Documente Academic

Documente Profesional

Documente Cultură

APA - Earthquakes Safeguards

Încărcat de

Patrice AudetDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

APA - Earthquakes Safeguards

Încărcat de

Patrice AudetDrepturi de autor:

Formate disponibile

GDE,R240.

4/19/00 8:46 AM

Page 1

A P A

T h e E n g i n e e r e d Wo o d A s s o c i a t i o n

HOMEOWNERS

GUIDE

EARTHQUAKE

SAFEGUARDS

1997 APA THE ENGINEERED WOOD ASSOCIATION ALL RIGHTS RESERVED. ANY COPYING, MODIFICATION, DISTRIBUTION OR OTHER USE OF THIS PUBLICATION OTHER THAN AS EXPRESSLY AUTHORIZED BY APA IS PROHIBITED BY THE U.S. COPYRIGHT LAWS.

GDE,R240.0

4/19/00 8:46 AM

Page 2

A P A

T h e E n g i n e e r e d Wo o d A s s o c i a t i o n

DO

THE

RIGHT

THING

RIGHT

Wood is good. It is the earths natural, energy efficient and renewable

building material.

Engineered wood is a better use of wood. It uses less wood to make

more wood products.

Thats why using APA trademarked plywood, oriented strand board and APA EWS

glued laminated timbers is the right thing to do.

A few facts about wood.

Were not running out of trees. One-third of the United States land base

731 million acres is covered by forests. About two-thirds of that 731 million acres is

suitable for repeated planting and harvesting of timber. But only about half of the land

suitable for growing timber is open to logging. Most of that harvestable acreage also is

open to other uses, such as camping, hiking, hunting, etc.

Were growing more wood every day. American landowners plant more than

two billion trees every year. In addition, millions of trees seed naturally. The forest

products industry, which comprises about 15 percent of forestland ownership, is

responsible for 41 percent of replanted forest acreage. That works out to more than one

billion trees a year, or about three million trees planted every day. This high rate of

replanting accounts for the fact that each year, 27 percent more timber is grown

than is harvested.

Manufacturing wood is energy

efficient. Wood products made up

47 percent of all industrial raw materials

manufactured in the United States, yet

consumed only 4 percent of the energy

needed to manufacture all industrial raw

materials, according to a 1987 study.

Material

Percent of

Production

Percent of

Energy Use

Wood

47

Steel

23

48

Aluminum

Good news for a healthy planet. For every ton of wood grown, a young forest

produces 1.07 tons of oxygen and absorbs 1.47 tons of carbon dioxide.

Wood. Its the right product for the environment.

NOTICE:

The recommendations in

this guide apply only to

panels that bear the APA

trademark. Only panels

bearing the APA trademark

are subject to the

Associations quality

auditing program.

A PA

RED

GINEE TION

THE EN

SSOCIA

A

D

O

WO

RATED

ING

SHEATH CH

2

15/3 IN

32/1D6FOR SPACING

SIZE

RE 1

EXPOSU

000

PS 1-95

C-D

PRP-10

GDE,R240.0

4/19/00 8:47 AM

Page 3

CONTENTS

Earthquakes and Buildings . . . . . . .4

Shear Walls . . . . . . . . . . . . . . . . . .5

Cripple Walls . . . . . . . . . . . . . . . . .6

he massive destruction caused by

Californias 1989 Loma Prieta earthquake jolted many homeowners out of

complacency and into action. As a result,

seismic retrofit has become a popular remodeling

project. Although the quake was tragic, it proved

in a dramatic way what engineers, architects and

builders have known for years: wood-frame

construction is inherently more resistant to

earthquake damage than other types of

construction.

Retrofit Case Study . . . . . . . . . . . . .7

New Construction Case Study . . . . .8

Foundations and Foundationto-Wall Connections . . . . . . . . . . . .9

Other Substructure Attachments . .12

Chimneys . . . . . . . . . . . . . . . . . . .13

General Hazard Reduction . . . . . .13

APA Wood Structural Panels . . . . .14

Additional Information . . . . . . . . .15

The earthquake also showed that the proper

use of wood structural panels can help a home

survive a major earthquake with little or no

damage. When engineers from APA The

Engineered Wood Association arrived in

California a few days after the quake, they

observed a marked difference between the

performance of wood-frame buildings with

adequate seismic design details and the

performance of homes without such features.

This APA Homeowners Guide for Earthquake

Safeguards shows some of the ways APA wood

structural panels can be used to protect a home,

its contents and most importantly its

inhabitants, from damage or injury during

an earthquake.

