Documente Academic

Documente Profesional

Documente Cultură

Chapter 9 - Answer

Încărcat de

agnesDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter 9 - Answer

Încărcat de

agnesDrepturi de autor:

Formate disponibile

MANAGEMENT ACCOUNTING- Solutions Manual

CHAPTER 9

SYSTEMS DESIGN: ACTIVITY-BASED COSTING

AND MANAGEMENT

I.

Questions

1. The three levels available are: Level 1, in which a company uses a

plantwide overhead rate; Level 2, in which a company uses departmental

overhead rates; and Level 3, in which a company uses activity-based

costing.

2. New approaches to costing are needed because events of the last few

decades have made drastic changes in many organizations. Automation

has greatly decreased the amount of direct labor required to manufacture

products; product diversity has increased in that companies are

manufacturing a wider range of products and these products differ

substantially in volume, lot size, and complexity of design; and total

overhead cost has increased to the point in some companies that a

correlation no longer exists between it and direct labor.

3. The departmental approach to assigning overhead cost to products relies

solely on volume as an assignment base. Where diversity exists between

products (that is, where products differ in terms of number of units

produced, lot size, or complexity of production), volume alone is not

adequate for overhead costing. Overhead costing based on volume will

systematically overcost high-volume products and undercost low-volume

products.

4. Process value analysis (PVA) is a systematic approach to gaining an

understanding of the steps associated with a product or service. It

identifies all resource-consuming activities involved in the production

process and labels these activities as being either value-added or nonvalue-added. Thus, it is the beginning point in designing an activity-based

costing system since management must know what activities are involved

with each product before activity centers can be designated and cost

drivers established. Also, PVA helps management to eliminate any nonvalue-added activities and thereby streamline operations and minimize

costs.

5. The four general levels of activities are:

11-1

Chapter 11 Systems Design: Activity-Based Costing and Management

1. Unit-level activities, which are performed each time a unit is

produced.

2. Batch-level activities, which are performed each time a batch of goods

is handled or processed.

3. Product-level activities, which are performed as needed to support

specific products.

4. Facility-level activities, which simply sustain a facilitys general

manufacturing process.

6. First, activity-based costing increases the number of cost pools used to

accumulate overhead costs. Second, it changes the base used to assign

overhead costs to products. And third, it changes a managers perception

of many overhead costs in that costs that were formerly thought to be

indirect (such as depreciation or machine setup) are identified with

specific activities and thereby are recognized as being traceable to

individual products.

7. The two chief limitations are: First, the portion of overhead costs that

relate to facility-level activities are still usually allocated to products on

some arbitrary basis, such as machine-hours or direct labor-hours. Critics

of activity-based costing argue that facility-level activities account for the

bulk of all overhead costs in some companies. Second, high measurement

costs are involved in operating an activity-based costing system. That is,

the system requires the tracking of large amounts of detail and the

completion of many separate computations in order to determine the cost

of a unit or product.

8. Yes, activity-based costing can be used in service organizations. It has

been successfully implemented, for example, in railroads, hospitals, banks

and data service companies.

9. A resource driver is a measure of the quality of resources consumed by an

activity.

10. An activity driver is a measure of frequency and intensity of demands

placed on activities by cost objects.

11. Two-stage allocation is a procedure that first assigns a firms resource

costs, namely factory overhead cost, to cost pools, and then to cost

objects.

12. Two major advantages of ABM are:

11-2

Systems Design: Activity-Based Costing and Management Chapter 11

a. ABM measures the effectiveness of the key business processes and

activities, and identifies how they can be improved to reduce costs and

improve the customer value.

b. ABM improves the management focus by allocating resources to key

value-added activities, key customers, key products, and continuous

improvement methods to maintain the firms competitive advantage.

13. When direct labor is used as an allocation base for overhead, it is

implicitly assumed that overhead cost is directly proportional to direct

labor. When cost systems were originally developed in the 1800s, this

assumption may have been reasonably accurate. However, direct labor has

declined in importance over the years while overhead has been increasing.

This suggests that there is no longer a direct link between the level of

direct labor and overhead. Indeed, when a company automates, direct

labor is replaced by machines; a decrease in direct labor is accompanied

by an increase in overhead. This violates the assumption that overhead

cost is directly proportional to direct labor. Overhead cost appears to be

driven by factors such as product diversity and complexity as well as by

volume, for which direct labor has served as a convenient measure.

14. Employees may resist activity-based costing because it changes the rules

of the game. ABC changes some of the key measures, such as product

costs, used in making decisions and may affect how individuals are

evaluated. Without top management support, employees may have little

interest in making these changes. In addition, if top managers continue to

make decisions based on the numbers generated by the traditional costing

system, subordinates will quickly conclude that the activity-based costing

system can be ignored.

