Documente Academic

Documente Profesional

Documente Cultură

HONEYWELL VBN2 VBN3 Control Ball Valves PDF

Încărcat de

Marcello PorrinoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HONEYWELL VBN2 VBN3 Control Ball Valves PDF

Încărcat de

Marcello PorrinoDrepturi de autor:

Formate disponibile

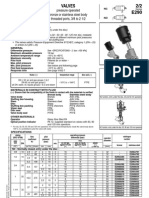

VBN2, VBN3 Control Ball Valves

With Threaded Connections

PRODUCT DATA

FEATURES

All Models

Sizes from 1/2 to 2-1/2 inches with internal (female)

NPT connections.

Equal percentage or linear flow characteristics.

Choice of four, factory-installed actuation control

schemes: Floating, Modulating (2-10 V), Spring Return

2-Position, Spring Return Modulating/Floating.

VBN2...A

Field configurable for normally open or normally

closed fail-safe position.

Removable manual operating handle to control valve

during installation or in an event of power failure.

ANSI Class IV seat leakage specification (0.01% of CV).

VBN2...D

Optional NEMA 3R (IP54) rated enclosure for outdoor

applications.

Actuator can be mounted on the valve in any of four

positions.

VBN2 (Two-way)

APPLICATION

The VBN2 Two-Way and the VBN3 Three-Way Control Ball

Valves control hot and chilled water with glycol solutions up to

50% in heating, ventilating, and air conditioning (HVAC)

systems to provide two-position or modulating functions.

These valve assemblies can be ordered with or without

factory-mounted non-spring return or spring return directcoupled actuators (DCA).

Sizes up to 3 inches.

Wide CV choices from 0.38 to 266.

Nickel-chrome plated brass or 316 stainless steel valve

ball and stem.

VBN3 (Three-way)

Wide CV choices from 0.33 to 109.

Valve installs in a globe valve T pattern, no extra

elbows or piping required.

Nickel-chrome plated brass valve ball and stem.

Mixing or Diverting control.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 7

Operation and Checkout .................................................. 11

Typical Specifications ....................................................... 12

63-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

SPECIFICATIONS

Maximum Differential Pressure: See Table 7.

Flow Characteristics:

Two-way: Equal Percentage with flow control insert.

Linear with full port.

Three-way: Port A to AB: Equal Percentage.

Port B to AB: Linear.

Models: See Table 4.

Dimensions: See Fig. 1 and 2.

Body Style: Two-way ball valve, straight-through flow, full or

reduced port using patented flow control insert.

Three-way ball valve, A-B-AB flow, full or reduced port

using patented flow control insert.

Internal NPT connections.

Materials:

Body: Forged Brass (ASTM B283).

Flow Optimizer: Noryl

Ball and Stem:

Two-way: Nickel-chrome Plated Brass or 316 Stainless

Steel.

Three-way: Nickel-chrome Plated Brass.

Stem Seals: EPDM O-rings.

Ball Seals: Reinforced TEFLON Seals with EPDM O-rings.

Body Size:

1/2 to 3 inches NPT (two-way).

1/2 to 2-1/2 inches NPT (three-way).

Flow Capacity: See Tables 1 and 2.

Approvals Standards:

Valves: ANSI Class IV close-off/leakage (maximum 0.01% of

CV let by)

Actuators: See literature for the given actuator.

Body Pressure Rating (maximum): 360 psi (2482 kPa) at

250F (121C).

Controlled Medium: Water or Glycol solutions up to 50%. Not

suitable for combustible gases.

Parts and Accessories:

5112-11 replacement mounting kit for Honeywell direct coupled

actuators. See Fig. 19.

Medium Temperature Range:

-22 to +250F (-30 to +121C).

Registered Trademark of the

Registered Trademark of E I

General Electric Company

DuPont de Nemours

Table 1. Two-Way CV Values.

CV Designator

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3"

a

B

D

0.38 0.68

0.31 0.63

E

1.3

1.2

F

2.0

G

2.6

2.5

H

4.7

4.3

4.4

4.4

J

8.0

7.4

9.0

8.3

K

11.7a

10.1

14.9

14.7a

15.3

25

23

29a

26

37

30

44a

41a

41

42

45

49

54a

172a

210

202a

266a

102a

57

55

63

74

71

72

82

100

101

108a

124

162

145 a

Denotes full port valve (with no insert). Provides linear flow control.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE wholesaler or distributor, refer to the

TRADELINE Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In CanadaHoneywell Limited/Honeywell Limite, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

62-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

Table 2. Three-Way CV Values.

CV Designator

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

a

B

0.33

C

0.59

0.40

0.40

D

0.66

0.65

E

1.0

1.3

1.3

F

2.4

2.4

2.3

G

3.8

3.5

H

4.3

J

8.0

7.0

8.6

8.7

8.3

4.5

4.1

4.0

K

11.0 a

14.9

12.7

13.4

22

19 a

24

24

31

27

32a

34a

38

38

61

57

83

74

109

100a

Denotes full port valve (with no insert). Provides linear flow control.

Rangeability

Rangeability is a measure of a valve's controllability

(sometimes referred to as its Turndown Ratio). Rangeability is

a measured property and is expressed as the ratio of a valve's

maximum flow rate to its minimum controllable flow rate.

Table 3. Rangeability of two-way actuated ball valves

Valve Size

Cv

0.38

0.68

1.3

2.0

1/2"

2.6

4.7

8.0

11.7

0.31

0.63

1.2

2.5

4.3

3/4"

7.4

10.1

14.7

29

4.4

9.0

15.3

1"

26

44

54

* Data not available at time of printing

Rangeability

41

17

52

*

321

159

390

251

41

17

52

321

159

*

390

251

1503

159

390

1040

484

1263

1207

Valve Size

Cv

4.4

8.3

14.9

25

1-1/4"

37

41

102

23

30

41

1-1/2"

74

172

42

57

71

100

2"

108

210

266

45

55

72

2-1/2"

101

162

202

49

63

82

3"

124

145

* Data not available at time of printing

Rangeability

159

390

1040

*

484

1207

1263

484

*

603

1263

558

603

*

287

*

558

750

877

250

*

287

558

750

877

250

287

558

750

877

62-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

F

D

A

C

Pipe

Model

Size

No.