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 4

EARTHQUAKES

AND BUILDINGS

In an earthquake the ground rocks,

twists, heaves and subsides, changing

direction and speed all the while. Such

violent and chaotic ground movement

sets buildings in motion. Houses tend

to shift off their foundations and some

structural elements may overturn

(Figure A). Houses literally come apart

at the seams, section by section and

piece by piece. But wood-frame houses,

if properly attached to the foundation

and tied together structurally, can resist

seismic loads and reduce the likelihood

of earthquake damage.

The light weight of wood-frame buildings results in less force from inertia.

Less force means less damage (Figure

B). Woods natural flexibility also is an

advantage when seismic forces are

brought to bear. The nailed joints in

wood-frame buildings dissipate energy

and motion.

But woods inherent earthquake resistance must be accompanied by design

and construction techniques that take

advantage of those characteristics.

Wood structural panels nailed to wall

framing add rigid bracing, help resist

lateral loads and help tie framing members together. Bolted connections at the

sill plate/foundation joint help keep the

house in one spot. Securely connected

wall, floor and roof framing also help tie

a house together and make it a single,

solid structural unit. Proper connections are a major factor in holding a

house together during an earthquake.

Modern building codes require seismic

design elements in new construction.

Those elements typically include the

measures mentioned above. Consult

your local building codes for the

requirements in your area. Older houses

frequently need retrofitting if they are to

withstand earthquakes. While this

brochure deals primarily with retrofit

applications, the same principles apply

to new construction.

FIGURE B

WHEN THE GROUND MOVES

This series of illustrations shows, in

an exaggerated way, what a house

goes through during and after a

simple north-south lurch. Illustration

courtesy of Fine Homebuilding

magazine.

Building at

rest; ground

at rest

Southern

lurch begins

Northern

lurch begins

Ground at rest

FIGURE A

THE EFFECT OF LATERAL FORCE ON STRUCTURAL ELEMENTS

Ground

at rest;

building

continues

to move

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 5

SHEAR WALLS

FIGURE C

Installing wood structural panels to

create shear walls is the best-known way

to strengthen wood-frame buildings. A

shear wall is more than the sum of its

parts. Its a system a single unit that

ties together the floor, roof, walls and

foundation to give a building greater

resistance to lateral loads. Professional

engineering may be required to design

shear walls for some houses. In most

cases however, nominal nailing schedules recommended by APA for panel-toframing connections will provide

adequate shear resistance (Figure C).

The top of a shear wall is fastened to the

second floor or roof framing and the

bottom is fastened to the sill plate. The

sill plate is in turn fastened to the foundation at regular intervals as required by

local codes.

Most exterior walls of wood-frame

houses can become shear walls. When

retrofitting, remove board sheathing and

apply wood structural panels directly to

framing. In many cases, the original

siding can be re-applied over the panels.

SHEAR WALL CORNER DETAIL

Studs

APA panels

nailed to studs

and to sill plate.

Materials

APA Rated Sheathing or APA Rated

Siding panels are recommended.

Common nails should be used to fasten

APA Rated Sheathing to framing. For

APA Rated Siding, use hot-dipped

galvanized box nails.

Alternatively, a single layer of APA panel

siding nailed directly to blocked and

anchored framing can serve as both

a structural shear wall and as

exterior siding.

Doing the Job

Panel installation should begin at the

corners of the house. Space APA panels

1/8 inch at ends and edges unless otherwise specified by the manufacturer.

Spacing allows panels to expand and

contract with changes in moisture conditions. Nails should be installed

6 inches o.c. along panel edges and

12 inches o.c. at intermediate supports.

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 6

CRIPPLE WALLS

FIGURE D

Cripple walls, the short stud walls

between the floor and foundation of

some houses, were one of the most

common points of failure during the

Loma Prieta earthquake. Turning

the cripple wall into a shear wall

reduces the risk of collapse during

an earthquake.

Materials

APA Rated Sheathing or APA Rated

Siding panels are recommended.

Common nails are adequate for sheathing panels. Hot-dipped galvanized box

nails are suggested for siding panels.

CRIPPLE WALL WITH APA PANELS INSTALLED TO CREATE SHEAR WALL

APA panels

Nails 6" o.c. on panel edges,

12" o.c. at intermediate supports.

3/4" vent holes

with 1/4" x 1/4"

wire screen

Sill plate

Anchor bolt

Doing the Job

As with ordinary shear walls, panel

installation should begin at the corners.

The panels can be installed on the

inside or the outside of the cripple wall

framing. Panels should be placed horizontally on cripple walls shorter than

four feet and vertically on those four feet

or higher. If the panels are installed on

the inside of the framing, drill a row of

3/4-inch-diameter vent holes five inches

above the sill plate and a second row

five inches below the top plate of the

cripple wall. The holes should be centered between framing members for

even and efficient ventilation (Figure D).

