Documente Academic

Documente Profesional

Documente Cultură

ITP - General Fill For The Roads - Sample

Încărcat de

zubairTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ITP - General Fill For The Roads - Sample

Încărcat de

zubairDrepturi de autor:

Formate disponibile

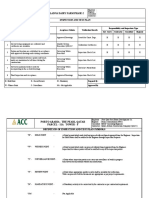

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

Controlling

Document

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

Acceptance

Criteria

Frequency

QC Approval

ADPC submittal

review code 1 or

code 2

Prior to start

the work on

site

Approved ADPC

review sheet

with code 1 or

code 2

QC Approval

ADPC submittal

review code 1 or

code 2

Prior to start

the work on

site

Approved shop

drawing

QC Approval

Prior to start

the work on

site

IFC drawing

QC Approval

ADPC submittal

review code 1 or

code 2

Prior to start

the work on

site

Approved Material

Inspection

Request

Approved test

report

Preliminary Work / Document Review

A

1.01

Method Statement

1.02

Shop Drawing

1.03

Notice of operation

1.04

Material submittal and approval

Exhibit D part

1 Appendix

1 Specific

Constructio

n

Requiremen

ts, rev E

ADM

Standards,

section 11

clause

200.06h

ADM

standards

section 1-2,

clause

102.08

Exhibit D

Scope of

works

Technical

Specificatio

n Clause

2.1.3

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

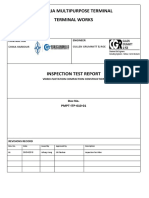

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

S - Surveillance

R Record Review

Ite

m

No.

Test Inspection Activity

Description

1.05

Verification of Original Ground

Level survey

KPIZ Exhibit D As per IFC Drawing

Scope of

Works

clause

3.16.1 up to

3.16.3

Prior to start

the activity

1.06

Manual Excavation to locate &

protect existing utilities

ADM

Visual Inspection

Standards

Section II-5

clause

205.04

Every

excavation of

existing

utilities

Material Testing / Review

2.01

Test imported or excavated Borrow

Material to determine suitability

Sieve Analysis passing Sieve AASHTO T-27 Max 20%

AASHTO T-88,

no.200

T-11

Maximum Particle Size

Exhibit D,

Shall not exceed

attachment

100mm

C particular

specification

for

2.01.

1

2.01.

2

Controlling

Document

ITP No.

Rev. No

Date:

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

Acceptance

Criteria

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

Frequency

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

Field Survey Data

and Report

(FM-260-ATTACH

01)

(FM-260-ATTACH

02)

(FM-260-ATTACH

03)

(FM-260-ATTACH

04)

FM-260-V8-003

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

R/S

R/S

1 sample every Approved test

3000m3

report

1 sample every Approved test

3000m3

report

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

2.01.

3

2.01.

4

2.01.

5

2.01.

6

2.01.

7

Liquid Limit

Plastic Limit & Plasticity

Index

Moisture Density

Relationship

California Bearing Ratio (Lab

CBR)

Organic content

2.01.

8

Water soluble sulphate

2.01.

9

Chloride content

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Controlling

Document

Acceptance

Criteria

earthworks

and filling

clause 4.2

AASHTO T-89 Max 40%

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

1 sample every

3000m3

1 sample every

3000m3

1 sample every

3000m3

1 sample every

3000m3

1 sample every

3000m3

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

test

test

Test

Test

Test

Less than 5%

1 sample every Approved Test

3000m3

report

Less than 5%

1 sample every Approved Test

3000m3

report

AASHTO T-90 Max 6%

AASHTO T

180

AASHTO T

193

Exhibit D, Part

2

Attachment

C Particular

Specificatio

n Clause 4.2

Exhibit D, Part

2

Attachment

C Particular

Specificatio

n Clause 4.2

Exhibit D, Part

2

Attachment

C Particular

Frequency

1001-260-V8-0000-00136

006

As determined by

testing

Minimum 15%

Less than 2%

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

Approved

Report

Approved

Report

Approved

report

Approved

report

Approved

report

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

2.01.