1/2"

VBN2A

3/4"

1"

VBN2B

VBN2C

CV

Dimensions inches (mm)

B

0.38, 0.68, 1.3, 2.0, 2.6, 4.7, 11.7

2-3/8 (60)

3-7/16 (87)

6-5/8 (168)

3 (76)

4 (102)

8-1/8 (206)

1 (0.5)

8.0

2-5/8 (67)

3-11/16 (94)

6-1/2 (165)

3 (76)

4 (102)

8-5/16 (211)

1 (0.5)

0.31, 0.63, 1.2, 2.5, 4.3, 7.4, 14.7

2-3/8 (60)

3-7/16 (87)

6-7/16 (164)

3 (76)

4 (102)

8-1/8 (206)

1 (0.5)

10.1, 29

2-5/8 (67)

3-11/16 (94)

6-1/2 (165)

3 (76)

4 (102)

8-5/16 (211)

1 (0.5)

9.0

3-3/4 (95)

3-11/16 (94)

7-1/16 (179)

3 (76)

4 (102)

8-5/16 (211)

1 (0.5)

3 (76)

3-15/16 (100)

6-3/4 (171)

3 (76)

4 (102)

8-11/16 (221)

1.4 (0.6)

4.4, 15.3, 54

26, 44

1-1/4"

1-1/2"

VBN2D

VBN2E

Weight

lb (kg)

4-3/8 (111)

4-7/16 (113)

7-3/8 (187)

3 (76)

4 (102)

8-7/8 (225)

2.4 (1.1)

3 (76)

3-15/16 (100)

6-11/16 (170)

3 (76)

4 (102)

8-11/16 (221)

1.4 (0.6)

37, 102

3-5/8 (92)

4-7/16 (113)

7 (178)

3 (76)

4 (102)

9-1/16 (231)

2.4 (1.1)

23, 30, 74

3-3/8 (86)

3-15/16 (100)

6-15/16 (176)

3 (76)

4 (102)

9-1/16 (231)

2.4 (1.1)

41, 172

3-3/4 (95)

5-3/16 (132)

7-1/16 (179)

3 (76)

4 (102)

8-7/8 (225)

3.2 (1.5)

4 (102)

5-3/16 (132)

7-3/16 (183)

3 (76)

4 (102)

8-7/8 (225)

3.2 (1.5)

4.4, 8.3, 14.9, 25, 41

2"

VBN2F

42, 108

57, 71, 100, 210, 266

4-3/8 (111)

5-3/4 (146)

7-7/16 (189)

3 (76)

4 (102)

10-1/2 (267)

5 (2.3)

2-1/2"

VBN2G

45, 55, 72, 101, 162, 202

4-3/4 (121)

5-3/4 (146)

7-9/16 (192)

3 (76)

4 (102)

10-1/2 (267)

5.5 (2.5)

3"

VBN2H

49, 63, 82, 124, 145

5 (127)

5-7/8 (149)

7-11/16 (195)

3 (76)

4 (102)

10-11/16 (271)

5.9 (2.7)

M23550

Fig. 1. VBN2 dimensions in inches (millimeters).

F

B

E

G

A

C

Pipe

Size

Model

No.

CV

A

Dimensions inches (mm)

C

D

E

Weight

lb (kg)

2.4 (1.1)

1/2"

VBN3A

0.33, 0.59, 1.0, 2.4, 4.3, 8.0

3-1/2 (90)

3-5/16 (84)

7 (178)

3 (76)

4 (102)

9-3/8 (238)

2-3/8 (60)

3/4"

VBN3B

0.40, 0.66, 1.3, 2.4, 3.8, 7.0, 11.0

2-13/16 (71)

3-5/16 (84)

6-1/2 (168)

3 (76)

4 (102)

8-13/16 (224)

2 (51)

2 (0.9)

1"

VBN3C

0.40, 0.65, 1.3, 2.3, 3.5

3-13/16 (97)

3-5/16 (84)

7-5/16 (186)

3 (76)

4 (102)

9-1/2 (241)

2-3/4 (70)

2.8 (1.3)

8.6, 22

4.5, 14.9, 31

1-1/4"

1-1/2"

VBN3D

VBN3E

2-1/2"

VBN3F

VBN3G

3-13/16

6-13/16 (173)

3 (76)

4 (102)

9-13/16 (249)

2-5/8 (67)

2.6 (1.2)

4 (102)

7-13/16 (198)

3 (76)

4 (102)

10-13/16 (275)

3-1/4 (83)

3.3 (1.5)

4.1, 8.7, 19.0

3 (76)

3-13/16

6-13/16 (173)

3 (76)

4 (102)

9-13/16 (249)

2-1/2 (64)

2.5 (1.1)

12.7, 27, 34

3-5/8 (92)

4 (102)

7-5/16 (186)

3 (76)

4 (102)

10-5/16 (262)

2-3/4 (70)

2.8 (1.3)

4.0, 8.3, 13.4, 32

4-1/2 (114)

4 (102)

7-13/16 (198)

3 (76)

4 (102)

10-13/16 (275)

3-1/4 (83)

3.3 (1.5)

4 (102)

4-1/2 (114)

7-5/16 (186)

3 (76)

4 (102)

11 (279)

3-1/4 (83)

3.3 (1.5)

3.3 (1.5)

24, 61

2"

3 (76)

4-1/2 (114)

24, 38, 57

4 (102)

4-1/2 (114)

7-5/16 (186)

3 (76)

4 (102)

11 (279)

3-1/4 (83)

83, 109

5 (127)

5-13/16

7-13/16 (198)

3 (76)

4 (102)

12-5/16 (313)

3-3/4 (95)

3.8 (1.7)

38, 74, 100

5 (127)

5-13/16

7-13/16 (198)

3 (76)

4 (102)

12-5/16 (313)

3-3/4 (95)

3.8 (1.7)

M23551

Fig. 2. VBN3 dimensions in inches (millimeters).

62-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

Table 4. Model Selection.