The vent holes should be covered

with 1/4" x 1/4" galvanized wire screen

to prevent mice from entering the

wall cavity.

Foundation

Failed Cripple Wall

Inadequate cripple walls, like the one pictured above, were a major point of failure in the Loma

Prieta earthquake. Photo courtesy of Fine Homebuilding magazine.

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 7

RETROFIT

CASE STUDY

Santa Cruz Victorians Become

Seismic Design Laboratory

In 1989, at the corner of Center and

Elm streets in downtown Santa Cruz,

Calif., architect Michael OHearn unwittingly created a laboratory for the study

of wood structural panels in seismic

design applications.

On that corner, at 214 and 210 Elm

Street, were two identical Victorian

style homes. According to OHearn,

the twins were built 90-100 years ago,

by the same builder, with identical

materials and using the same

construction techniques.

By 1984, when OHearn bought them,

both houses had been through multiple

remodels. Although originally designed

as single family homes, 210 Elm Street

had become a five-plex and 214 a fourplex. OHearn remodeled the pair

yet again.

He started with #210, installing APA

Rated wood structural panels as a shear

element on cripple-wall framing. The sill

plate also was bolted to the foundation.

OHearn was well aware of the shear

resistance provided by the panels and

knew of their value in seismic design

applications. The plywood served as

our shear element throughout, he said.

Unfortunately, there was no time to

install new panels at #214 before

Oct. 17, 1989 the date of the 7.1

magnitude Loma Prieta earthquake.

The building came apart in four sections, OHearn said. Five people

were in the house when the quake

struck, but luckily, no one was

seriously injured.

repair, he said. The whole building

had to be jacked up and slid back

together on a new foundation.

By contrast, 210 Elm St., with its wood

structural panel shear walls, suffered

only minor damage.

For homes more than 20 years old

located in areas of seismic activity,

I strongly urge owners to carefully consider seismic retrofit, OHearn said.

Its cheaper to retrofit now than to

repair after a quake.

The one that we had done some seismic structural work on (#210) probably cost us $5,000 to repair. The other

one (#214) cost us $260,000 to

In a sense, 214 Elm Street served as the

control element in this unlikely experiment, the results of which only confirmed OHearns thinking on the value

of wood structural panels in seismic

design applications.

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 8

NEW CONSTRUCTION

CASE STUDY

Seismically Safe Designs

Dont Have to Be Boring

When Tom and Chris Gaspich built

their new house, in Aptos, Calif., they

had no idea it would become a testament to the value of wood structural

panels in seismic design applications.

But it did.

Nor did they realize that on Oct. 17,

1989 just three days after the housewarming part northern California

would be rocked by the most devastating earthquake in decades. But

it happened.

When the last aftershocks subsided, the

Gaspich house stood firm while hundreds of other structures in the area

were rendered uninhabitable.

Architect Elsbeth Newfield, of Los

Gatos, Calif., attributes the homes

structural soundness to extensive use of

structural panel shear walls.

The 2,200-square-foot house sits on a

bluff overlooking the Pacific Ocean just

ten miles from the epicenter of the

Loma Prieta earthquake. An existing

slab on the 4,900-square-foot lot limited the footprint of the house and

forced Newfield to include an 18-inch

crawl space in order to put the plumbing where it belonged.

While the crawl space raised the house

and improved the ocean view, it also

created a problem. Local codes limited

the height of the roof plate to no more

than 12 feet above grade. To compensate for the loss of 18 inches of height

in the second story, Newfield left the

ceiling open all the way to the peak of

the 10:12-pitch roof.

Theres not a flat ceiling in the house,

Newfield said. The roof is the ceiling.

The unusually steep pitch of the roof

provides a wealth of interior space and a

good deal of visual drama.

Newfield used APA-trademarked wood

structural panels to make up for rigidity

and structural stability lost by eliminat-

ing the second floor ceiling joists. The

shear walls are sheathed with 3/4-inch

and 5/8-inch APA Rated Sheathing,

Exposure 1. The roof sheathing consists

of 15/32-inch APA Rated Sheathing,

Exposure 1. She specified 3/4-inch APA

Rated Sturd-I-Floor tongue & groove for

the first- and second-story diaphragm

floor. Exterior walls are covered with

19/32-inch APA Rated Siding 303,

Texture 1-11.

We literally could not have done it

without plywood, Newfield said. The

Gaspich house shows that wood structural panels can make an earthquakeresistant house architecturally daring

without sacrificing structural integrity.

