Documente Academic

Documente Profesional

Documente Cultură

Technical Data Sheet for STLA-2835DB TOP LED

Încărcat de

jayveeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Data Sheet for STLA-2835DB TOP LED

Încărcat de

jayveeDrepturi de autor:

Formate disponibile

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

SPECIFICATION

Customer

Type

Customer No.

ERP

ERP No.

APPROVED SIGNATURES

Research & Development Center

APPROVE

CHECK

DRAW

(Version NO.): A

(Release Date): 2012-10-18

This page is only for confirming the part No., for specific data sheet please download from our website at

www.sennikko.jp

1 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Part No. Description

S

Product Series

L: Lighting

B: Backlight

F: Flashlight

S: Special

Size

Angle

Identification Code

X1 X2 X3 X4 - X5 X6 X7 - X8 X9

Product Info.

Emitting Color

D=Daylight White, N=Nature White,

W=Warm White,

R=Red,G=Green, B=Blue, A=Amber

Power

Product Type

TTOP LED

PPOWER LED

CCERAMIC LED

SSIDE VIEW LED

MMolding

A

COB

COB

COB

2 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Features

Package Size: 3.5(L) 2.8(W) 0.65 (T) mm

Silicone Packed

Suitable for different working environment

Super long lifetime: 30000HRs

Anti UV

White colors are available in (5000K- 7500K)

Wide viewing angle (21/2=120)

Device Selection Guide

ITEM

Resin

Bonding Wire

Lens Color

Dice

MATERIALS

Silicone

1mil Au

Water Clear

InGaN

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE DEVICES

Applications

Indoor lighting: Fluorescent lamp, tube

Commercial illumination and displays: Advertising

words, light box

Decorative lighting: light strip

Automotive interior auxiliary lighting

Other illumination and displays

3 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

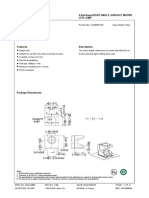

Package Outline Dimensions

Recommended solder pad for MTLA-2835 series

STLA-2835

Note: 1. UNIT: MM [INCH].

2. The tolerances unless mentioned is 0.2 mm.

0.2 mm

4 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Absolute Maximum Ratings

Working Current @ IF = 60mA

(Ta=25)

Parameter

Symbol

Rating

Unit

Reverse Voltage

VR

Forward Current

IF

90

mA

Operating Temperature

Topr

-40 +80

Storage Temperature

Tstg

-40 +80

Soldering Temperature

Tsol

260(for 10 seconds)

Junction Temperature

Tj

115

Power Dissipation

Pd

300

mW

Peak Forward Current

(Duty 1/10 @ 1KHz)

IFP

200

mA

Electro-Optical Characteristics

Parameter

Viewing Angle

Reverse Current

Ta=25

Condition

Symbol

Min.

Typ.

Max.

Unit

21/2

-----

120

------

deg

If=60mA

IR

-----

-----

50

VR=5V

5 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Bin Code of Luminous Flux

Luminous Flux

Code

Luminous Flux

Range

lm

Color Rendering

Index

Luminous Flux

Code

Luminous Flux Color Rendering

Range

Index

lm

LLM028

24-27

70

LLM024

21-24

80

Note: Tolerance of Luminous Flux is 10%.

