Documente Academic

Documente Profesional

Documente Cultură

Productivity Improvement Techniques Towards Maintaining Competitiveness

Încărcat de

eddiekuangDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Productivity Improvement Techniques Towards Maintaining Competitiveness

Încărcat de

eddiekuangDrepturi de autor:

Formate disponibile

CQE Training & Consultancy (0187064-K)

Registered Office : No. 46, Lorong Bintang, Taman Tasik Permai, 34000 Taiping, Perak. Malaysia.

Operating Office : No. 85A (1st. Floor), Jalan Barrack, 34000 Taiping, Perak. Malaysia.

T : +605-805 2722 / +605-808 8028 F : +605-805 2721 M : +6012-505 2720 / +6012-550 2721

E : cqetrg@streamyx.com or cqetraining@gmail.com

PRODUCTIVITY IMPROVEMENT

TECHNIQUES (PIT) TOWARDS MAINTAINING

COMPETITIVENESS

(PUBLIC / IN-HOUSE TRAINING PROGRAMME)

SBL

Scheme

Introduction

Successful revolutions deliver a new order. With Quality and Productivity, a company aspires to a new

order of higher performance which ultimately must be world class in standard. World class performance

comes from world class practices which is in turn created by world class management. With the

implementation of AFTA 2003 and WTO, every organization is facing more competitive challenges and

fighting for survival due to the globalization effects. Various efforts such as cost down, improving

Quality, Cost and Delivery (QCD), improving Productivity, integrating systems to synergy the limited

resources, re-engineering, excellence customer services and others are aiming to bring the organization

to a new level towards world class standard. In this context, Productivity Improvement Techniques

(PIT) is one of the alternative that most of the organization is employing to assist them continuously

striving for excellence in everything they do.

Learning Outcomes/Objectives

Also available as

in-house programme

Upon return to workplace, participants will be able to :

Understand the important and significance of the Productivity in the business environment ;

Learn the various productivity concepts and measures in actual work place ;

Means and methods for implementing relevant productivity activities in actual work place

that bring added values to the organization ;

Strive to improve total productivity scenario in and culture in the organization.

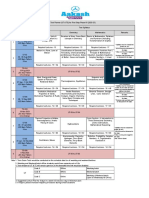

CONTENTS

PRODUCTIVITY

Introduction & Background

Definition

Prepared by : Mr . Eddie Kuang

Copyright 2012. All Rights Reserved

-1-

CQE Training & Consultancy (0187064-K)

Registered Office : No. 46, Lorong Bintang, Taman Tasik Permai, 34000 Taiping, Perak. Malaysia.

Operating Office : No. 85A (1st. Floor), Jalan Barrack, 34000 Taiping, Perak. Malaysia.

T : +605-805 2722 / +605-808 8028 F : +605-805 2721 M : +6012-505 2720 / +6012-550 2721

E : cqetrg@streamyx.com or cqetraining@gmail.com

PRODUCTIVITY IMPROVEMENT TECHNIQUES

METHOD STUDY

1. Outline Process Chart

2. Flow Process Chart

3. Flow Diagram

4. String Diagram

MS Excel Worksheet

Analysis

5. Multiple Activitiy Chart

6. Travel Chart

7. Workplace Layout

WORK MEASUREMENT

1. Time Study

2. Observed Time

3. Rating

4. Basic Time

5. Allowances

6. Standard Time

7. Time Study Sheets

REFERENCE MODELS

1. Labour Productvity Model

2. Capacity Planning Model

3. Cycle Time Model

TOTAL PRODUCTIVE MAINTENANCE

MATERIAL COST REDUCTION

COSTING

BENCHMARKING

REFERENCES

Prepared by : Mr . Eddie Kuang

Copyright 2012. All Rights Reserved

-2-

CQE Training & Consultancy (0187064-K)

Registered Office : No. 46, Lorong Bintang, Taman Tasik Permai, 34000 Taiping, Perak. Malaysia.

Operating Office : No. 85A (1st. Floor), Jalan Barrack, 34000 Taiping, Perak. Malaysia.