15. Unit-level activities are performed for each unit that is produced. Batchlevel activities are performed for each batch regardless of how many units

are in the batch. Product-level activities must be carried out to support a

product regardless of how many batches are run or units produced.

Customer-level activities must be carried out to support customers

regardless of what products or services they buy. Organization-sustaining

activities are carried out regardless of the companys precise product mix

or mix of customers.

16. Organization-sustaining costs, customer-level costs, and the costs of idle

capacity should not be assigned to products. These costs represent

resources that are not consumed by the products.

II. True or False

11-3

Chapter 11 Systems Design: Activity-Based Costing and Management

1. True

2. True

3. False

4. True

5. False

6. False

7. True

8. True

III. Exercises

Exercise 1

Activity

Activity

Classification

Examples of

Traceable

Costs

Labor cost;

depreciation

Examples of

Cost

Drivers

a. Materials are moved

from the receiving

dock to product flow

lines by a materialhandling crew

Batch-level

b. Direct labor workers

assemble various

products

Unit-level

Direct labor

cost; indirect

labor cost;

labor benefits

Direct laborhours

c. Ongoing training is

Facility-level*

Space cost;

training costs;

administration

costs

Hours of

training time;

number trained

d. A product is

designed by a

specialized design

team

Product-level

Space cost;

supplies used;

depreciation of

design

equipment

Hours of

design time;

number of

engineering

change orders

e. Equipment setups

are performed on a

regular basis

Batch-level

Labor cost;

supplies used;

depreciation of

equipment

Number of

setups; hours

or setup time

f. Numerical control

(NC) machines are

used to cut and

shape materials

Unit-level

Power;

supplies used;

maintenance;

depreciation

Machinehours; number

of units

of equipment;

space cost

provided to all

employees in the

company

Number of

receipts;

pounds handled

* Personnel administration and training costs might be traceable in part to the

facility-level and in part to other activity centers at the unit-level, productlevel, and batch-level.

Exercise 2

11-4

Systems Design: Activity-Based Costing and Management Chapter 11

1.

2.

3.

4.

5.

plantwide overhead rate

volume

two stage, stage, stage

Process value analysis

Unit-level

6.

7.

8.

9.

10.

Batch-level

Product-level

Facility-level

high-volume, low-volume, low-volume

activity centers

Exercise 3

a.

b.

c.

d.

e.

f.

g.

h.

Various individuals manage the parts inventories.

A clerk in the factory issues purchase orders for a

job.

The personnel department trains new production

workers.

The factorys general manager meets with other

department heads such as marketing to

coordinate plans.

Direct labor workers assemble products.

Engineers design new products.

The materials storekeeper issues raw materials to

be used in jobs.

The maintenance department performs periodic

preventative maintenance on general-use

equipment.

Product-level

Batch-level

Organizationsustaining

Organizationsustaining

Unit-level

Product-level

Batch-level

Organizationsustaining

Note: Some of these classifications are debatable and may depend on the

specific circumstances found in particular companies.

Exercise 4

Sales (P1,650 per standard model glider 10 standard

model gliders + P2,300 per custom designed glider 2

custom designed gliders)......................................................................................

P21,100

Costs:

Direct materials (P462 per standard model glider 10

standard model gliders + P576 per custom

designed glider 2 custom designed gliders).................................................

P5,772

Direct labor (P19 per direct labor-hour 28.5 direct

labor-hours per standard model glider 10 standard

model gliders + P19 per direct labor-hour 32 direct

labor-hours per custom designed glider 2 custom

designed gliders)..............................................................................................

6,631

Supporting manufacturing (P18 per direct labor-hour

6,282

28.5 direct labor-hours per standard model glider

11-5

Chapter 11 Systems Design: Activity-Based Costing and Management

10 standard model gliders + P18 per direct laborhour 32 direct labor-hours per custom designed

glider 2 custom designed gliders).................................................................

Order processing (P192 per order 3 orders).....................................................

576

Custom designing (P261 per custom design 2 custom

designs)............................................................................................................

522

Customer service (P426 per customer

1 customer).......................................................................................................

426

20,209

Customer margin......................................................................................................

P 891

Exercise 5

Requirement 1

The predetermined overhead rate is computed as follows:

Predetermined

overhead rate

P290,000

50,000 DLHs

P5.80 per DLH

The unit product costs under the companys traditional costing system are

computed as follows:

Special

Regular

Direct materials................................................................................................................

P60.00

P45.00

Direct labor......................................................................................................................

