Documente Academic

Documente Profesional

Documente Cultură

Eje m13 m15 Data Sheet

Încărcat de

Dejan MitrovićDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Eje m13 m15 Data Sheet

Încărcat de

Dejan MitrovićDrepturi de autor:

Formate disponibile

Powerful and efficient with

3-phase AC drive motor

Extremely manoeuvrable

due to compact design

High driving and cornering

stability due to integrated

support wheels

Maintenance-free gel battery

and integrated charger

Built-in weighing

system (optional)

EJE M13/M15

Electric Pedestrian Pallet Truck (1,300/1,500 kg)

The EJE M13 and EJE M15 trucks were specially developed for

the internal transfer of lighter goods. The 0.6-kW drive motor

supports the transport of pallets and goods weighing up to

1500 kg over short distances. Therefore the EJE M13 and EJE

M15 are ideal for use in small and medium-sized companies

with an occasional need for goods transport.

Thanks to the maintenance-free, powerful 3-phase AC motor,

energy consumption is reduced and the best conditions are

provided for rapid and cost-efficient goods throughput.

This gives the EJE M13 and EJE M15 their advantages, particularly in confined spaces: Their compact design, the low

front end length (l2) of just 435 mm and the low overall height

guarantee maximum manoeuvrability and offer every operator

an optimum view of the fork tips.

In addition, two sprung and cushioned support wheels ensure

safe and stable travel. A gel battery used in conjunction with a

built-in charger allows for flexible operation, without having to

fill up the battery with water.

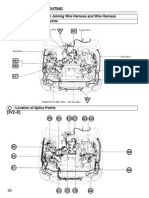

EJE M13/M15

h14

max.

h1

l

c

h14

min.

s

h3

m12

h13

y

l2

l1

b1

b10

a

2

b11 b5 b12

l6

Ast

a

2

As at: 05/2016

Misc.

Electrics

Performance

data

Basic dimensions

Wheels / frame

Weights

Identification

Technical data in line with VDI 2198

3)

4)

5)

1)

2)

1.1

Manufacturer (abbreviation)

1.2

Model

Jungheinrich

1.3

Drive

1.4

Manual, pedestrian, stand-on, seated, order picker operation

1.5

Load capacity/rated load

Q t

1.6

Load centre distance

c mm

EJE M13

EJE M135)

EJE M15

EJE M155)

EJE M15

1.5

1.5

Electric

pedestrian

1.3

1.3

1.5

600

1.8

Load distance

x mm

914

894

914

894

764

1.9

Wheelbase

y mm

1,212

1,212

1,212

1,212

1,062

2.1.1

Net weight incl. battery (see row 6.5)

kg

214

253

219

258

219

2.2

Axle load with load front/rear

kg

696 /

1,018

716 / 1,037

700 /

1,019

720 /

1,038

700 /

1,019

162 / 52

184 / 69

166 / 53

188 / 70

166 / 53

2.3

Axle load without load front/rear

kg

3.1

Tyres

TPU/PU

3.2

Tyre size, front

mm

230x65

3.3

Tyre size, rear

mm

80x70

3.4

Additional wheels (dimensions)

mm

2 x 80x40

3.5

Wheels, number front/rear ( = driven wheels)

3.6

Tread width, front

b10 mm

1x+2/4

460

3.7

Tread width, rear

b11 mm

368

4.4

Lift

h3 mm

120

4.9

Height of tiller in drive position min. / max.

h14 mm

740 / 1,190

4.15

Height, lowered

h13 mm

85

90

85

90

85

4.19

Overall length

l1 mm

1,585

1,605

1,585

1,605

1,435

4.20

Length to face of forks

l2 mm

435

455

435

455

435

4.21

Overall width

b1/b2 mm

6502)

650

6502)

650

6502)

4.22

Fork dimensions

s/e/l mm

55 / 172 /

1,150

60 / 182 /

1,150

55 / 172 /

1,150

60 / 182 /

1,150

55 / 172 /

1,000

4.25

Width across forks

b5 mm

5401)

550

5401)

550

5401)