T : +605-805 2722 / +605-808 8028 F : +605-805 2721 M : +6012-505 2720 / +6012-550 2721

E : cqetrg@streamyx.com or cqetraining@gmail.com

TRAINING METHODOLOGY

The program would be conducted by using the following materials / aids:Course Note

LCD / OHP

Group Activities / Workshop

Video Showing

Lecturettes

DURATION

2 Days

PARTICIPANTS

Production, Operation, Quality and Supporting Department executives and supervisors who are

involved in quality and productivity improvement projects execution and implementation.

Prepared by : Mr . Eddie Kuang

Copyright 2012. All Rights Reserved

-3-

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Aiag-Vda Fmea Handbook Training: (In-House / Public Training Programme)Document3 paginiAiag-Vda Fmea Handbook Training: (In-House / Public Training Programme)eddiekuang100% (1)

- 58.EQA Act127 Introductiry Training PDFDocument4 pagini58.EQA Act127 Introductiry Training PDFeddiekuangÎncă nu există evaluări

- Registration Form: SBL SchemeDocument1 paginăRegistration Form: SBL SchemeeddiekuangÎncă nu există evaluări

- Lean Warehouse / Supply Chain Management (SCM) Training: (Public / In-House Training Programme)Document4 paginiLean Warehouse / Supply Chain Management (SCM) Training: (Public / In-House Training Programme)eddiekuangÎncă nu există evaluări

- Integrated Environmental and OH&S Management Systems Introductory & Awareness TrainingDocument4 paginiIntegrated Environmental and OH&S Management Systems Introductory & Awareness TrainingeddiekuangÎncă nu există evaluări

- Iso13485:2016 Medical Devices Qms Internal Audit TrainingDocument4 paginiIso13485:2016 Medical Devices Qms Internal Audit TrainingeddiekuangÎncă nu există evaluări

- Geometric Dimensioning and Tolerancing (GD&T) : CQE Training & Consultancy PLTDocument2 paginiGeometric Dimensioning and Tolerancing (GD&T) : CQE Training & Consultancy PLTeddiekuangÎncă nu există evaluări

- 16.MINITAB Software Application Training Couse Outline 2days - SPCDocument4 pagini16.MINITAB Software Application Training Couse Outline 2days - SPCeddiekuangÎncă nu există evaluări

- Iso13485:2016 Medical Devices Qms Clause by Clause Deep Dive TrainingDocument4 paginiIso13485:2016 Medical Devices Qms Clause by Clause Deep Dive TrainingeddiekuangÎncă nu există evaluări

- Process Validation Training (PVT) : (Public / In-House Training Programme)Document4 paginiProcess Validation Training (PVT) : (Public / In-House Training Programme)eddiekuangÎncă nu există evaluări

- Productivity Improvement Techniques (Pit) Towards Maintaining CompetitivenessDocument3 paginiProductivity Improvement Techniques (Pit) Towards Maintaining CompetitivenesseddiekuangÎncă nu există evaluări

- Process Validation Training (PVT) : (Public / In-House Training Programme)Document4 paginiProcess Validation Training (PVT) : (Public / In-House Training Programme)eddiekuangÎncă nu există evaluări

- Cycle Time Management (CTM) : (Public / In-House Training Programme)Document4 paginiCycle Time Management (CTM) : (Public / In-House Training Programme)eddiekuangÎncă nu există evaluări

- 35.process Validation TRGDocument4 pagini35.process Validation TRGeddiekuangÎncă nu există evaluări

- 41.FMEA HIRARC CourseOutline 2daysDocument4 pagini41.FMEA HIRARC CourseOutline 2dayseddiekuangÎncă nu există evaluări

- 44.ohsas18001 2007 Osh IatrainingDocument4 pagini44.ohsas18001 2007 Osh IatrainingeddiekuangÎncă nu există evaluări

- 35.process Validation TRGDocument4 pagini35.process Validation TRGeddiekuangÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 576 1 1179 1 10 20181220Document15 pagini576 1 1179 1 10 20181220Sana MuzaffarÎncă nu există evaluări

- Ideal Weight ChartDocument4 paginiIdeal Weight ChartMarvin Osmar Estrada JuarezÎncă nu există evaluări