9.60

7.20

Manufacturing overhead (0.8 DLH P5.80 per DLH;

0.6 DLH P5.80 per DLH)........................................................................................

4.64

3.48

Unit product cost..............................................................................................................

P74.24

P55.68

Requirement 2

The activity rates are computed as follows:

(a)

Estimated

Overhead

Activities

Cost

Supporting direct labor...............................

P150,000

Batch setups...............................................

P60,000

Safety testing..............................................

P80,000

(b)

Total

Expected Activity

50,000 DLHs

250 setups

100 tests

(a) (b)

Activity Rate

P3 per DLH

P240 per setup

P800 per test

Manufacturing overhead is assigned to the two products as follows:

Special Product:

(a)

Activity Cost Pool

Activity Rate

Supporting direct labor..........................................................

P3 per DLH

Batch setups..........................................................................

P240 per setup

Safety testing.........................................................................

P800 per test

11-6

(b)

Activity

8,000 DLHs

200 setups

80 tests

(a) (b)

ABC Cost

P24,000

48,000

64,000

Systems Design: Activity-Based Costing and Management Chapter 11

Total

P136,000

Regular Product:

(a)

Activity Cost Pool

Activity Rate

Supporting direct labor..........................................................

P3 per DLH

Batch setups..........................................................................

P240 per setup

Safety testing.........................................................................

P800 per test

Total

(b)

Activity

42,000 DLHs

50 setups

20 tests

(a) (b)

ABC Cost

P126,000

12,000

16,000

P154,000

Activity-based costing unit product costs are computed as follows:

Special

Direct materials...................................................................................................

P60.00

Direct labor.........................................................................................................

9.60

Manufacturing overhead (P136,000 10,000 units; P154,000

70,000 units)..................................................................................................

13.60

Unit product cost.................................................................................................

P83.20

Regular

P45.00

7.20

2.20

P54.40

IV. Problems

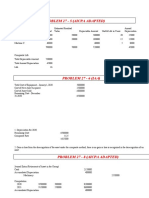

Problem 1

Cost

Systems

Traditional cost system

ABC system

Labor

Machining

Setup

Production order

Material handling

Parts administration

Pool

Rate

350%

Cost Driver

Consumption

P10,000

Cost

Assignment

P35,000

10%

P25/hour

P10/hour

P100/order

P20/requisition

P40/part

P10,000

800 hours

100 hours

12 orders

5 requisitions

18 parts

P 1,000

20,000

1,000

1,200

100

720

P24,020

Problem 2

Requirement 1

(a)

11-7

Chapter 11 Systems Design: Activity-Based Costing and Management

Total overhead

= P200,000 + P32,000 + P100,000 + P120,000

= P452,000

Overhead rate

= P452,000 / 50,000 direct labor hours

= P9.04 per direct labor hour

Overhead assigned to proposed job = P9.04 x 1,000 direct labor hours

= P9,040

(b) Total cost of proposed job:

Direct materials

Direct labor 10,000

Overhead applied

Total cost

P 6,000

9,040

P25,040

(c) Companys bid = Full manufacturing cost x 120% = P25,040 x 120%

= P30,048

Requirement 2

(a) Maintenance :

P200,000 / 20,000

Materials handling: P32,000 / 1,600

=

Setups:

P100,000 / 2,500 =

Inspection:

P120,000 / 4,000 =

= P10 per machine hour

P20 per move

P40 per setup

P30 per inspection

Overhead assigned to proposed job:

Maintenance (P10 x 500)

Material handling (P20 x 12)

Setups (P40 x 2)

Inspection (P30 x 10)

Total overhead assigned to job

P5,000

240

80

300

P5,620

(b) Total cost of proposed project:

Direct materials

Direct labor 10,000

Overhead applied

Total cost

P 6,000

5,620

P21,620

(c) Companys bid = Full manufacturing cost x 120% = P21,620 x 120%

11-8

Systems Design: Activity-Based Costing and Management Chapter 11

= P25,944

The bid price of P25,944 was determined as follows:

Direct materials

Direct labor

Overhead assigned:

Maintenance (P10 x 500)

Material handling (P20 x 12)

Setups (P40 x 2)

Inspections (P30 x 10)

Total overhead assigned to job

Total cost

Markup

Bid price

P6,000

10,000

P5,000

240

80

300

5,620

P21,620

120%

P25,944

Problem 3 (Activity-Based Costing)

Requirement 1

The first-stage allocation of costs to the activity cost pools appears below:

Activity Cost Pools

Processing Supporting

Orders

Customers

Other

Assemblin

g Units

Manufacturing

overhead

Selling and

administrative

overhead

Total cost

Total

P250,000

P175,000

P25,000

P50,000

P500,000

30,000

P280,000

135,000

P310,000

75,000

P100,000

60,000

P110,000

300,000

P800,000

Requirement 2

The activity rates for the cost pools are:

Assembling units

Processing orders

Supporting customers

(a)

Total Cost

P280,000

P310,000

P100,000

11-9

(b)

Total Activity

1,000 units

250 orders

100 customers

(a) (b)

Activity Rate

P280 per unit

P1,240 per order

P1,000 per customer

Chapter 11 Systems Design: Activity-Based Costing and Management

Requirement 3

The overhead cost attributable to Lucky Sale would be computed as follows:

(a)

Activity Rate

P280 per unit

P1,240 per order

P1,000 per customer

Activity Cost Pools

Assembling units

Processing orders

Supporting customers

(b)

Activity

80 units

4 orders

1 customer

(a) x (b)

ABC Cost

P22,400

P4,960

P1,000

Requirement 4

The customer margin can be computed as follows:

Sales (P595 per unit x 80 units)

Costs:

Direct materials (P180 per unit x 80 units)

Direct labor (P50 per unit x 80 units)

Unit-related overhead (above)

Order-related overhead (above)

Customer-related overhead (above)

Customer margin

P47,600

P14,400

4,000

22,400

4,960

1,000

P

46,760

840

Problem 4 (Activity-Based Costing as an Alternative to Traditional

Product Costing)

Requirement 1

a. When direct labor-hours are used to apply overhead cost to products, the

companys predetermined overhead rate would be:

Predetermined

overhead rate

=

=

Manufacturing overhead cost

Direct labor hours

P1,480,000

20,000 DLHs

11-10

P74 per DLH

Systems Design: Activity-Based Costing and Management Chapter 11

b.

Model

HY5

Direct materials......................................................................

P35.00

Direct labor:

P20 per hour 0.2 DLH, 0.4 DLH....................................

4.00

Manufacturing overhead:

P74 per hour 0.2 DLH, 0.4 DLH....................................

14.80

Total unit product cost............................................................

P53.80

AS2

P25.00

8.00

29.60

P62.60

Requirement 2

a. Predetermined overhead rates for the activity cost pools:

(a)

Estimated

Activity Cost Pool

Total Cost

Machine setups.................P180,000

Special milling..................P300,000

General factory.................

P1,000,000

(b)

Estimated

Total Activity

250 setups

1,000 MHs

20,000 DLHs

(a) (b)

Activity Rate

P720 per setup

P300 per MH

P50 per DLH

The overhead applied to each product can be determined as follows:

Model HY5

(a)

Predetermined

Activity Cost Pool

Overhead Rate

Machine setups....................................................................................

P720 per setup

Special milling.....................................................................................

P300 per MH

General factory....................................................................................

P50 per DLH

Total manufacturing overhead cost (a).................................................

Number of units produced (b).............................................................

Overhead cost per unit (a) (b)..........................................................

(b)

Activity

150 setups

1,000 MHs

4,000 DLHs

(a) (b)

Overhead

Applied

P108,000

300,000

200,000

P608,000

20,000

P30.40

Model AS2

Activity Cost Pool

(a)

Predetermined

Overhead Rate

11-11

(b)

Activity

(a) (b)

Overhead

Applied

Chapter 11 Systems Design: Activity-Based Costing and Management

Machine setups....................................................................................

P720 per setup

100 setups

Special milling.....................................................................................

P300 per MH

0 MHs

General factory....................................................................................

P50 per DLH

16,000 DLHs

Total manufacturing overhead cost (a).................................................

Number of units produced (b).............................................................

Overhead cost per unit (a) (b)..........................................................

P 72,000

0

800,000

P872,000

40,000

P21.80

b. The unit product cost of each model under activity-based costing would be

computed as follows:

Model

HY5

AS2

Direct materials........................................................................................................

P35.00

P25.00

Direct labor (P20 per DLH 0.2 DLH; P20 per DLH 04.DLH)...........................

4.00

8.00

Manufacturing overhead (above)..............................................................................

30.40

21.80

Total unit product cost...............................................................................................

P69.40

P54.80

Comparing these unit cost figures with the unit costs in Part 1(b), we find

that the unit product cost for Model HY5 has increased from P53.80 to

P69.40, and the unit product cost for Model AS2 has decreased from

P62.60 to P54.80.