4.32

Ground clearance, centre of wheelbase

m2 mm

4.33

Aisle width for pallets 1000 1200 sideways

Ast mm

1,643

1,663

1,643

1,663

1,493

4.34

Aisle width for pallets 800 1200 lengthways

Ast mm

1,843

1,863

1,843

1,863

1,693

1,357

1,357

1,357

1,357

1,207

24 / 904)

24 / 904)

35

4.35

Turning radius

Wa mm

5.1

Travel speed, laden/unladen

km/h

5.2

Lift speed, laden/unladen

m/s

0.05 / 0.06

5.3

Lowering speed, laden/unladen

m/s

0.08 / 0.04

5.8

Max. gradeability, laden/unladen

5.10

Service brake

6.1

Drive motor, output S2 60 min.

kW

0.6

6.2

Lift motor kW output at S3 5 %

kW

1.2

6.3

Battery as per DIN 43531 /35/36 A, B, C, no

6.4

Battery voltage/ nominal capacity

V/Ah

6.5

Battery weight

kg

6.6

Energy consumption according to VDI cycle

kWh/h

8.1

Type of drive control

8.4

Sound pressure level at operator's ear as per EN 12053

4.5 / 5

4 / 10

electric

no

24 / 653)

24 / 653)

24 / 904)

35

35

53

53

53

0.24

0.24

0.27

0.27

0.27

AC SpeedControl

dB (A)

66

670 mm also possible

If b5 = 670 mm, b1/b2 = 670 mm

Specification battery voltage/nominal capacity at K20; at K5: 24V, 53.3Ah

Specification battery voltage/nominal capacity at K20; at K5: 24V, 70Ah

with integrated weighing function

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Benefit from the advantages

Optimal stability due to spring load

support wheels

Innovative drive and control technology

Motors with 3-phase AC technology

offer many advantages and more

efficiency while simultaneously reducing

the operating costs thanks to the perfect

match with our own controllers:

High efficiency levels with excellent

energy management.

Rapid directional change without delay.

No carbon brushes mean the drive

motor is maintenance-free.

Energy efficiency

Economic energy management increases

the efficiency and lifetime of the battery

and components:

Smart shut down: the EJE M13 shuts

down automatically after 30 minutes

without use.

Energy recovery due to regenerative

braking.

Ergonomic designed tiller head

Compact design

Thanks to their compact design, the EJE

M13 and the EJE M15 are perfect for use

in confined spaces.

High manoeuvrability due to short

chassis dimension and low overall

height.

Important instruments such as battery

discharge indicator, hourmeter, emergency disconnect and key are centrally

located on the truck.

Sufficient storage space even with

slender design.

Ergonomic operations

The trucks are perfectly adapted to the

ergonomic needs of the operator:

Reduced force required while steering

due to low-mounted tiller.

Dual-sided operation of tiller handle

for ergonomic and safe use.

Optimum stability

The EJE M13 and EJE M15 have two

sprung support rollers installed along-

Weighing device (optional)

side the drive wheel. These increase the

stability of the truck, thereby reducing

the risk of transport damage. Entry rollers

have also been fitted to the fork tips on

the standard model to ensure the easy

picking up of pallets.

Safe operation

Various safety measures reduce the risk

of injury for operators and guarantee a

high level of safety:

Reduced risk of foot injuries due to low

ground clearance of only 35 mm.

Additional protection due to the complete closed housing, in particular the

lift cylinder.

Options

As an option, the EJE M13 and the EJE

M15 can be ordered with a weighing system. This enables goods to be weighed

and moved using just one truck. Four

weighing cells provide optimal results

with a deviation of less than 1% across

the entire weighing range.

The German production

facilities in Norderstedt,

Moosburg and Landsberg

are certified.

