Documente Academic

Documente Profesional

Documente Cultură

Archivos 47 A

Încărcat de

toto-gmbhTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Archivos 47 A

Încărcat de

toto-gmbhDrepturi de autor:

Formate disponibile

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

MODEL

EK

ORBINOX SPAIN Pol.Ind. s/n-20270 ANOETA. Tel:+34 943 698030 Fax:+34 943 653066 e-mail:orbinox@orbinox.com

ORBINOX CANADA, ORBINOX USA,

USA, ORBINOX BRAZIL, ORBINOX SPAIN, ORBINOX UK, ORBINOX FRANCE,

ORBINOX GERMANY,

GERMANY, ORBINOX INDIA, ORBINOX CHINA,

CHINA, ORBINOX S.E.A.

www.orbinox.com

MODEL

EK

INDEX

Page

0. - Description ......................................................................

1. - Handling .........................................................................

2. - Installation .......................................................................

3. - Actuators ........................................................................

4. - Maintenance ......................................................

4.1. - Gland packing replacement ................

4.2. - Seal replacement ..........................................

4.3. - Lubrication ......

5. - Storage .........................................................

6. - Parts list & drawing .........................................................

2

2

3

6

6

7

8

9

10

11

0.- DESCRIPTION

The EK model knife gate is a uni-directional wafer valve designed for general industrial service

applications. The design of the body and seat assures non-clogging shut-off with suspended solids.

The EK valve complies with the following European directives:

- DIR 2006/42/EC

2006/42/EC (machines)

- DIR 97/23/EC (PED) Fluid: Group 1 (b), 2 (Cat. I, mod.A)

It may also comply with the directive DIR 94/9/EC (Explosive Atmospheres):

Atmospheres):

The EK valve may comply with the directive regarding equipment and protective systems for their

use in explosive atmospheres. In these cases, the logotype

shall appear on the identification

label of the valve. This label shows the exact classification of the zone where the valve can be

used. The user will be liable for its use in any other zone.

This directive only applies in the following atmospheric conditions:

0,8 bar P 1,2 bar

-20C < T < 60C

Any increase in temperature due to frictional warmth is negligible, since the relative speed of

the moving parts is extremely low.

The risk analysis associated to this directive does not take into account the fluid that goes

through the valve, even when such fluid produces an explosive atmosphere. The user must take

into account the risks that the fluid generates, such as:

Heating of the valve surface.

Generation of electrostatic charges caused by displacement of the fluid.

Shock waves caused by the installation (water hammer), internal crashes generated by the

pellets or the risks due to foreign bodies susceptible of being present in the installation.

1.- HANDLING

The valves are packed according to the appropriate transport standards. If you receive the packing

damaged, please inform the transport company in writing and contact your Orbinox representative.

www.orbinox.com

EDITION 02-2013

EK-2/11

MODEL

EK

When handling an Orbinox valve please pay attention to the following points:

Do NOT attach lifting gear to the valve

valve actuators or gate guards.

guards

They are not designed to bear the weight, and could easily be damaged.

Do NOT lift the valve by the valve bore.

bore

This can cause damage to the seating surfaces and seals.

Check that selected lifting gear is rated to carry the weight of the valve.

The valve can be handled using eyebolts, soft straps or slings.

Eyebolts: make sure the eyebolts have the same thread as the boltholes and they are all well

secured. Ideally when using lifting gear to move an Orbinox valve, it should be supported by

two or more eyebolts screwed into the tapped fixing holes in the valve body.

Soft straps: with the valve in the closed position, the straps should be placed between the

gland area and the bore such that the valve is balanced.

Fig. 1 Handling with eyebolts

Fig. 2 Handling with soft straps

www.orbinox.com

EDITION 02-2013

EK-3/11

MODEL

EK

2.- INSTALLATION

To avoid personal injury or damage to property from the release of process fluid:

-

Those in charge of handling and maintenance of the valve must be qualified and trained in

valve operations.

Use appropriate personal protection equipment (gloves, safety shoes, etc).

Shut off all operating lines to the valve and place a warning sign.

Isolate the valve completely from the process.

Release process pressure.

Drain the process fluid from the valve.

According to EN 1346313463-1 (15), during installation and maintenance operations, use hand

tools (non electric) with Working Allowance.