Requirement 3

It is especially important to note that, even under activity-based costing, 68%

of the companys overhead costs continue to be applied to products on the

basis of direct labor-hours:

Machine setups (number of setups)............................P 180,000

Special milling (machine-hours)................................. 300,000

General factory (direct labor-hours)........................... 1,000,000

Total overhead cost.....................................................P1,480,000

12%

20

68

100%

Thus, the shift in overhead cost from the high-volume product (Model AS2) to

the low-volume product (Model HY5) occurred as a result of reassigning only

32% of the companys overhead costs.

The increase in unit product cost for Model HY5 can be explained as follows:

First, where possible, overhead costs have been traced to the products rather

than being lumped together and spread uniformly over production. Therefore,

11-12

Systems Design: Activity-Based Costing and Management Chapter 11

the special milling costs, which are traceable to Model HY5, have all been

assigned to Model HY5 and none assigned to Model AS2 under the activitybased costing approach. It is common in industry to have some products that

require special handling or special milling of some type. This is especially true

in modern factories that produce a variety of products. Activity-based costing

provides a vehicle for assigning these costs to the appropriate products.

Second, the costs associated with the batch-level activity (machine setups)

have also been assigned to the specific products to which they relate. These

costs have been assigned according to the number of setups completed for

each product. However, since a batch-level activity is involved, another factor

affecting unit costs comes into play. That factor is batch size. Some products

are produced in large batches and some are produced in small batches. The

smaller the batch, the higher the cost per unit of the batch activity. In the

case at hand, the data can be analyzed as shown below.

Model HY5:

Cost to complete one setup [see 2(a)]......................................... P720

Number of units processed per setup

(20,000 units 150 setups)...................................................133.33

Setup cost per unit (a) (b)....................................................... P5.40

Model AS2:

Cost to complete one setup (above)............................................ P720

Number of units processed per setup

(40,000 units 100 setups)................................................... 400

Setup cost per unit (a) (b)....................................................... P1.80

(a)

(b)

(a)

(b)

Thus, the cost per unit for setups is three times as great for Model HY5, the

low-volume product, as it is for Model AS2, the high-volume product. Such

differences in cost are obscured when direct labor-hours (or any other volume

measure) is used as the basis for applying overhead cost to products.

In sum, overhead cost has shifted from the high-volume product to the lowvolume product as a result of more appropriately assigning some costs to the

products on the basis of the activities involved, rather than on the basis of

direct labor-hours.

11-13

Chapter 11 Systems Design: Activity-Based Costing and Management

V. Multiple Choice Questions

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

A

D

C

B

A

D

A

B

D

C

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

B

D

C

A

C

D

D

C

B

A

21.

21.

22.

23.

24.

25.

26.

27.

28.

29.

D

A

B

A

B

D

B

C

A

C

11-14

S-ar putea să vă placă și

- Investment in Equity Securities - Problem 16-2, 16-3, 16-10. and 16-11Document6 paginiInvestment in Equity Securities - Problem 16-2, 16-3, 16-10. and 16-11Jessie Dela CruzÎncă nu există evaluări

- Ch16 Receivables Management PDFDocument4 paginiCh16 Receivables Management PDFjdiaz_646247Încă nu există evaluări

- Module 2 Management ScienceDocument9 paginiModule 2 Management ScienceGenesis Roldan100% (1)

- Chapter 07 - Test BankDocument11 paginiChapter 07 - Test Bankwasif ahmedÎncă nu există evaluări

- Chapter 5Document20 paginiChapter 5Clyette Anne Flores Borja100% (1)

- Test Bank For Cornerstones of Cost Management 2nd Edition by Hansen PDFDocument23 paginiTest Bank For Cornerstones of Cost Management 2nd Edition by Hansen PDFJyasmine Aura V. AgustinÎncă nu există evaluări

- Management Science MidDocument10 paginiManagement Science MidKaren Kaye PasamonteÎncă nu există evaluări

- Name: Berdon, Beverly Bernadeth V. Section: BSOA 4-2Document3 paginiName: Berdon, Beverly Bernadeth V. Section: BSOA 4-2Bernadeth BerdonÎncă nu există evaluări

- Problem 4-9Document2 paginiProblem 4-9maryaniÎncă nu există evaluări

- Inventory Control ModelsDocument34 paginiInventory Control ModelsExequielCamisaCrusperoÎncă nu există evaluări

- Prelim Exam - For PrintingDocument4 paginiPrelim Exam - For PrintingThat's FHEVulousÎncă nu există evaluări

- Activity Based Costing (ABC)Document8 paginiActivity Based Costing (ABC)Nah HamzaÎncă nu există evaluări

- Module 10. Simple Linear Regression Regression AnalysisDocument6 paginiModule 10. Simple Linear Regression Regression AnalysisGaile YabutÎncă nu există evaluări