10

Test Inspection Activity

Description

Check Sampling of Testing

for Geotextile material

Fabric Weight

Tensile Strength

Elongation

Puncture Strength

Burst Strength

Tear Strength

Permeability

Flow Rate

Strength Retention

Controlling

Document

ITP No.

Rev. No

Date:

Specificatio

n Clause 4.2

ADM

Standards

Section II-7

clause

207.05

TYPE 1

TYPE 2

100gm/m2 /

ASTM D 1910

135gm/m2

ASTM D 1682 560N

900N

ASTM D 1682

20%

ASTM D 751

20%

ASTM D 3786 200N

600N

ASTM D 1117

AASHTO M

288

AASHTO M

288

ASTM D 1682

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

Approved Test

report

Approved Test

report

First delivery of Approved Test

report

each supplier

First delivery of

each supplier Approved Test

report

S - Surveillance

R Record Review

Acceptance

Criteria

860KPA /

2200KPA

80N

225N

0.01cm/sec / .

01cm/sec

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

1001-260-V8-0000-00136

006

Frequency

First delivery of

each supplier

First delivery of

each supplier

First delivery of

each supplier

First delivery of

each supplier

First delivery of

each supplier

First delivery of

each supplier

First delivery of

each supplier

Approved Test

report

Approved Test

report

Approved Test

report

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Controlling

Document

Acceptance

Criteria

Frequency

2.01.

11

Check suitability of

Capillary break material

Los Angeles Abrasion

Soundness (Sodium)

Soundness (Magnesium)

Sand Equivalent

Liquid Limit

Plasticity Index

Sulphate Content

Chloride Content

Flakiness Index

Elongation

ADM

Standards

section III-2

clause

302.02

AASHTO T96

(ASTM

C131)

AASHTO

T104

AASHTO

T140 (ASTM

C88)

AASHTO

T176 (ASTM

D-2419)

AASHTO T89

(ASTM

D4318)

AASHTO T90

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

12% MAX

15% MAX

25% MINI.

35% MAX.

6.0% MAX.

0.50% MAX

1.0% MAX

35% MAX.

35% MAX.

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

Approved Test

report

40 MAX

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

Approved Test

report

25l/s/m2. /

25l/s/m2.

560N

900N

1001-260-V8-0000-00136

006

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

Approved test

report

Approved test

report

Approved test

report

Approved test

report

Approved test

report

Approved test

report

Approved test

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

Specific Gravity

S - Surveillance

R Record Review

Controlling

Document

Acceptance

Criteria

2.20 MIN.

Max Dry Density

(ASTM D

4318)

B.S 1377

C.B.R at 98% of M.D.D

B.S 812

65% Min.

2.10 gr/cc Min.

B.S 812

Sieve size analysis

100mm

75mm

50mm (2)

25mm (1)

12.5mm (1/2)

9.5mm (3/8)

% Passing

B.S 812

100

AASHTO

T100 & T85

AASHTO

T180D

AASHTO

T193 (ASTM

D1883)

75 to 100

As per CTI

1001-260V9-000000010

ITP No.

Rev. No

Date:

25 to 75

10 to 50

5 to 20

0 to 3

Frequency

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1 test every

1000m3

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

report

Approved test

report

Approved test

report

Approved test

report

Approved test

report

Approved test

report

Approved test

report

Approved test

report

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

Approved test

report

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

Controlling

Document

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Acceptance

Criteria

Frequency

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

Approved test

report

Approved test

report

Approved test

report

Approved test

report

Construction Phase

3.01. Clearing and Grubbing at site

1

ADM

Removal of all dead Prior to start

Inspection

standards

trees, brush or other

next activity

checklist

section II-3

objectionable

of each area. (FM-260-V8-001)

clause

vegetation.

(FM-260-V8-002)

All stumps roots or

203.05

(FM-260-V8-003)

AASHTO Tmats shall be

193

removed to a depth

not less than 90cm

below Subgrade.