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 9

FOUNDATIONS AND

FOUNDATION-TO WALL CONNECTIONS

FIGURE E

TYPICAL MECHANICAL WEDGE ANCHOR BOLT

While shear walls can strengthen a

house, they are only one of several steps

that can be taken to lessen the likelihood of earthquake damage. Good

seismic design starts with the foundation. Three kinds of foundations are

covered in this brochure: post and

pier; poured concrete walls; and

slab-on-grade.

Nut

Washer

Sill plate

The Uniform Building Code requires

foundation plates or sill plates to be

bolted to the foundation with 1/2-inchdiameter bolts spaced no more than six

feet apart. One bolt must be placed

within 12 inches of each end of each

section of the plate. If an existing house

has no connections, or if the connections dont meet code requirements,

retrofitting should be considered.

Anchor bolts are the most common way

to attach a house to its foundation, but

a thorough inspection of the foundation

should precede bolting. The concrete

must be strong enough to hold the

anchor bolts. If the concrete is weak or

deteriorating and drilling holes for bolts

is likely to cause cracks or crumbling,

the foundation should be replaced.

Foundation

Anchor Bolts

Anchor bolts are manufactured in a

variety of types and sizes. Mechanical

wedge anchor bolts are the type most

commonly used in seismic retrofit applications (Figure E). A metal collar near

the tip of the conical end is what makes

mechanical wedge anchor bolts work.

Once the bolt is in place, a few turns on

the nut will lift the bolt and expand the

collar, locking it in place. Anchor bolts

must be installed before panels are

nailed to the wall framing. Once

installed, the panels will block access

to the sill plate. In new construction,

L bolts or J bolts, inserted when the

foundation is poured, are the most

common type of anchor bolt.

1997 APA - The Engineered Wood Association

4/19/00 8:47 AM

Page 10

GDE,R240.0

Post-and-Pier Foundations

The most common problem with

post-and-pier foundations during an

earthquake is the tendency of posts to

shift off piers and beams to shift off

posts. Failure at either of these points

can cause the substructure, and sometimes the entire house, to collapse. But

steps can be taken to strengthen post

and pier foundations. Bolting posts to

piers and beams is the most common

method. Lateral support can be

achieved by installing 2x4s as diagonal

bracing from one post to the next.

Predrilled steel T-straps are

recommended for attaching beams to

posts. For attaching posts to piers,

predrilled, shop-fabricated, heavy gauge,

bent sheet metal connectors are recommended (Figure F).

FIGURE F

REINFORCING POST AND PIER FOUNDATIONS

Beam

Nailed structural-panel tie across

beams joints

8d nails

3/8" structural panel gusset each side

Post

Poured Concrete Foundation Walls

In new construction, poured concrete

walls are the most common type of

foundation for supporting raised

wood floors.

In houses built prior to modern building codes the foundation and sill plate

are not always attached, but retrofitting

with anchor bolts can substantially

improve a homes ability to withstand

an earthquake. There are two ways of

bolting sills to concrete foundations:

vertical and horizontal.

Horizontal bolting In horizontal bolting, a structural steel plate is needed to

tie the sill plate to the foundation. The

steel plate is attached to the sill plate

with lag screws and to the foundation

with anchor bolts.

FIGURE G

HORIZONTAL BOLTING

Add a shim between

plate and sill.

Vertical bolting can be accomplished

only if there is enough workspace

between the top of the sill plate and the

bottom of the wall top plate. Horizontal

bolting is useful where space between

foundation and floor is minimal.

Vertical bolting Vertical bolting is the

easiest way to attach a house to its

foundation. Mechanical wedge anchor

bolts are the only hardware needed.

Using a rotating-hammering drill or

rotohammer, simply drill the holes for

the anchor bolts through the sill plate

and into the foundation, then install

the bolts.

10

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 11

Slab-on-grade Foundations

Bolting sills to slab-on-grade foundations requires removal of exterior siding

or interior plaster or wallboard. The

code requirements for bolting slab-ongrade foundations are the same as those

for poured concrete foundation walls

and the job is done in the same way.

Mechanical wedge anchor bolts are the

only hardware needed.

FIGURE H

SHEAR WALL HOLD-DOWN ANCHOR

APA RATED SHEATHING

or APA RATED SIDING 303

Studs

1/4" steel bracket

Shear Wall Hold-down Anchors

Once the sill plate is bolted to the foundation, shear wall hold-down anchors

should be installed at each corner of the

house. While anchor bolts help keep a

building seated on its foundation, shear

wall hold-down anchors help prevent

walls from overturning. A steel bracket,

like the one pictured in Figure H, is

recommended. Anchor bolts are suggested for attaching the brackets to the

foundation. Lag screws or machine

bolts can be used to fasten the brackets

to wall framing (Figure H).