CV

Valve

Fitting

Body/Flow Type

Size

T/P

Trim

Enclosure

Actuator

VB = valve, ball

N = Female NPT threaded

2 = 2 way equal percentage, or linear flow characteristic, as noted in Table 1.

3 = 3 way mixing equal percentage, or linear flow characteristic, as noted in Table 2.

inch S.I. metric

A

1/2

DN15

B

3/4

DN20

C

1

DN25

D

1-1/4 DN32

E

1-1/2 DN40

F

2

DN50

G

2-1/2 DN65

H

3

DN80

B

C

D

E

F

.

T

U

CV Designator

1

See Table 1 for Two-way valves.

See Table 2 for Three-way valves.

2

3 = ANSI 300 Valve construction

P = Plated (chrome or nickel)

S = Stainless Steel

0 = no enclosure

R = NEMA 3R enclosure

X = no actuator

A = NSR, Floating

B = NSR, Modulating

C = SR, 2-Position, 24 Vac

D = SR, Floating/Modulating

VB

Application Notes

Proper Use

IMPORTANT

Valve sizing is important for correct system operation.

Undersized valves do not have sufficient capacity at

maximum load. Oversized valves do not have

sufficient authority over the load in modulating

applications.

Oversized valves can initiate cycling and the seat and

ball can be damaged because of the restricted

opening.

These valves are only for use in cold, warm, hot water systems

and for steam applications. They are designed for a medium

temperature range of from 35 to 250F, at a maximum pressure

of 360 psig VBN valves are to be operated with the appropriate

Honeywell direct coupled actuators only.

Water should be properly filtered, treated and conditioned

according to local conditions and the recommendations of the

boiler or chiller manufacturers. The installation of a strainers

and filters is recommended.

IMPORTANT

The presence of excessive iron oxide (red rust) in the

system voids the valve warranty.

62-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

Effective CV

When valves are mounted between pipe reducers, there is a

decrease in actual valve capacity because the reducers create

additional pressure losses in the system. This is especially true

for ball valves because of their high capacity.

Table 5. Effective CVs Using Pipe Reducers (Two-way)

Valve

Size

(in.) 1/2" 3/4"

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3"

62-2648

0.38

0.68

1.3

2.0

2.6

4.7

8.0

11.7

0.38

0.68

1.3

2.0

2.5

4.3

6.5

7.9

0.31

0.63

1.2

2.5

4.3

7.4

10.1

14.7

29

Effective CV

Pipe Size (NPT)

1" 1-1/4" 1-1/2" 2" 2-1/2" 3"

0.38 0.38

0.68 0.68

1.3

1.3

2.0

2.0

2.5

2.4

4.1

3.9

5.7

5.4

6.7

6.2

0.31 0.31

0.63 0.63

1.2

1.2

2.5

2.5

4.3

4.2

7.2

6.4

9.6

9.1

7.1

6.5

21.1 17.1

4.4

4.4

9.0

8.9

15.3 14.9

26

24

44

37

54

42

4.4

8.3

14.9

25

37

41

102

4"

5"

The CV values in Tables 4 and 5 are a guideline. Use the

Effective CV, not the valve CV by itself, to more accurately

apply a control valve to the piping system. Multiply the CV

value by 0.865 to get the capacity in KVS, if metric units are

required.

Table 6. Effective CVs Using Pipe Reducers (Three-way)

Valve

Size

(in.) 1/2" 3/4"

1/2"

0.31

0.63

1.2

2.5

4.2

6.8

8.8

6.2

15.4

4.4

8.8

14.4

22

31

34

4.4

8.3

14.8

25

35

39

79

23

30

41

74

172

3/4"

4.4

4.4

4.3

8.7

8.6

8.6

13.8 13.5 13.4

20

19

19

26

24

23

28

26

25

4.4

4.4

4.4 4.4

8.2

8.2

8.2 8.1

14.5 14.3 14.2 14.0

23

22

22 22

31

30

29 28

34

32

31 29

53

46

42 39

22

22

22 22 21

29

28

28 27 27

39

37

36 35 34

64

56

52 48 47

101

77

67 60 57

42

41

41 40 40

57

56

54 52 51

71

69

65 62 61

100

94

87 79 72

108 100 92 83 79

210 165 135 111 102

266 190 146 117 106

45

44 43 42

55

53 51 50

72

67 63 61

101 88 80 76

162 119 101 94

202 132 109 101

49 46 45

63 57 55

82 69 67

124 90 85

145 97 91

1"

1-1/4"

0.33

0.59

1.0

2.4

4.3

8.0

0.33

0.59

1.0

2.4

4.3

8.0

0.40

0.66

1.3

2.4

3.8

12.6

0.40

0.65

1.3

2.3

3.5

4.5

8.6

14.9

22

31

Effective CV

Pipe Size (NPT)

1" 1-1/4" 1-1/2" 2" 2-1/2" 3"

0.30

0.60

1.0

2.3

4.0

7.9

0.40

0.66

1.3

2.4

3.8

11.7

0.40

0.65

1.3

2.3

3.5

4.5

8.6

14.9

22

31

0.30

0.60

1.0

2.3

3.8

5.7

0.40

0.66

1.3

2.4

3.7

10.7

0.40

0.65

1.3

2.3

3.5

4.5

8.5

14.6

21

28

4.1

7.7

8.7

12.7

19

27

34

1-1/2"

2"

2-1/2"

0.40

0.66

1.3

2.4

3.7

10.4

0.40

0.65

1.3

2.3

3.5

4.5

8.4

14.1

20

25

4.0

7.7

8.6

12.6

19

26

33

4.0

8.3

13.4

24

32

61

0.40

0.65

1.3

2.3

3.5

4.5

8.3

13.5

18.0

22

4.0

7.6

8.6

12.4

19

25

30

4.0

8.2

13.3

23

31

55

24

38.

57

83

109

0.40

0.65

1.3

2.3

3.5

4.4

8.2

13.3

18.0

21

4.0

7.6

8.5

12.3

18.1

24

28

4.0

8.2

13.2

23

30

50

24

38

56

70

101

38

74

100

0.40

0.65

1.3

2.3

3.5

4.4

8.2

13.1

17.0

21

4.0

7.6

8.5

12.2

17.9

23

27

4.0

8.2

13.2

22

29

47

24

37

54

75

92

37

68

87

4"

5"

4.0

7.6

8.5

12.2

17.6

23

27

4.0

8.2

13.1

22

27

44

24

37

52

70

83

37

65

79

Flow Characteristics

The VBN2 Two-Way Ball Valves have:

an equal percentage flow characteristic with characterized

flow control insert.

a linear flow characteristic with full port balls.

