Documente Academic

Documente Profesional

Documente Cultură

US7361326

Încărcat de

Lily DianaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

US7361326

Încărcat de

Lily DianaDrepturi de autor:

Formate disponibile

llllllllllllllllllllllllllllllllllllllllllllllllll"IlllllllllllllIllllllll

USOO5l98206A

United States Patent [191

[11]

Schoubye

[45]

[54] CONDENSING SULFURIC ACID VAPORS

To PRODUCE SULFURIC ACID

[75]

Inventor:

[56]

Patent Number:

Date of Patent:

5,198,206

Mar. 30, 1993

References Cited

FOREIGN PATENT DOCUMENTS

Peter Schoubye, Horsholm, Denmark

705824 3/1965 Canada .............................. .. 423/522

1052188 12/1966 United Kingdom .............. .. 423/522

[73]

Assignee:

Haldor Topsoe A/S, Denmark

2072542 10/1981 United Kingdom -

2117368 10/1983 United Kingdom .

[21] Appl' No:

.

623,409

_

Primary Examiner-Gregory A. Heller

Attorney, Agent, or Firm-Ostrolenk, Faber, Gerb &

[22] PCT Filed.

May 22, 1989

Soffen

[86] PCT No.:

371 Date:

PCI/DK89/00l33

Dec. 6, 1990

[57]

ABSTRACT

When condensing sulfuric acid from gases containing

Dec 6 1990

from a power station, a substantial decrease of the

wow/12025

amount minute droplets of sulfuric acid (the so-called

acid mist) escaping to the surroundings is obtained, even

in cases where the sulfuric acid plant is equipped with

102(e) Date

[87] PCT Pub. NO:

sulfuric acid vapor and steam in excess, e.g. originating

PCT Pub. Date: Dec. 14, 1989

[30]

Foreign Application Priority Data

Jun. 9, 1988 [DK]

[51]

[52]

_

Denmark ........................... .. 3125/88

Int. Cl.5 ..................... .. C01B 17/74; COlB 17/ 82

U.S. Cl. .................................. .. 423/522; 423/528;

an aerosol ?lter, if minute nucleation cores are incorpo

rated into the gas in an amount of 109 to 1012 solid parti

cles per Nm3 per 0.1- % H2SO4-vapor in the gas. The

nucelation cores may, e.g., be generated by combusting

hydrocarbons with>2 carbon atoms or silicones, or

added as smoke from an electric are or welding.

423/529

[58]

19 Claims, 4 Drawing Sheets

Field of Search ...................... .. 434/522, 528, 529

.1

AIR

US. Patent

Mar. 30, 1993

Sheet 1 of 4

5,198,206

AIR

US. Patent

Mar. 30, 1993

Sheet 2 of4

m

9

0N.

mp

QEOMaNmI m hCuUdE.

w_2.mx0Z=o\m.iDO

_ 5,198,206

.QEN

US. Patent

Mar. 30, 1993

Sheet 3 of 4

5,198,206

4% FILTER

3L

g TA1

36E E. _'

38;

FIG. 3

L0;

HZO-VAPOURM 42

___[X

I I

_

22

_\3O

/32

20

AIR

"'\.../

I -_\_Q

24

S02

TA;

35

- I:

1/30

28

T1 J

SULFURIC

ACID

US. Patent

Mar. 30, 1993

FIGL

Shget 4 of 4

5,198,206

5,198,206

CONDENSING SULFURIC ACID VAPORS T0

PRODUCE SULFURIC ACID

ward direction (optionally in part crosscurrently)

within certain speci?ed limits.

The process known from this publication has been

improved according to DK patent application No.

FIELD OF THE INVENTION

2989/88 so as to be particularly but not exclusively

The present invention relates to a process in the pro

duction of sulfuric acid to condense sulfuric acid va

pours from a gas mixture containing 0.01 to 10% by vol.

suitable for use when condensing sulfuric acid from

gases having a low content of vapours of H2804. Such

gases may originate from ?ue gases and other industrial

waste gases; S02 therein has then been'oxidized to S03

of H1804 vapour, calculated under the assumption that

$03 is fully hydrated, and 0 to 50% by vol. of aqueous

over a sulfuric acid catalyst and reacted with steam.

vapour, by direct or indirect cooling in a sulfuric acid

The condensation takes place in a large number of tubes

which each in the top has a small ?lter causing a drop of

tower.

pressure of typically 5 to 10 mbar, the gas containing

BACKGROUND OF THE INVENTION

sulfuric acid ?owing in an upward direction in counter

15

current with the gaseous coolant ?owing in a down

When producing sulfuric acid the acid is in many

ward direction externally around the tubes. A

cases obtained in the form af vapours of H2SO4 in ad

prerequisite for the ability of this ?lter to separate the

mixture with aqueous vapour (i.e. steam). This is for

instance the case in the important sulfuric acid process

acid droplets/acid mist (and to allow sulfuric acid to

which consists of a catalytic oxidation, normally over

?ow downwards through the tubes in countercurrent

an alkali promoted vanadium catalyst, of S02 to form

with the gas) down to a residual content of the above

S03 which is subsequently hydrated by steam to form

cooling process. This sulfuric acid process is important,

i.a., in connection with the puri?cation of ?ue gases for

mentioned about 40 mg/Nm3 is that the temperatures

TA1 and TA; of the cooling air to and from, respec

tively, the condenser and the temperature T; of gas

leaving the tube and ?lter satisfy the following three

sulfur.

conditions:

sulfuric acid vapour, and that must be condensed in a

When condensing the sulfuric acid vapours, which

can take place by cooling under various circumstances,

a socalled acid mist (sulfuric acid mist) is formed, i.e. a

kind of aerosol consisting of very small droplets of

sulfuric acid in the gas mixture from which the sulfuric

acid is condensed and which will normally contain

steam in a larger amount than that needed for the full

hydration of S03 into H2804. It important to prevent

the escape of substantial amounts of the acid mist to the

surroundings; for environmental reasons a maximum of

escape of sulfuric acid mist is ?xed at about 40 mg

H2S04/Nm3, corresponding to 9 ppm H2804.

It is known to regulate the escape of acid mist by

regulating the temperature of the coolant. Thus, there is

described in DK patent speci?cation No. 145,457 (U.S.

T2-TA1<90' c.

(3)

wherein T4 is the sulfuric acid dew point of the feed gas

passed to the tubes, ais the percentage by volume of

H2804 in this gas under the assumption that S03 is

completely hydrated to H2804 and T2 is the tempera

ture at which the vapour pressure of H2504 is about 2 x

l0-6 bar in equilibrium with the partial steam pressure

prevailing at the outlet of the top of the tubes (corre

sponding to about 2 ppm sulfuric acid vapour; T2 usu

ally is between 100 and 125 C.)