Bolts to framing

size as required

Sill Plate

Bolt to foundation

Concrete foundation

11

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 12

OTHER SUBSTRUCTURE

ATTACHMENTS

FIGURE I

FRAMING ANCHOR CONNECTIONS

The sill-to-foundation attachment is not

the only critical connection. Its important to remember that reinforcing one

connection transfers stresses to the next

weakest connection. Attaching the sill

plate to the foundation, or the posts,

beams and piers to one another, is not

enough to ensure seismic resistance.

Framing Anchor Connections

Framing anchors transmit stresses

between framing members once the sill

plate is attached to the foundation.

They also tie framing members together.

Figure I shows some of the ways framing anchors can be installed to

strengthen connections between floor

joist and sill plate, and floor joist and

band joist.

Floor joist

Band joist

Nails

Framing anchors

Concrete foundation

Floor Framing

Blocking between floor joists will help

prevent the joists from tipping over and

collapsing during an earthquake. Floor

joists should be blocked at all supports

and fastened to the band joist and

sill plate.

12

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 13

CHIMNEYS

Masonry chimneys are sometimes built

on their own foundations and are not

always structurally tied to the house. It

can be difficult to strengthen them and

they frequently collapse during earthquakes. One of the best ways to minimize damage from a collapsing masonry

chimney is to install wood structural

panels on the attic floor. The panels will

help stop falling bricks from crashing

through the ceiling and into the home.

Materials

23/32 APA Rated Sheathing.

Hardware

8d nails.

Doing the Job

Beginning along the wall next to the

chimney, nail panels to ceiling joists. If

the chimney is not along a wall, begin

next to the chimney itself. Install nails

6 inches o.c., making sure panels lie

flat and flush. Where necessary, trim

panels to fit around the chimney and

ceiling edges.

GENERAL HAZARD

REDUCTION

Even in structurally sound, earthquakeresistant buildings, damage from a

major earthquake can be significant and

expensive to repair. The contents of a

building often represent more of a hazard than the building itself. Nonstructural elements, such as plumbing,

mechanical and electrical systems

should be secured to prevent flooding,

fire and electrical shock.

Water heaters and other large appliances, such as furnaces, washers, dryers

and refrigerators, should be bolted or

strapped in place. If these appliances

move during a quake, their size and

weight can cause damage or injury.

Bookcases, china closets and other

pieces of furniture also should be

secured. Heavy or breakable items

should not be stored on high shelves

where they could fall and cause damage

or injury.

Broken gas lines are always a concern

after an earthquake. Many repairable

buildings have burned in fires caused by

gas leaks. Automatic safety valves,

which can be installed at the gas meter,

will shut off the gas during a major

quake and help prevent leaks.

Collapsed Masonry Chimney

Masonry chimneys, like the one shown above, can easily collapse during a quake. Reinforcing

the attic floor with APA panels can reduce the chances of damage and injury due to falling

bricks. While the chimney shown fell outside the house, a second chimney fell inside and

destroyed a bedroom ceiling.

13

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 14

APA WOOD

STRUCTURAL PANELS

The construction systems described in

this brochure are based on designs

using APA wood structural panels. APA

trademarked panels conform to standards based on either the panels

intended end use, or the way the panel

is manufactured. Some panels meet the

requirements of both standards.

APA Performance Standards

Performance standards set requirements based on a panels end use,

while manufacturing standards

prescribe minimum manufacturing

requirements. APA performance-rated

panels are manufactured under the

provisions of APA PRP-108, Performance

Standards and Policies for Structural-Use

Panels, or under Voluntary Product

Standard PS 2-92, Performance Standard

for Wood-Based Structural-Use Panels. The

performance standards establish performance criteria for uniform, concentrated

and impact load capacities, fastenerholding ability, racking resistance,

dimensional stability, and bond durability. In addition to veneered plywood,

APA performance standards encompass

such other structural panel products as

composites and oriented strand board

(OSB). Panels conforming to the performance standard are referred to as APA

Rated Sheathing, APA Rated Sturd-IFloor or APA Rated Siding.

Manufacturing Standards

The manufacturing standard employed

by APA is called U.S. Product Standard

PS 1-95 for Construction and Industrial

Plywood. This voluntary standard was

developed cooperatively by the U.S.

Department of Commerce and the

construction and industrial plywood

industry. PS 1-95 establishes requirements for producing, marketing and

specifying construction and

industrial plywood.

Advantages of

APA Trademarked Panels

APA panels possess a unique combination of characteristics that make them

an invaluable material in seismic

design applications.

14

Strength APA panels resist racking, or

in-plane shape distortion. Because of

their resistance to splits they have excellent fastener-holding capabilities and

can be nailed very near panel edges.

Relative to their strength, wood structural panels are lightweight and easy to

handle, work and install.