- Cost Accounting and ControlDocument3 paginiCost Accounting and ControlRoderica RegorisÎncă nu există evaluări

- 2Document13 pagini2Ashish BhallaÎncă nu există evaluări

- PPP Mfg. Co. Unit Cost Data REVIEWDocument58 paginiPPP Mfg. Co. Unit Cost Data REVIEWNikki GarciaÎncă nu există evaluări

- Irish CorporationDocument3 paginiIrish CorporationAngeline RamirezÎncă nu există evaluări

- Chapter 7 - Compound Financial Instrument (FAR6)Document5 paginiChapter 7 - Compound Financial Instrument (FAR6)Honeylet SigesmundoÎncă nu există evaluări

- Chapter Seven SolutionsDocument60 paginiChapter Seven SolutionsaishaÎncă nu există evaluări

- Chapter 11: Development Policymaking and The Roles of Market, State, and Civil SocietyDocument5 paginiChapter 11: Development Policymaking and The Roles of Market, State, and Civil SocietyMarc BuenoÎncă nu există evaluări

- Cfas Chapter 16 4Document3 paginiCfas Chapter 16 4Iana Jane BuronÎncă nu există evaluări

- AE 22 M TEST 3 With AnswersDocument6 paginiAE 22 M TEST 3 With AnswersJerome MonserratÎncă nu există evaluări

- Chapter 1 Answer Cost Accounting PDFDocument5 paginiChapter 1 Answer Cost Accounting PDFCris VillarÎncă nu există evaluări

- CVP ExercisesDocument7 paginiCVP ExercisesEunize Escalona100% (1)

- Machinery and Capitl ExpendituresDocument3 paginiMachinery and Capitl ExpendituresZes OÎncă nu există evaluări

- MAC (ALL MCFMS) - CORRIGE G1+G2+G3 DRILL Mid-Testing Questions (W2019)Document30 paginiMAC (ALL MCFMS) - CORRIGE G1+G2+G3 DRILL Mid-Testing Questions (W2019)Ram Kumar Chowdary VinjamÎncă nu există evaluări

- Accounting 4 Premiums, Warranties and Deferred RevenuesDocument2 paginiAccounting 4 Premiums, Warranties and Deferred RevenuesMicaela EncinasÎncă nu există evaluări

- Solman de Leon 2016 PDFDocument95 paginiSolman de Leon 2016 PDFZo Thelf0% (1)

- Answers - Chapter 1 Vol 2 2009Document10 paginiAnswers - Chapter 1 Vol 2 2009Shiela PilarÎncă nu există evaluări

- Chapter 7Document18 paginiChapter 7Raven Vargas DayritÎncă nu există evaluări

- Exercise 5-3Document12 paginiExercise 5-3Angelica NatanÎncă nu există evaluări

- Chapter 3 Answer Cost AccountingDocument17 paginiChapter 3 Answer Cost AccountingJuline Ashley A CarballoÎncă nu există evaluări

- Sunu 2Document1 paginăSunu 2ahmedÎncă nu există evaluări

- xACC 213Document10 paginixACC 213CharlesÎncă nu există evaluări

- Cost - Concepts and ClassificationsDocument23 paginiCost - Concepts and ClassificationsYehetÎncă nu există evaluări

- FAR 04-11.a Depletion of Mineral ResourcesDocument4 paginiFAR 04-11.a Depletion of Mineral ResourcesAi NatangcopÎncă nu există evaluări

- Activity 3 CAMINGAWAN BSMA 2B PDFDocument7 paginiActivity 3 CAMINGAWAN BSMA 2B PDFMiconÎncă nu există evaluări

- Fair Value Model: Home My Courses ACC211 - 6387 - 2021-2022 - 2NDSEM-SEM - CAE 5th To 8th Examinations/Assessments Final ExamDocument2 paginiFair Value Model: Home My Courses ACC211 - 6387 - 2021-2022 - 2NDSEM-SEM - CAE 5th To 8th Examinations/Assessments Final Examkaeya alberichÎncă nu există evaluări

- Problem 2 10Document9 paginiProblem 2 10Carl Jaime Dela CruzÎncă nu există evaluări

- Inventory Management PDFDocument21 paginiInventory Management PDFReverie SevillaÎncă nu există evaluări

- MidtermsDocument8 paginiMidtermsRhea BadanaÎncă nu există evaluări

- This Study Resource Was Shared Via: Solution 23-2 Answer DDocument5 paginiThis Study Resource Was Shared Via: Solution 23-2 Answer DDummy GoogleÎncă nu există evaluări