In the following the expression sulfuric acid tower

Pat. No. 4,348,373) a process for preparing concen

means a packed absorption tower as described in US.

trated sulfuric acid from gases containing S03 and ex

patent speci?cation Ser. No. 4,348,373 (DK 145,457) or

cess of H20. The gas is cooled and the sulfuric acid

condensed and concentrated in two steps in an absorp 45 a tower containing tubes as described in one of the other

publications mentioned above.

tion tower containing ?ller bodies. In the lowermost

step the feed gas is passed upwardly countercurrently

BRIEF DESCRIPTION OF THE INVENTION

with the condensed acid,the concentration of which is

thereby increased In the subsequent step the sulfuric

acid vapour is absorbed in sulfuric acid recycled

It has, however, been surprisingly found that the

?lterability of the droplets in the acid mist is highly

through the layer containing ?ller bodies. The content

of sulfuric acid mist is kept down by virtue of a speci?ed

regulation of the temperature; by this the recycle acid is

dependent on the content of small particles in the gas

before the condensing starts, under otherwise the same

conditions of operation. These particles serve as nuclei

around which the sulfuric acid vapour condenses, so

removed from the tower. Remaining acid mist is re

moved in an aerosol ?lter placed after the absorption

called nucleation cores or nucleation seeds.

More fully explained the content of acid mist in the

gas discharged to the surroundings from a sulfuric acid

tower is reduced if according to the invention. the gas

containing the sulfuric acid vapours of which is to be

From DK patent application No. 1361/ 82.(GB patent

speci?cation No. 2,117,368) there is known a process 60 condensed is given a content of 109 to 1012 solid parti

cles per Nm3 per 0.1% H2S04-vapour before the in?ow

for preparing sulfuric acid in which sulfuric acid vapour

of the gas into the sulfuric acid tower, calculated under

in gases containing 0.01 to 10% H2804 vapour and 0 to

the assumption that S03 here is completely hydrated to

30% steam is condensed in vertical, 9as cooled, acid

resistant tubes. The presence of large amounts of acid

H2804.

This process is universal and may be used both in

mist in the gas after the condensing is avoided accord 65

zone. The ?lter is a low velocity ?lter operating at a

linear velocity below 1 m/s and with a pressure drop

above 20-30 mbar.

ing to this patent by keeping the temperature difference

industrial processes having the production of sulfuric

between the sulfuric acid-containing gas streaming in an

upward direction and the coolant streaming in a down

ric acid,including highly concentrated sulfuric acid,as a

acid as the main purpose and in the production of sulfu

5,198,206

by-product from the puri?cation of industrial waste

various types of bag ?lters especially those are pre

ferred that contain a membrane of Te?on (polytet

rafluoroethylene) which hold back all particles down to

gases, for instance ?ue gases from power stations.

According to the invention the nucleation according

to the invention thus may be carried out under cooling

a diameter below 0.01 pm. The smoke is then heated in

in a packed sulfuric acid tower in countercurrent with 5 a heat exchanger 5 to about 390 C.,and by direct heat

circulating sulfuric acid as coolant, in other words uti

ing with an oil burner 6 heated to 420 C. in a reactor in

lizing otherwise the process known from DK patent

which about 96% of the content of SO; in the gas is

converted to S03 by the aid of an alkali promoted vana

speci?cation No. 145,457 (U.S. Pat. No. 4,248,373).

The process according to the invention may also be

dium catalyst This catalyst has the further property that

in operation it catches about 95% of the remaining

practized under cooling of the gas mixture containing

sulfuric acid in substantially vertical, externally cooled

contents of dust in the gas, this because the surface of

the catalyst is moistened with a melt of alkali pyrosul

fates. The SO3-containing gas is thereafter cooled in the

tubes in which the gas mixture ?ows from the bottom in

an upward direction in countercurrent with a prefera

bly gaseous external coolant, i.e. in accordance with the

method known from GB patent speci?cation No.

2,117,368.

15

The invention has especially been useful in combina

tion with the process known from DK patent applica

tion No. 2989/88 and an advantageous embodiment

heat exchanger 5 to about 250 C. whereby the major

part of the content of S03 in the gas is hydrated to

H2504 vapour which is thereafter condensed to liquid

sulfuric acid in vertical, air-cooled glass tubes in a sulfu

ric acid condenser 8 (glass tube-tower) in which the gas

consequently is characterized in using it when condens 20 is cooled to 100' C. and the cooling air is at the same

time heated from typically 20 C. to 190 C. The glass

ing the sulfuric acid vapours which after the condensing

tubes have the same dimensions and operate at the same

?ow downwards through the tubes as liquid, highly

concentrated sulfuric acid, said H2SO4-vapours coming

conditions as simulated in the experimental apparatus

from gases containing 0.01 to 10% by vol. of H2504

shown in FIG. 3, except that the air ?ows crosscur

vapour, calculated under the assumption made herein 25 rently and six strokes in countercurrent with the gas in

before, and 0 to 50% by vol. of steam, the gas being

the tubes. At the top of each of the glass tubes there has

admitted from the bottom at a temperature of at least

been mounted a drop ?lter for separating droplets of

the sulfuric acid dew point at the conditions of pressure

sulfuric acid as described in Danish patent application

No. 2989/88. Filter 4 and S02 reactor 7 normally will

during the flow in the upward direction to an exit tem 30 ensure that the number of particles in the gas is smaller

perature T; which is lower than the temperature at

than optimum for the separation of sulfuric acid in the

which the vapour pressure of H2804 is about 2X10-6

drop ?lters, which of course is a prerequisite for opti

bar in equilibrium with the partial pressure of steam

mizing the separation of acid droplets by the addition of

prevailing at the outlet of the tubes in the top, the tubes

particles to the gas stream.

and temperature prevailing in the tube,and being cooled

being cooled externally with a gaseous medium ?owing

substantilaly countercurrently with the sulfuric acid

comaining gas, said gaseous medium thereby being

35

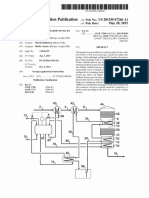

Reference numeral 20 denotes a blower which in

many cases may advantageously be placed at this site of

the plant; in other cases it is presupposed to be present

heated from an inlet temperature TA1 of 0-50" C. to an

somewhere else in the total installation, e. g. as a blower

'of fresh air to the boiler.

