Documente Academic

Documente Profesional

Documente Cultură

OneCAD Whitepaper What Is FEA 2013

Încărcat de

Ruth Pauline HutapeaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

OneCAD Whitepaper What Is FEA 2013

Încărcat de

Ruth Pauline HutapeaDrepturi de autor:

Formate disponibile

Your Design Partner

What is FEA & CFD? And more importantly what it means to you?

While we could get into the mathematics and engineering and how it works what's most important to our clients is

"What's it going to do for me?" and "How will it help my products?".

FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) are both branches of CAE (computeraided engineering ) whereby we're using the power of computers to solve what can be the most complicated

engineering problems.

FEA & CFD involves some of the highest levels of mathematics, engineering, computer programming and computer

software & hardware specifications, and can give amazing results that can be displayed in picture and diagram

format that is easily understood.

Top left: CFD simulation of 4 engine

aircraft "jet blast" against C-shaped blast

fence.

Top right & lower left: examples of

results of FEA studies - red shows high

stress areas.

Lower right: CFD simulation of wind load

on solar energy panels.

Both FEA & CFD allow us to validate and optimize our designs to best ensure that we meet our goals for the

required safety, performance and quality standards. This can be done before any materials are cut and fastened

together. FEA & CFD methods are widely accepted as the best form of simulation for real world situations but like

all areas of engineering and science it is constantly improving through new knowledge obtained by research &

development.

With FEA you can solve, for example, static structural problems, mass transport, heat transfer, dynamics, stability

and radiation problems. In the simplest form, FEA helps answer the question of how strong is my new design. In the

more complicated problems you can simulate on the computer what happens in a car accident to the vehicle, the

driver and the passengers and then use these answers to design safer vehicles.

325 Renfrew Drive, Suite 202, Markham, ON Canada L3R 9S8

(905) 943-7667 Fax (905) 943-7411 info@onecad.com www.onecad.com

Page 1 of 2

Your Design Partner

FEA gives us the chance to answer the "what if" scenarios. What if we use a different material, that is lighter or

stronger and more cost-effective to manufacture? What if we change the design due to a new manufacturing

process? Will it fail? Will it withstand the forces? Where do we need to improve it? Now that we know the weak

points, what if we use larger (stronger) cross sections in this area? (i.e. thicker beams) Where is it "over-designed"?

Where can we save on materials and costs since the loads in these areas are lower than other areas?

With CFD we can calculate the path of the fluid flow of a liquid or gas and how it behaves or reacts in respect to the

objects that it encounters along its pathway. Many people may be familiar with seeing videos of wind tunnel testing

of the air flow over a new car design showing how "sleek" and "smooth" the car is as it cuts through the wind. This

is all done with the goal of making the car more aerodynamic and ultimately more fuel efficient. Performing a CFD

study on the vehicle allows us to simulate the wind tunnel test and run all the possible "what if" scenarios so that we

can test as many different designs changes as we wish before choosing the best and finishing our design.

CFD simulation of jet blast against jet blat fence.

With a CFD study, the analyst can also determine the forces that the fluid projects onto the objects in its path and

using those values, in a subsequent FEA study, they can determine how the structure of the object is affected by

the fluid. For example, at OneCAD we use CFD to test the design of our jet blast fence and its efficiency to deflect

the jet blast based on our client's needs (i.e. to deflect the flow over a roadway or building). We then with FEA apply

the resultant pressures obtained from the CFD on the face of the fence surface to verify the strength of the fence

structure.

Bottom Line: Utilizing FEA & CFD while still in the design stage is the best way to optimize a design and solve

problems before they happen resulting in better and safer products and overall lower costs during the lifecycle of

the product.

About OneCAD Solutions Ltd.

OneCAD Solutions is the 911 of mechanical design services. OneCAD provides mechanical engineering

contract design services, 3D CAD & 2D drafting, FEA & CFD analysis and reverse engineering. OneCAD will

work on your design projects when overtime wont keep you on schedule and hiring your next designer cant be

justified. OneCAD is authorized by the Professional Engineers of Ontario to offer professional engineering

services.