Before installation, inspect the valve body and components for any damage that may have

occurred during shipping or storage. Make sure the internal cavities within the valve body are

clean. Inspect the pipeline and mating flanges, making sure the pipe is free of foreign material and

that the flanges are clean.

The valve is unidirectional. It should be installed with pressure exerted against the seat. The words

SEAT SIDE are marked on the valve body to indicate the position of the valve seat. Installation

and the correct orientation with respect to the direction of the flow is the responsibility of the user.

It should be noted that the direction of flow and differential pressure, do not always coincide.

www.orbinox.com

EDITION 02-2013

EK-4/11

EK

MODEL

Special care should be taken to maintain the correct distance between the flanges and to ensure

that they are parallel to the valve body. Incorrect alignment of the valve can cause

deformations, which can lead to difficulties in operation.

The following table gives the maximum torque values for the valve fixing bolts. Also

shown is the maximum depth (T) allowed for the tapped blind boltholes drilled into the

valve body.

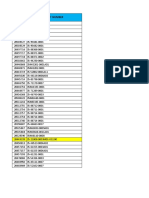

DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

900

1000

1200

T

(mm)

10

10

10

10

10

14

14

18

18

22

24

24

24

24

20

20

20

20

30

Kg.m

11

11

15

15

19

19

23

23

28

28

34

34

The valve can be mounted in any position with regard to the pipe. However, it is advisable to place

it vertically in horizontal pipeline (A) if the installation allows it. (Please consult the technical

department at Orbinox).

With larger diameters (> 300 mm), heavy actuators (pneumatic, electric, etc.), or with the valve

installed horizontally (B) or at an angle (C) on a horizontal pipeline, the installation will require the

construction of suitable supports. (See the following diagram and consult the technical department

at Orbinox).

A

C

C*

C*

A*

* For these positions please consult Orbinox.

In vertical pipelines, the construction of suitable supports is always required (for further information

please consult the technical department at Orbinox).

Once the valve is installed, test that the flanges have been fastened correctly and that all electrical

and/or pneumatic connections have been properly made.

.

www.orbinox.com

EDITION 02-2013

EK-5/11

MODEL

EK

These instructions must be observed when installing an Orbinox knife gate valve in an ATEX zone:

Make sure the valve is ATEX marked according to the requested zone and it includes all antistatic devices.

Check continuity between the body of the valve and the pipe (test in accordance with EN

12266-2 Standard, annex B, points B.2.2.2. and B.2.3.1).

This check must be done every time the valve has been removed from the line, serviced, and

put back to the line.

The operation of automated valves is limited only with fitted gate covers.

First, operate the valve with no flow in the pipeline. Then test operation and valve seal with flow. It

should be noted that the packing material might settle in shipping/storage, which can cause minor

leakage. This can be remedied by tightening the gland follower (6) during installation. The nuts

shall be tightened gradually and crosswise until the leakage stops (see the next figure). Check that

there is no metal contact between the gland follower (6) and the gate (2).

If the glandfollower nuts are pulled to hard, the force needed to operate the valve will increase, the

valve function will be affected and the box packing lifetime will be shortened.

The table below shows the maximum torque value for tightening the glandfollower nuts.

DN

50 - 100

125 - 200

250 - 1200

Torque

Torque (N.m)

20

30

35

Once performance has been tested, the valve can be put into operation.

3.- ACTUATORS

3.1. - Handwheel

To open the valve, turn the handwheel (12) anticlockwise. To close, turn the handwheel

clockwise.

3.2. - Lever

To operate the valve with this device, first loosen the locking clamp located on the top of the

yoke (10). Then either open or close the valve by moving the lever in the desired direction.

Finally, fix the position of the lever with the locking clamp.

www.orbinox.com

EDITION 02-2013

EK-6/11

MODEL

EK

3.3. - Pneumatic

Valves are usually supplied with a double acting pneumatic actuator although, upon request,

we can supply single-acting actuators. In either case the feed pressure can vary between 3,5

and 10 Kg/cm2.However, the size of the actuator for each valve has been designed for a

feed pressure of 6 Kg/cm2.

It is essential for a good maintenance of the cylinder that air should be well dried, filtered

and lubricated.

It is recommended to actuate the cylinder 3-4 times before the start up, once it is installed in

the pipeline.