All depressions

formed by removal

of stump roots shall

be refilled with

approved borrow

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

Controlling

Document

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Acceptance

Criteria

Frequency

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

material.

3.01. Check existing Subgrade material

2

and removal of unsuitable

ADM

material

standards

CBR @ 95% MDD

Section II,

clause

206.05

ADM

Standards

Section II

clause

207.04

3.01. Staking out of the works

3

If CBR value is 5% to As per site

Approved Test

10% cut 30cm

condition /

Report

below top of finish

Every 500 LM FM-260-V8-003

Subgrade and fill

whichever is

with borrow

less

material of 25%

CBR.

W/

R

W/R

S/R

If CBR value is 5% cut

45cm below top of

finish Subgrade and

fill with borrow

material of 25%

CBR

10% CBR value for all

existing Subgrade

ADM

The level and

From the start Field survey

standards

alignment shall be

of the

request data.

section II-3

in accordance to IFC

activity

(FM-260-ATTACH

clause

drawing.

01)

203.03

(FM-260-ATTACH

02)

(FM-260-ATTACH

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

3.01. Checking of compaction trial

4

before main filling

3.01. Placement of borrow material for

5

filling

Check Existing Ground

Layer Thickness

In Situ Density (Sand Cone

Method)

Controlling

Document

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Acceptance

Criteria

Frequency

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

03)

(FM-260-ATTACH

04)

ADM

Minimum of 95% MDD First layer of fill Approved test

standards

before

report

section II-6

commencem

clause

ent of main

206.02d.

filling works

ADM

standards

section II-6

clause

206.02b

ADM

standards

section II-6

clause

206.02c.

To be cut and

Prior to filling Approved test

scarified according

of first layer

report

FM-260-V8-003

to IFC drawing

Maximum15cm of

Every layer of

Survey report

compacted depth

filling

(FM-260-ATTACH

(10cm max depth

01)

in inaccessible

(FM-260-ATTACH

areas.)

02)

(FM-260-ATTACH

03)

1 per 1500m2

(FM-260-ATTACH

Minimum 95%

04)

FM-260-V8-003

Approved test

Exhibit D, part

report

2 att.C

FM-260-V8-003

particular

specs

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

1 per 750m2

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

W/

R

W/R

W/

R

W/R

S/R

W/

R

W/R

W/

W/R

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

3.01.

6

In-situ CBR Test

Optimum Moisture Content

Capillary Break layer, Geogrid

& Geotextile installation

Laying of Geotextile

Controlling

Document

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Acceptance

Criteria

Frequency

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

clause 3.4 CBR of minimum 15%

AASHTO T191

ASTM D 1556

Exhibit D Part

Minimum 95% of MDD

2

OMC -2% to +4%

Attachment

C, Particular

Specificatio

ns clause

3.5

AASHTO T-93,

T-217

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

1 test every

Approved test

100 LM run

report

or 1000m2

FM-260-V8-003

whichever is

less

W/

R

Approved test

report

FM-260-V8-003

H

Inspection

Free from cuts and

Every laying

Checklist

damage

for Geotextile

(FM-260-V8 Shall be laid loosely

020)

parallel to the

centerline with a

minimum of 300mm

Every laying

overlap.

Laying of Geogrid material (S30 or

for Geogrid

Free

from

cuts

and

similar equivalent)

Inspection

damage

CTI no.: 1001Checklist

Shall

be

laid

on

the

260-V9(FM-260-V8top

of

capillary

0000-00005

ADM

Standards

Section II

clause

207.05

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

S/R

W/

R

S/R

W/

R

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

Laying of capillary break

Layer Thickness

Compaction Degree

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Controlling

Document

Acceptance

Criteria

Frequency

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

break layer lapping

020)

with the bottom

Every laying

membrane layer.

for capillary

break layer

ADM

Maximum of 15cm

Standards

compacted depth.