325 Renfrew Drive, Suite 202, Markham, ON Canada L3R 9S8

(905) 943-7667 Fax (905) 943-7411 info@onecad.com www.onecad.com

Page 2 of 2

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- 68rfe IntroductionDocument71 pagini68rfe IntroductionThePokeOne83% (6)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Preparing For Pre-Employment Math TestingDocument8 paginiPreparing For Pre-Employment Math TestingNathaliene ItliongÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Seven Seals of Revelation and The SevenDocument14 paginiThe Seven Seals of Revelation and The Sevenyulamula100% (2)

- IELTS Writing Task 2 Band 9 SamplesDocument40 paginiIELTS Writing Task 2 Band 9 SamplesRuth Pauline Hutapea100% (1)

- AutoCAD® 2007 TutorialDocument29 paginiAutoCAD® 2007 Tutorialzekazak100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- EPC Template: Engineering, Procurement and Construction AgreementDocument59 paginiEPC Template: Engineering, Procurement and Construction Agreementjunaid112Încă nu există evaluări

- Facelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger FaceDocument136 paginiFacelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger Faceugur gebologluÎncă nu există evaluări

- GMP DOC & QUALITY PRINCIPLESDocument38 paginiGMP DOC & QUALITY PRINCIPLESchandraswamitelgo100% (2)

- Experience PDF1Document159 paginiExperience PDF1Ruth Pauline HutapeaÎncă nu există evaluări

- PTW QuestionareDocument63 paginiPTW QuestionareIshtiaq Ahmad100% (2)

- How To Write Great EssaysDocument129 paginiHow To Write Great EssaysnuluparthaÎncă nu există evaluări

- Peptan - All About Collagen Booklet-1Document10 paginiPeptan - All About Collagen Booklet-1Danu AhmadÎncă nu există evaluări

- CMC4 Controller Technical Support DocumentDocument148 paginiCMC4 Controller Technical Support DocumentZurab ChanturiaÎncă nu există evaluări

- 05 Askeland ChapDocument10 pagini05 Askeland ChapWeihanZhang100% (1)

- Openstack Deployment Ops Guide PDFDocument197 paginiOpenstack Deployment Ops Guide PDFBinank PatelÎncă nu există evaluări

- What Does You Power Bill Pay ForDocument1 paginăWhat Does You Power Bill Pay ForRuth Pauline HutapeaÎncă nu există evaluări

- History of BatikDocument21 paginiHistory of BatikRuth Pauline Hutapea100% (1)

- Tsunami Analysis 2017Document56 paginiTsunami Analysis 2017Ruth Pauline HutapeaÎncă nu există evaluări

- Lecture6 BENCHMARKSOFCRUDEOILS PDFDocument33 paginiLecture6 BENCHMARKSOFCRUDEOILS PDFRuth Pauline HutapeaÎncă nu există evaluări

- 6429 22HC Worksheets CalendarDocument1 pagină6429 22HC Worksheets CalendarAsmir CoricÎncă nu există evaluări

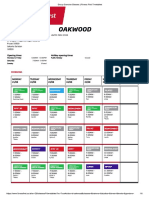

- Oakwood ScheduleDocument5 paginiOakwood ScheduleRuth Pauline HutapeaÎncă nu există evaluări

- Excel Logical Functions: Guide To Topics: For A Result That... ... Is A Logical Value (True or False) UseDocument33 paginiExcel Logical Functions: Guide To Topics: For A Result That... ... Is A Logical Value (True or False) UserajÎncă nu există evaluări

- List of Engineering Companies Aug 2012Document6 paginiList of Engineering Companies Aug 2012Muhammad ZubairÎncă nu există evaluări

- Nine Document Management Risks OnBaseDocument11 paginiNine Document Management Risks OnBaseRuth Pauline HutapeaÎncă nu există evaluări

- 4.5.4 Inspections and AuditsDocument7 pagini4.5.4 Inspections and AuditsRuth Pauline HutapeaÎncă nu există evaluări

- Oleg Private English Brochure Final 12 Oktober 2016Document1 paginăOleg Private English Brochure Final 12 Oktober 2016Ruth Pauline HutapeaÎncă nu există evaluări

- Wedding Music LiturgyDocument8 paginiWedding Music LiturgyRuth Pauline HutapeaÎncă nu există evaluări

- Customer Code Customer Name Credit LimitDocument7 paginiCustomer Code Customer Name Credit LimitRuth Pauline HutapeaÎncă nu există evaluări

- Writing Task 2 Band 8 - 9Document23 paginiWriting Task 2 Band 8 - 9Emad MerganÎncă nu există evaluări

- Test PDFDocument74 paginiTest PDFRuth Pauline HutapeaÎncă nu există evaluări

- Writing Task 2 Band 8 - 9Document23 paginiWriting Task 2 Band 8 - 9Emad MerganÎncă nu există evaluări

- TheLordBlessYou LyricsDocument1 paginăTheLordBlessYou LyricsRuth Pauline HutapeaÎncă nu există evaluări