3.4. - Electric actuator

Depending on the type or make of the electric actuator, specific instructions (i.e. a

manufacturers manual) will be supplied.

Allowed actuators for ATEX zones: Hand wheel, Chain Wheel, Bevel Gear, Lever, Pneumatic

Actuator (double acting ONLY)

ONLY and Electric Motor

Make sure these actuators are ATEX marked according to the requested zone.

Maximum travel speed of the gate must equal or below 0,05 m/s

4.- MAINTENANCE

The valve must not undergo any modifications without a previous agreement with ORBINOX.

ORBINOX shall not be liable for any damages that may arise due to the use of non original parts or

components

To avoid personal injury or damage to property from the release of process fluid:

- Those in charge of handling and maintenance of the valve must be qualified and trained in

valve operations.

- Use appropriate personal protection equipment (gloves, safety shoes, etc).

- Shut off all operating lines to the valve and place a warning sign.

- Isolate the valve completely from the process.

- Release process pressure.

- Drain the process fluid from the valve.

- According to EN 1346313463-1 (15), during installation and maintenance operations, use hand

tools (non electric) with Working Allowance.

The only maintenance required is to change the gland packing (6) or the seal (3) if the valve is a

resilient seated type.

The life of these elements will depend on the working conditions of the valve such as: pressure,

temperature, abrasion, chemical action, number of operations, etc.

4.1. - Replacement of the gland packing (6):

1) Depressurise the circuit and place the valve in close position.

2) Remove the gate guards (for automatically actuated valves only).

3) - Non rising stem.Photo 1: Release the stem nut (8) from the gate (2).

- Rising stem valves.Photo 2: Release the spindle or stem (9) from the gate (2).

www.orbinox.com

EDITION 02-2013

EK-7/11

MODEL

EK

Photo 1

4)

5)

6)

7)

8)

9)

10)

11)

12)

Photo 2

Loosen the screws of the yoke (10) and remove it (without loosing the actuator).

Loosen the nuts of the gland follower (7) and remove it. (Photo 3).

Remove the old packing rings (6) and clean the stuffing box.

Insert the new packing rings (6), making sure that the ring joints alternate (the first on one

side of the gate, the next on the other and so on). (Photo 4).

Once the necessary packing rings (6) have been inserted, proceed with a steady initial

tightening of the gland follower (7). (Photo 3).

Place the yoke (10) (with the actuator) and screw it.

Fix the stem nut (8) to the gate. (Non rising stem. Photo 1) or fix the stem (9) to the gate (2)

(Rising stem valves. Photo 2).

Remount the gate guards (for automatically actuated valves only).

Carry out some operations with a loaded circuit and then re-tighten the gland follower (7)

to prevent leakage.

Photo 3

Photo 4

4.2. - Replacement of the seal (3) (only applicable to resilient seated valves):

1) Remove the valve from the pipeline.

2) Remove the gate guards (for automatically actuated valves only).

3) Release the stem nut (8) from the gate (2). (Non rising stem.Photo 1) or release the spindle

or stem (9) from the gate (2). (Rising stem valves.Photo 2).

4) Loosen the screws of the yoke (10) and remove it (without loosing the actuator).

5) Loosen the nuts of the gland follower (7) and remove it.(Photo 3)

6) Remove the old packing (6) and the gate (2) and clean the stuffing box.

7) Remove the seal retainer ring (5) which supports the seal (3).

8) Remove the worn seal (3) and clean the seal housing.

9) Insert the new seal (3) in the retainer ring (5).

.

www.orbinox.com

EDITION 02-2013

EK-8/11

MODEL

EK

If the valve has PTFE seal (3): first, place an O-ring (4) in the retainer ring (5) and later

place the PTFE seal (3). (see the following detail).

EPDM / NITRILE

5

PTFE

5

10) Insert the seal retainer ring (5) and the seal (3) altogether by hammering gently around the

edge.

11) Remount the gate (2).

12) Once the necessary packing rings (6) have been inserted, proceed with a steady initial

tightening of the gland follower (7). (Photo 3) following the steps of point 4.1.

4.3. - Lubrication:

Lubricate the stem every 30 days with a calcium-based grease with the following

characteristics: highly water resistant, low ash content, and excellent adherence.