In the plant shown in FIG. 1 the addition of nucleat

outlet temperature TA; satisfying the condition

mph-3040a C.

ing particles takes place by the aid of an oil ?red support

where Td and a have the meanings de?ned hereinbe

fore.

burner 6 which thereby has two functions controlled

automatically by the aid of a process computer 9, viz. to

DETAILED DESCRIPTION OF THE

keep the temperature of the gas passed to the S02 con

INVENTION

45 verter at a ?xed temperature (420 C.),which is

The process according to the invention will be de

achieved by regulating the introduction of the oil into

scribed more fully in the following, partly with refer

the burner; and to generate the optimum amount of

ence to the drawings in which

nucleation particles, which takes part by a simultaneous

FIG. 1 schematically shows a plant suitable for carry

regulation of the ratio air/oil passed to the burner in

ing out the process according to the invention,

such way that the signal to the process computer from

FIG. 2 represents curves showing the content of acid . an automatically operating acid mist meter 10 in the gas

mist in the discharge gas after an aerosol ?lter and after

after the sulfuric acid condenser shows a minimum of

the addition of varying amounts of solid particles,

content of acid mist in the gas, or at least that the con

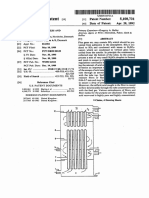

FIG. 3 schematically shows an experimental appara

' tent of acid mist is below a ?xed maximum of 10 ppm

tus, and

'

55

FIG. 4 a ?lter employed in this apparatus.

FIGS. 3 and 4 are identical with FIGS. 2 and 3 in DK

patent application No. 2989/88

In FIG. 1 a plant is shown in which the process ac

H1804. The process computer performs the regulation

according to commonly known principles. If instead of

heating the gas before the S02 reactor with an oil or

propane gas ?red burner it is chosen to use indirect

cording to the present invention may be expediently 60 heating, the addition of particles may expediently take

place as smoke from an electric are or from burning

carried out in connection with the puri?cation of the

smoke from a power station boiler stoked with sulfur

containing coal or oil. The smoke from a boiler -1 is

cooled in an air preheaterZ and then in a trim boiler 3

to about 200 C. ahead of a dust ?lter 4 in which the 65

content of ?y ash and dust particles of the smoke is

separated to a content of below 20 mg/Nm3 preferably

to below 5 mg/Nm3' by the aid of a bag ?lter. Amongst

hydrocarbons, or an aerosol of a solution of, e.g., iron

sulfate. The rate of the addition of particles is regulated

by the aid of a regulation loop containing a continu

ously operating meter for the content of acid mist in the

gas after the sulfuric acid condenser. As dust ?lter a bag

?lter is preferred because this ensures best that the parti

cles will be present in de?cit.

5,198,206

Whereas an operating plant as shown in FIG. 1 con

tains a very large number of tubes, e.g. for a power

station having a capacity of 300 MW a number of the

acid mist after the ?lter when smoke from a cigarette,

sparks from a grindstone or smoke from electrowelding

etc. was added to the air supplied to the blower 20

magnitude of 60,000 tubes, the experimental plant

(FIG. 3); or when smoke from the combustion of hydro

shown in FIG. 3 contains one tube only. It has a capac

carbons containing more than two carbon atoms in the

molecule was added, provided that the air/fuel ratio

was adjusted to render the ?ame faintly luminous.

When larger amounts of smoke were added the content

of acid mist after the ?lter again increased strongly. The

it with steam and gaseous S0; to obtain a desired gas

composition. The gas mixture is heated further to about 10 acid mist content after the ?lter in the experiments re

ported in Table 1 could also be in?uenced strongly by

420' C. in an electric heater 24 after which it is passed

altering solely the charge on the blower 20 used in these

through a catalytic reactor 26 in which about 96% of

experiments; the blower was an ordinary domestic vac

the content of SO; in the gas is oxidized to form S03 by

uum cleaner of the brand Nil?sk , equipped with a

the aid of a sulfuric acid catalyst of known type contain

commutator motor which is cooled by the air passing

ing vanadium and potassium as active components.

the blower The content of droplets of sulfuric acid in

Subsequently the gas is cooled in a heat exchanger 28 to

the gas after the ?lters dropped signi?cantly when the

about 250 C. (T1) before entering a sulfuric acid con

load on the motor was increased by throttling a valve

denser consisting of a single glass tube 30 having a

inserted in the air stream before or after the blower. At

length of 6 m, an id. (inner diameter) of 36 mm and an

o.d. (outer diameter) of 40 mm. In the upper 5.4 m of 20 the stronger load the commutators will sparkle more,

whereby an increased amount of particles of coal and

the length of the glass tube it is encased in a bigger tube

metal are delivered to the air from the electrical point of

32 through which cooling air is passed from a blower

contact with the rotor of the motor. These observations

34, causing the gas stream in tube 30 to be cooled conn

are described more fully in the following.

tercurrently with the air stream in the outer tube The

ity to treat up to 20 Nm3/h gas containing sulfuric acid,

prepared by taking in air from the room by the aid of a

blower 20, heat the air in an electric heater 22 and mix

outer tube is insulated with 100 mm mineral wool. The 25

The measurings of the acid mist were carried out

cooling air can be introduced via one of a plurality of

with a continuously operating photometric aerosol

valves 36, 38, 4-0 and 42; hereby the cooled zone can be

adjusted to 5.4, 4.95, 4.55 or 4.05 rn, respectively. The

conditions of ?ow of the cooling air are adapted in a

manner such that the heat transmission value (hv) at the 30

meter which was frequently calibrated by chemical

determinations of the content of H2804 in the gas; the

determinations were made according to the method

described in EPA directive EPA-600/3-84056 (April ,

outer side of the tube is as in a corresponding tube in an

1984). The conditions of operation so far as ?ow, tem

industrial plant.

peratures, length of the cooling zone and drop of pres

sure are concerned, were selected from Table l and

FIG. 4 shows one of several possible ?lter types for

now repeated with varying contents of nucleation parti

use in the experimental plant. FIG. 4 is identical with

FIG. 3 in DK patent application No. 2989/88 and that 35 cles

By repeating experiment No. l-l the following con

?lter is denoted ?lter A. It consists of a cylindrical glass

tents of H2804 in the gas after the ?lter A were found.

tube, hereinafter denoted ?lter cartridge 50, having an

a) 6 to 10 ppm when using pure inlet air and the same

inner diameter of 46 mm and a length of 200 mm. The

motor load as in the original experiment;

?lter cartridge 50in the bottom has a neck 52 the outer

b) the acid mist dropped to about 1 ppm when in

diameter of which is 40 mm; by the aid of an outer 40

creasing the load to a value near the load limit of the

tightly ?tting Te?on sleeve 54 it is connected to

motor, after which the acid mist appeared to increase

the glass tube 30 having the same outer diameter. The

anew when overloading the motor;

drop of pressure through the ?lter cartridge is measured

0) 50 to 100 ppm with pure air when instead of the

by the aid of a branched pipe 56 led through the sleeve.