Inspection

section III-2 Shall not vary from

1 test every

more than 8mm

clause

Checklist

100 linear

from the total

302.06c

(FM-260-V8meter or

thickness.

020)

1000m2

whichever is

98% max dry density

less

ADM

Standards

Inspection

section III-2

clause

Checklist

302.06c

(FM-260-V8001)

3.01. Check Final levels and evenness of ADM

7

the surface

Standards

Section II-8

clause

208.03

The max. gap 1 checked

every 20m

between the road

determined

Subgrade surface

by the qc

and the testing

engineer

edge shall not be

greater than 2cm.

Variation in the falls to

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

Approved survey

report

(FM-260-ATTACH

01)

(FM-260-ATTACH

02)

(FM-260-ATTACH

03)

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

W/

R

S/R

W/

R

W/R

W/

R

S/R

R Review

Record/ Documents review

INSPECTION AND TEST PLAN

ITP Scope Description: General Fill for the Roadways / Subgrade

Project:

Client

Job No.

Khalifa Port

Abu Dhabi Ports Co. ADPC

1001-260

Nature of Inspection

H Hold Point

W Witness Point

Ite

m

No.

Test Inspection Activity

Description

ITP No.

Rev. No

Date:

S - Surveillance

R Record Review

Controlling

Document

Acceptance

Criteria

cross-sections of the

road

shall

not

exceed 0.4 percent.

Frequency

1001-260-V8-0000-00136

006

Inspection Authority

1 Supervisor

2 QC /QA

Form of

Record /

1

Verification

Document

3 - PMC

4 Third Party

Inspection

Remarks

2

3

4

(FM-260-ATTACH

04)

Levels

of

the

finished

surface

shall not vary by

more than 2cm.

Variation in crosssectional slope shall

not

exceed

0.8

percent

Post Construction Phase

4.01

All As-built records

4.02

Submittal of all Test Reports

ADM

According to all IFC

specification

drawing

section 1-1

clause

101.03

As per

According to all ITP

required

test required

according to

the test on

ITP

H Hold Point

Written notification required. Contractor may not

proceed beyond this point without written confirmation

of the Employer

W Witness Point

Written notification required but

contractor may proceed if Employers

representatives do not attend.

On completion Approved as-built

of the work

submittals

On completion Approved test

of the work

reports

S Surveillance

No notification required but activity may

be subjected to Employer surveillance/

monitoring

R Review

Record/ Documents review

S-ar putea să vă placă și

- MS Site and FenceDocument11 paginiMS Site and FenceSahabzada AamirÎncă nu există evaluări

- ITP For PlasteringDocument2 paginiITP For PlasteringPrasanna KumarÎncă nu există evaluări

- Inspection & Test Plan (Itp) : Road WorkDocument1 paginăInspection & Test Plan (Itp) : Road WorkLOPA THANDARÎncă nu există evaluări

- Quality InductionDocument15 paginiQuality InductionaleemmurtazaÎncă nu există evaluări

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 paginiProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKÎncă nu există evaluări

- PC-ITP-001 - Backfilling and ExcavationDocument2 paginiPC-ITP-001 - Backfilling and ExcavationHusam zayedÎncă nu există evaluări

- Installation of LV Cables: Inspection and Test Plan ForDocument1 paginăInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirÎncă nu există evaluări

- Project Internal Audit Procedure: SheetalkumarDocument4 paginiProject Internal Audit Procedure: SheetalkumarTwin BullsÎncă nu există evaluări

- Contractor Quality Control Plan For Electrical Equipment InstallationDocument7 paginiContractor Quality Control Plan For Electrical Equipment Installationhasan_676489616Încă nu există evaluări

- Mitp For Surveying Setting Out ApprovedDocument4 paginiMitp For Surveying Setting Out ApprovedMogu MohanÎncă nu există evaluări

- QM Plan ProcedureDocument13 paginiQM Plan ProcedureHans JonesÎncă nu există evaluări