Stiffness APA panels resist deflection

when confronted with the movement

and shifting forces of an earthquake.

That means buildings with wood

structural panel roofs, walls and

floors are less likely to collapse

during an earthquake.

Impact Resistance APA panels

improve upon woods well-known

ability to absorb shock. Their

construction and large size

distributes impact loads.

Workability APA panels can be

worked with ordinary tools and basic

carpentry skills. They can be cut,

routed, jointed, drilled, glued and fastened. Panels also can be bent to form

curved surfaces without losing strength.

For more information on performance

standards and grade designations ask for

the APA Product Guide: Grades and

Specifications, Form J20.

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 8:47 AM

Page 15

ADDITIONAL INFORMATION

About APA The Engineered Wood Association

APA The Engineered Association is a nonprofit trade association whose

member mills produce approximately 70 percent of the wood structural

panel products manufactured in North America.

The Associations trademarks appear only on products manufactured by

member mills. The marks signify that the manufacturer is committed to

APAs rigorous program of quality inspection and testing and that panel

quality is subject to verification through APA audit.

The audit procedures verify that the manufacturer is in conformance with

APAs standards, set forth in APA PRP-108 Performance Standards and Policies

for Structural-Use Panels, PS 2-92, Performance Standards for Wood-Based

Structure-Use Panels or with the Department of Commerce U.S. Product

Standard PS 1-95 for Construction and Industrial Plywood.

APAs services go far beyond quality testing and inspection. Research and

promotion programs play important roles in developing and improving

plywood and other panel construction systems, and in helping users and

specifiers to better understand and apply panel products.

Always insist on panels bearing the mark of quality the APA trademark.

Your APA panel purchase is not only your highest possible assurance of

product quality, but an investment in the many trade services that APA

provides on your behalf.

Other Publications

While nothing will make a home completely earthquake-proof, the measures outlined in this brochure can make a house more earthquake resistant. For more information on wood structural panels in seismic design

applications, ask for the following APA publications:

APA Design/Construction Guide: Diaphragms, Form L350

$1

APA Design/Construction Guide: Residential & Commercial, Form E30

$4

APA Product Guide: Grades & Specifications, Form J20

$2

Design Concepts for Building in High Wind and Seismic Zones, Form W650 $1

The product use recommendations in this publication are based on APA The Engineered

Wood Associations continuing programs of laboratory testing, product research, and comprehensive field experience. However, because the Association has no control over quality of

workmanship or the conditions under which engineered wood products are used, it cannot

accept responsibility for product performance or designs as actually constructed. Because

engineered wood product performance requirements vary geographically, consult your local

architect, engineer or design professional to assure compliance with code, construction, and

performance requirements.

15

1997 APA - The Engineered Wood Association

GDE,R240.0

4/19/00 9:08 AM

Page 16

EARTHQUAKE SAFEGUARDS

H O M E O W N E R ' S

G U I D E

We have field representatives in most

major U.S. cities and in Canada who can help

answer questions involving APA trademarked

products. For additional assistance in specifying

APA engineered wood products, get in touch with

your nearest APA regional office. Call or write:

WESTERN REGION

7011 So. 19th St. P.O. Box 11700

Tacoma, Washington 98411-0700

(253) 565-6600 Fax: (253) 565-7265

EASTERN REGION

2130 Barrett Park Drive, Suite 102

Kennesaw, Georgia 30144-3681

(770) 427-9371 Fax: (770) 423-1703

U.S. HEADQUARTERS

AND INTERNATIONAL

MARKETING DIVISION

7011 So. 19th St. P.O. Box 11700

Tacoma, Washington 98411-0700

(253) 565-6600 Fax: (253) 565-7265

Addres

eb

s

W

www.apawood.org

PRODUCT SUPPORT HELP DESK

(253) 620-7400

E-mail Address: help@apawood.org

(Offices: Antwerp, Belgium; Bournemouth,

United Kingdom; Hamburg, Germany; Mexico City,

Mexico; Tokyo, Japan.) For Caribbean/Latin

America, contact headquarters in Tacoma.

The product use recommendations in this publication are based on APA The Engineered Wood

Associations continuing programs of laboratory

testing, product research, and comprehensive field

experience. However, because the Association has

no control over quality of workmanship or the conditions under which engineered wood products are

used, it cannot accept responsibility for product

performance or designs as actually constructed.

Because engineered wood product performance

requirements vary geographically, consult your

local architect, engineer or design professional to

assure compliance with code, construction, and

performance requirements.