Daylight White Bin Code of CIE1931

10%

CIE

6 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Color coordinates

DB1

DB2

DB3

DC1

DC2

DC3

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

0.3101

0.3029

0.3063

0.3114

0.3025

0.3199

0.3167

0.3146

0.3129

0.3231

0.3091

0.3315

0.3034

0.2913

0.2996

0.2997

0.2958

0.3082

0.3101

0.3029

0.3063

0.3114

0.3025

0.3199

0.3072

0.2828

0.3034

0.2913

0.2996

0.2997

0.3139

0.2945

0.3101

0.3029

0.3063

0.3114

0.3139

0.2945

0.3101

0.3029

0.3063

0.3114

0.3205

0.3061

0.3167

0.3146

0.3129

0.3231

DD1

DD2

DD3

DE1

DE2

DE3

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

0.3234

0.3263

0.3196

0.3347

0.3158

0.3432

0.3301

0.3379

0.3263

0.3464

0.3225

0.3549

0.3167

0.3146

0.3129

0.3231

0.3091

0.3315

0.3234

0.3263

0.3196

0.3347

0.3158

0.3432

0.3205

0.3061

0.3167

0.3146

0.3129

0.3231

0.3272

0.3178

0.3234

0.3263

0.3196

0.3347

0.3272

0.3178

0.3234

0.3263

0.3196

0.3347

0.3339

0.3295

0.3301

0.3379

0.3263

0.3464

DF1

DF2

DF3

DG1

DG2

DG3

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

CIE-x

CIE-y

0.3367

0.3496

0.3329

0.3581

0.3291

0.3665

0.3434

0.3613

0.3396

0.3697

0.3358

0.3782

0.3301

0.3379

0.3263

0.3464

0.3225

0.3549

0.3367

0.3496

0.3329

0.3581

0.3291

0.3665

0.3339

0.3295

0.3301

0.3379

0.3263

0.3464

0.3405

0.3411

0.3367

0.3496

0.3329

0.3581

0.3405

0.3411

0.3367

0.3496

0.3329

0.3581

0.3472

0.3528

0.3434

0.3613

0.3396

0.3697

Note: Tolerance of Color coordinates is 0.01.

xy

0.01

Bin Range of Forward Voltage

Group

Min VF(V)

Max VF(V)

Group

Min VF(V)

Max VF(V)

VF2007

2.8

3.0

VF2010

3.4

3.6

VF2008

3.0

3.2

VF2011

3.6

3.8

VF2009

3.2

3.4

Note:Tolerance of Forward Voltage is 0.1V.

0.1V

7 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Relative Spectral Power Distributi

Electrical Characteristics

ewing Angle

8 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Guideline for Soldering

Handing of an SMD LED should be done only when the package has been cooled down to below 40 or

less. This is to prevent SMD LED failures due to thermal-mechanical stress during handing.

1. Hand Soldering

A soldering iron of less than 20W is recommended to be used in Hand Soldering. Please keep the

temperature of the soldering iron under 300 while soldering. Each terminal of the LED is to go for less than

3 second and for one time only.

Be careful because the damage of the product is often started at the time of the hand soldering.

2. Reflow Soldering

Recommended reflow soldering conditionLead-free solder

Note: 1. We recommend the reflow temperature 245(+/-5).The maximum soldering temperature should

be limited to 260

2. Reflow soldering should not be done more than two times.

3. When soldering, do not put stress on the LEDs during heating.

9 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Test items and results of reliability

Test Item

Test conditions

Test Duration

Sample NO.

Solderability

T=26055Sec

22

Temperature Cycle

-40(30min) ~25

(5min) ~100(30min)

100cycles

50

Ta=1003

1000 hrs

50

Ta=-403

1000 hrs

50

Temperature Humidity Storage

Ta=603,

RH=90%3%

1000 hrs

50

Life Test 1

1

Ta=253,

If=60mA

1000 hrs

22

Life Test 2

2

Ta=253,

If=90mA

1000 hrs

22

Ta=603,

RH=90%3%,

If=60mA

240 hrs

22

High Temperature Storage

Low Temperature Storage

High Temperature Life Test

10 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Tape and Reel

Note:

1. The number of loaded products in the reel is 4000ea.

2. All dimensions are in millimeters (tolerance: 0.2).

4000pcs

mm,

0.2

3. Scale: None.

11 /20

Technical Data Sheet

Part Number: STLA-2835DB -

0.2W

TOP LED

Working Current @ IF = 60mA

Dry Packaging and Packaging

12 /20

Technical Data Sheet

Part Number: STLA-2835DB -

0.2W

TOP LED

Working Current @ IF = 60mA

Test Circuit

NOTE: All temperatures refer to the topside of the package, measured on the package body surface.

Handling Precautions

1. Over-current-proof

Customer must apply resistors for protection; otherwise slight voltage shift will cause big current change

(Burn out will happen).

(

2. Cleaning

2.1 When necessary, cleaning should occur only with isopropyl alcohol (IPA) at room temperature (25C)

for a duration of no more than one minute. Dry at room temperature for 15 minutes before use.

(25C)

(IPA)

15

2.2 The influence of ultrasonic cleaning on the SMD LED depends on factors such as ultrasonic power and

the way the SMD LEDs are mounted. Ultrasonic cleaning should be pre-qualified to ensure this will not

cause damage to the SMD LEDs.