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocument20 pagini04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraÎncă nu există evaluări

- Soil Compaction Test ReportDocument7 paginiSoil Compaction Test ReportAkash SharmaÎncă nu există evaluări

- Appendix H: Design and Construction Manual Design RequirementsDocument17 paginiAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelÎncă nu există evaluări

- Accessories ListDocument10 paginiAccessories ListShashank HegdeÎncă nu există evaluări

- Cb2 Q Zen 05 60211 Itp For Earth Work - Rev.bDocument6 paginiCb2 Q Zen 05 60211 Itp For Earth Work - Rev.bAnonymous wIPMQ5rhÎncă nu există evaluări

- Inspection and Test Plan (ITP) for Suspending Ceiling InstallationDocument2 paginiInspection and Test Plan (ITP) for Suspending Ceiling Installationexia1992Încă nu există evaluări

- ITP 63113 XX Stockpile ITP (Working)Document6 paginiITP 63113 XX Stockpile ITP (Working)soni10483Încă nu există evaluări

- Storm Drain Flushing Method StatementDocument12 paginiStorm Drain Flushing Method Statementarshad iqbalÎncă nu există evaluări

- ITP EverythingDocument5 paginiITP EverythingAkram SayeedÎncă nu există evaluări

- Method Statement of Mass Concrete Block Precast WorksDocument41 paginiMethod Statement of Mass Concrete Block Precast WorksShams JogÎncă nu există evaluări

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 paginiIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedÎncă nu există evaluări

- ITP C 005 (Structural Concrete)Document4 paginiITP C 005 (Structural Concrete)segun ajibolaÎncă nu există evaluări

- Itp GuidelinesDocument5 paginiItp GuidelinesSilla ShameerÎncă nu există evaluări

- Contractor Monthly Quality Report SummaryDocument11 paginiContractor Monthly Quality Report SummaryKarthik KumarÎncă nu există evaluări

- ProcurementDocument6 paginiProcurementDenmark CostanillaÎncă nu există evaluări

- Italian-Thai Density Test ResultsDocument9 paginiItalian-Thai Density Test ResultsJovanni RodriguezÎncă nu există evaluări

- J910-Dh02-P10zen-040010 - (Ahf) Field Itp For Precast Box Culvert Installation Work - Rev.aDocument16 paginiJ910-Dh02-P10zen-040010 - (Ahf) Field Itp For Precast Box Culvert Installation Work - Rev.arudi sarifudinÎncă nu există evaluări

- A Qac Pro 000 38951Document30 paginiA Qac Pro 000 38951Amin GÎncă nu există evaluări

- Itp For Installation of FormworksDocument1 paginăItp For Installation of FormworksImho TepÎncă nu există evaluări

- ITP For Handrail WeldingDocument2 paginiITP For Handrail WeldingKumar AbhishekÎncă nu există evaluări

- SKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTDocument6 paginiSKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTVinod MasaniÎncă nu există evaluări

- Scaffold ChecklistDocument5 paginiScaffold ChecklistMohamed GhariebÎncă nu există evaluări

- Programme On Quality Control & Assurance: Sankha Bhattacharya, Housing Devolopment LimitedDocument25 paginiProgramme On Quality Control & Assurance: Sankha Bhattacharya, Housing Devolopment Limitedsankha07Încă nu există evaluări

- Itp - EifsDocument22 paginiItp - Eifssathiyaprasath100% (1)

- Saudi Aramco Fence Inspection ChecklistDocument3 paginiSaudi Aramco Fence Inspection ChecklistAbuAhmedQuaziÎncă nu există evaluări

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocument2 paginiKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanÎncă nu există evaluări

- ITP Is The Minimum Requirement of The Activities For Quality Control and Inspection of The FieldDocument3 paginiITP Is The Minimum Requirement of The Activities For Quality Control and Inspection of The FieldvigneshÎncă nu există evaluări

- Inspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CDocument1 paginăInspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CYash SharmaÎncă nu există evaluări