A ?lter medium 58 is placed in the ?lter cartridge; it 45 abovementioned vacuum cleaner there was employed a

blower in which the air did not come into contact with

consists of ?laments of a ?uorocarbon polymer having

the motor. Puri?cation of the inlet air in a bag ?lter did

a thickness of 0.3 mm and knitted to form a web having

not alter the content of acid mist appreciably.

a width of about 150 mm, the web being rolled to ?t into

In the following experiments a blower was used in

the cartridge. This roll has the same diameter as the

which the air did not come into contact with the motor.

internal diameter of the ?lter cartridge. The ?lamentous

d) The addition of a few cm3/sec. welding smoke

material constitutes about 7% of the volume of the roll.

from electrowelding with, e.g.,iron electrodes to the

When the droplets of sulfuric acid present in the gas

feed gas at 14 Nm3/h, caused the acid mist after the

move upwards through the roll the droplets are caught

?lter to drop anew to 0 to 1 ppm H2804. Larger

and agglomerate to form large drops which ?ow down

amounts of welding smoke, however, increased the acid

wards in countercurrent with the gas and pass further

mist drastically. By the addition of about 100 cm3/sec.

down in the glass tube.

welding smoke the content of acid mist rose to almost

A number of experimental results have been reported

in DK patent application No 2989/ 88, in part by the aid

1000 ppm, which means that almost all of the content of

H2804 in the inlet gas to the tube passed through the

of Tables. Some of Table l of that application has been

repeated hereinafter as Table l; in this T1 is the tempera 60 aerosol ?lter A. Another embodiment of the ?lter, de

noted Bl, with the same drop of pressure as ?lter A,

ture of the gas at the inlet into the tubes, m/s denotes the

was not more efficient than ?lter A whereas a ?lter B2

gas velocity through the ?lter, expressed in meters per

(A, B1 and B2 refer to the ?lters employed in DK

second, and Ap is the drop of pressure through the

2989/ 88) removed the acid mist down to 50 to 100 ppm

?lter, expressed in mbar millibars). Td, TA1 and TA; have

65 after the ?lter when overdosing the welding smoke.

the meanings given hereinbefore.

e) The acid mist also disappeared to below 1 ppm

When repeating these experiments it was surprisingly

H2804 by the addition to the feed gas of an aerosol of

found that by otherwise unaltered conditions of opera

iron sulfate particles prepared from an aerosol in air of

tion one measured a signi?cant drop in the content of

5,198,206

droplets of a 20% solution of ferrous sulfate which was

atomized by the aid of compressed air, after which the

minimize the acid mist seems to approach zero. At 6%

H2804 in the feed gas an effect of the particle concen

tration can still be seen and it appears to have its opti

mum at a concentration between 2 and 10 times the

content of water in the droplets was evaporated at 300

C. before the solid residue was added to the gas. It was

necessary to atomize 5 to 10 cm3/min. of the solution of 5 optimum particle concentration at 0.5% H2804. It is

observed that at 6% H1804 and a feed gas stream below

iron sulfate in order to obtain optimum removal of the

11 Nm3/H per glass tube (having an inner diameter of

acid mist.

36 mm) and optimum temperature conditions and opti

f) The addition to the gas before the S02 reactor of

smoke from the combustion of Diesel oil in an oil burner

gave the effect illustrated in FIG. 2 on the content of

acid mist after the aerosol ?lter. The addition of about

mum content of particles it is possible to obtain below

10 ppm H2804 in the outlet gas from the tube without

?ltering the gas in or after the tube.

In the experiments conducted so far it has not been

5% oil smoke in the gas passed to the condensing tube

possible to make absolute measurings of the amount or

reduced the acid mist to 0 to 1 ppm whereas the addi

tion of larger amounts of oil smoke caused the content ' the size of the particle added during the experiments

described. The content of particles in the optimum

of acid mist after the ?lter to rise to several hundred

ppm H2804. By lowering the excess of air in the ?ame

smoke produced by the combustion of hydrocarbons

so as to render the flame more yellow, yet without

gave no or only faintly visible haziness in the smoke

whereas the active welding or cigarette smoke is bluish,

this indicates that the particles must be smaller than

line in FIG. 2) needed to reduce the content of acid mist

to the minimum of 0 to 1 ppm was lowered. This indi 20 about 0.6 pm. The Telfon membrane ?lter dis

sooting appreciably, the amount of oil smoke (the dash

cates that very minute coal particles in the smoke act as

nucleation particles and that the particles entirely or

partly pass through the S02 reactor for the catalytic

oxidation of 80; without getting combusted.

g) Smoke from the combustion of propane and butane 25

had substantially the same effect on the acid mist as had

smoke from oil ?ring. Smoke from the combustion of

ethane had a weaker effect and was only active at air

de?cit. Smoke from the combustion of methane had no

effect on the acid mist, not even at air de?cit, suppos

edly because the methane ?ame could not be caused to

cussed under h) according to the manufacturer removes

particles down to below 0.01 pm but attempts at study

ing the particles from oil smoke and welding smoke

caughton such a ?lter failed, probably because they

penetrate into the ?lter. However, one can estimate the

optimum concentration of particles on the basis of the

following considerations on the mode of operation of

the particles:

During the condensing of the sulfuric acid in the

tubes the H2504 vapour in the gas ?lm on the tube walls

is supercooled. In case of a genuine ?lm condensing the

produce carbon particles in this experiment.

sulfuric acid vapour diffuses through this supercooled

h) The insertion in the gas stream before the S02

reactor of a very ef?cient bag ?lter having a Telon @

membrane, which detains all particles of a size above

gas ?lm and condenses on the walls. Sulfuric acid va

pour presumably (because of the low surface tension of

sulfuric acid) cannot be supercooled more than l0-30

about 0.01 pm, gave a content of H2504 after the aero

C. below the dew point before a spontaneous nucleation

sol ?lter of 50 to 100 ppm H2804 irrespectively of how

of sulfuric acid droplets takes place in the supercooled

much air was added before the bag ?lter from a spar

kling commutator motor, welding smoke or smoke from

?lm. The supercooled acid vapour continues to con

combusting hydrocarbons as described under f) and

g).This shows that particles and no other parameters in

connection with the experiments just reported caused

dense on these droplets and when passing upwardly

through the tube they will grow to a size such that they

are either thrown out onto the tube wall, or can be

easily removed by a coarse drop ?lter in the top of the

tube; this provided that there is not formed too many

droplets relative to the amount of acid vapour at the

In other experiments repeating the conditions of op 45 disposal of the growth of the drops. An increased tem

perature difference between the gas in the tubes and the

eration reported in Tables 1, 2 and 3 in DK 2989/88 it

the effect demonstrated on the content of H2804 in the

gas after the aerosol ?lter.