The VBN3 Three-Way Ball Valves have:

between ports A and AB: an equal percentage flow

characteristic.

between ports B and AB: a linear flow characteristic.

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

Required Torque

1.

Both Honeywell non-spring return and spring return low torque

direct coupled actuators can be utilized with the VBN2 and

VBN3 valves. VB valves use a patented seat design that

reduces the torque needed from the actuator. A 35 lb-in. DCA

provides sufficient torque to close the valve at rated close-off.

(See Table 6.) These ratings exceed most HVAC application

requirements.

Table 7. Close-off, Differential Pressure Ratings.

Valve Type

2 way

3 way

Valve Size

1/2, 3/4

1", 1-1/4, 1-1/2, 2",

2-1/2, 3"

1/2, 3/4, 1"

1-1/4, 1-1/2, 2",

2-1/2

Close-off Pressure

Rating (psi)

130

100

50

2.

3.

4.

Clean the lines upstream of particles larger than 1/16 in.

diameter (welding slag, pipe scale and other contaminants).

Proceed with installation once the system specifics

(expansion/contraction of the system and its medium as

well as operating pressures) are within tolerances.

Eliminate air from system.

Two-way valves are marked to show flow direction.

IMPORTANT

Flow arrows must point in the direction of the flow for

proper operation.

NOTE: For three-way valve mounting, see Fig. 3 through 4.

AB PORT

SUPPLY

40

INSTALLATION

RETURN

A PORT

AB PORT

RETURN

COIL

A PORT

COIL

B PORT

B PORT

SUPPLY

DIVERTING

MIXING

M13737

When Installing this Product...

1.

2.

3.

4.

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

Check ratings given in instructions and on the product to

ensure the product is suitable for your application.

Installer must be a trained, experienced service technician.

After installation is complete, check out product operation as provided in these instructions.

Fig. 3. Three-way ball valve flow orientation (not to scale).

FULL

HEAT

HEATING COIL

AB

VB3

5 GPM

5 GPM

Preparation

PROPORTIONED

HEAT

CAUTION

AB

Equipment Damage Hazard

Foreign particles like dirt and metal chips can damage

the ball seals.

For trouble-free operation of the product, good

installation practice must include initial system flushing,

and chemical water treatment. Clean the lines

upstream of particles larger than 1/16 inch diameter

(welding slag, pipe scale, sand and other suspended

particulate). Use of a 50 micron (or finer) system side

stream filter is suggested. Remove all filters before

flushing.

Do not use boiler additives, solder flux and wetted

materials which are petroleum based or contain mineral

oil, hydrocarbons, or ethylene glycol acetate.

Compounds which can be used, with minimum 50%

water dilution, are diethylene glycol, ethylene glycol,

and propylene glycol (antifreeze solutions).

If installing these valves in an addition to, or retrofitting

an existing building, do not assume that the fluid in the

existing piping meets these criteria.

VB3

B

2.5 GPM

2.5 GPM

5 GPM

SUPPLY

MAIN

RETURN

MAIN

NO

HEAT

AB

VB3

B

5 GPM

NO FLOW

THROUGH COIL

5 GPM

M19523

Fig. 4. Three-way mixing valve operation with coil bypass.

62-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

MIXED

DISCHARGE

WATER TO

HEAT LOAD

T POSITION ON TOP OF

3 WAY BALL VALVE STEM

STEM

VB3

AB

A

B

BYPASS

A

AB A

FULL FLOW

(ONLY FOR

2-WAY BODIES)

BOILER

PUMP

AB

M13736

Fig. 5. Boiler bypass for reset control.

AB

AB

VB3

A

B

FULL FLOW

PUMP

AB

BOILER

AB

B

A AND B MIXED

TO AB,OR

B

A AND B DIVERTED

FROM AB, DEPENDING ON FLOW DIRECTION.

M13735

Fig. 6. Supply mixing for reset control.

5.

AB

A

Stem rotation:

a. For two-way valves:

(1) Clockwise to close.

(2) Counterclockwise to open.

b. For three-way valves:

(1) Clockwise to increase B to AB flow.

(2) Counter clockwise to increase A to AB flow.

Fig. 7. Orientation of ball in valve

6.

Valve must be mounted with the actuator/bracket above

the valve body. Do not install the valve with the stem

below horizontal or upside down. (See Fig. 7 and 8.)

NOTE: After valves have been installed in the piping,

the installer can determine the ball orientation

within the valve from the notches in the top of

the valve stem. For two-way valves, the lengthwise direction of the notch indicates the flow

through the ball (i.e. when the notch is parallel

to the axis of the valve between A and B ports,

the ball will allow flow through the valve). For

three-way valves, the flow can be determined

by the orientation of the T shaped notch in the

valve stem, as shown in Fig. 7.

M19525

Fig. 8. Vertical valve installation

62-2648

M23450

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

Wiring

45

Valves with Non-Spring Return Actuators (MN6105, MN7505)

45

FLOATING ACTUATOR

Direct

Service/Off

Reverse

M19526

Fig. 9. Acceptable valve angle from vertical

CONTROLLER

Mechanical Installation

The valves are tapped in NPT and should be sealed with an

approved pipe sealant. Torque should not exceed 75 lb-ft.

1

24 VAC

See Fig. 1 and 2 for valve dimensions. Refer to actuator

literature for actuator dimensions.

Mounting Plate Adjustment

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CONNECTION REQUIRED FOR SPST CONTROL.

The Actuator Mounting Plate can be rotated to a different

position for installation in confined spaces. This is

accomplished as follows:

1. Remove the handle from the shaft and set it aside.

2. Remove the two screws that hold the stem assembly to

the mounting plate and set them aside.

3. Remove and set aside the stem assembly.

4. Remove and set aside the two screws that attach the

mounting plate to the valve.