SMD LED

13 /20

Technical Data Sheet

Part Number: STLA-2835DB -

0.2W

TOP LED

Working Current @ IF = 60mA

3. Storage

3.1

Dont open moisture proof bag before the products are ready to use.

3.2

Before opening the package: The LEDs should be kept at 30 or less and 90%RH or less.

30( )

3.3

90%( )

After opening the package: The LED's floor life are 24 hours under 30 or less and 70% RH or less.

If unused LEDs remain, it should be stored in moisture proof packages.

( )

4. Baking

It is recommended to bake before soldering when the pack is unsealed after 24hrs. The conditions are as

followings:

24

4.1

65 3 x (24hrs) and 5%RH, taped reel type

4.2

100 3 x (4hrs), bulk type

4.3

130 3 x (2hrs), bulk type

5. Operating

Compare to epoxy encapsulant that is hard and brittle, silicone is softer and flexible. Although its

characteristic significantly reduces thermal stress, it is more susceptible to damage by external mechanical

force. As a result, special handling precautions need to be observed during assembly using silicone

encapsulated LED products. Failure to comply might leads to damage and premature failure of the LED.

14 /20

Technical Data Sheet

Part Number: STLA-2835DB -

0.2W

TOP LED

Working Current @ IF = 60mA

5.1

Handle the component along the side surfaces by using forceps or appropriate tools.

5.2

Do not directly touch or handle the silicone lens surface. It may damage the internal circuitry.

5.3

Do not stack together assembled PCBs containing exposed LEDs. Impact may scratch the silicone

lens or damage the internal circuitry.

15 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

5.4 The outer diameter of the SMD pickup nozzle should not exceed the size of the LED to prevent air

leaks. The inner diameter of the nozzle should be as large as possible.

5.5 A pliable material is suggested for the nozzle tip to avoid scratching or damaging the LED surface

during pickup.

5.6 The dimensions of the component must be accurately programmed in the pick-and-place machine to

insure precise pickup and avoid damage during production.

5.7

Users should be cautioned not to stare at the light of this LED product. The bright light can damage

the eye.

16 /20

Technical Data Sheet

Part Number: STLA-2835DB -

0.2W

TOP LED

Working Current @ IF = 60mA

Chemicals Tested as Harmful

In testing, SN has found the

following chemicals to be harmful to the LEDs. SN recommends

not using these chemicals anywhere in an LED system. The fumes from even small amounts of these

chemicals may damage the LEDs.

Chemicals that might outgas aromatic hydrocarbons (e.g., toluene, benzene, xylene)

Methyl acetate or ethyl acetate (i.e., nail polish remover)

Cyanoacrylates (i.e., Superglue)

Glycol ethers (including Precision Electronics Cleaner - dipropylene glycol monomethyl ether)

Formaldehyde or butadiene

bleach

Cleaner spray

activator

thread locker

Sulfurbromideiodine chloride

17 /20

Technical Data Sheet

Part Number: STLA-2835DB -

0.2W

TOP LED

Working Current @ IF = 60mA

ESD Protection During Production

Electric static discharge can result when static-sensitive products come in contact with the operator or

other conductors.

The following procedures may decrease the possibility of ESD damage:

1. Minimize friction between the product and surroundings to avoid static buildup.

2.All production machinery and test instruments must be electrically grounded.

3.Operators must wear anti-static bracelets.

4.Wear anti-static suit when entering work areas with conductive machinery.

5.Set up ESD protection areas using grounded metal plating for component handling.

ESD

6.All workstations that handle IC and ESD-sensitive components must maintain an electrostatic potential of

150V or less.

IC

150V

7.Maintain a humidity level of 50% or higher in production areas.

50%

8.Use anti-static packaging for transport and storage.

9.All anti-static equipment and procedures should be periodically inspected and evaluated for proper

functionality.

18 /20

Technical Data Sheet

Part Number: STLA-2835DB

0.2W

TOP LED

Working Current @ IF = 60mA

Thermal Management

1. Thermal design of the end product is of paramount importance.Please consider the heat generation of the

LED when making he system design. The coefficient of temperature increase per input electric power is

affected by the thermal resistance of the circuit board and density of LED placement on the board ,as well as

other components. It is necessary to avoid intense heat generation and operate within the maximum ratings

given in this specification.