- Writing Task 2 Band 8 - 9Document23 paginiWriting Task 2 Band 8 - 9Emad MerganÎncă nu există evaluări

- STM Engineering Services1Document22 paginiSTM Engineering Services1Ruth Pauline HutapeaÎncă nu există evaluări

- Mk5 MooringSystem PDFDocument2 paginiMk5 MooringSystem PDFRuth Pauline HutapeaÎncă nu există evaluări

- 0930-AlexaaDocument30 pagini0930-AlexaaRuth Pauline HutapeaÎncă nu există evaluări

- The Issue of Body ShamingDocument4 paginiThe Issue of Body ShamingErleenÎncă nu există evaluări

- Hci01 HumanComputerInteraction OverviewDocument140 paginiHci01 HumanComputerInteraction OverviewAlexSpiridonÎncă nu există evaluări

- A. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Document12 paginiA. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Nur HaeniÎncă nu există evaluări

- Deconstructing Product Design Exploring The Form, Function, Usability, Sustainability, and Commercial Success of 100 Amazing Products PDFDocument100 paginiDeconstructing Product Design Exploring The Form, Function, Usability, Sustainability, and Commercial Success of 100 Amazing Products PDFMontserrat CifuentesÎncă nu există evaluări

- Eco 301 Final Exam ReviewDocument14 paginiEco 301 Final Exam ReviewCảnh DươngÎncă nu există evaluări

- Scope of Incubator CentersDocument3 paginiScope of Incubator Centersanon_542600428Încă nu există evaluări

- TG KPWKPDocument8 paginiTG KPWKPDanmar CamilotÎncă nu există evaluări

- 1.9 Bernoulli's Equation: GZ V P GZ V PDocument1 pagină1.9 Bernoulli's Equation: GZ V P GZ V PTruong NguyenÎncă nu există evaluări

- Oposa vs. Factoran 224 Scra 792Document28 paginiOposa vs. Factoran 224 Scra 792albemartÎncă nu există evaluări

- Advancements in Organic Rankine Cycle System Optimisation For Combined Heat and Power Applications Components Sizing and Thermoeconomic ConsiderationsDocument14 paginiAdvancements in Organic Rankine Cycle System Optimisation For Combined Heat and Power Applications Components Sizing and Thermoeconomic ConsiderationsGuadalupe Abigail Rueda AguileraÎncă nu există evaluări

- MRP Format MbaDocument6 paginiMRP Format Mbasankshep panchalÎncă nu există evaluări

- Infineum Ilsa Gf-6 API SP e JasoDocument28 paginiInfineum Ilsa Gf-6 API SP e JasoDanielÎncă nu există evaluări

- Mobile-Friendly Cooperative WebDocument7 paginiMobile-Friendly Cooperative WebWahyu PÎncă nu există evaluări

- Implementing a JITD system to reduce bullwhip effect and inventory costsDocument7 paginiImplementing a JITD system to reduce bullwhip effect and inventory costsRaman GuptaÎncă nu există evaluări

- Polifur 1K Synthetic Top Coat MSDS Rev 2 ENDocument14 paginiPolifur 1K Synthetic Top Coat MSDS Rev 2 ENvictorzy06Încă nu există evaluări

- CVR College of Engineering: UGC Autonomous InstitutionDocument2 paginiCVR College of Engineering: UGC Autonomous Institutionshankar1577Încă nu există evaluări

- E TN SWD Csa A23 3 94 001 PDFDocument9 paginiE TN SWD Csa A23 3 94 001 PDFRazvan RobertÎncă nu există evaluări

- Repair Max II Pump 310894lDocument20 paginiRepair Max II Pump 310894lAndreina FajardoÎncă nu există evaluări

- Learn R For Applied StatisticsDocument457 paginiLearn R For Applied StatisticsyasortyÎncă nu există evaluări

- Encrypt and decrypt a file using AESDocument5 paginiEncrypt and decrypt a file using AESShaunak bagadeÎncă nu există evaluări

- ARTS 9 Q4 Week 1Document3 paginiARTS 9 Q4 Week 1Elaissa MaglanqueÎncă nu există evaluări

- Assignment No. 8 (Culture 1) : Discuss The Significance of Montessori Cultural Exercises.? Hfodhfsfnsfsfsajk AnsDocument10 paginiAssignment No. 8 (Culture 1) : Discuss The Significance of Montessori Cultural Exercises.? Hfodhfsfnsfsfsajk Anseman zahraÎncă nu există evaluări