was found that under such conditions one must observe

coolant on the other side of the tube wall causes an

increased supercooling of the film and thereby an in

the rules laid down as conditions (1), (2) and (3) herein

creased number of droplets; this causes, notably at low

before,whereas they cannot be transferred directly to

the process known from e.g. DK 145,457 in which the 50 contents of H2804 in the feed gas, that the droplets do

coolant is condensed sulfuric acid.

not reach the size of at least 2 pm which is essential to

The addition of particles to the gas only alters the

allow them to be separated in the drop ?lters while

causing drops of pressure below 10 mbar. It is difficult

width of the temperature range and the minimum con

to control this spontaneous nucleation in the gas phase

tent of H2804 obtainable after the aerosol ?lter. This is

and it involves serious limitations in the operation of the

due to the fact that the presence in the feed gas of either

process; these limitations are avoided by the controlled

addition to the feed gas of particles acting as nucleation

rowing of the range and an increase of the minimum

cores to form precizely the optimum number of droplets

content of H2804 obtainable after the ?lter and/or an

of sulfuric acid. When too many particles are present

increase of the drop of pressure over the ?lter necessary

to obtain a certain minimum content of H2504. Inciden 60 too many droplets are formed and thereby a di?icultly

tally, it has been ascertained that the removal of acid

?ltrable acid mist is formed; if on the other hand too few

a too low or a too high content of particles causes nar

mist has its highest sensitivity to variations in the parti

particles are present the supersaturation/supercooling

cle content of the gas at concentrations of H2804 below

will be to high and cause spontaneous nucleation

about 0.5% in the feed gas and that the optimum parti

cle concentration increases almost proportionally to the

H2SO4-concentration up to about 0.5% H2804 in the

feed gas. At higher concentrations of H2804 the in

crease of the concentration of solid particles needed to

It does not seem that there is any limitation with

respect to the chemical composition of the solid parti

cles, or with respect to their size,to enable them to act as

nucleation cores. However, they should be as small as

possible in order to be able to pass, for instance, a cata

5,198,206

10

pass the gas stream with this admixture through a layer

lytic reactor for the oxidation of S02, and in order to

cause no noticeable pollution of the sulfuric acid pro

duced

Based on the assumption that each particle forms one

acid droplet, it can be easily calculated from the for

of a sulfuric acid catalyst at a temperature of 360 to

500 C. for the oxidation of S02 into S03 which is by

drated under the action of steam, and if desired to cool

the gas stream to 0200 C. above its sulfuric acid dew

point before it is fed to the sulfuric acid tower.

mula below that there is requested, for example,

2.6x l011 particles/Nm3 to condense 0.1% of H2804 in

the feed gas in the form of droplets of sulfuric acid

having a size of 3 pm, the droplets being separated in

Expediently the particles are added by the admixture

of smoke from the combustion of hydrocarbons, prefer

ably having at least 2 carbon atoms per molecule, either

the ?lter at a concentration of 75% sulfuric acid and a

the air/fuel ratio 7t of the burner or the added amount of

density of 1.6 g/em3. As far as orders of magnitude are

hydrocarbons being regulated by the aid of an auto

matic regulation loop containing an analyzer for mea

suring the content of sulfuric acid droplets in the gas

concerned this is in accordance with experiment d)

reported hereinabove and carried out with welding

smoke. The welding smoke admitted contained about 1

gram of iron oxide per Nm3, probably having an aver

age diameter of 0.1 um. Accordingly, the smoke con

after it has left the sulfuric acid tower or the means for

separating droplets of sulfuric acid, signals from the

analyzer continuously adjusting and correcting )t or the

tained about 6 X lOlparticles per Nm3; this corresponds

added amount of smoke so as to ensure that the content

to an addition of about 1.6 cm3 welding smoke per sec

of sulfuric acid droplets in the gas becomes as Small as

ond in order to obtain 2.6X l011 particles/Nm3 in the 14

possible and preferably below 10 ppm H2804 in the

Nm3/h of feed gas to the tube. In spite of big uncertain 20 discharge gas.

ties in such calculations, this is consistent with what was

When the smoke gas from the boiler contains a high

established experimentally. At least it can be concluded

concentration of particles having a size below 1 pm,

with a good range of certainty that for optimum separa

which is frequently the case when ?ring with coal dust,

tion of the droplets of sulfuric acid there should be

it is even possible according to the invention to give the

25

added between 109 and 1012 particles present per Nm3

gas passed to the sulfuric acid condenser the desired

feed gas to the tubes per 0.1% H2504 vapour in the feed

content of nucleation particles by the controlled addi

gas. It is important for the purity of the condensed

tion of small particles from the ?ue gas by the following

method: The ?y ash-containing gas from the boiler is

sulfuric acid that the nucleation particles are small. For

instance, 2.6X 1011 particles having a size of 0.1 pm per

0.1% H2CO4 in the gas would give a content'of 80 ppm

by weight of iron oxide in the concensed sulfuric

acid, whereas particles having a size of 0.05 pm would

give 10 ppm in the acid.

According to the invention one therefore cools the

subdivided into a stream, normally a main stream, from

which all or nearly all of the particles are removed in an

efficient bag ?lter, e.g. in a bag ?lter equipped with

Te?on membranes, and another, normally lesser

stream which is regulated in the above manner and

which is caused to bypass the ?lter and is subsequently

gas mixture in substantially vertical, externally cooled

admixed into the main stream ahead of the sulfuric acid

condenser. It is especially convenient to admix said

tubes wherein the feed gas ?ows from the bottom in an

upward direction countercurrently with an external

coolant which is preferably gaseous.

second stream into the ?rst one before the S02 reactor

in order to thereby oxidize its content of S0; to form

S03, and furthermore to remove the content in the

lesser stream of coarse particles, above about 1 pm, for

instance in a cyclone or a small electrostatic ?lter, be

cause the coarse particles will settle in the S02 reactor

Conveniently there has been mounted near, in or on

the top of each tube, in gastight connection therewith, a

means for separating droplets of sulfuric acid present in

the gas. Means should also be arranged to ensure that

the droplets ?ow back, downwards through the tube.

The relationship between n = the number of particles

or droplets per Nm3 of the gas; 0 = the content of

particles or droplets in the gas expressed as g/Nm3; o

= the density of the particles or droplets expressed in

g/em3; and d = the diameter of the particles or droplets

expressed in cm (1 cm: 10,000 pm), is

The concentration c of sulfuric acid droplets in the

gas is calculated from the expression:

45

and also will pollute the condensed sulfuric acid with

out contributing substantially to the nucleation.

However, it may also be advantageous to add the

particles in the form of smoke from metal or metal

oxides generated in an electric arc in which the amount

of particles added per unit of time is regulated in a way

so as to obtain minimum content of droplets of sulfuric

acid after the gas has left the tube or the means for

separating droplets of sulfuric acid.