- Field Quality Plan For LgfsDocument7 paginiField Quality Plan For LgfsUday PratapÎncă nu există evaluări

- Mumbai Trans Harbour Link Project Non-Conforming Item ProcedureDocument15 paginiMumbai Trans Harbour Link Project Non-Conforming Item ProcedureDeepak UpadhayayÎncă nu există evaluări

- Inspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselDocument1 paginăInspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselNikki RobertsÎncă nu există evaluări

- PMPT Itp 010Document3 paginiPMPT Itp 010hz135874Încă nu există evaluări

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 paginiInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoÎncă nu există evaluări

- ITP-CI-026a-02 (Building Finishing Works)Document4 paginiITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyÎncă nu există evaluări

- 002 - ITP Earthworks - Revision 2.0Document12 pagini002 - ITP Earthworks - Revision 2.0randyÎncă nu există evaluări

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- CREC Construction Inspection Equipment ProcedureDocument3 paginiCREC Construction Inspection Equipment ProcedureStephen David GozunÎncă nu există evaluări

- Site Inspection and Test Plan for EarthworkDocument10 paginiSite Inspection and Test Plan for EarthworkMohammed Mujahid100% (1)

- Concrete Inspection and Testing PlanDocument3 paginiConcrete Inspection and Testing PlanMohammed Ghareib NasrÎncă nu există evaluări

- QCP - BuildingsDocument4 paginiQCP - BuildingsMitendra Kumar ChauhanÎncă nu există evaluări

- Cable Containment ITPDocument1 paginăCable Containment ITPwagwahkiabatheÎncă nu există evaluări

- Qap PDFDocument11 paginiQap PDFNirajan MarwaitÎncă nu există evaluări

- Excavation and Backfill Inspection PlanDocument9 paginiExcavation and Backfill Inspection PlanShewale PravinÎncă nu există evaluări

- Field Installation, Inspection & Test PlanDocument2 paginiField Installation, Inspection & Test PlanSaiful Ahda100% (1)

- CEMENT PLASTERING CHECKLISTDocument1 paginăCEMENT PLASTERING CHECKLISTsankuj5354Încă nu există evaluări

- Itp For Gravel Surfacing and Dust PreventionDocument7 paginiItp For Gravel Surfacing and Dust PreventionShewale PravinÎncă nu există evaluări

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 paginiLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyÎncă nu există evaluări

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pagini050-Itp For Installation of Air Intake Filter PDFKöksal PatanÎncă nu există evaluări

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pagini045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- Cor-Ohs-Taf-000-000 Oshad Audit Checklist, V1Document9 paginiCor-Ohs-Taf-000-000 Oshad Audit Checklist, V1zubairÎncă nu există evaluări

- NBI-EHS-CH-15 Inspection & Testing ProcedureDocument6 paginiNBI-EHS-CH-15 Inspection & Testing ProcedurezubairÎncă nu există evaluări

- Cor-Ohs-Taf-000-000 Oshad Audit Checklist, V1Document9 paginiCor-Ohs-Taf-000-000 Oshad Audit Checklist, V1zubairÎncă nu există evaluări

- FirstTimeQuality Inspection Test Plan Form V2Document1 paginăFirstTimeQuality Inspection Test Plan Form V2Kerwin Britton100% (1)

- ITP - General Fill For The Roads - SampleDocument12 paginiITP - General Fill For The Roads - SamplezubairÎncă nu există evaluări

- Ageism in An Aging SocietyDocument11 paginiAgeism in An Aging SocietydavidÎncă nu există evaluări

- Worksheet 8 - Interview QuestionsDocument4 paginiWorksheet 8 - Interview QuestionsAR_writing_samplesÎncă nu există evaluări

- SPEE Monograph 3 DiscussionDocument34 paginiSPEE Monograph 3 DiscussionManuel RodriguezÎncă nu există evaluări

- Correlation AnalysisDocument7 paginiCorrelation Analysisapi-339611548Încă nu există evaluări