2. The equation

indicates correlation between Tj and Ta ,and the equation

indicates correlation

between Tj and Ts

Tj = Ta + Rthj-a *W

Tj = Ts + Rthj-s *W

Tj = dice junction temperature: C

Tj =

Ta = ambient temperature:C

Ta =

Ts = solder point temperature:C

Ts=

Rthj-a = heat resistance from dice junction temperature to ambient temperature : C / W

Rthj-s = heat resistance from dice junction temperature to Ts measuring point : C / W

W = inputting power (IFx VF) : W

19 /20

Technical Data Sheet

Part Number: STLA-2835DB -

0.2W

TOP LED

Working Current @ IF = 60mA

Humidity Indicator Card

After the moisture barrier bag is opened, make sure that Humidity Indicator Card does not become red at

30%RH. Otherwise, Devices require baking again under below conditions.

65 3 x (24hrs) and 5%RH, taped reel type

65 3 x (24hrs) and 5%RH,

20 /20

S-ar putea să vă placă și

- Specification LR770D: SSC CustomerDocument12 paginiSpecification LR770D: SSC CustomerMangesh GaikwadÎncă nu există evaluări

- Especificacion Tecnica LEDDocument10 paginiEspecificacion Tecnica LEDJorge Herrero GarcíaÎncă nu există evaluări

- Full-Color LED Lamp Specification SheetDocument8 paginiFull-Color LED Lamp Specification SheetNicholas RichardsonÎncă nu există evaluări

- CLAA215FA01Document31 paginiCLAA215FA01sorintvrÎncă nu există evaluări

- VLMW41.... - .... : Vishay SemiconductorsDocument8 paginiVLMW41.... - .... : Vishay SemiconductorsaldairlucasÎncă nu există evaluări

- Huanan Electronics LCD Module Spec SheetDocument13 paginiHuanan Electronics LCD Module Spec SheetJoana NogueiraÎncă nu există evaluări

- Manual de Servicio Sony KDL-32BX300 Chasis AZ1-FKDocument32 paginiManual de Servicio Sony KDL-32BX300 Chasis AZ1-FKLogicooltechÎncă nu există evaluări

- 9619 Sony KDL-22BX300 KDL-32BX300 Chassis AZ1-FK Televisor LCD Manual de ServicioDocument32 pagini9619 Sony KDL-22BX300 KDL-32BX300 Chassis AZ1-FK Televisor LCD Manual de ServicioFavgFavgÎncă nu există evaluări

- ICL8069 - Low Voltage Reference - Intersil CorporationDocument6 paginiICL8069 - Low Voltage Reference - Intersil Corporationwlen2012Încă nu există evaluări

- SAW09H0A 4040 - 64V 20maDocument21 paginiSAW09H0A 4040 - 64V 20mafranf44Încă nu există evaluări

- Shenzhen Aohai Optoelectronics Co., LTD: Product DatasheetDocument10 paginiShenzhen Aohai Optoelectronics Co., LTD: Product DatasheetMatthew OsbornÎncă nu există evaluări

- NTC Thermistor SMD Type Specification SheetDocument25 paginiNTC Thermistor SMD Type Specification SheetwoodyyinÎncă nu există evaluări

- Approval Sheet: LCD ModuleDocument24 paginiApproval Sheet: LCD ModuleJoaquinÎncă nu există evaluări

- White Backlight LED Technical SpecificationDocument6 paginiWhite Backlight LED Technical SpecificationanzuresinkÎncă nu există evaluări

- ET-3528W-1B1W: Cool WhiteDocument22 paginiET-3528W-1B1W: Cool Whitesonyfrancis1970Încă nu există evaluări

- Property of Lite-On Only FeaturesDocument11 paginiProperty of Lite-On Only FeaturesBLUEE009Încă nu există evaluări

- Specification of LCD Module JHD639Document23 paginiSpecification of LCD Module JHD639kaifansariÎncă nu există evaluări

- Sensor Itr 8102 EncoderDocument6 paginiSensor Itr 8102 EncoderburdadebueyÎncă nu există evaluări

- Technical Data Sheet Opto Interrupter: FeaturesDocument6 paginiTechnical Data Sheet Opto Interrupter: FeaturesAntonio CarrascoÎncă nu există evaluări

- CLAA201WA04Document31 paginiCLAA201WA04Иван Алексиев100% (1)

- Switch Pushbutton A01 A1 A02 A03 ENGDocument23 paginiSwitch Pushbutton A01 A1 A02 A03 ENGmyÎncă nu există evaluări