It has proven particularly expedient to add the parti

cles by combusting silicone oils in admixture with a

?uid hydrocarbon fuel (in this speci?cation ?uid

(5)

means either liquid or gaseous) in a burner, in a manner

where a is the percent per volume of H2504 vapour

corresponding to 0 under the assumption that the drop

such that the smoke from the burnercontains particles

of SiO;. This smoke is mixed with the ?ue gas before it

enters the sulfuric acid tower; and preferably between

dust ?lter 4 and blower 20 in FIG. 1. When combusting

(.(ruljiaricaciddmpletr) =4380 X a/BgdropIem/Nm3

lets were all evaporated,and B is the percent by weight

of H2SO4in the droplets (B is typically 75%w H2804).

To avoid that the gas during the condensing contains

too big a number of particles it is possible to purify the

gas for its content of solid particles before the addition

of the solid particles as described, preferably by the aid

of a bag ?lter.

in this manner Diesel oil admixed with 0.05 to 0.5 % w

of silicone oil, or when mixing vapours of siloxanes

having a vapour pressure above 0.01 mbar into the

combustion air to pass to the burner, it is only necessary

65 to add about 4X 10-8 g of S02 per Nm3 ?ue gas contain

In practice it is convenient according to the invention

ing 0.1% H2504 vapour to obtain optimum separation

to add the solid particles to a gas stream containing S02

and a stoichiometric excess of H20 and subsequently

of acid mist; this corresponds to a diameter of about 50

A (Angstrdm units) of the particles of SiOg.

5,198,206

11

12

TABLE 1

Exp.

No.

Experiments with feed gas containing 1000 ppm

H2504 + 7% H2O. Td = 185 C. TAZ > 155 C. Dew

point for 2 ppm H2504 and 7% B20 is 109 C.

Feed Cooled

ppm H2504

stream, zone,

T1

'1'; TA TA; before after

Nm3/h

m

'c.

'c.

'c.

'c.

?lter

m/s

1-1

1-2

1-3

l-4

1-5

l-6

1-7

1-8

H0

1-11

1-12

1-13

1-14

1-15

H6

1-17

H8

1-19

l-Zl

14

14

14

14

14

14

14

14

18

9

9

9

14

14

14

14

14

14

14

5.4

4.95

4.5

4.05

4.05

4.05

5.4

4.5

5.4

4.5

4.05

4.05

5.4

5.4

5.4

5.4

5.4

5.4

5.4

250

250

250

250

250

250

230

250

250

250

250

250

250

250

280

250

250

250

250

100

100

100

100

95

90

70

70

100

100

100

100

112

112

100

100

100

80

112

1-22

l-23

20

20

20

20

20

20

20

20

20

20

20

20

50

20

20

10

0

0

50

194

184

170

151

138

124

150

145

173

198

193

193

188

205

200

201

205

177

190

600

600

700

700

700

800

600

700

900

150

200

200

600

700

700

700

800

700

600

14

5.4

270

14

5.4

270

125

50

200

600 .

112

20

220

Ap

8

8

10

40

200

400

30

100

6

10

12

5

20

15

8

10

20

10

5

3.2

3.2

3.2

3.2

3.2

3.1

2.9

2.9

4.1

2.05

2.05

2.05

3.3

3.3

3.2

3.2

3.2

3.0

3.3

8

8

8

8

8

8

7

7

12

4

4

8

9

9

8

8

8

7

6

15

3.4

10

3.3

INDUSTRIAL USE OF THE INVENTION

It is expected that this invention will be industrially

at least the dew point of sulfuric acid at the conditions

important especially in removing sulfur dioxide from

of pressure and temperature prevailing in the tube, the

roasting processes and from ?ue gases from power 30 feed gas being cooled during the flow in the upward

plants, notably middle sized and large power plants, and

direction to an exit temperature T2 which is lower than

in such highly efficient manner that almost no acid mist

will escape to the atmosphere. The invention hence will

the temperature at which the vapor pressure of H2804

is about 2X10"6 bar in equilibrium with the partial

contribute much to diminish air pollution in industrial

pressure of aqueous vapor prevailing at the outlet of the

35 tubes in the top, the tubes being cooled externally with

areas.

I claim:

a gaseous medium flowing substantially countercur

1. A process for producing sulfuric acid comprising

rently with the sulfuric acid-containing gas, said gase

ous medium thereby being heated from an inlet temper

condensing sulfuric acid vapors from a gas mixture

containing 0.01 to 10% by vol. of H2504 vapor, calcu

ature TA1 of 0 to 50 C. to an outlet temperature TA;

lated under the assumption that S03 is fully hydrated,

satisfying the condition

and 0 to 50% by vol. of aqueous vapor, by direct or

indirect cooling in a sulfuric acid tower, including the

step of adding before inflow-of the gas into the tower a

TA2<T4-30 10a 0.

where T4 is the sulfuric acid dew point, expressed in

C., of the gas passed to the tubes and a is % by vol. of

smoke or an aerosol of solid particles having a content

of 109 to 1012 solid particles per Nm3 per 0.1% H2504 45 sulfuric acid vapor, calculated under the assumption

that $03 in the gas is completely hydrated to H2504. .

vapor in the gas at entry thereof into the tower, calcu

6. A process as claimed in claim 5, further comprising

lated under the assumption that $03 in the tower is

means for separating droplets of sulfuric acid present in

completely hydrated to H2804.

the gas mounted near, in or on top of each tube in gas

2. A process as claimed in claim 1, wherein the cool

tight connection therewith, said droplets ?owing back

ing of the gas mixture takes place in a packed sulfuric

from said means, downwards through the tube.

acid tower countercurrently with circulating sulfuric

7. A process as claimed in claim 1, wherein solid

acid as coolant.

particles having a diameter below 1pm are added to the

3. A process as claimed in claim 1, wherein the cool

ing of the gas mixture takes place in substantially verti

gas.

8. A process as claimed in claim 7, wherein solid

cal, externally cooled tubes in which the gas mixture

particles having a diameter of 0.002 to 01pm are added

?ows from a bottom of the tubes in an upward direction

in countercurrent with an external coolant.

4. A process as claimed in claim 3, wherein a gaseous

coolant is employed.

to the gas.

9. A process as claimed in claim 1, further comprising

the step of purifying feed gas for contents of solid parti

cles originally present before adding the solid particles.

