Documente Academic

Documente Profesional

Documente Cultură

Pipe Penetrations, Hydrotite

Încărcat de

Anonymous 4MgjVGDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pipe Penetrations, Hydrotite

Încărcat de

Anonymous 4MgjVGDrepturi de autor:

Formate disponibile

Installation Guidelines

Pipe Penetrations - Hydrotite

For CJ0725-3K-AD and DSS0220-AD profiles

PIPE PENETRATIONS

BLOCKOUT PENETRATIONS

Hydrotite is an expanding rubber sealing material with

superior water sealing characteristics. From undersea

tunnels and water supply systems to civil engineering

projects, Hydrotite is able to contribute to water sealing

measures and help prevent problems associated with

water leakage. Hydrotite consists of a combination of

expanding (hydrophilic) material and non-expanding

chloroprene rubber co-extruded together to form a single

strip. The expanding section is blue and the non-expanding

section being black. Hydrotite has the ability to expand in

the presence of water or moisture, creating a self sealing

pressure seal within the joint. The co-extruded design

means that the expansion is directed across the joint for

maximum water sealing performance.

For pipe penetrations where block outs have been used

the Hydrotite is bonded around the diameter of the pipe

and also around the perimeter of the block out. This will

ensure that there is no waterpath left for any water to

enter or escape the structure.

Hydrotite can be used for sealing of pipe penetrations,

blockouts, conduits, etc. through walls and floor slabs in

structures such as reservoirs, sewerage and water

treatment plants, swimming pools, basements and

tunnels.

Hydrotite is suitable for poured in-situ pipe penetrations or

where block outs have been used to form the pipe

penetration.

IN-SITU PIPE PENETRATIONS

For in-situ pipe penetrations Hydrotite is bonded around

the diameter of the pipe prior to concrete placement, the

concrete is then poured around the pipe. The Hydrotite is

now locked between the pipe and the concrete, as the

water travels along the pipe it will come into contact with

the Hydrotite which will absorb the water and start to

expand. The pressure Hydrotite creates upon expansion

will shut off the water path ensuring excellent sealing

(refer to the basic installation guidelines).

PARCHEM

CONCRETE REPAIR

INSTALLATION GUIDELINES

FEBRUARY 08

www.parchem.com.au

7 Lucca Road, Wyong NSW 2259

If the Hydrotite is only bonded to the pipe and not the

perimeter of the block out, a waterpath may be created

between the original cast in-situ wall/floor and the infill

used in the block out. Installing Hydrotite around the

perimeter of the blockout ensures a watertight structure.

The remaining void is then filled with a non-shrink grout

or good quality concrete mix (refer to basic installation

guidelines).

MULTIPLE PIPE PENETRATIONS

For Penetrations where multiple pipes exist apply

Hydrotite around each individual pipe as well as any

perimeter blockout.

PROFILE SELECTION

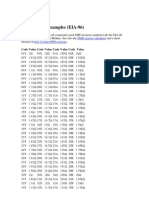

Hydrotite DSS0220-AD waterstop*

2 x 20 mm

25 m roll

Hydrotite CJ0725-3K--AD waterstop*

7 x 25 mm

10 m roll

Leakmaster Gun Grade waterstop 320 ml cartridge

*These profiles available with pressure sensitive selfadhesive.

FLOORING

Sales 1800 801 108

JOINTING SYSTEMS

Technical 1800 812 864

WATERPROOFING

ABN 80 069 961 968

Pipe Penetrations - Hydrotite

BASIC INSTALLATION GUIDELINES

4) SMOOTH SURFACES

FOR CAST IN-SITU PIPE PENETRATIONS

1) Clean surface of pipe to make sure it is free from dirt,

dust, oils, etc.

2) Peel protective backing paper off Hydrotite a section at a

time, apply Hydrotite to the surface of the pipe, press firmly,

making sure that the Hydrotite if fully bonded together to

the pipe and the two ends are firmly butted together.

3) Pour concrete around pipe making sure concrete is

properly compacted and vibrated around pipe.

FOR WHEN BLOCKOUTS HAVE BEEN FORMED

1) Clean surface of pipe to make sure surface is free from

dirt, dust, oils, etc.

2) Peel protective backing paper off Hydrotite a section at

a time, apply Hydrotite to the surface of the pipe, press

firmly, making sure that the Hydrotite if fully bonded

together to the pipe and the two ends are firmly butted

together.

Peel protective backing paper off Hydrotite, a section at a

time, turn Hydrotite over and press firmly onto smooth

concrete surface in the centre of the wall, making sure the

Hydrotite is fully bonded to the concrete and that all joins or

changes in direction are a firm neat butt join.

ROUGH SURFACES

Apply to centre of the wall a good bead (10 mm x 10 mm) of

Leakmaster Gun Grade waterstop. The Leakmaster is to be

applied to a clean, dry surface via a standard caulking gun.

Do not place infill until Leakmaster had cured sufficiently to

avoid displacement.

5) Use a non-shrink grout or good quality mix ensuring

blockout is completely filled with no voids or porous areas

left in the structure or around the waterstops.

Minimum of 50 mm cover of concrete over Hydrotite for

reinforced concrete and 100 mm cover of concrete for un

reinforced concrete based on concrete strength of 22.5N/

mm. Preferably Hydrotite should be placed into the middle

of the joint to ensure maximum cover of concrete.

