 2197 39.1 2120 54.0

1700 2013 21.6 1915 35.0 1837 48.3

1500 1730 19.0 1632 30.8 1554 42.6

1300 1448 16.5 1350 26.7 1272 37.0

2720 4367 42.8 4249 69.7

2500 3976 39.4 3558 64.1

2300 3621 36.2 3502 59.0

33 2100 3265 33.1 3146 53.8

1900 2909 29.9 2791 48.7

1700 2553 26.8 2435 43.6

1500 2198 23.6 2079 38.5

1300 1842 20.5 1724 33.3

Maximum pressure rise for size

33 is 550 mbar See performance

chart for details.

The volume of air delivered is measured at inlet conditions of 15C and 1013 mbar absolute

HR

Size

Speed

rpm

300 mbar

500 mbar

700 mbar

1000 mbar

m3/

kW

hour

m3/

kW

hour

m3/

kW

hour

m3/ kW

hour

2080

4226 43 4100 69 4001 96 3878 135

1900

3817 39 3692 63 3592 87 3470 123

1700

3363 35 3238 57 3138 78 3016 110

41

1500

2909 31 2783 50 2684 69 2562 97

1300

2455 27 2329 43 2230 60 2107 84

1100

2001 23 1875 37 1776 51 1653 71

900 1546 19 1421 30 1322 41 1199 58

2080

5921 59 5750 95 5614 132

1900

5350 54 5179 87 5043 121

1700

4715 48 4544 78 4408 108

42

1500

4081 42 3909 69 3774 95

1300

3446 37 3275 60 3139 83

1100

2811 31 2640 50 2504 70

900 2177 25 2006 41 1870 57

2080

7530 73 7319 120

1900

6806 67 6595 110

1700

6002 60 5791 98

43

1500

5197 53 4987 87

1300

4393 46 4183 75

1100

3589 39 3378 63

900

2785 3 2574 52

Maximum pressure rise for size

43 is 550 mbar See performance

chart for details.

Net Weight

Size 31: 236kg

Size 41: 500kg

Size 32: 282kg

Size 42: 600kg

Size 33: 306kg

Size 43: 680kg

Bridge Mills, Huddersfield Road, Holmfirth, West Yorkshire HD9 3TW

Tel: 01484 691858 Fax: 01484 680467

Email: sales@hrblowers.co.uk

Following the Companys policy of constant development, we reserve the right to alter any detail

specified or illustrated in this publication without notice and without incurring any obligation to

provide such modifications on machines previously delivered.

S-ar putea să vă placă și

- Positive Displacement Air Blowers - Sizes 3& 4: Based On SuccessDocument2 paginiPositive Displacement Air Blowers - Sizes 3& 4: Based On SuccessRobert R. TiinÎncă nu există evaluări

- Positive Displacement Air Blowers - Sizes 1 & 2: Based On SuccessDocument2 paginiPositive Displacement Air Blowers - Sizes 1 & 2: Based On SuccessRobert R. TiinÎncă nu există evaluări

- Sany Excavators SY135 Tier 3Document9 paginiSany Excavators SY135 Tier 3csbersama100% (2)

- Compresores Serie-A ChampionDocument4 paginiCompresores Serie-A ChampionFrancisco100% (1)

- Sany Excavators SY135CDocument9 paginiSany Excavators SY135Ccsbersama100% (4)

- Mhi Integrally Geared CompressorsDocument6 paginiMhi Integrally Geared CompressorscandhareÎncă nu există evaluări

- Volvo Crawler Excavators: More Care. Built inDocument12 paginiVolvo Crawler Excavators: More Care. Built inAnonymous 0PuvmpoÎncă nu există evaluări

- Premium Transmission Gear BoxDocument80 paginiPremium Transmission Gear BoxShipra Shalini83% (6)

- Highly efficient two-stage rotary screw compressor specificationDocument9 paginiHighly efficient two-stage rotary screw compressor specificationbiberiusÎncă nu există evaluări

- Powerful ZAXIS-3G Series ExcavatorsDocument11 paginiPowerful ZAXIS-3G Series ExcavatorsJi Uvex83% (6)