5. A process as claimed in claim 3, further comprising

10. A process as claimed in claim 1, wherein the step

condensing the sulfuric acid vapors which after the

of adding the solid particles comprises adding the solid

condensing flow downwards through the tubes as liq

particles to a feed gas stream containing 80; and a

uid, highly concentrated sulfuric acid, said sulfuric acid

stoichiometric excess of H10, said gas stream thereafter

vapors originating from a feed gas containing 0.01 to

10% by vol. of H2504 vapor, calculated under the as 65 being passed through a layer of a sulfuric acid catalyst

at a temperature of 360 to 500 C. to oxidize S0; to

sumption that S03 in the tower is completely hydrated

S03, the S03 being hydrated under the influence of

to H2804, and 0 to 50% by vol. of H20 vapor, the feed

gas being admitted from the bottom at a temperature of

aqueous vapor.

13

5,198,206

14

cles in the form of smoke from metal or metal oxides

11. A process is claimed in claim 10, further compris

ing the step of cooling the gas stream to a temperature

in the range of 0 to 200 C. above the sulfuric acid dew

point of the gas stream before admitting the gas stream

generated in an electric arc.

16. A process as claimed in claim 1, further compris

ing the step of setting the automatic regulation loop so

as to ensure a sulfuric acid droplets content in discharge

into the sulfuric acid tower.

12. A process as claimed in claim 1, wherein the step

gas below 10 ppm of H2804.

17. A process as claimed in claim 1, wherein the step

of adding the solid particles comprises adding smoke

of adding the solid particles comprises adding the parti

from combustion of hydrocarbons in a burner to the gas

cles as an aerosol of a solution of a metal salt or a sus

mixture, the air fuel ratio in the burner being continu

ally adjusted by means of an automatic regulation loop

containing an analyzer for measuring sulfuric acid drop

pension of particles, liquid present in the aerosol being

lets content in the gas mixture after the gas has left the

18. A process as claimed in claim 10 wherein the feed

gas stream is a stream of dust-containing fuel gas from

evaporated before the aerosol reaches the sulfuric acid

tower.

sulfuric acid tower, signals from the analyzer continu

ally adjusting and correcting the air/fuel ratio.

15

of adding the solid particles comprises adding smoke

tower into a ?rst stream from which substantially

all particles are removed and a second stream from

from the combustion of hydrocarbons to the gas mix

ture, the amount of smoke from the combustion of hy

drocarbons added being continually adjusted by means 20

of an automatic regulation loop containing an analyzer

for measuring sulfuric acid droplets content in the gas

mixture after it has left the sulfuric acid tower, signals

from the analyzer continually adjusting and correcting

the amount of smoke admitted.

combustion of fossil fuel, and

(i) the gas stream is divided before reaching the cata

lyst or between the catalyst and the sulfuric acid

13. A process as claimed in claim 1, wherein the step

25

which at most particles having a diameter above

about 0.5 pm are removed, and

(ii) the first and second streams are united before

reaching the sulfuric acid tower.

19. A process as claimed in claim 1, wherein the step

of adding the solid particles comprises providing the

particles by combusting together with a ?uid fuel, a

silicon-containing component selected from the group

consisting of silicone oils and siloxanes, smoke from the

combustion of the silicon-containing component being

14. A process as claimed in claim 12, wherein the

smoke from the combustion of hydrocarbons contains

at least 2 carbon atoms per molecule.

15. A process as claimed in claim 1, wherein the step 30 admixed into the gas mixture.

I

of adding the solid particles comprises adding the parti

35

45

50

55

65

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- LAMPIRAN 5 Flowsheet Unit SynloopDocument1 paginăLAMPIRAN 5 Flowsheet Unit SynloopLily DianaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Lampiran 1perhitungan Tugas KhususDocument3 paginiLampiran 1perhitungan Tugas KhususLily DianaÎncă nu există evaluări

- Soal TOEFL - Reading ComprehensionDocument3 paginiSoal TOEFL - Reading ComprehensionElizabeth PoedjionoÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 1Document12 pagini1Lily DianaÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Lampiran 4 Quenching Design 105 DDocument1 paginăLampiran 4 Quenching Design 105 DLily DianaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Fulbright Master Application Form 1Document10 paginiFulbright Master Application Form 1Print WarnetÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Msds Molten SulphurDocument9 paginiMsds Molten SulphurLily DianaÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Membrane Filtration HandbookDocument129 paginiMembrane Filtration Handbookmario_nqn89% (9)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Danone at A GlanceDocument21 paginiDanone at A GlanceGudang ErsopÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Pertemuan 02 Rancangan Pabrik (14 Oktober 2015)Document15 paginiPertemuan 02 Rancangan Pabrik (14 Oktober 2015)Lily DianaÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Pertemuan 05 Rancangan Pabrik (04 November 2015)Document15 paginiPertemuan 05 Rancangan Pabrik (04 November 2015)Lily DianaÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- PDF Abstrak Id Abstrak-20376774Document1 paginăPDF Abstrak Id Abstrak-20376774Lily DianaÎncă nu există evaluări

- LAMPIRAN 5 Flowsheet Unit SynloopDocument1 paginăLAMPIRAN 5 Flowsheet Unit SynloopLily DianaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Moist Air PropertiesDocument12 paginiMoist Air PropertiesLily DianaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Paten Sulfur Mixer PDFDocument7 paginiPaten Sulfur Mixer PDFLily DianaÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Paten Kak DeviDocument33 paginiPaten Kak DeviLily DianaÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Furfural PatentDocument5 paginiFurfural PatentLily DianaÎncă nu există evaluări

- Us 20140309468Document4 paginiUs 20140309468Lily DianaÎncă nu există evaluări

- Pertemuan 05 Rancangan Pabrik (04 November 2015)Document15 paginiPertemuan 05 Rancangan Pabrik (04 November 2015)Lily DianaÎncă nu există evaluări

- PaperDocument10 paginiPaperLily DianaÎncă nu există evaluări

- Konversi Sulfur Di Proses Pembakaran 1 PDFDocument6 paginiKonversi Sulfur Di Proses Pembakaran 1 PDFLily DianaÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Proses Wsa 2 PDFDocument2 paginiProses Wsa 2 PDFLily DianaÎncă nu există evaluări

- Us 20150147266 A 1Document18 paginiUs 20150147266 A 1Lily DianaÎncă nu există evaluări

- Us5108731 PDFDocument12 paginiUs5108731 PDFLily DianaÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- 10195en Rev6 PDFDocument8 pagini10195en Rev6 PDFLily DianaÎncă nu există evaluări

- Topsoe Wet Gas Sulphuric Acid (WSA) TechnologyDocument8 paginiTopsoe Wet Gas Sulphuric Acid (WSA) Technologytsaleh100% (1)

- Us 8138371Document10 paginiUs 8138371Lily DianaÎncă nu există evaluări

- Topsoe Wet Gas Sulphuric Acid (WSA) TechnologyDocument8 paginiTopsoe Wet Gas Sulphuric Acid (WSA) Technologytsaleh100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Wsa Condenser PDFDocument21 paginiWsa Condenser PDFLily DianaÎncă nu există evaluări