Jungheinrich Aktiengesellschaft

Friedrich-Ebert-Damm 129

D-22047 Hamburg

Telephone +49 40 6948-0

Telefax +49 40 6948-1777

info@jungheinrich.com

www.jungheinrich.com

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EJE M13/M15_062016_en_ZKW_000

Centralized control instruments

S-ar putea să vă placă și

- PCCP Minimum StandardDocument3 paginiPCCP Minimum StandardJanssen Gerardo Valbuena100% (4)

- Cirrus SR2X Flight Operations Manual - PerspectiveDocument218 paginiCirrus SR2X Flight Operations Manual - Perspectivecash flowÎncă nu există evaluări

- Ecdis Symbols and AbbreviationsDocument2 paginiEcdis Symbols and AbbreviationsChim LieuÎncă nu există evaluări

- Zorra Raymond 102XMDocument9 paginiZorra Raymond 102XMcolive1Încă nu există evaluări

- Forklift Project Report 1 PDFDocument43 paginiForklift Project Report 1 PDFfahamith ahamed67% (3)

- Ha15ip Manual ServicioDocument65 paginiHa15ip Manual ServicioP GÎncă nu există evaluări

- LTX 70 80 Ltx-t08 en ManualDocument186 paginiLTX 70 80 Ltx-t08 en ManualmyunusanisÎncă nu există evaluări

- Service Manual En: Reflex RR B, E RR B, E CCDocument486 paginiService Manual En: Reflex RR B, E RR B, E CCjoseÎncă nu există evaluări

- LPE200 - Fixed Side ProtectionDocument3 paginiLPE200 - Fixed Side ProtectionLui DavidÎncă nu există evaluări

- Afczp0bb (Combiacx Acex Ing)Document81 paginiAfczp0bb (Combiacx Acex Ing)Anselmo ValÎncă nu există evaluări

- SM-XF-12T-IC Forklift-202012-EN-CEDocument126 paginiSM-XF-12T-IC Forklift-202012-EN-CEmirko coppiniÎncă nu există evaluări

- Toyota BT Optio MDocument8 paginiToyota BT Optio MMohammad Shahin HossainÎncă nu există evaluări

- Adtzp0bb (AC1-ing)Document62 paginiAdtzp0bb (AC1-ing)mirko coppiniÎncă nu există evaluări

- BL, 3rd, DhakapowerDocument2 paginiBL, 3rd, DhakapowerbappysaÎncă nu există evaluări

- 266 1395823971606 enDocument226 pagini266 1395823971606 enÁrgyó András-BotondÎncă nu există evaluări

- Productspecificaties Linde K Smalle Gangen TruckDocument2 paginiProductspecificaties Linde K Smalle Gangen TruckVagabond HuynhÎncă nu există evaluări

- SM - Lwe.180.200 ParametersDocument19 paginiSM - Lwe.180.200 ParametersTotalÎncă nu există evaluări

- Workshop Manual XR-AC: Workshop Manual Id. Nr. First Issue: 05/04 Last RevisionDocument337 paginiWorkshop Manual XR-AC: Workshop Manual Id. Nr. First Issue: 05/04 Last RevisionHéctor Carpio MartínÎncă nu există evaluări

- Electric Powered Forklift: WWW - Toyota-Forklifts - EuDocument8 paginiElectric Powered Forklift: WWW - Toyota-Forklifts - EuValentinÎncă nu există evaluări

- Still EXV 10 12 NewDocument5 paginiStill EXV 10 12 NewfennyÎncă nu există evaluări

- Ere K 20Document107 paginiEre K 20juanchilovatoÎncă nu există evaluări

- 2200yrm1229 (06 2008) Us enDocument20 pagini2200yrm1229 (06 2008) Us enEWERTON100% (1)

- Sted Installation GuideDocument13 paginiSted Installation GuideVũ Nguyễn MinhÎncă nu există evaluări

- Sevcon SC2000 Manual - With Calibrator Section PDFDocument58 paginiSevcon SC2000 Manual - With Calibrator Section PDFRicardo Marquez ValenciaÎncă nu există evaluări

- Ace4 2uc 1 Can TillerDocument156 paginiAce4 2uc 1 Can TillerASIFÎncă nu există evaluări

- Xilin Catálogo 2014 Porta Paletes e StackersDocument59 paginiXilin Catálogo 2014 Porta Paletes e Stackerskashif AliÎncă nu există evaluări

- Model 1243 Sepex: Separately Excited Electronic Motor Speed ControllerDocument3 paginiModel 1243 Sepex: Separately Excited Electronic Motor Speed ControllerkarimÎncă nu există evaluări