- Centrifugal Compressors SRLDocument20 paginiCentrifugal Compressors SRLsammar_10Încă nu există evaluări

- Motor Grader Terex DimensionDocument16 paginiMotor Grader Terex DimensionMaulana Fajriansyah100% (2)

- Series: Hydraulic ExcavatorDocument19 paginiSeries: Hydraulic ExcavatorAldy Anugrah Ardana0% (1)

- BREIDERT DB Series (Soler Palau Co.)Document18 paginiBREIDERT DB Series (Soler Palau Co.)adeel_akhtarÎncă nu există evaluări

- Mechanical MaintanenceDocument311 paginiMechanical MaintanenceSandeep VijayakumarÎncă nu există evaluări

- Cat D6GDocument16 paginiCat D6GShailesh Khodke75% (4)

- E 314C SpecalogDocument16 paginiE 314C SpecalogArmando Muñoz100% (1)

- D VipDocument6 paginiD VipClemente Rafael Marval EscalonaÎncă nu există evaluări

- C20D WindJet Air ProductsDocument28 paginiC20D WindJet Air Productscepong89Încă nu există evaluări

- Boge Screw CompressorDocument16 paginiBoge Screw CompressorarjmandquestÎncă nu există evaluări

- Elliott CompressorsDocument7 paginiElliott CompressorsQuarkantÎncă nu există evaluări

- 3,000-7,000 IC Pneumatic Forklift Trucks PDFDocument26 pagini3,000-7,000 IC Pneumatic Forklift Trucks PDFForklift Systems IncorporatedÎncă nu există evaluări

- Boge Oil-Free Screw Compressors - SO SeriesDocument16 paginiBoge Oil-Free Screw Compressors - SO SeriesAir Repair, LLCÎncă nu există evaluări

- Tuthill Blower Spec - 02Document8 paginiTuthill Blower Spec - 02Kari ConwayÎncă nu există evaluări

- Cs 583 eDocument16 paginiCs 583 easadiqbalansariÎncă nu există evaluări

- ZW100-G 1.1-1.6 Cum PDFDocument5 paginiZW100-G 1.1-1.6 Cum PDFSriram NambiÎncă nu există evaluări

- Hydraulic Excavator Hydraulic Excavator: Model Code Engine Rated Power Operating Weight Backhoe BucketDocument17 paginiHydraulic Excavator Hydraulic Excavator: Model Code Engine Rated Power Operating Weight Backhoe BucketJovanka JadrovskaÎncă nu există evaluări

- Hsm-003 Complete CatalogDocument36 paginiHsm-003 Complete Catalogemuno008Încă nu există evaluări

- Static Data Description Assembly Order NoDocument29 paginiStatic Data Description Assembly Order NoMROstop.comÎncă nu există evaluări

- Morin TYCO ValvesDocument16 paginiMorin TYCO ValvesaravindÎncă nu există evaluări

- HoodedProp CatalogDocument52 paginiHoodedProp CatalogTed K NagaraÎncă nu există evaluări

- Screw CompressorDocument2 paginiScrew CompressorRiti AdhikariÎncă nu există evaluări

- Compresor ElliotDocument12 paginiCompresor ElliotMARTINA FERRARIÎncă nu există evaluări

- Masina Multifunctionala de Doborat ArboriDocument16 paginiMasina Multifunctionala de Doborat ArboritwacacaÎncă nu există evaluări

- CX210B Hydraulic Excavator Powerful Performance & Low CostsDocument20 paginiCX210B Hydraulic Excavator Powerful Performance & Low CostsMario Torres Del Valle100% (1)

- Gearbox SuperDocument15 paginiGearbox Super10delpiÎncă nu există evaluări

- Static Data Description Assembly Order NoDocument29 paginiStatic Data Description Assembly Order NoMROstop.comÎncă nu există evaluări

- Boletin Tecnico No. 3 Turbinas de Vapor ElliottDocument12 paginiBoletin Tecnico No. 3 Turbinas de Vapor Elliottcristobal_tl227750% (2)

- Series21&41 CatalogDocument16 paginiSeries21&41 CatalogWillin08Încă nu există evaluări