- Explainable AI in The Context of Data Engineering: Unveiling The Black Box in The PipelineDocument6 paginiExplainable AI in The Context of Data Engineering: Unveiling The Black Box in The PipelineInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Challenges of International Standards On AuditingDocument7 paginiChallenges of International Standards On AuditingMuhammad Haiqhal Bin Mohd Noor AzmanÎncă nu există evaluări

- TricycleDocument10 paginiTricyclechancer01Încă nu există evaluări

- BSBTWK401 Student Copy Build and Maintain Business RelationshipsDocument37 paginiBSBTWK401 Student Copy Build and Maintain Business Relationshipsfiseha bekeleÎncă nu există evaluări

- Adaptive Reuse As A StrategyDocument10 paginiAdaptive Reuse As A StrategyAlexandru ȚîrcăÎncă nu există evaluări

- SAS - Session - 16.0 Research 2Document3 paginiSAS - Session - 16.0 Research 2Angel Grace Palenso QuimzonÎncă nu există evaluări

- In An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product RepresentationDocument34 paginiIn An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product Representationpalaniappan_pandianÎncă nu există evaluări

- IntroductionDocument61 paginiIntroductionShakeel AhmedÎncă nu există evaluări

- 0412055511MarkovChainDocument508 pagini0412055511MarkovChaincartamenes100% (4)

- Resume (Ateebuddin)Document3 paginiResume (Ateebuddin)sam09132Încă nu există evaluări

- Statistics 1 Discrete Random Variables Past ExaminationDocument24 paginiStatistics 1 Discrete Random Variables Past ExaminationAbid FareedÎncă nu există evaluări

- TeachStarter 709102 TeachStarter Starter Sheet Chance and Data Maths Investigation Roll Me A SixDocument2 paginiTeachStarter 709102 TeachStarter Starter Sheet Chance and Data Maths Investigation Roll Me A SixIuliana IgnatÎncă nu există evaluări

- Approaches of ManagementDocument6 paginiApproaches of ManagementJhk BiiÎncă nu există evaluări

- Chapter 15, Software Life CycleDocument79 paginiChapter 15, Software Life CycleRahim KhanÎncă nu există evaluări

- Mitchell and Jolley-Research Design Explained-359-381Document23 paginiMitchell and Jolley-Research Design Explained-359-381Gaby Fitria BahriÎncă nu există evaluări

- Distance 6 User's GuideDocument358 paginiDistance 6 User's Guidecretinusmaximus100% (1)

- BAFAC12X - Intermediate Accounting 1 & 2 - UpdatedDocument12 paginiBAFAC12X - Intermediate Accounting 1 & 2 - UpdatedNicole Daphne FigueroaÎncă nu există evaluări

- Applied Behavior AnalysisDocument7 paginiApplied Behavior AnalysisduliniÎncă nu există evaluări

- Bus Stat. 11Document48 paginiBus Stat. 11Shela RamosÎncă nu există evaluări

- Research Methods Project (Shoaib)Document30 paginiResearch Methods Project (Shoaib)mahuaÎncă nu există evaluări

- Low Intensity Laser Therapy in Bone Healing and OsteoporosisDocument80 paginiLow Intensity Laser Therapy in Bone Healing and OsteoporosisNguyễn Xuân PhongÎncă nu există evaluări

- Entrepreneurship - For StudentsDocument111 paginiEntrepreneurship - For StudentsAdrian Jay BeloyÎncă nu există evaluări

- Master Thesis Writing GuidelinesDocument21 paginiMaster Thesis Writing Guidelinessoltoianu_irinaÎncă nu există evaluări

- Breadth RequirementsDocument2 paginiBreadth RequirementsJulian ChoÎncă nu există evaluări

- What Is A Classification EssayDocument3 paginiWhat Is A Classification Essayzzcpllaeg100% (2)

- CPSM BasicsDocument15 paginiCPSM BasicsProsenjit Das0% (1)