Special requirements for ATEX valves:

valves

- The maintenance personnel must be made fully aware of the risks of explosion, and it is advisable

that they receive specific training regarding ATEX.

- Periodicity of check and evaluation of graphite packing status and valve electrical conductivity

must be determined by end user according to valve working conditions. In any case, once the

valve is put into operation, the packing area must be revised after the valve has been stroked 100

times or after 3 months of operation, whatever happens first. After this preliminary check, new

checking periods must be determined by end user based on the results of this first check.

- Clean the valve periodically to prevent dust accumulation. Do not sweep or dump the dust. Always

use a vacuum cleaner system

- Dead en service is not allowed.

- Do not apply any new coating to the valve. Should it require new coating, please contact our

closest representative.

- Allowed seals: EPDM, VITON, NITRILE, GRAPHITE and METAL (no seal)

- Allowed packing: ST and GRAPHITE packing

- Any other materials but those above are not allowed to be used in ATEX zones.

- In order to keep the ATEX approval, always use original spares from Orbinox.

Washer

DIN 6798A (This washer guarantees continuity among carbon steel parts, coated

in epoxy, yoke and body and stainless steel guards for coating thicknesses up to

200 microns)

ST and GR packing

o ORBINOX ST: Synthetic packing impregnated with PTFE

o GR: Graphite packing

MONTERO Ecograflex 780R

.

www.orbinox.com

EDITION 02-2013

EK-9/11

MODEL

EK

- After any maintenance of ATEX valves, it is mandatory to check that the valve is earthed through

the pipe, and there is continuity among the different valve components, such as the body, the gate,

the supports, and guards (test in accordance with EN 12266-2 Standard, annex B, points B.2.2.2.

and B.2.3.1).

MAXIMUM FLUID TEMPERATURES

Atmosphere

Gas/air, steam/air, and mist/air

Dust/air

80% of minimum fluid ignition

temperature, minus 10K

2/3 of minimum dust cloud ignition

temperature minus 85K

Note: these maximum fluid temperatures apply to all categories. The differences between

categories are the consideration of foreseeable malfunction cases and rare malfunctions cases

MAXIMUM SEAL AND PACKING TEMPERATURES

Max Temperature

(C)

C)

Max Temperature

(C)

C)

SEAL

EPDM

VITON

NITRILE

GRAPHITE

120

200

120

600

PACKING

ST

GRAPHITE

240

600

Note: Most of the times seals maximum temperature capacity is the key limitation factor when

evaluating valve maximum working temperatures. In ATEX zones these temperatures must be

compared to those above related to limitation of fluids temperatures.

Always consider the most restrictive as maximum valve working temperature.

5.- STORAGE

For long storage periods keep the valves indoors in a safe and dry place and protect it from any

impact and or vibrations.

Storing temperatures: -10C/14F to +40C/104F

Valves must be stored in either full open or full closed position.

For any component installed in the valves, electric motors, solenoid valves, etc, please refer to their

own instructions manuals

www.orbinox.com

EDITION 02-2013

EK-10/11

MODEL

EK

6.- PARTS LIST & DRAWINGS

1. - BODY

2. - GATE

3. - SEAL

4. - O-RING (only if the seal 3 is PTFE)

5. - K RING

6. - PACKING

7. - GLAND FOLLOWER

8. - STEM NUT

9. - STEM

10. - YOKE

11. - BUSHING

12. - HANDWHEEL

13. - SPRING PIN

14. - KNOB

www.orbinox.com

EDITION 02-2013

EK-11/11

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- 2011 Hyundai Service Electrical PartsDocument82 pagini2011 Hyundai Service Electrical PartsJose QuirozÎncă nu există evaluări

- Piston Engine FundamentalDocument62 paginiPiston Engine Fundamentalkp subedi100% (1)

- Thickener Erection ProcedureDocument4 paginiThickener Erection Procedurehari prasad100% (1)

- Lube Oil System in Turbine - Instrumentation BasicsDocument5 paginiLube Oil System in Turbine - Instrumentation BasicsWren DsilvaÎncă nu există evaluări

- High Voltage Cable PDFDocument2 paginiHigh Voltage Cable PDFNachoPérezCarrilloÎncă nu există evaluări