Form No. R240A/Revised May 1997/0200

A P A

T h e E n g i n e e r e d Wo o d A s s o c i a t i o n

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Canadian Foundation Engineering Manual 4thDocument503 paginiCanadian Foundation Engineering Manual 4thyusefmejia86% (35)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Project Name Project Duration Construction of A 2 Storey BuildingDocument4 paginiProject Name Project Duration Construction of A 2 Storey Buildingjoan67% (3)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Lexicon Dictinary Ver 3.1Document18 paginiLexicon Dictinary Ver 3.1dongpc1Încă nu există evaluări

- Top10 Key Attributes WPDocument8 paginiTop10 Key Attributes WPPatrice AudetÎncă nu există evaluări

- 131-13025-00 - Issued For Permit - Struct PDFDocument8 pagini131-13025-00 - Issued For Permit - Struct PDFJust HendraÎncă nu există evaluări

- Roof Tile Boral Technical Manual - Nov17 - FDocument88 paginiRoof Tile Boral Technical Manual - Nov17 - FzainuddinmohddaminÎncă nu există evaluări

- Sander and Sandpaper StorageDocument16 paginiSander and Sandpaper StoragePatrice Audet100% (1)

- How-To's: For All Band Saw BladeDocument1 paginăHow-To's: For All Band Saw BladePatrice AudetÎncă nu există evaluări

- Four-Bin Trash and Recycling Cabinet: ModerateDocument21 paginiFour-Bin Trash and Recycling Cabinet: ModeratePatrice AudetÎncă nu există evaluări

- 7 Tips For Exterior Renderings With Vray NotesDocument10 pagini7 Tips For Exterior Renderings With Vray NotesPatrice AudetÎncă nu există evaluări

- 7 Tips For Interior Renderings With Vray NotesDocument9 pagini7 Tips For Interior Renderings With Vray NotesPatrice AudetÎncă nu există evaluări

- Hockey Tactics 2020 Bonus McDavid DraisaitlDocument27 paginiHockey Tactics 2020 Bonus McDavid DraisaitlPatrice Audet100% (1)

- 7 Tips For Interior Renderings With Vray NotesDocument9 pagini7 Tips For Interior Renderings With Vray NotesPatrice AudetÎncă nu există evaluări

- Basic Workbench With DrawersDocument21 paginiBasic Workbench With DrawersFrancois VaaltynÎncă nu există evaluări

- Complete PMP Certification GuideDocument92 paginiComplete PMP Certification GuidePatrice Audet75% (4)

- TDMBMN Ep Dok Bus $sus $aof $v12Document48 paginiTDMBMN Ep Dok Bus $sus $aof $v12Patrice AudetÎncă nu există evaluări

- Movento Installer's Guide: For More Information VisitDocument2 paginiMovento Installer's Guide: For More Information VisitPatrice AudetÎncă nu există evaluări

- Movento Ep Dok Bus $sus $aof $v6Document40 paginiMovento Ep Dok Bus $sus $aof $v6Patrice AudetÎncă nu există evaluări

- PMP Certification GuideDocument47 paginiPMP Certification GuideJaveed A. Khan100% (2)

- Good Building Practices Guideline PDFDocument262 paginiGood Building Practices Guideline PDFPatrice Audet100% (1)

- APA - Engineered Wood Construction GuideDocument20 paginiAPA - Engineered Wood Construction GuidePatrice AudetÎncă nu există evaluări

- Guidelines For The Structural Provisions For The Repair, Alteration, Addition and Change of Use of Existing BuildingsDocument52 paginiGuidelines For The Structural Provisions For The Repair, Alteration, Addition and Change of Use of Existing BuildingsTeknikSipilUsmÎncă nu există evaluări

- APA Force Transfer Around OpeningsDocument12 paginiAPA Force Transfer Around Openingsmike wilson100% (1)

- Compositechapters1 3 PDFDocument32 paginiCompositechapters1 3 PDFPatrice AudetÎncă nu există evaluări

- APA - I-Joist Construction Details Can LSDDocument55 paginiAPA - I-Joist Construction Details Can LSDPatrice AudetÎncă nu există evaluări

- Floor Joist Vibration IIDocument0 paginiFloor Joist Vibration II74747474Încă nu există evaluări

- Floor Joist Vibration IIDocument0 paginiFloor Joist Vibration II74747474Încă nu există evaluări

- Diaphragm FlexibilityDocument7 paginiDiaphragm FlexibilityPatrice AudetÎncă nu există evaluări

- Design Example of Wood Diaphragm Using Envelope MethodDocument14 paginiDesign Example of Wood Diaphragm Using Envelope MethodPatrice AudetÎncă nu există evaluări

- Design of Stacked Multistorey Wood Shearwalls Using A Mechanics Based ApproachDocument19 paginiDesign of Stacked Multistorey Wood Shearwalls Using A Mechanics Based ApproachPatrice AudetÎncă nu există evaluări