- Jungheinrich II Etv Etm 320 325 Spec EnglishDocument4 paginiJungheinrich II Etv Etm 320 325 Spec EnglishAsif Javed100% (1)

- SepEx 1266 Controller ManualDocument66 paginiSepEx 1266 Controller ManualAzer QurbanovÎncă nu există evaluări

- The Perfect Electric Forklift Truck, Whatever Your NeedsDocument40 paginiThe Perfect Electric Forklift Truck, Whatever Your NeedsEkansh AroraÎncă nu există evaluări

- 5G Smart Port Whitepaper enDocument27 pagini5G Smart Port Whitepaper enWan Zulkifli Wan Idris100% (1)

- Brochure Complete Pedestrian Pallet Truck RangeDocument32 paginiBrochure Complete Pedestrian Pallet Truck RangeGo WolowitzÎncă nu există evaluări

- Data Sheet Efg 213 215 216k 216 218k 218 220Document4 paginiData Sheet Efg 213 215 216k 216 218k 218 220Dejan MitrovićÎncă nu există evaluări

- Jungheinrich II Etv Etm 214 216 Spec EnglishDocument4 paginiJungheinrich II Etv Etm 214 216 Spec EnglishEmreÎncă nu există evaluări

- FM-X Technical Data Driver Seated Reach TruckDocument11 paginiFM-X Technical Data Driver Seated Reach TruckAnwar DeenÎncă nu există evaluări

- Ep16nt PDFDocument4 paginiEp16nt PDFBa MamadouÎncă nu există evaluări

- Still - MXDocument8 paginiStill - MXtomy112Încă nu există evaluări

- 4,000-6,500 LB Electric Forklift Trucks PDFDocument16 pagini4,000-6,500 LB Electric Forklift Trucks PDFForklift Systems IncorporatedÎncă nu există evaluări

- Safety Instructions: EnglishDocument4 paginiSafety Instructions: EnglishAdrian FerreyraÎncă nu există evaluări

- EPT-20-20RA Operation ManualDocument43 paginiEPT-20-20RA Operation ManualRonald PiedrahitaÎncă nu există evaluări

- Workshop Manual: To Get The To Get TheDocument158 paginiWorkshop Manual: To Get The To Get TheAlexandre Alves100% (1)

- 6Huylfh0Dqxdo %: Valid From Serial Number: 425801AADocument98 pagini6Huylfh0Dqxdo %: Valid From Serial Number: 425801AAК ШÎncă nu există evaluări

- Linde Brochure 387-388 DR PDFDocument12 paginiLinde Brochure 387-388 DR PDFSohailAhmadÎncă nu există evaluări

- Jungheinrich EJC Z14 Z16 Operating Instruction 50470245 06.2005 deDocument87 paginiJungheinrich EJC Z14 Z16 Operating Instruction 50470245 06.2005 deKobelco RepairÎncă nu există evaluări

- Ficha Técnica LWE130Document8 paginiFicha Técnica LWE130brunoneroniÎncă nu există evaluări

- Instruction Handbook Electric Reack TruckDocument28 paginiInstruction Handbook Electric Reack TruckVladimirÎncă nu există evaluări

- 1212&12P (13C) - OkDocument54 pagini1212&12P (13C) - OkEriflonaÎncă nu există evaluări

- Ficha Técnica Empilhadeiras FM X en 2020 TD WebDocument12 paginiFicha Técnica Empilhadeiras FM X en 2020 TD WebRaquel MartinsÎncă nu există evaluări

- MX T6 MX T8 MX T10 MX T12 MX T15 MX T16: User Manual Please Read Carefully Before Using MX LoaderDocument32 paginiMX T6 MX T8 MX T10 MX T12 MX T15 MX T16: User Manual Please Read Carefully Before Using MX LoaderAlin Ioan TirnovanÎncă nu există evaluări

- Baoli 3ruote ACDocument87 paginiBaoli 3ruote ACmirko coppiniÎncă nu există evaluări

- Curtis Product Brochure 2011Document20 paginiCurtis Product Brochure 2011lfsauthierÎncă nu există evaluări

- PM PML PLLDocument262 paginiPM PML PLLDave Mooney100% (1)