5. Remove and set aside hold-down ring from mounting

plate.

6. Rotate mounting plate around valve top to the desired

position.

Fig. 10. Wiring for On/Off Control

FLOATING ACTUATOR

Direct

Service/Off

Reverse

NOTE: Take note of the screw hole positions on the valve.

They limit the mounting plate positions.

7.

8.

9.

10.

Lower ring down to valve body and engage it in the new

position relative to the mounting plate.

Tighten screws to valve body securing the mounting

plate.

Reattach the stem assembly to the mounting plate.

If desired, replace the handle on the shaft.

NOTE: See Fig. 19 for valve exploded view.

3.

FLOATING

CONTROLLER

1

24 VAC

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M18946A

Fig. 11. Wiring for Floating Control

Electrical Installation

1.

2.

M18945A

If necessary, remove actuator wiring cover.

Wire actuator using Figures 10 through 18 for the

application required.

Replace cover.

62-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

ACTUATOR

PROPORTIONAL ACTUATOR

2

-10 Vdc

0 -10 Vdc

0

-10 Vdc

-10 Vdc

FEEDBACK

24 VAC

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

2 24 VDC SUPPLY ACCEPTABLE.

1

3 SET SWITCH TO FLOATING.

PROPORTIONAL

CONTROLLER

24 VAC

FEEDBACK

M19573A

Fig. 14. Wiring for Floating Control (Floating mode setting)

+

2

ACTUATOR

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

0(2)-10 VDC OF 0(4)-20 mA CONTROL SIGNAL ACCEPTABLE.

SET CONTROL SIGNAL DIP SWITCH TO "OFF" FOR VOLTAGE.

SET TO "ON" FOR CURRENT.

24 VAC

1

2

2

3

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

M18947A

Fig. 12. Wiring for Modulating Control

+

FEEDBACK

Valves with Spring Return Actuators (MS7505, MS8105)

24 VAC

SPST

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

SPDT

2 24 VDC SUPPLY ACCEPTABLE.

3 SET SWITCH TO MODULATING.

M19576A

Fig. 15. Override to full open (Modulating mode setting)

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

ACTUATOR

2 24 VDC SUPPLY ACCEPTABLE.

SPST

ACTUATOR

M19718B

2

3

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

+

FEEDBACK

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

SPST

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

M22289

Fig. 13. Wiring for On/Off Control

2 24 VDC SUPPLY ACCEPTABLE.

3 SET SWITCH TO MODULATING.

M19577A

Fig. 16. Override to full closed (Modulating mode setting)

62-2648

10

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

HANDLE (REMOVABLE) FOR

MANUALLY ROTATING SHAFT**

ACTUATOR

1

24 VAC

1

2

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

OR +

OR N/A

FEEDBACK

+

3

FEEDBACK

SCREWS (2)**

STEM ASSEMBLY COVER**

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

STEM ASSEMBLY**

2 24 VDC SUPPLY ACCEPTABLE.

3 SET SWITCH TO MODULATING.

M19574A

ACTUATOR

1

24 VAC

1

2

4 TO 20 mA

PROPORTIONING

CONTROLLER

2

490 TO 510

OHMS,

1/2 W

MINIMUM

OR +

OR N/A

FEEDBACK

+

3

FEEDBACK

SCREWS (2)**

BOLT**

ANTI-ROTATION

BRACKET**

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

MOUNTING

PLATE**

WING NUT**

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

VALVE STEM COUPLER

2 24 VDC SUPPLY ACCEPTABLE.

VALVE BODY

3 SET SWITCH TO MODULATING.

M22282A

Fig. 17. Wiring for Proportioning Controllers

(Modulating mode setting)

**INCLUDED IN REPLACEMENT KIT (PART NO. 5112-11)

M13738

24 VAC

2

ACTUATOR

1

2

24 VAC

3

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

COM

OR N/A

FEEDBACK

NOTE: All identified parts except for the valve body and

aluminum valve stem coupler are included in

Replacement Kit (part no. 5112-11)

OR +

HOT

Fig. 19. Valve assembly exploded view.

OPERATION AND CHECKOUT

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

ACTUATOR

24 VAC

1

2

2

3

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2 24 VDC SUPPLY ACCEPTABLE.

3 SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M22288

Fig. 18. Wiring for Proportioning controllers operating

multiple actuators (Modulating mode setting)

11

Once both the mechanical and electrical installations are

complete:

1. Cycle the actuator to verify that the direction of rotation

suits the control sequence.

2. If the rotation direction is incorrect:

a. For 2-position control actuators: Remount actuator

on the bracket.

b. For floating control actuators: Reverse two control

signal wires (CW/CCW).

c. For analog control actuators either:

(1) Reposition reverse/direct acting switch, or

(2) Remount actuator on the bracket.

3. If the control scheme requires fail-safe operation, ensure

that, upon removal of power, the fail position coincides

with the control sequence.

4. If the fail safe position is incorrect, remove and reinstall

the actuator in the opposite orientation as follows:

62-2648

VBN2, VBN3 CONTROL BALL VALVES WITH THREADED CONNECTIONS

a. Loosen the shaft coupling bolt using a 10 mm

wrench.

b. Loosen all other mounting bolts connecting the

actuator to the mounting bracket, and set aside.

c. Remove the actuator from the valve shaft.

d. Move the actuator coupling to the opposite side of

the actuator, as displayed in Figure 20.

M19579A

Fig. 20. Mounting shaft coupling to actuator opposite side.

(1) Remove the retainer clip from the shaft coupling

and set it aside for later use.

(2) Remove shaft coupling from one side of the actuator.

(3) Replace the shaft coupling on the opposite side

of the actuator, aligning it based on the stroke

labelling.

(4) Replace the retainer clip on the shaft coupling

using the groove of the coupling.

e. Reconnect the actuator to the valve mounting

bracket by replacing the screws previously removed

(step b)

f. Tighten the shaft coupling bolt using a 10 mm

wrench.