- 21 Financial Assets at Fair Value: Solution 21-1 Answer CDocument30 pagini21 Financial Assets at Fair Value: Solution 21-1 Answer CLayÎncă nu există evaluări

- Inventory Cost Formulas LCNRV Fs DisclosuresDocument15 paginiInventory Cost Formulas LCNRV Fs DisclosuresKawhileonard LeonardÎncă nu există evaluări

- IA 1 Valix 2020 Ver. Problem 27-5 - Problem 27-7Document2 paginiIA 1 Valix 2020 Ver. Problem 27-5 - Problem 27-7Ariean Joy DequiñaÎncă nu există evaluări

- CfasDocument32 paginiCfasLouiseÎncă nu există evaluări

- Sol. Man. - Chapter 16 - Ppe Part 2 - Ia Part 1BDocument10 paginiSol. Man. - Chapter 16 - Ppe Part 2 - Ia Part 1BMahasia MANDIGAN100% (1)

- FIN1S Prelim ExamDocument7 paginiFIN1S Prelim ExamYu BabylanÎncă nu există evaluări

- Corrections: Suggested SolutionDocument5 paginiCorrections: Suggested SolutionZairah FranciscoÎncă nu există evaluări

- VALLEJOS-ACCTG 301-Retail Inventoy Method-Hand OutDocument5 paginiVALLEJOS-ACCTG 301-Retail Inventoy Method-Hand OutEllah RahÎncă nu există evaluări

- Accounting - Prob.3Document2 paginiAccounting - Prob.3Dellosa, Jierstine Shaney R.Încă nu există evaluări

- Chap16 ProblemsDocument20 paginiChap16 ProblemsYen YenÎncă nu există evaluări

- Chapter 13 - Gross Profit MethodDocument7 paginiChapter 13 - Gross Profit MethodLorence IbañezÎncă nu există evaluări

- Answer Keys Activity NoDocument7 paginiAnswer Keys Activity NoDalia ElarabyÎncă nu există evaluări

- Toaz - Info Reviewer Computations Horngren PRDocument355 paginiToaz - Info Reviewer Computations Horngren PRNah HamzaÎncă nu există evaluări

- Chapter 11 - AnswerDocument6 paginiChapter 11 - AnswerJhudzxkie VhientesaixÎncă nu există evaluări

- Roikhanatun Nafi'Ah, Activity Based Costing SummaryDocument3 paginiRoikhanatun Nafi'Ah, Activity Based Costing SummaryRoikhanatun Nafi'ahÎncă nu există evaluări

- CH 04Document20 paginiCH 04Jennifer GueÎncă nu există evaluări

- Lecture On AbcDocument9 paginiLecture On AbcJames Ryan AlzonaÎncă nu există evaluări

- Activity Based CostingDocument9 paginiActivity Based CostingAmitÎncă nu există evaluări

- Spss Sop4 FCDocument2 paginiSpss Sop4 FCagnesÎncă nu există evaluări

- Spss Sop3 ObcDocument2 paginiSpss Sop3 ObcagnesÎncă nu există evaluări

- SPSS Sop7Document2 paginiSPSS Sop7agnesÎncă nu există evaluări

- 0.50 .79 Accepted Not Significant: at 0.05 Level of SignificanceDocument1 pagină0.50 .79 Accepted Not Significant: at 0.05 Level of SignificanceagnesÎncă nu există evaluări

- Sop5 4Document1 paginăSop5 4agnesÎncă nu există evaluări

- Sop5 3Document1 paginăSop5 3agnesÎncă nu există evaluări

- SOP5Document1 paginăSOP5agnesÎncă nu există evaluări

- Competencies Objectives Procedures Time Fram e Person-In-Charge Key Result IndicatorDocument5 paginiCompetencies Objectives Procedures Time Fram e Person-In-Charge Key Result IndicatoragnesÎncă nu există evaluări

- Sop3 5Document15 paginiSop3 5agnesÎncă nu există evaluări

- Sop5 2Document1 paginăSop5 2agnesÎncă nu există evaluări

- Multiple-Choice QuestionsDocument17 paginiMultiple-Choice QuestionsathenaÎncă nu există evaluări

- Categorized Ba GoDocument3 paginiCategorized Ba GoagnesÎncă nu există evaluări

- TTHHDocument15 paginiTTHHagnesÎncă nu există evaluări

- Budgeting: Dr. Varadraj BapatDocument41 paginiBudgeting: Dr. Varadraj BapatagnesÎncă nu există evaluări

- Chapter 20 - AnswerDocument4 paginiChapter 20 - AnsweragnesÎncă nu există evaluări