- Модел Still FM14 характеристикиDocument12 paginiМодел Still FM14 характеристикиДеляна НемскаÎncă nu există evaluări

- Lwe140, 160Document4 paginiLwe140, 160MA TotalforkliftÎncă nu există evaluări

- BT Very Narrow Aisle Truck R-Series VRE150Document4 paginiBT Very Narrow Aisle Truck R-Series VRE150Rani Cahyani GustiÎncă nu există evaluări

- US Model Walkie Reach Stacker Operation and Maintenance Manual - 2018.3Document93 paginiUS Model Walkie Reach Stacker Operation and Maintenance Manual - 2018.3Benjamin GodinaÎncă nu există evaluări

- Jungheinrich AG: Germany - EngineeringDocument8 paginiJungheinrich AG: Germany - EngineeringSwagata DharÎncă nu există evaluări

- 3 Wheel Electric Forklift Trucks 2,500-3,200 LB PDFDocument14 pagini3 Wheel Electric Forklift Trucks 2,500-3,200 LB PDFForklift Systems IncorporatedÎncă nu există evaluări

- Operation & Maintenance Manual: Zhejiang Noblelift Equipment Joint Stock Co.,LtdDocument77 paginiOperation & Maintenance Manual: Zhejiang Noblelift Equipment Joint Stock Co.,LtdМикола Попович100% (1)

- Brosur Mitsubishi Forklift 5tonDocument10 paginiBrosur Mitsubishi Forklift 5tonAmri Anwar100% (1)

- Assembly Section: Mast - Contact Combilift Quoting The Truck Serial Number For Mast Parts ManualDocument71 paginiAssembly Section: Mast - Contact Combilift Quoting The Truck Serial Number For Mast Parts ManualJesus PintoÎncă nu există evaluări

- Manual de Partes Clark EPX20-32Document60 paginiManual de Partes Clark EPX20-32colive1Încă nu există evaluări

- Brushless DC Permanent Magnet Motor Controller: Model 1226BLDocument6 paginiBrushless DC Permanent Magnet Motor Controller: Model 1226BLSam Hal Yuss100% (1)

- Repair Manual SWE100 - 120 IxionDocument148 paginiRepair Manual SWE100 - 120 IxionjoseÎncă nu există evaluări

- 1220 (15B)Document50 pagini1220 (15B)Luis Alberto Rivas GarciaÎncă nu există evaluări

- Data Sheet Ejc m10 eDocument4 paginiData Sheet Ejc m10 eDejan MitrovićÎncă nu există evaluări

- EMC 110 B10 Data SheetDocument4 paginiEMC 110 B10 Data SheetDejan Mitrović100% (1)

- EJE I25 EJC I15 I15z Data SheetDocument4 paginiEJE I25 EJC I15 I15z Data SheetDejan MitrovićÎncă nu există evaluări

- Stacker BrochureDocument24 paginiStacker BrochureDejan MitrovićÎncă nu există evaluări

- Eje 112i Data SheetDocument4 paginiEje 112i Data SheetDejan MitrovićÎncă nu există evaluări

- Eje 112i Data SheetDocument4 paginiEje 112i Data SheetDejan MitrovićÎncă nu există evaluări

- Data Sheet Am 22Document4 paginiData Sheet Am 22Carlos DiazÎncă nu există evaluări

- Moving Mast and Pantograph Reach Trucks OverviewDocument4 paginiMoving Mast and Pantograph Reach Trucks OverviewDejan MitrovićÎncă nu există evaluări

- Data Sheet Ejc m10 eDocument4 paginiData Sheet Ejc m10 eDejan MitrovićÎncă nu există evaluări

- Jungheinrich Hand Pallet Trucks Complete RangeDocument20 paginiJungheinrich Hand Pallet Trucks Complete RangeDejan MitrovićÎncă nu există evaluări

- Jungheinrich Hand Pallet Trucks Complete RangeDocument20 paginiJungheinrich Hand Pallet Trucks Complete RangeDejan MitrovićÎncă nu există evaluări

- Data Sheet Etr 230 235 340 345 335dDocument4 paginiData Sheet Etr 230 235 340 345 335dDejan MitrovićÎncă nu există evaluări