- Modbus-1 3eDocument4 paginiModbus-1 3ekelpiusÎncă nu există evaluări

- M190PW01 V0Document28 paginiM190PW01 V0Tomescu MarianÎncă nu există evaluări

- T420HW06 V2Document29 paginiT420HW06 V2Reinaldo GuillenÎncă nu există evaluări

- AT090TN10 - ManualDocument22 paginiAT090TN10 - ManualRazvan FlorinÎncă nu există evaluări

- Uc 2710Document6 paginiUc 2710pic18f4550Încă nu există evaluări

- 64x128 Graphics LCD Datasheet V1 1 .0Document32 pagini64x128 Graphics LCD Datasheet V1 1 .0Rohan DervankarÎncă nu există evaluări

- Service Manual: PhilipsDocument39 paginiService Manual: PhilipsRogerio E. SantoÎncă nu există evaluări

- Features Applications: D D D D D D DDocument10 paginiFeatures Applications: D D D D D D DHairfhwÎncă nu există evaluări

- 7 Segment LA5622-S2 DatasheetDocument6 pagini7 Segment LA5622-S2 Datasheetcris_itdÎncă nu există evaluări

- 2835 SMD LED Data SheetDocument8 pagini2835 SMD LED Data SheetSIBOÎncă nu există evaluări

- DP PDFDocument52 paginiDP PDFbrightstardustÎncă nu există evaluări

- Data Sheet: HLMP-RL20, HLMP-SL20Document9 paginiData Sheet: HLMP-RL20, HLMP-SL20Anonymous pMVR77x1Încă nu există evaluări

- lsd815 65 XX PFDocument9 paginilsd815 65 XX PFDavid MoodyÎncă nu există evaluări

- Nichia NF2L757DRT V1 DatasheetDocument20 paginiNichia NF2L757DRT V1 DatasheetJoseph NiksaÎncă nu există evaluări

- Data Sheet: HCPL-3120/J312 HCNW3120Document27 paginiData Sheet: HCPL-3120/J312 HCNW3120onafetsÎncă nu există evaluări

- 20C x 4L LCD Module SpecificationsDocument17 pagini20C x 4L LCD Module SpecificationsAleksandar LomovicÎncă nu există evaluări

- TLP291 4 PDFDocument14 paginiTLP291 4 PDFBruno SilvaÎncă nu există evaluări

- Strato 35 Series and 70 Series :: ROAL Living EnergyDocument5 paginiStrato 35 Series and 70 Series :: ROAL Living EnergyroalscribdÎncă nu există evaluări

- Color Fastness M228B&C Rotawash Manual (Rev1.1)Document22 paginiColor Fastness M228B&C Rotawash Manual (Rev1.1)sayeed hossenÎncă nu există evaluări

- 4.0X4.0Mm Right Angle Surface Mount Led LampDocument6 pagini4.0X4.0Mm Right Angle Surface Mount Led LampAlberto Valenzuela UrzúaÎncă nu există evaluări

- TM12864G3CCWGWA-1 Ver 1.0Document28 paginiTM12864G3CCWGWA-1 Ver 1.0Olga PlohotnichenkoÎncă nu există evaluări

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDocument6 paginiLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaÎncă nu există evaluări

- Sony Dsr-pd175 - pd177 - pd198 Service ManualDocument249 paginiSony Dsr-pd175 - pd177 - pd198 Service ManualPrime Lens100% (4)

- SI-8100QL Switching RegulatorsDocument2 paginiSI-8100QL Switching RegulatorsiamisterdÎncă nu există evaluări

- BC1602K Series VER01Document28 paginiBC1602K Series VER01Jeremiah DayÎncă nu există evaluări

- 1717949Document2 pagini1717949vikas_ojha54706Încă nu există evaluări

- MCD288 DVD Micro Theatre: /all VersionsDocument39 paginiMCD288 DVD Micro Theatre: /all VersionsLeonelHernandezÎncă nu există evaluări

- D+led-Ld5rDocument6 paginiD+led-Ld5rJulia EchazarretaÎncă nu există evaluări

- Beginning Digital Electronics through ProjectsDe la EverandBeginning Digital Electronics through ProjectsEvaluare: 5 din 5 stele5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Soldering electronic circuits: Beginner's guideDe la EverandSoldering electronic circuits: Beginner's guideEvaluare: 4.5 din 5 stele4.5/5 (9)