- Caterpillar Cb214e 224e 225e Specalog 1032 Eng (01f)Document12 paginiCaterpillar Cb214e 224e 225e Specalog 1032 Eng (01f)Huayta Apaza JacintoÎncă nu există evaluări

- Honda CBR250R Engine CutoutDocument7 paginiHonda CBR250R Engine CutoutOmkar SheteÎncă nu există evaluări

- 7-PDF - 4 - 2. PC300 - 300LC-7 (1 2 3 6 9)Document1 pagină7-PDF - 4 - 2. PC300 - 300LC-7 (1 2 3 6 9)Denny PanjaitanÎncă nu există evaluări

- 01 Chemical ProcessDocument333 pagini01 Chemical ProcessDavid ValladaresÎncă nu există evaluări

- BV300 Sopladora Oleo MacDocument2 paginiBV300 Sopladora Oleo MacLeopoldo PerezÎncă nu există evaluări

- ENGINEDocument23 paginiENGINEMohamed SaiedÎncă nu există evaluări

- Cs - Cp-533e Specalog (Qehq9995)Document16 paginiCs - Cp-533e Specalog (Qehq9995)Sanggalangi LatinroÎncă nu există evaluări

- G1-001-12-EN - Blowers Over View PDFDocument20 paginiG1-001-12-EN - Blowers Over View PDFherrerafaridÎncă nu există evaluări

- Static Data Description Assembly Order No.: Do Not Use Airstroke in Shaded Area Without Consulting FirestoneDocument29 paginiStatic Data Description Assembly Order No.: Do Not Use Airstroke in Shaded Area Without Consulting FirestoneMROstop.comÎncă nu există evaluări

- Brochure BEGEMANN BS Pumps-Low ResolutionDocument6 paginiBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorÎncă nu există evaluări

- 16H Motor Grader: Global VersionDocument30 pagini16H Motor Grader: Global VersionsuryarisÎncă nu există evaluări

- Frick Xjf-Xjs 95 To 151Document4 paginiFrick Xjf-Xjs 95 To 151Harry EP Situmorang100% (4)

- Standard Equipment: Engine Upperstructure Zaxis240H / Zaxis240Lch (Heavy-Duty Version)Document9 paginiStandard Equipment: Engine Upperstructure Zaxis240H / Zaxis240Lch (Heavy-Duty Version)Ery BudiariantoÎncă nu există evaluări

- Elliott YR Turbines: Flexibility and Reliability for Decades of ServiceDocument8 paginiElliott YR Turbines: Flexibility and Reliability for Decades of ServiceOscar Barajas BÎncă nu există evaluări

- Centrifugal Compressors MAN-GEDocument20 paginiCentrifugal Compressors MAN-GEIbc Cbs Ibc CbsÎncă nu există evaluări

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionDe la EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionEvaluare: 4 din 5 stele4/5 (1)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDe la EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallEvaluare: 4 din 5 stele4/5 (8)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDe la EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreEvaluare: 4.5 din 5 stele4.5/5 (11)

- Construction and Manufacture of AutomobilesDe la EverandConstruction and Manufacture of AutomobilesEvaluare: 5 din 5 stele5/5 (1)

- Melt Viscometer For PET Testing Intrinsic Viscosity (IV) and Melt Viscosity (MV) MeasurementDocument3 paginiMelt Viscometer For PET Testing Intrinsic Viscosity (IV) and Melt Viscosity (MV) MeasurementAnjum ParkarÎncă nu există evaluări

- DS-2TD4136-25/50: Thermal & Optical Bi-Spectrum Network Speed DomeDocument5 paginiDS-2TD4136-25/50: Thermal & Optical Bi-Spectrum Network Speed Domeal lakwenaÎncă nu există evaluări

- 1.0 A Negative Voltage Regulators MC7900 Series: TO 220 T Suffix Case 221abDocument17 pagini1.0 A Negative Voltage Regulators MC7900 Series: TO 220 T Suffix Case 221abjoseÎncă nu există evaluări

- PS 663x ENGDocument10 paginiPS 663x ENGtoseruÎncă nu există evaluări

- Radio Shack 20-314 Aka Pro-79 Scanner Owners ManualDocument52 paginiRadio Shack 20-314 Aka Pro-79 Scanner Owners Manualeh2677Încă nu există evaluări