For detailed actuator information, see Honeywell literature:

63-2607MS7505/MS8105 Actuator Product Data

63-2632MN6105/MN7505 Floating Actuator Product Data

63-2633MN6105/MN7505 Modulating Actuator Product

Data

TYPICAL SPECIFICATIONS

Ball Valve

Valve housing shall consist of forged brass rated at no less

than 360 psi at 250F. Standard valve ball shall consist of

chemically nickel-plated brass. Manufacturer shall be able to

provide optional 316 stainless steel ball and stem for two-way

valves. Valve shall have a blow-out proof stem with two EPDM

O-rings with minimum 600 psi rating. Manufacturer shall be

able to provide glass-filled polymer ball insert to make flow

control equal percentage. Valves shall be Honeywell. Two-way

valves shall have EPDM O-rings behind ball seals to allow for a

minimum close-off pressure of 100 psi with actuator which

provides 35 lb-in. torque for 1/2 to 3 inches sizes. Valve shall

be available with a minimum of 53 unique CV values. Valve

shall be available with threaded (FNPT) end connections.

Three-way valves shall be installed in a T configuration with

actuator perpendicular to shaft. Valve shall not require elbows

of any kind. Three-way valves shall have EPDM O-rings

behind ball seals to allow for a minimum close-off pressure of

40 psi with an actuator that provides 35 lb-in. torque for 1/2 to

2-1/2 inches sizes. Three-way valves must be available in both

mixing and diverting configurations and shall be available with

a minimum of 42 unique CV values. Valve shall be available

with threaded (FNPT) end connections.

Valve Actuator

Control valve actuator shall accept analog modulating

[(0)2-10 Vdc], floating (tri-state), or two-position signal as

indicated in the control sequence. Actuators shall be by

Honeywell. Actuator shall provide minimum torque required for

full valve shutoff position. Wiring terminals shall be provided for

installation to control signal and power wiring.

Actuator shall be available with housing suitable for outdoor

installation.

Accessories Identification tags shall be available for all valves;

tags shall be indelibly marked with CV, model number, and tag

location.

Automation and Control Solutions

Honeywell International Inc.

Honeywell Limited-Honeywell Limite

1985 Douglas Drive North

35 Dynamic Drive

Golden Valley, MN 55422

Toronto, Ontario M1V 4Z9

customer.honeywell.com

U.S. Registered Trademark

2006 Honeywell International Inc.

62-2648 C.H. 08-06

S-ar putea să vă placă și

- 5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Document8 pagini5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Hdhm TdhÎncă nu există evaluări

- Butterfly Valve, Grooved End, Globe, Model GLR300GDocument9 paginiButterfly Valve, Grooved End, Globe, Model GLR300Grahu2260Încă nu există evaluări

- Model BFV-N Butterfly Valve Grooved End Technical Data General DescriptionDocument4 paginiModel BFV-N Butterfly Valve Grooved End Technical Data General DescriptionPatricio SabettaÎncă nu există evaluări

- Model BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionDocument8 paginiModel BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionMERCURE GARINDOLPGÎncă nu există evaluări

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De la EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Evaluare: 3.5 din 5 stele3.5/5 (3)

- 4418 Amot ValvesDocument4 pagini4418 Amot ValvesBernardo Amaya DojaqueÎncă nu există evaluări

- Gas-Liquid And Liquid-Liquid SeparatorsDe la EverandGas-Liquid And Liquid-Liquid SeparatorsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 paginiValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuÎncă nu există evaluări

- Vickers DG4V-3 DG4V-3S 6xDocument32 paginiVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroÎncă nu există evaluări

- Norgren V51 Solenoid ManualDocument5 paginiNorgren V51 Solenoid ManualjadetorresÎncă nu există evaluări

- TFP950 10 2010Document6 paginiTFP950 10 2010elpelaracingÎncă nu există evaluări

- SDM 080 eDocument28 paginiSDM 080 eseaqu3stÎncă nu există evaluări

- Ev DG05Document14 paginiEv DG05mtbecerrapÎncă nu există evaluări

- DGMPC 5 Check Valve Eaton Vickers PDFDocument10 paginiDGMPC 5 Check Valve Eaton Vickers PDFsandyread4uÎncă nu există evaluări

- SD 14 eDocument12 paginiSD 14 eseaqu3stÎncă nu există evaluări

- Dorot 68-De - El - MRDocument6 paginiDorot 68-De - El - MRJosé Daniel ArenasÎncă nu există evaluări

- BFV STD - SpecdamperDocument39 paginiBFV STD - Specdamperkselvan_1Încă nu există evaluări

- Technical Information Series BVMM General Description: Ball ValvesDocument6 paginiTechnical Information Series BVMM General Description: Ball ValvesAliArababadiÎncă nu există evaluări

- Bermad: Fire ProtectionDocument4 paginiBermad: Fire ProtectionalbertoÎncă nu există evaluări

- Valves SpecificationDocument13 paginiValves Specificationkselvan_1Încă nu există evaluări

- Fisher v150Document16 paginiFisher v150Doug LambÎncă nu există evaluări

- Manifold Swagelok Ms 01 178Document16 paginiManifold Swagelok Ms 01 178papashoÎncă nu există evaluări

- F.F. Pressure Reducing Valve With Inox SeatDocument4 paginiF.F. Pressure Reducing Valve With Inox SeatAlen KuzmanovicÎncă nu există evaluări

- Keystone Betterfly Valves AR1 y AR2 KEYMC-0025-USDocument4 paginiKeystone Betterfly Valves AR1 y AR2 KEYMC-0025-USpca97Încă nu există evaluări

- Model 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesDocument4 paginiModel 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesFaull JackmanÎncă nu există evaluări

- SD25Document20 paginiSD25Mauricio Ariel H. OrellanaÎncă nu există evaluări

- BVR BOP: Technical Instruction ManualDocument9 paginiBVR BOP: Technical Instruction ManualGregory StewartÎncă nu există evaluări

- Bellimo b222 Lf24 S UsDocument3 paginiBellimo b222 Lf24 S UsGamo42Încă nu există evaluări

- MNL 043 02Document70 paginiMNL 043 02George Iankov100% (2)

- BallValues PDFDocument12 paginiBallValues PDFDevdatt WaghuleÎncă nu există evaluări