- Digital LED Thermometer with Microcontroller AVR ATtiny13De la EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Evaluare: 5 din 5 stele5/5 (1)

- Design Guidelines for Surface Mount TechnologyDe la EverandDesign Guidelines for Surface Mount TechnologyEvaluare: 5 din 5 stele5/5 (1)

- Archi ConsultantsDocument2 paginiArchi ConsultantsjayveeÎncă nu există evaluări

- Vinoth Kumar Jaganathan: Dongwoo Surfacetech (India) PVT LTD.Document2 paginiVinoth Kumar Jaganathan: Dongwoo Surfacetech (India) PVT LTD.jayveeÎncă nu există evaluări

- Fabsil Smooth (Silicone Softener) : A High Viscosity Organo Modified SiloxaneDocument2 paginiFabsil Smooth (Silicone Softener) : A High Viscosity Organo Modified SiloxanejayveeÎncă nu există evaluări

- Tender High CourtDocument43 paginiTender High CourtjayveeÎncă nu există evaluări

- INCA LED Tube Light Technical Specification SheetDocument1 paginăINCA LED Tube Light Technical Specification SheetjayveeÎncă nu există evaluări

- LTTLI36W Twin Tube Light Technical Specification Details.18.11.2016Document1 paginăLTTLI36W Twin Tube Light Technical Specification Details.18.11.2016jayveeÎncă nu există evaluări

- Avani Avittam (Upakarma) 2017 in Tamil PDFDocument4 paginiAvani Avittam (Upakarma) 2017 in Tamil PDFjayveeÎncă nu există evaluări

- Christo ResumeDocument3 paginiChristo ResumejayveeÎncă nu există evaluări

- Final Mailing List Khair 2012Document752 paginiFinal Mailing List Khair 2012sonal_arya100% (1)

- Kreios G1: Product Family DatasheetDocument4 paginiKreios G1: Product Family DatasheetjayveeÎncă nu există evaluări

- Handbook On Corporate Social Responsibility in IndiaDocument32 paginiHandbook On Corporate Social Responsibility in IndiaSKDÎncă nu există evaluări

- Suresh SalesreportDocument19 paginiSuresh SalesreportjayveeÎncă nu există evaluări

- Final Mailing List Khair 2012Document752 paginiFinal Mailing List Khair 2012sonal_arya100% (1)

- Coimbatore-Customs House Agencts - Office BearersDocument1 paginăCoimbatore-Customs House Agencts - Office BearersjayveeÎncă nu există evaluări

- Technical CatalogueDocument115 paginiTechnical CataloguejayveeÎncă nu există evaluări

- Handbook On Corporate Social Responsibility in IndiaDocument32 paginiHandbook On Corporate Social Responsibility in IndiaSKDÎncă nu există evaluări

- Top Ten Engg Colleges in ChennaiDocument3 paginiTop Ten Engg Colleges in ChennaijayveeÎncă nu există evaluări

- LED Lighting: Getting It Right: Did You Know?Document4 paginiLED Lighting: Getting It Right: Did You Know?jayveeÎncă nu există evaluări

- Inca Led - Product SlideDocument1 paginăInca Led - Product SlidejayveeÎncă nu există evaluări

- Sen NikkōDocument2 paginiSen NikkōjayveeÎncă nu există evaluări

- List of AICTE approved engineering colleges in KeralaDocument3 paginiList of AICTE approved engineering colleges in KeralajayveeÎncă nu există evaluări

- Iimu CSR ReportDocument19 paginiIimu CSR ReportjayveeÎncă nu există evaluări

- Atma-Automotive Tyre MfrsDocument3 paginiAtma-Automotive Tyre MfrsjayveeÎncă nu există evaluări

- List of Industries in and Around ChennaiDocument5 paginiList of Industries in and Around Chennaijayvee100% (1)

- CST Top100 2014Document2 paginiCST Top100 2014jayveeÎncă nu există evaluări

- 75 Self Financing CollegesDocument11 pagini75 Self Financing CollegesjayveeÎncă nu există evaluări

- Ramprakas Postcode ListDocument92 paginiRamprakas Postcode ListjayveeÎncă nu există evaluări

- MEP Chennai List 2016Document3 paginiMEP Chennai List 2016jayveeÎncă nu există evaluări

- List of Colleges Under EETP: KarnatakaDocument34 paginiList of Colleges Under EETP: KarnatakaIndiajayvee100% (1)