- RubricsDocument1 paginăRubricsBeaMaeAntoniÎncă nu există evaluări

- MINIMENTAL, Puntos de Corte ColombianosDocument5 paginiMINIMENTAL, Puntos de Corte ColombianosCatalina GutiérrezÎncă nu există evaluări

- Approach To Vaginal Discharge in ChildrenDocument12 paginiApproach To Vaginal Discharge in ChildrensujataÎncă nu există evaluări

- Lesson 3 The Prodigal SonDocument2 paginiLesson 3 The Prodigal Sonapi-241115908Încă nu există evaluări

- Thesis FulltextDocument281 paginiThesis FulltextEvgenia MakantasiÎncă nu există evaluări

- The Training Toolbox: Forced Reps - The Real Strength SenseiDocument7 paginiThe Training Toolbox: Forced Reps - The Real Strength SenseiSean DrewÎncă nu există evaluări

- Influencing Factors Behind The Criminal Attitude: A Study of Central Jail PeshawarDocument13 paginiInfluencing Factors Behind The Criminal Attitude: A Study of Central Jail PeshawarAmir Hamza KhanÎncă nu există evaluări

- Chapter 12 Social Structural Theories of CrimeDocument5 paginiChapter 12 Social Structural Theories of CrimeKaroline Thomas100% (1)

- List de VerbosDocument2 paginiList de VerbosmarcoÎncă nu există evaluări

- Serological and Molecular DiagnosisDocument9 paginiSerological and Molecular DiagnosisPAIRAT, Ella Joy M.Încă nu există evaluări

- Digital TransmissionDIGITAL TRANSMISSIONDocument2 paginiDigital TransmissionDIGITAL TRANSMISSIONEla DerarajÎncă nu există evaluări

- SHS11Q4DLP 21st CentFinalDocument33 paginiSHS11Q4DLP 21st CentFinalNOEMI DE CASTROÎncă nu există evaluări

- ID2b8b72671-2013 Apush Exam Answer KeyDocument2 paginiID2b8b72671-2013 Apush Exam Answer KeyAnonymous ajlhvocÎncă nu există evaluări

- Assignment Class X Arithmetic Progression: AnswersDocument1 paginăAssignment Class X Arithmetic Progression: AnswersCRPF SchoolÎncă nu există evaluări

- Percy Bysshe ShelleyDocument20 paginiPercy Bysshe Shelleynishat_haider_2100% (1)

- Awareness and Usage of Internet Banking Facilities in Sri LankaDocument18 paginiAwareness and Usage of Internet Banking Facilities in Sri LankaTharindu Thathsarana RajapakshaÎncă nu există evaluări

- BedDocument17 paginiBedprasadum2321Încă nu există evaluări

- Focus Charting of FDocument12 paginiFocus Charting of FRobert Rivas0% (2)

- Simple Future Tense & Future Continuous TenseDocument2 paginiSimple Future Tense & Future Continuous TenseFarris Ab RashidÎncă nu există evaluări

- Equine PregnancyDocument36 paginiEquine Pregnancydrdhirenvet100% (1)

- Business Finance and The SMEsDocument6 paginiBusiness Finance and The SMEstcandelarioÎncă nu există evaluări

- Sample Midterm ExamDocument6 paginiSample Midterm ExamRenel AluciljaÎncă nu există evaluări

- Critical Care NursingDocument46 paginiCritical Care Nursingraquel_racoÎncă nu există evaluări

- Hedonic Calculus Essay - Year 9 EthicsDocument3 paginiHedonic Calculus Essay - Year 9 EthicsEllie CarterÎncă nu există evaluări

- Windows SCADA Disturbance Capture: User's GuideDocument23 paginiWindows SCADA Disturbance Capture: User's GuideANDREA LILIANA BAUTISTA ACEVEDOÎncă nu există evaluări

- Edc Quiz 2Document2 paginiEdc Quiz 2Tilottama DeoreÎncă nu există evaluări

- UT & TE Planner - AY 2023-24 - Phase-01Document1 paginăUT & TE Planner - AY 2023-24 - Phase-01Atharv KumarÎncă nu există evaluări

- RR 10-76Document4 paginiRR 10-76cheska_abigail950Încă nu există evaluări