- Maritime AwarenessDocument5 paginiMaritime AwarenessMuhammad AijazÎncă nu există evaluări

- Location of Connector Joining Wire Harness and Wire Harness: Location of Ground PointsDocument8 paginiLocation of Connector Joining Wire Harness and Wire Harness: Location of Ground PointsHugo E. TorresÎncă nu există evaluări

- Fuel Supply Pump RemovalDocument16 paginiFuel Supply Pump RemovalKaren Tapia garciaÎncă nu există evaluări

- Energy Storage in EhvDocument22 paginiEnergy Storage in Ehvrathijit sinhaÎncă nu există evaluări

- DESIRO UK Electrical Multiple Unit FamilyDocument4 paginiDESIRO UK Electrical Multiple Unit FamilyVíctor FaucheretÎncă nu există evaluări

- AIEP Practical Application WorkDocument8 paginiAIEP Practical Application WorkScribdTranslationsÎncă nu există evaluări

- IELTS 15, Test 1 Answer Key, Academic ReadingDocument6 paginiIELTS 15, Test 1 Answer Key, Academic ReadingpeymanÎncă nu există evaluări

- Honda C70 Book Manual PDFDocument207 paginiHonda C70 Book Manual PDFraymacsor100% (1)

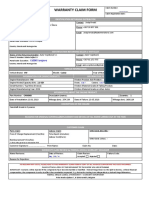

- Warranty Claim Form: 1000 SarajevoDocument1 paginăWarranty Claim Form: 1000 SarajevoJosip KvesicÎncă nu există evaluări

- Product Recommendation JCB Telescopic Handlers 535-95 (63 KW) Stage III (2011-2013)Document4 paginiProduct Recommendation JCB Telescopic Handlers 535-95 (63 KW) Stage III (2011-2013)Valmaq Prestação Serviço LdaÎncă nu există evaluări

- Maximization of Natural Gas Liquids Production FroDocument9 paginiMaximization of Natural Gas Liquids Production Froerwin_carryÎncă nu există evaluări

- Global Pearl - Global Petro TechDocument1 paginăGlobal Pearl - Global Petro TechMike JonesÎncă nu există evaluări

- Kmci CyyzDocument7 paginiKmci CyyzmcameraÎncă nu există evaluări

- Dutch Traffic ManagementDocument84 paginiDutch Traffic ManagementJulieÎncă nu există evaluări

- Flight Operations Manual: 6.1.13 Demonstration PolicyDocument4 paginiFlight Operations Manual: 6.1.13 Demonstration PolicyAndres Alfonso Aldana PardoÎncă nu există evaluări

- Yugoslav Order of Battle Prior To The Invasion of YugoslaviaDocument23 paginiYugoslav Order of Battle Prior To The Invasion of YugoslaviaChristopher ServantÎncă nu există evaluări

- A005A600620-Simos Injection and Ignition System (6-Cyl 2 4 LTR)Document45 paginiA005A600620-Simos Injection and Ignition System (6-Cyl 2 4 LTR)vmarius2dÎncă nu există evaluări

- Wiring Diagram - AutodataDocument6 paginiWiring Diagram - AutodataHenry Wilian De La Cruz SandovalÎncă nu există evaluări

- 2010 Chrysler SebringDocument444 pagini2010 Chrysler SebringHELEN QUIROGAÎncă nu există evaluări

- TRX Guide Line: For Excess, Surplus TRX CalculationsDocument8 paginiTRX Guide Line: For Excess, Surplus TRX CalculationsambroserfÎncă nu există evaluări

- Nihal Gabr: 2A Membrane, and TransportDocument55 paginiNihal Gabr: 2A Membrane, and Transportbody fayezÎncă nu există evaluări

- TDS Biotum PGB 50 70 0618Document2 paginiTDS Biotum PGB 50 70 0618Jose CastroÎncă nu există evaluări

- G.R. No. 114167 Coastwise V CADocument5 paginiG.R. No. 114167 Coastwise V CAOjie SantillanÎncă nu există evaluări

- Design and Analysis of Flying Wing UAV UDocument7 paginiDesign and Analysis of Flying Wing UAV UMariana FeijoÎncă nu există evaluări