3) Clean surface of the wall/floor to make sure surface is

free from dirt, dust, oils, debris, etc.

In Situ Pipe

Penetration

Hydrotite

Hydrotite

Blockout

Penetration

Blockout

Penetration

Blockout

Penetration

Leakmaster

Hydrotite

Hydrotite

When thin walled PVC pipes are used there is a possibility the PVC pipe may bend inward due to the

expansion pressure of Hydrotite. It is not recommended using less than 5 mm wall thickness PVC pipes.

PARCHEM

CONCRETE REPAIR

INSTALLATION GUIDELINES

FEBRUARY 08

www.parchem.com.au

7 Lucca Road, Wyong NSW 2259

FLOORING

Sales 1800 801 108

JOINTING SYSTEMS

Technical 1800 812 864

WATERPROOFING

ABN 80 069 961 968

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Smoke Alarm Maintenance ChecklistDocument2 paginiSmoke Alarm Maintenance Checklistananthu.u100% (2)

- Metco 16C 10-040Document8 paginiMetco 16C 10-040JSH100Încă nu există evaluări

- Chrony Beta and GammaDocument36 paginiChrony Beta and GammaÁdám MajorÎncă nu există evaluări

- Various Allowances Referred To 7th CPCDocument73 paginiVarious Allowances Referred To 7th CPCGiri KumarÎncă nu există evaluări

- Msi ms-7222 Rev 3.0 SCH PDFDocument30 paginiMsi ms-7222 Rev 3.0 SCH PDFRodney RibeiroÎncă nu există evaluări

- Physical Pharmacy Answer Key BLUE PACOPDocument34 paginiPhysical Pharmacy Answer Key BLUE PACOPprincessrhenetteÎncă nu există evaluări

- Maison À BordeauxDocument5 paginiMaison À BordeauxSpam TestÎncă nu există evaluări

- Variable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ADocument72 paginiVariable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ARidha AbbassiÎncă nu există evaluări

- One Pipe Steam DesignDocument44 paginiOne Pipe Steam Designreyes hernandezÎncă nu există evaluări

- Manual Técnico Sony HDC-DX70Document72 paginiManual Técnico Sony HDC-DX70Cristian MoraisÎncă nu există evaluări

- A Research Paper On Design and Analysis of Shaftless Steam TurbineDocument5 paginiA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDÎncă nu există evaluări

- Aurora: AE MC-120 SeriesDocument2 paginiAurora: AE MC-120 SeriestasoÎncă nu există evaluări

- First-Man-Up User ManualDocument24 paginiFirst-Man-Up User ManualJoshuaÎncă nu există evaluări

- SMD Resistor ExamplesDocument5 paginiSMD Resistor Examplesmarcbuss100% (1)

- 4 Contamination Control 2Document61 pagini4 Contamination Control 2Vijay RajaindranÎncă nu există evaluări

- Bloor Research On Data MigrationDocument13 paginiBloor Research On Data MigrationivahdamÎncă nu există evaluări

- EOT CRANE - Rev 2Document6 paginiEOT CRANE - Rev 2Koushik BhaumikÎncă nu există evaluări

- Export Dataset To PDF in ASP NetDocument2 paginiExport Dataset To PDF in ASP NetWilliamÎncă nu există evaluări

- KolkataSTK5 16092019Document9 paginiKolkataSTK5 16092019Nausheen RahmanÎncă nu există evaluări

- US Hex Bolt SizesDocument2 paginiUS Hex Bolt SizesYana Jarang OlÎncă nu există evaluări

- Flight DynamicsDocument57 paginiFlight DynamicsDexto100% (2)

- DUNAN Fan Coil UnitDocument14 paginiDUNAN Fan Coil UnitDjordjeÎncă nu există evaluări

- Ceramic Materials: Introduction!: MCEN90014: Materials ! ! !dr. K. Xia! ! ! !1!Document5 paginiCeramic Materials: Introduction!: MCEN90014: Materials ! ! !dr. K. Xia! ! ! !1!hamalÎncă nu există evaluări

- Calculation Rail Beam (Hoist Capacity 3 Ton)Document4 paginiCalculation Rail Beam (Hoist Capacity 3 Ton)Edo Faizal2Încă nu există evaluări

- Clutch ListDocument42 paginiClutch ListAnkan MitraÎncă nu există evaluări

- Standard Terms & Conditions of Sale Pre-Engineered BuildingsDocument18 paginiStandard Terms & Conditions of Sale Pre-Engineered BuildingsHongducBuiÎncă nu există evaluări

- EST 2011B v1.0 Configuration 10/28/2018 7:43 AMDocument2 paginiEST 2011B v1.0 Configuration 10/28/2018 7:43 AMbagusÎncă nu există evaluări

- Mitsubishi 4g13 Engine ManualDocument6 paginiMitsubishi 4g13 Engine ManualJose Luis Caceres Severino100% (1)

- Home,: A Solace To Which A Journey Is Never Too Long..Document25 paginiHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyÎncă nu există evaluări

- BX-74 / BX-78: Sliding Gate Operator BX SeriesDocument24 paginiBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovÎncă nu există evaluări