- Chapter 11 - AnswerDocument31 paginiChapter 11 - AnsweragnesÎncă nu există evaluări

- Chapter 7 - AnswerDocument17 paginiChapter 7 - AnsweragnesÎncă nu există evaluări

- TuyjDocument51 paginiTuyjagnesÎncă nu există evaluări

- Chapter-5 Overheads Cost Under ABC MethodDocument10 paginiChapter-5 Overheads Cost Under ABC MethodAdi PrajapatiÎncă nu există evaluări

- ABC Blocher SolutionsDocument73 paginiABC Blocher Solutionsmayankgrover8658% (12)

- Chapter 5 SolutionsDocument58 paginiChapter 5 SolutionsJingjing ZhuÎncă nu există evaluări

- Notes Management AccountingDocument23 paginiNotes Management AccountingAbidÎncă nu există evaluări

- Solution Manual12Document66 paginiSolution Manual12Kai Darul Salim80% (5)

- Lectures Notes Strategic Cost Management PDFDocument27 paginiLectures Notes Strategic Cost Management PDFVikasNegiVipulÎncă nu există evaluări

- Warehouse and Inventory Management: Unit IvDocument111 paginiWarehouse and Inventory Management: Unit IvKumar AdityaÎncă nu există evaluări

- Advanced Cost AccountingDocument5 paginiAdvanced Cost AccountingPrathamesh ChawanÎncă nu există evaluări

- ABC Analysis HandoutsDocument11 paginiABC Analysis HandoutsTushar DuaÎncă nu există evaluări

- Ae 313 Prelims ExamDocument7 paginiAe 313 Prelims ExamNicole ViernesÎncă nu există evaluări

- Case 05-68Document10 paginiCase 05-68saad bin sadaqatÎncă nu există evaluări

- Activity Based Costing AssignmentDocument2 paginiActivity Based Costing AssignmentJolina Yheun LobosÎncă nu există evaluări

- BMT6125 - Costing-Methods-And-Techniques - TH - 1.0 - 55 - BMT6125 - 54 AcpDocument2 paginiBMT6125 - Costing-Methods-And-Techniques - TH - 1.0 - 55 - BMT6125 - 54 AcpchrisÎncă nu există evaluări

- Managerial Accounting, 4th Edition Davis, Davis 2020 Test Bank and Instructor Solution ManualDocument12 paginiManagerial Accounting, 4th Edition Davis, Davis 2020 Test Bank and Instructor Solution ManualAdam Kramer0% (1)

- 1 - Traditional ABC and Time-Driven ABCDocument32 pagini1 - Traditional ABC and Time-Driven ABCEdiSukarmantoÎncă nu există evaluări

- Chapter 4 Activity Based Costing MCDocument23 paginiChapter 4 Activity Based Costing MCShaneen AdorableÎncă nu există evaluări

- Chapter 7 Activity Based CostingDocument5 paginiChapter 7 Activity Based CostingCh KingÎncă nu există evaluări

- Benefit and Limitation of Active Based Costing (ABC)Document1 paginăBenefit and Limitation of Active Based Costing (ABC)smmnorÎncă nu există evaluări

- Example - Chapter 5Document2 paginiExample - Chapter 5Khánh Vy Hà VũÎncă nu există evaluări

- The 7 Principles of Supply Chain ManagementDocument10 paginiThe 7 Principles of Supply Chain Managementmela917Încă nu există evaluări

- Answers To 11 - 16 Assignment in ABC PDFDocument3 paginiAnswers To 11 - 16 Assignment in ABC PDFMubarrach MatabalaoÎncă nu există evaluări

- Activity Based CostingDocument10 paginiActivity Based CostingEdi Kristanta PelawiÎncă nu există evaluări

- Problem 7 Job Order Costing Jessica Company Cma CompressDocument27 paginiProblem 7 Job Order Costing Jessica Company Cma CompressKryzzel Anne JonÎncă nu există evaluări

- First Time Login Guide MsDocument6 paginiFirst Time Login Guide MskonosubaÎncă nu există evaluări

- F5 Part I Becker 2017Document246 paginiF5 Part I Becker 2017cabienoÎncă nu există evaluări

- MAS-Chapter 7Document3 paginiMAS-Chapter 7Mae CruzÎncă nu există evaluări

- Test 2Document61 paginiTest 2Tiktak TakÎncă nu există evaluări

- SAPDocument313 paginiSAPG Gopala Krishna Gudladona100% (1)

- Types of CostingDocument14 paginiTypes of CostingAparna Patel BarbieÎncă nu există evaluări

- Ac040 NoteDocument54 paginiAc040 NoteAdam OngÎncă nu există evaluări