- DS2 12 ValveDocument9 paginiDS2 12 ValvejpmanikandanÎncă nu există evaluări

- SDM140EDocument36 paginiSDM140Eseaqu3stÎncă nu există evaluări

- CA44 CatalogDocument14 paginiCA44 CatalogtunradotÎncă nu există evaluări

- DV-5 Automatic Water Control Valve Deluge Fire Protection Systems 1-1/2 Inch To 8 Inch (DN40 To DN200) General DescriptionDocument34 paginiDV-5 Automatic Water Control Valve Deluge Fire Protection Systems 1-1/2 Inch To 8 Inch (DN40 To DN200) General DescriptionOscar GallettoÎncă nu există evaluări

- 521B1166 DKCFNPD043A102 StandardsolenoidvalveVDHT GB LowresDocument33 pagini521B1166 DKCFNPD043A102 StandardsolenoidvalveVDHT GB LowreslayetajÎncă nu există evaluări

- L2 Series NumaticsDocument15 paginiL2 Series NumaticsElmer HuashuayoÎncă nu există evaluări

- HPCO2Document23 paginiHPCO2Abdul RahmanÎncă nu există evaluări

- Manual Valve Bul 2531-M11 D1VLDocument12 paginiManual Valve Bul 2531-M11 D1VLsajay_suryaÎncă nu există evaluări

- DP1 ValveDocument3 paginiDP1 ValvejpmanikandanÎncă nu există evaluări

- FP 730-59 Data Sheet PDFDocument4 paginiFP 730-59 Data Sheet PDFCarlos TarquinoÎncă nu există evaluări

- Valvaluas Neumaticas PDFDocument15 paginiValvaluas Neumaticas PDFWalter LrÎncă nu există evaluări

- Series 4 - CAMOZZI General Valves and Solenoid Valves 1Document15 paginiSeries 4 - CAMOZZI General Valves and Solenoid Valves 1ShahÎncă nu există evaluări

- fp50 fp100 fp200Document10 paginifp50 fp100 fp200ducmanh83Încă nu există evaluări

- 3 Valve ManifoldDocument16 pagini3 Valve Manifoldwengjf83Încă nu există evaluări

- Valvula Check 6000 Lbsv3xDocument6 paginiValvula Check 6000 Lbsv3xMaik AmayaÎncă nu există evaluări

- FC 700E-3X-BO Product Page EnglishDocument4 paginiFC 700E-3X-BO Product Page EnglishLuis Alberto Serrano MesaÎncă nu există evaluări

- SD 6 eDocument16 paginiSD 6 eseaqu3stÎncă nu există evaluări

- Guth VSR Modulating ValvesDocument8 paginiGuth VSR Modulating ValvesRaul Guevara TorresÎncă nu există evaluări

- Catalogue: Automatic Control ValvesDocument44 paginiCatalogue: Automatic Control ValvesHeri SetyantoÎncă nu există evaluări

- Super Duplex Stainless Steel Vic-Ball ValveDocument4 paginiSuper Duplex Stainless Steel Vic-Ball Valvemayukhguha88Încă nu există evaluări

- 3-Piece Stainless Steel Ball Valve: Series We02Document4 pagini3-Piece Stainless Steel Ball Valve: Series We02Alvaro Muñoz BÎncă nu există evaluări

- C101 C102 Series Combination Pump - ValvesDocument12 paginiC101 C102 Series Combination Pump - ValvesRFIGUEROACÎncă nu există evaluări

- V5197A Firing Rate Gas Valve: FeaturesDocument8 paginiV5197A Firing Rate Gas Valve: Featuresadriano_ASRÎncă nu există evaluări

- RGS c1518Document2 paginiRGS c1518Amila AbeywickramaÎncă nu există evaluări

- Razvodni VentilDocument17 paginiRazvodni VentilalexkeserÎncă nu există evaluări

- Valves BarendsenDocument63 paginiValves BarendsenidontlikeebooksÎncă nu există evaluări

- Honeywell Web600 PDFDocument16 paginiHoneywell Web600 PDFMarcello PorrinoÎncă nu există evaluări

- HONEYWELL TR20s WallModulesInstallation PDFDocument4 paginiHONEYWELL TR20s WallModulesInstallation PDFMarcello PorrinoÎncă nu există evaluări

- Honeywell VF20 PDFDocument3 paginiHoneywell VF20 PDFMarcello PorrinoÎncă nu există evaluări

- Honeywell Sensor Temperatura C7041C2003 PDFDocument2 paginiHoneywell Sensor Temperatura C7041C2003 PDFMarcello PorrinoÎncă nu există evaluări

- HONEYWELL PUL SPYDER Specification Data PDFDocument8 paginiHONEYWELL PUL SPYDER Specification Data PDFMarcello PorrinoÎncă nu există evaluări

- HONEYWELL - NPB-2X-RS485 Installation Instruction 95-7778 PDFDocument4 paginiHONEYWELL - NPB-2X-RS485 Installation Instruction 95-7778 PDFMarcello PorrinoÎncă nu există evaluări

- ECC Products Catalogue PDFDocument160 paginiECC Products Catalogue PDFamitbslpawarÎncă nu există evaluări

- Honeywell - 63-2515 - ML7421 - Data Sheet PDFDocument8 paginiHoneywell - 63-2515 - ML7421 - Data Sheet PDFMarcello PorrinoÎncă nu există evaluări

- HONEYWELL - Differential Pressure Switches DPS-Series PDFDocument3 paginiHONEYWELL - Differential Pressure Switches DPS-Series PDFMarcello PorrinoÎncă nu există evaluări

- Honeywell C7632a B Sensor Co2 PDFDocument4 paginiHoneywell C7632a B Sensor Co2 PDFMarcello PorrinoÎncă nu există evaluări

- RT Film InterpretationDocument20 paginiRT Film InterpretationMOhammed PatelÎncă nu există evaluări

- Galvanized Rebar Vs Epoxy RebarDocument4 paginiGalvanized Rebar Vs Epoxy RebarvintagerulzÎncă nu există evaluări

- Multipole Circular Connectors: Brad - M12Document1 paginăMultipole Circular Connectors: Brad - M12Леха ЯнчукÎncă nu există evaluări

- Odwadniacz Termostatyczny th13Document1 paginăOdwadniacz Termostatyczny th13Fernando Moreno pereiraÎncă nu există evaluări