- Design Example of Wood Diaphragm Using Envelope MethodDocument14 paginiDesign Example of Wood Diaphragm Using Envelope MethodPatrice AudetÎncă nu există evaluări

- Design of Nonstructural Systems and ComponentsDocument42 paginiDesign of Nonstructural Systems and ComponentsJV LopezÎncă nu există evaluări

- Scope of Work: Qty. Unit Unit Rate Amount PreliminariesDocument46 paginiScope of Work: Qty. Unit Unit Rate Amount PreliminariesAlvin EstayÎncă nu există evaluări

- Mass Piling Submission PDFDocument1 paginăMass Piling Submission PDFHung NguyentheÎncă nu există evaluări

- Curtain Walls - WBDG - Whole Building Design GuideDocument19 paginiCurtain Walls - WBDG - Whole Building Design GuideRaji100% (1)

- Final - CPM and PERT - Example - 2Document4 paginiFinal - CPM and PERT - Example - 2Gauri WaikarÎncă nu există evaluări

- Researchpaper Design of Steel Frame Industrial Building Compared With ReinforcedDocument5 paginiResearchpaper Design of Steel Frame Industrial Building Compared With Reinforcedbasanth babuÎncă nu există evaluări

- S U S A N M U I R D E S I G N: North Elevation West ElevationDocument1 paginăS U S A N M U I R D E S I G N: North Elevation West Elevationserge BoivinÎncă nu există evaluări

- DG475 Tilt Low-RiseDocument8 paginiDG475 Tilt Low-RisevillaavaloncrÎncă nu există evaluări

- App 037Document19 paginiApp 037Hung Nguyen VanÎncă nu există evaluări

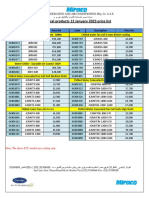

- Carrier Local Price List 12.01.23Document1 paginăCarrier Local Price List 12.01.23No name100% (1)

- Lysaght Architectural Detailing Manual Roof Wall Flashing V2 June 2013Document40 paginiLysaght Architectural Detailing Manual Roof Wall Flashing V2 June 2013Vas SteelÎncă nu există evaluări

- Pre-Thesis Complete Report Format - R18ar005Document21 paginiPre-Thesis Complete Report Format - R18ar005Tharun ReddyÎncă nu există evaluări

- Building Construction SystemDocument19 paginiBuilding Construction SystemSyaza Mohd Bakhori G19A0134Încă nu există evaluări

- 234301-Jawaher Al MusailhiDocument32 pagini234301-Jawaher Al MusailhiArch. John Bernard AbadÎncă nu există evaluări

- Updates On Revision To ASHRAE Standard 90.2: Including Roof Reflectivity For Residential BuildingsDocument11 paginiUpdates On Revision To ASHRAE Standard 90.2: Including Roof Reflectivity For Residential BuildingsnubazÎncă nu există evaluări

- BS4 End TermDocument2 paginiBS4 End TermShubham SinghÎncă nu există evaluări

- Boundary Wall After CorrectionDocument7 paginiBoundary Wall After CorrectionHarish Kumar MahavarÎncă nu există evaluări

- Optimum Selection of Cooling TowerDocument29 paginiOptimum Selection of Cooling TowerNikhil JhaÎncă nu există evaluări

- Brochure BraceboardDocument12 paginiBrochure Braceboardchancer2Încă nu există evaluări

- Construction Timeline Template: Gantt Chart - x000DDocument8 paginiConstruction Timeline Template: Gantt Chart - x000DAj AsiaoÎncă nu există evaluări

- Building ServicesDocument9 paginiBuilding ServicesPriya SinghalÎncă nu există evaluări

- P BCA Green Mark Certification For Building (NREB Ver 3)Document62 paginiP BCA Green Mark Certification For Building (NREB Ver 3)dandumuc_00Încă nu există evaluări

- Okotel - Sheet - A102 - SectionsDocument1 paginăOkotel - Sheet - A102 - Sectionsmasumba patrickÎncă nu există evaluări

- Water TankDocument51 paginiWater TankDaniel Okere100% (4)

- Rates FoundationDocument17 paginiRates FoundationMihir PanchalÎncă nu există evaluări

- Kamin-Kessel 45 101 GBDocument4 paginiKamin-Kessel 45 101 GBsebkahnÎncă nu există evaluări

- Spot Detail (Grooves at Ramp) : 120Mm Thk. + Fin Ramp Concrete SlabDocument1 paginăSpot Detail (Grooves at Ramp) : 120Mm Thk. + Fin Ramp Concrete Slabamantz91Încă nu există evaluări