- SFA160Document5 paginiSFA160scamalÎncă nu există evaluări

- HYBT Series: Assembling Terminal BlockDocument8 paginiHYBT Series: Assembling Terminal Blockanon_670965762Încă nu există evaluări

- Pump IntakeDocument6 paginiPump IntakeAnonymous CMS3dL1T100% (1)

- Solwezi General Mental Health TeamDocument35 paginiSolwezi General Mental Health TeamHumphreyÎncă nu există evaluări

- Antenatal AssessmentDocument9 paginiAntenatal Assessmentjyoti singhÎncă nu există evaluări

- Metal Oxides Semiconductor CeramicsDocument14 paginiMetal Oxides Semiconductor Ceramicsumarasad1100% (1)

- Biology GCE 2010 June Paper 1 Mark SchemeDocument10 paginiBiology GCE 2010 June Paper 1 Mark SchemeRicky MartinÎncă nu există evaluări

- Enterprise Architecture A General OverviewDocument45 paginiEnterprise Architecture A General OverviewraducooÎncă nu există evaluări

- Balajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFDocument228 paginiBalajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFvramaniitkÎncă nu există evaluări

- Product Differentiation and Market Segmentation As Alternative Marketing StrategiesDocument7 paginiProduct Differentiation and Market Segmentation As Alternative Marketing StrategiesCaertiMÎncă nu există evaluări

- Njhs Application EssayDocument4 paginiNjhs Application Essaycjawrknbf100% (2)

- ES1 Work Panel DatasheetDocument3 paginiES1 Work Panel DatasheetGerardo Alberto Navarro LopezÎncă nu există evaluări

- SLU Missalette 2016 Capping (Not-Final)Document18 paginiSLU Missalette 2016 Capping (Not-Final)Teanu Jose Gabrillo TamayoÎncă nu există evaluări

- Sustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Document408 paginiSustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Randall WestÎncă nu există evaluări

- Accounting Students' Attitude Towads AccountingDocument29 paginiAccounting Students' Attitude Towads AccountingSham Salonga Pascual50% (2)

- WP1019 CharterDocument5 paginiWP1019 CharternocnexÎncă nu există evaluări

- Carmina GadelicaDocument37 paginiCarmina GadelicaoniricsÎncă nu există evaluări

- Impact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityDocument14 paginiImpact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityYo Vivo Fit Pablo y KarlaÎncă nu există evaluări

- Resistance and ResisivityDocument2 paginiResistance and ResisivityDeddy KismanaÎncă nu există evaluări

- Ragavendhar Seeks Entry Software JobDocument2 paginiRagavendhar Seeks Entry Software JobfferferfÎncă nu există evaluări

- Penilaian Risiko Kerja Menggunakan Metode Hirarc Di Pt. Sinar Laut Indah Natar Lampung SelatanDocument7 paginiPenilaian Risiko Kerja Menggunakan Metode Hirarc Di Pt. Sinar Laut Indah Natar Lampung SelatanIndun InsiyahÎncă nu există evaluări

- Effectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting OperationDocument10 paginiEffectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting Operationchandan kumar100% (1)

- Literature Revisited: Understanding Key Concepts and Applying Analytical SkillsDocument31 paginiLiterature Revisited: Understanding Key Concepts and Applying Analytical SkillsMuhammad Furqan Aslam Awan100% (2)

- Introduction To The Philosophy of The Human Person Quarter I - Module 2Document26 paginiIntroduction To The Philosophy of The Human Person Quarter I - Module 2Katrina TulaliÎncă nu există evaluări

- Sample ResumeDocument3 paginiSample Resumeapi-380209683% (6)

- Open MPDocument30 paginiOpen MPmacngocthanÎncă nu există evaluări

- VANSINA, Jan. Art History in AfricaDocument250 paginiVANSINA, Jan. Art History in AfricaRaphaelTim100% (1)

- Transistor Amplifier Operating ParametersDocument21 paginiTransistor Amplifier Operating ParametersReddyvari VenugopalÎncă nu există evaluări

- Ubc 2015 May Sharpe JillianDocument65 paginiUbc 2015 May Sharpe JillianherzogÎncă nu există evaluări

- Book 2 - Test 1Document2 paginiBook 2 - Test 1Đức LongÎncă nu există evaluări