- c01Document21 paginic01Mustafa BakırÎncă nu există evaluări

- Line Follower and Bluetooth Controlled RobotDocument11 paginiLine Follower and Bluetooth Controlled RobotIJRASETPublicationsÎncă nu există evaluări

- 1957 Raytheon Tube Short Form Data GuideDocument54 pagini1957 Raytheon Tube Short Form Data GuideMARCELO F. MENEGASSOÎncă nu există evaluări

- Astm E415-2008Document9 paginiAstm E415-2008Syamsul AbdullahÎncă nu există evaluări

- Manual - 2389 Hs-Iso-Vac r2Document21 paginiManual - 2389 Hs-Iso-Vac r2Federico QuijanoÎncă nu există evaluări

- Promass 63 ManualDocument48 paginiPromass 63 Manualleopoldo alejandro antio gonzalezÎncă nu există evaluări

- Sa-Dar-Cv-W O74-004Document6 paginiSa-Dar-Cv-W O74-004Divakar PanigrahiÎncă nu există evaluări

- Technical Manual AIRVO 2Document33 paginiTechnical Manual AIRVO 2Jef RobboÎncă nu există evaluări

- ESP 9-Step DesignDocument31 paginiESP 9-Step Designeng.osama100% (2)

- HRSG Overview PDFDocument36 paginiHRSG Overview PDF55312714100% (6)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Sony kv-sw292m50 sw292m61 sw292m80 sw292n60 Chassis bx1l Ver.2.0Document189 paginiSony kv-sw292m50 sw292m61 sw292m80 sw292n60 Chassis bx1l Ver.2.0mrcrypto223Încă nu există evaluări

- Kimo mp120 Manometer DatasheetDocument2 paginiKimo mp120 Manometer Datasheetsantiago pomasoncoÎncă nu există evaluări

- Wiring Carrier 38ckc-c3wDocument2 paginiWiring Carrier 38ckc-c3wRay Ravel100% (1)

- Instruction Manual and Parts List For Compressed Air Filters DDX - DDXP - PDX - PDXP - QDXDocument88 paginiInstruction Manual and Parts List For Compressed Air Filters DDX - DDXP - PDX - PDXP - QDXAlonso GomezÎncă nu există evaluări

- Hanbook EmbracoDocument98 paginiHanbook EmbracoZETAQ2010Încă nu există evaluări

- TVS-5 - 23&PDocument65 paginiTVS-5 - 23&Phodhodhodsribd100% (1)

- 5040 - MASIBUS CONTROLLER User - Manual PDFDocument53 pagini5040 - MASIBUS CONTROLLER User - Manual PDFYUYWEGDYÎncă nu există evaluări

- Battery Radio Valve SetsDocument4 paginiBattery Radio Valve SetsVincent StanleyÎncă nu există evaluări

- Chass CN 220N (DTQ20D5 20D4 14D4)Document50 paginiChass CN 220N (DTQ20D5 20D4 14D4)Luis PerezÎncă nu există evaluări

- CEMS-2000BF DatasheetDocument5 paginiCEMS-2000BF DatasheetPajnuÎncă nu există evaluări

- NightVisionTechnology Seminar ReportDocument10 paginiNightVisionTechnology Seminar ReportAfrah RamsheedÎncă nu există evaluări

- 01 - MontagemDocument30 pagini01 - MontagemOmar Stalin Lucio Ron100% (1)

- History of ElectronicsDocument1 paginăHistory of ElectronicsRianna RamosÎncă nu există evaluări

- Steam Reformer HeatersDocument17 paginiSteam Reformer HeatersHassan HaiderÎncă nu există evaluări

- Manual Secador de Aire Wh-40Document56 paginiManual Secador de Aire Wh-40Marco Vargas100% (1)

- Lab Report Charge-To-Mass RatioDocument7 paginiLab Report Charge-To-Mass RatioAhmed SamiÎncă nu există evaluări

- Final Design Report Design of Secondary Heat Exchanger For The HT RDocument113 paginiFinal Design Report Design of Secondary Heat Exchanger For The HT Rnazmul hasanÎncă nu există evaluări

- Anyview - 500DRDocument3 paginiAnyview - 500DRfuturemedÎncă nu există evaluări

- Monolite SLADocument33 paginiMonolite SLAedgardÎncă nu există evaluări

- WE91ADocument27 paginiWE91Anergal_mclÎncă nu există evaluări

- Final Version - SYKhan Et AlDocument37 paginiFinal Version - SYKhan Et AlHassan AbdelmoamenÎncă nu există evaluări

- How to Improve English Speaking: How to Become a Confident and Fluent English SpeakerDe la EverandHow to Improve English Speaking: How to Become a Confident and Fluent English SpeakerEvaluare: 4.5 din 5 stele4.5/5 (56)

- Weapons of Mass Instruction: A Schoolteacher's Journey Through the Dark World of Compulsory SchoolingDe la EverandWeapons of Mass Instruction: A Schoolteacher's Journey Through the Dark World of Compulsory SchoolingEvaluare: 4.5 din 5 stele4.5/5 (149)

- The 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageDe la EverandThe 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageEvaluare: 5 din 5 stele5/5 (73)

- How to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipDe la EverandHow to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipEvaluare: 4.5 din 5 stele4.5/5 (1135)

- Dumbing Us Down: The Hidden Curriculum of Compulsory SchoolingDe la EverandDumbing Us Down: The Hidden Curriculum of Compulsory SchoolingEvaluare: 4.5 din 5 stele4.5/5 (496)

- Summary: The Laws of Human Nature: by Robert Greene: Key Takeaways, Summary & AnalysisDe la EverandSummary: The Laws of Human Nature: by Robert Greene: Key Takeaways, Summary & AnalysisEvaluare: 4.5 din 5 stele4.5/5 (30)

- Summary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisDe la EverandSummary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisEvaluare: 4 din 5 stele4/5 (6)

- Summary: I'm Glad My Mom Died: by Jennette McCurdy: Key Takeaways, Summary & AnalysisDe la EverandSummary: I'm Glad My Mom Died: by Jennette McCurdy: Key Takeaways, Summary & AnalysisEvaluare: 4.5 din 5 stele4.5/5 (2)

- Summary: The 5AM Club: Own Your Morning. Elevate Your Life. by Robin Sharma: Key Takeaways, Summary & AnalysisDe la EverandSummary: The 5AM Club: Own Your Morning. Elevate Your Life. by Robin Sharma: Key Takeaways, Summary & AnalysisEvaluare: 4.5 din 5 stele4.5/5 (22)