- Bluetooth Smart Car ManualDocument50 paginiBluetooth Smart Car ManualDiacono10Încă nu există evaluări

- IRB 6650S Product Manual 3HAC020993 001 - Revg - en PDFDocument477 paginiIRB 6650S Product Manual 3HAC020993 001 - Revg - en PDFMauricio Gonzaga Jr.Încă nu există evaluări

- 20 - RT-flex - Mechanical Features PDFDocument75 pagini20 - RT-flex - Mechanical Features PDFИгорь БакановÎncă nu există evaluări

- Powerful Solutions for Chemical Engineering ProjectsDocument19 paginiPowerful Solutions for Chemical Engineering Projectstoto-gmbhÎncă nu există evaluări

- DIY Modular Hydroponic Tower SystemDocument14 paginiDIY Modular Hydroponic Tower SystemconsultoriaALFAÎncă nu există evaluări

- Compact Pressure Switch, Flameproof Enclosure Ex D 02/2016: ApplicationsDocument2 paginiCompact Pressure Switch, Flameproof Enclosure Ex D 02/2016: Applicationstoto-gmbhÎncă nu există evaluări

- SC12 Data Sheet: SC12-20-FR-SR-MD-06-V-X3Document1 paginăSC12 Data Sheet: SC12-20-FR-SR-MD-06-V-X3toto-gmbhÎncă nu există evaluări

- Bartec GlandDocument2 paginiBartec GlandjagateesanÎncă nu există evaluări

- DS PV3330 en Co 1718Document5 paginiDS PV3330 en Co 1718toto-gmbhÎncă nu există evaluări

- PCV Data Sheet: PCV-06F-06M-13-023-VDocument1 paginăPCV Data Sheet: PCV-06F-06M-13-023-Vtoto-gmbhÎncă nu există evaluări

- Schematic: L15 0 Conf General Installation 00Document1 paginăSchematic: L15 0 Conf General Installation 00toto-gmbhÎncă nu există evaluări

- SC12 Data Sheet: SC12-20-FR-SR-MD-06-V-X3Document1 paginăSC12 Data Sheet: SC12-20-FR-SR-MD-06-V-X3toto-gmbhÎncă nu există evaluări

- DS PV3330 en Co 1718Document5 paginiDS PV3330 en Co 1718toto-gmbhÎncă nu există evaluări

- DS PV3330 en Co 1718Document5 paginiDS PV3330 en Co 1718toto-gmbhÎncă nu există evaluări

- 0-In0640 0Document1 pagină0-In0640 0toto-gmbhÎncă nu există evaluări

- Schematic: SPR-08-06-P1-52-XX-P1-X 0 Conf General Installation 00Document1 paginăSchematic: SPR-08-06-P1-52-XX-P1-X 0 Conf General Installation 00toto-gmbhÎncă nu există evaluări

- BXS 04 04 E3 52 XX 00 V 77a 24D 30 K85Document1 paginăBXS 04 04 E3 52 XX 00 V 77a 24D 30 K85toto-gmbhÎncă nu există evaluări

- PCV 06F 06M 13 023 V PDFDocument1 paginăPCV 06F 06M 13 023 V PDFtoto-gmbhÎncă nu există evaluări

- Schematic: Mainstage Valve SolenoidDocument1 paginăSchematic: Mainstage Valve Solenoidtoto-gmbhÎncă nu există evaluări

- SPR-08 Data Sheet: SPR-08-06-P1-52-XX-P1-VDocument1 paginăSPR-08 Data Sheet: SPR-08-06-P1-52-XX-P1-Vtoto-gmbhÎncă nu există evaluări

- SPR-08 Data Sheet: SPR-08-06-P1-52-XX-P1-VDocument1 paginăSPR-08 Data Sheet: SPR-08-06-P1-52-XX-P1-Vtoto-gmbhÎncă nu există evaluări

- Catalog 5 PDFDocument13 paginiCatalog 5 PDFtoto-gmbhÎncă nu există evaluări

- SPR-08 Data Sheet: SPR-08-04-M6-52-XX-05-VDocument1 paginăSPR-08 Data Sheet: SPR-08-04-M6-52-XX-05-Vtoto-gmbhÎncă nu există evaluări