- Main Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayDocument3 paginiMain Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayAsep RifkyÎncă nu există evaluări

- 193 Um015 - en P PDFDocument736 pagini193 Um015 - en P PDFAdelson PimentelÎncă nu există evaluări

- Teleprotection For Distance Protection: To AchieveDocument5 paginiTeleprotection For Distance Protection: To AchievebijoyÎncă nu există evaluări

- Impact of Partial Shading On The Output Power of PV Systems Under Partial Shading ConditionsDocument10 paginiImpact of Partial Shading On The Output Power of PV Systems Under Partial Shading Conditionsshihab4806Încă nu există evaluări

- Recap, Recap Pro Features, and Recap 360 Web Services Faq: Autodesk Reality Solutions GroupDocument12 paginiRecap, Recap Pro Features, and Recap 360 Web Services Faq: Autodesk Reality Solutions GroupIlham Fadel MÎncă nu există evaluări

- Effective Strategies For Virtual Classroom ParticipationDocument3 paginiEffective Strategies For Virtual Classroom ParticipationRicha SinghÎncă nu există evaluări

- Buffering in Operating System - JavatpointDocument7 paginiBuffering in Operating System - JavatpointkkkkÎncă nu există evaluări

- Example To Manually Check and Create EDIFACT Signatures 2022-11-18Document10 paginiExample To Manually Check and Create EDIFACT Signatures 2022-11-18ralucaÎncă nu există evaluări

- 1/3-Inch 1.2Mp CMOS Digital Image Sensor With Global ShutterDocument123 pagini1/3-Inch 1.2Mp CMOS Digital Image Sensor With Global ShutteralkrajoÎncă nu există evaluări

- SC300 InglesDocument172 paginiSC300 InglesJorge MolinaÎncă nu există evaluări

- Cebora S.P.A.: Service ManualDocument27 paginiCebora S.P.A.: Service ManualJefferson ChangoluisaÎncă nu există evaluări

- HCI Designquestions AakashDocument2 paginiHCI Designquestions Aakashvijay1vijay2147Încă nu există evaluări

- KSK BenefitsDocument13 paginiKSK Benefitsksm256Încă nu există evaluări

- List of Important/ Useful SAP Technical Transaction Codes: ABAP DevelopmentDocument6 paginiList of Important/ Useful SAP Technical Transaction Codes: ABAP DevelopmentVenkatesh VykuntamÎncă nu există evaluări

- Chemgineering OGLASDocument2 paginiChemgineering OGLASSrdjanÎncă nu există evaluări

- Assignment - 1Document3 paginiAssignment - 1Abdul WadoodÎncă nu există evaluări

- Action Plans and EU Acquis Progress Report 2023 WEBDocument212 paginiAction Plans and EU Acquis Progress Report 2023 WEBRaza KandicÎncă nu există evaluări

- Security TrainingDocument14 paginiSecurity TrainingmmeridiusÎncă nu există evaluări

- Installation Manual for JUMONG General X-Ray MachineDocument50 paginiInstallation Manual for JUMONG General X-Ray MachineDaniel Parada Vanegas100% (3)

- Customer Portal - User Manual 2021-07Document58 paginiCustomer Portal - User Manual 2021-07Nurul HidayatÎncă nu există evaluări

- Philippine Merchant Marine School: First YearDocument5 paginiPhilippine Merchant Marine School: First YearCris Mhar Alejandro100% (1)

- Labview Pda Module Release Notes: © 2003 National Instruments Corp. All Rights Reserved. Printed in IrelandDocument14 paginiLabview Pda Module Release Notes: © 2003 National Instruments Corp. All Rights Reserved. Printed in IrelandMaynor JarquinÎncă nu există evaluări

- Erdt EssayDocument2 paginiErdt EssayJuan Carlos Dela CruzÎncă nu există evaluări

- E560 23ba23 DSDocument4 paginiE560 23ba23 DSJoao SantosÎncă nu există evaluări

- Date 18 March 2021 Name: Ayu Andira Class: 1A/03Document9 paginiDate 18 March 2021 Name: Ayu Andira Class: 1A/03ayu afÎncă nu există evaluări