- EnergyMaster Thermal Store ManualDocument16 paginiEnergyMaster Thermal Store ManualandrewsheldonÎncă nu există evaluări

- Asce 7-22 CH 03com - For PCDocument16 paginiAsce 7-22 CH 03com - For PCsharethefilesÎncă nu există evaluări

- ASTM B506-09 - Standard SpecificationDocument5 paginiASTM B506-09 - Standard SpecificationMarian Joyce MacadineÎncă nu există evaluări

- Undersluice Bay Design Report PDFDocument57 paginiUndersluice Bay Design Report PDFSubodh PoudelÎncă nu există evaluări

- Angulo CoronamientoDocument1 paginăAngulo CoronamientoJoel Pacheco DiazÎncă nu există evaluări

- Torsion by ACI 318-11-3SlidesPerPage.272121622Document17 paginiTorsion by ACI 318-11-3SlidesPerPage.272121622oqusousÎncă nu există evaluări

- Belimo Bu Butterfly Valve-125Document6 paginiBelimo Bu Butterfly Valve-125Jerry ChuÎncă nu există evaluări

- DSXF 2Document3 paginiDSXF 2Yokoyama AnnÎncă nu există evaluări

- Fatigue - A Complex Subject - Some Simple ApproximationsDocument107 paginiFatigue - A Complex Subject - Some Simple Approximationslcm327Încă nu există evaluări

- OM-SEQ-0512 (0) - DAIKIN - 37793 (BU) - EN - Operation Manuals - EnglishDocument9 paginiOM-SEQ-0512 (0) - DAIKIN - 37793 (BU) - EN - Operation Manuals - EnglishrheriÎncă nu există evaluări

- Beam Design For Moment, Shear & TorsionDocument6 paginiBeam Design For Moment, Shear & Torsionsidiq7Încă nu există evaluări

- Zam-Introduction (Steel)Document14 paginiZam-Introduction (Steel)lymacsausarangÎncă nu există evaluări

- SCI Ductile Iron Flanged FittingDocument12 paginiSCI Ductile Iron Flanged FittingSajad PkÎncă nu există evaluări

- Aero Engineering Thermodynamics Question BankDocument10 paginiAero Engineering Thermodynamics Question Bankmurjass85Încă nu există evaluări

- Shell and Tube Heat Exchangers FormulaDocument3 paginiShell and Tube Heat Exchangers FormulayuvionfireÎncă nu există evaluări

- 03 - How To Design Timber BridgesDocument41 pagini03 - How To Design Timber BridgesAgung TriraharjoÎncă nu există evaluări

- Building Technology Flashcards - QuizletDocument9 paginiBuilding Technology Flashcards - QuizletXYRHEN ZEEJAY GONZALESÎncă nu există evaluări

- Royal CordDocument1 paginăRoyal CordWilfredoJrReyÎncă nu există evaluări

- Logan Airport Expansion: Extech Exterior TecnhologiesDocument12 paginiLogan Airport Expansion: Extech Exterior TecnhologiesGowtham SrinivaasÎncă nu există evaluări

- Manual Equipo 2 y 3Document72 paginiManual Equipo 2 y 3Wakko20IPN100% (1)

- Nid Design BriefDocument7 paginiNid Design BriefRachel BeniÎncă nu există evaluări

- What Is PlumbingDocument22 paginiWhat Is PlumbingTroychristian MallariÎncă nu există evaluări

- Tegomer Dispersing at Its BestDocument32 paginiTegomer Dispersing at Its BestHiếu Mai ĐứcÎncă nu există evaluări

- Issue 03 Deterioration of Concrete - Types and Its Preventive MeasuresDocument8 paginiIssue 03 Deterioration of Concrete - Types and Its Preventive Measuresankurshah1986100% (1)

- Content of Design Standard 4S-10.01: Manufacture and Installation Specification For FRP StructuresDocument29 paginiContent of Design Standard 4S-10.01: Manufacture and Installation Specification For FRP StructuresJuan Ayala ValdebenitoÎncă nu există evaluări

- A 826 - A826m - 95 Qtgyni05nqDocument5 paginiA 826 - A826m - 95 Qtgyni05nqsachinguptachdÎncă nu există evaluări

- Electric Motor Control: DC, AC, and BLDC MotorsDe la EverandElectric Motor Control: DC, AC, and BLDC MotorsEvaluare: 4.5 din 5 stele4.5/5 (19)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDe la EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsEvaluare: 4.5 din 5 stele4.5/5 (12)

- Well Control for Completions and InterventionsDe la EverandWell Control for Completions and InterventionsEvaluare: 4 din 5 stele4/5 (10)

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDe la EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceÎncă nu există evaluări

- Solar Energy: Survive Easily on Solar Power Off the GridDe la EverandSolar Energy: Survive Easily on Solar Power Off the GridÎncă nu există evaluări

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDe la EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingÎncă nu există evaluări

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADe la EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningDe la EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningEvaluare: 5 din 5 stele5/5 (4)

- Thermal Power Plant: Design and OperationDe la EverandThermal Power Plant: Design and OperationEvaluare: 4.5 din 5 stele4.5/5 (23)

- Handbook on Battery Energy Storage SystemDe la EverandHandbook on Battery Energy Storage SystemEvaluare: 4.5 din 5 stele4.5/5 (2)

- Pipeline and Energy Plant Piping: Design and TechnologyDe la EverandPipeline and Energy Plant Piping: Design and TechnologyEvaluare: 5 din 5 stele5/5 (2)

- Global Landscape of Renewable Energy FinanceDe la EverandGlobal Landscape of Renewable Energy FinanceÎncă nu există evaluări

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe la EverandFlow Analysis for Hydrocarbon Pipeline EngineeringÎncă nu există evaluări

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsDe la EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsÎncă nu există evaluări

- Heat Transfer Engineering: Fundamentals and TechniquesDe la EverandHeat Transfer Engineering: Fundamentals and TechniquesEvaluare: 4 din 5 stele4/5 (1)

- The Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadDe la EverandThe Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadEvaluare: 4.5 din 5 stele4.5/5 (10)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)