- Cat KGV 1 13Document16 paginiCat KGV 1 13alexen2539Încă nu există evaluări

- GVO SeriesDocument20 paginiGVO Seriestoto-gmbhÎncă nu există evaluări

- Cat Teca9000Document28 paginiCat Teca9000toto-gmbhÎncă nu există evaluări

- Catalog 5 PDFDocument13 paginiCatalog 5 PDFtoto-gmbhÎncă nu există evaluări

- Trueline Reference Catalog KGVDocument20 paginiTrueline Reference Catalog KGVtoto-gmbhÎncă nu există evaluări

- Trueline Knife-Gate Valve CatalogueDocument12 paginiTrueline Knife-Gate Valve Cataloguetoto-gmbhÎncă nu există evaluări

- Knife Gate Cat - 2011 - 20130201082925 PDFDocument20 paginiKnife Gate Cat - 2011 - 20130201082925 PDFtoto-gmbhÎncă nu există evaluări

- Ar Chivos 1457 ADocument10 paginiAr Chivos 1457 Atoto-gmbhÎncă nu există evaluări

- With Bonnet: ModelDocument10 paginiWith Bonnet: Modeltoto-gmbhÎncă nu există evaluări

- Archivos 47 ADocument11 paginiArchivos 47 Atoto-gmbhÎncă nu există evaluări

- Archivos 794 ADocument11 paginiArchivos 794 Atoto-gmbhÎncă nu există evaluări

- Electric Motors, USADocument15 paginiElectric Motors, USAVanessa MendozaÎncă nu există evaluări

- IEC Standards for Power CablesDocument1 paginăIEC Standards for Power CablesLucian2001Încă nu există evaluări

- SU60 Data SheetDocument1 paginăSU60 Data SheetSamuel OdeiaddoÎncă nu există evaluări

- DIFLOK 4 BDocument1 paginăDIFLOK 4 BdeepakmudgilÎncă nu există evaluări

- Acme A349 Service ManualDocument34 paginiAcme A349 Service ManualCristian DavidÎncă nu există evaluări

- Sfu RatingsDocument6 paginiSfu RatingsShrikant KajaleÎncă nu există evaluări

- Ca1000 CN235Document3 paginiCa1000 CN235indra pratamaÎncă nu există evaluări

- 4 Pro EC44 Full Manual ENDocument274 pagini4 Pro EC44 Full Manual ENrogermantilla08Încă nu există evaluări

- Flyer - Z-Drive Assist Takaful ENG BM 25.2.21Document4 paginiFlyer - Z-Drive Assist Takaful ENG BM 25.2.21UstazFaizalAriffinOriginalÎncă nu există evaluări

- Srm-Ist: Industrial Training Bike ZoneDocument20 paginiSrm-Ist: Industrial Training Bike ZoneArsh ChoudharyÎncă nu există evaluări

- OBSM - Mandatory Annexes - Nov 2015Document41 paginiOBSM - Mandatory Annexes - Nov 2015Bibo KhoÎncă nu există evaluări

- IR 2945 PartsListDocument2 paginiIR 2945 PartsListezeizabarrenaÎncă nu există evaluări

- Quick Start Guide FBM 2180 Installation Instruction Rosemount en 80734Document16 paginiQuick Start Guide FBM 2180 Installation Instruction Rosemount en 80734gobilgobil100% (1)

- Jonnesway Part Number CatalogDocument94 paginiJonnesway Part Number CatalogMikhaylovMikkelsenÎncă nu există evaluări

- GMI Student ReportDocument3 paginiGMI Student ReportdmufqiÎncă nu există evaluări

- Armoire Midea MfgaDocument1 paginăArmoire Midea MfgalacothÎncă nu există evaluări

- Baumfolder FlexifoldDocument2 paginiBaumfolder FlexifoldKBR Graphics CanadaÎncă nu există evaluări

- Avionics Full NotesDocument126 paginiAvionics Full Notesnandhakumar sÎncă nu există evaluări

- Modelling of SOI-LDMOS TransistorDocument13 paginiModelling of SOI-LDMOS TransistorchaitudscÎncă nu există evaluări

- Mechatronics Project FinalDocument21 paginiMechatronics Project FinalAklesh GuptaÎncă nu există evaluări

- 2KJ3203Document1 pagină2KJ3203Banupriya BalasubramanianÎncă nu există evaluări