Documente Academic

Documente Profesional

Documente Cultură

Process Flow Diagram

Încărcat de

Robie RoqueDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Process Flow Diagram

Încărcat de

Robie RoqueDrepturi de autor:

Formate disponibile

DOC NO

REVISION

DATE

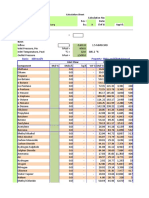

MASS BALANCE DIAGRAM OF RSFFPP PROJECT

BACKPASS

Width : 6.75m

Depth : 5.5m

Height : 18m

Backpass wall

: Fin welded

Tube material

: SA-213 T12

Tube size&thickness : 1.75"0.3"/ 1.5"x0.2"

Tube spacing

: 4.5"

FURANCE

Width

: 7.68m

Depth

: 6.6m

Height

: 34.2m

Volume

: 1,657m3

Furnace wall : Fin weld

Tube material : SA-210C

Tube size&thickness : 2.5"0.2"

Tube spacing : 3.5"

SOOTBLOWER

LOCATION

TYPE

Q'TY

Backpass

Backpass

Retract

1/2

12

8

CYCLONE

Quantity : 1/unit

Diameter(inside refractory) : 7m

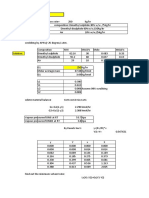

Steam turbine

Type : Single casing ,multi-stage,reaction blade,

non-reheat,extration-condensing

Live steam condition : 200T/H126barA538

Rated speed

: 3,600rpm

VHPS : 12.9 MPa(g)*541*200T/H

VHPS : 12.5 MPa(g)*538*200T/H

SOOTBLOWER

(35% BMCR)

(5.6TPH@MAX. LOAD)

TO FUEL

FEEDER

(A)

PA FAN

SA FAN

FLOW:150T/H FLOW:71T/H

PRESS:22.7KPa PRESS:19.1KPa

FA BLOWER

FLOW:10T/H

PRESS:51.6KPa

BOTTOM

ASH SILO

260M3*1ST

DeSOx &

BAG FILTER

SYSTEM

WATER

(30T/HR)

INTERMITTEN

Ca(OH)2

SILO

50M3*1ST

(67.2TPD)

(0KG/HR)

(151.2TPD)

(0 TPH)

TG EXT.4

TG EXT.3

Ca(OH)2

SLURRY

MIXING

TG EXT.5

[4]

DEAREATOR

(6)

[3]

[6]

NO.2 LPH

[1-1]

DFP

TG EXT.1

TG EXT.2

FROM

FROM

MPS HEADER

Mpa(G)

HP STEAM HEADER

120

13.

D

E

NO DES. NO DES.

1.3

Mpa(G)

[L]

5.4

(1)

CONDENSOR

PUMP

[M]

TO HP STEAM

[N]

[N]

[R]

[P]

406 425 VHPS CONVERT HPS

35

1.4

1.6

245 270 VHPS CONVERT MPS

14

-0.027

0.1

91

11.

12

0.1

0.3

126 160 TG EXT. 4

15

15

0.6

0.9

210 260 TG EXT. 3

378 386

0.0

0.5

35

60 DEMI. TANK OUTLET

38.

48

3.3

4.5

383 425 TG EXT. 2

1-1

189 193

0.0

0.5

35

60

#1 DFP INLET

50

129

4.9

6.2

421 475 TG EXT. 1

1-2

189 193

0.0

0.5

35

60

#2 DFP INLET

50.

120

4.7

5.4

406 425 TO HPS HEADER

176 193

1.4

2.1

39.

60

DFP OUTLET

27.

43

1.4

1.6

245 270 TG MPS HEADER

176 193

1.2

2.1

85

140 NO.1 LPH OUTLET

96.

96. #1 CONDEN. WATER

3.6

17

6.7

8.6

13.

21.

1.7

370 410 TO HPH HEATING

176 193

1.1

2.1

119 140 NO.2 LPH OUTLET

96.

96. TO DEMI. TANK

0.6

1.5

6.7

101 231

4.6

5.4

406 425 TO HPS PROCESS

206 230

0.5

164 200 BFP INLET

96.

55

62

1.3

1.6

245 270 TO MPS PROCESS

202 220

16.

23.

167 200 BFP OUTLET

50

200 TO POLISHER

6

10

0.4

1.2

1.3

1.6

245 270

TO TG PACKING STEAM

202 220

16.

23.

205 230 HPH OUTLET

50

200 POLISHER OUTLET

6.8

P

R

0.6

1.6

245 270

TO DEAREATOR HEATING

197 220

14.

15.16

205 230 ECO INLET

13.

21.

FROM HPH TO DEAERATOR

--

1.3

1.6

245 270

TO BAG FILTER HEATING

197 220

14

15.16

288 343 ECO OUTLET

50

50

FROM EXISTING CONDENSATE WATER

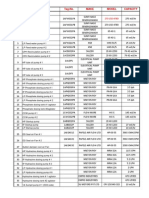

WATER TABLE

DESCRIPTION

TO MP TO UNIT#1 TO UNIT#2 TO UNIT#1 TO UNIT#2

DEAREATOR DEAREATOR

TG

STEAM TG PACKING

PROCESS STEAM

HEATING

HEATING

PACKING

STEAM

STEAM

DESCRIPTION

TO CONDENSATE BYPASS TANK

210 M3/HR

SILICA : 21ppm

RO UNIT

200M3/HR

*4ST

-- M3/HR

-- M3/HR

WASTE WATER

TREATMENT

SYSTEM

160 M3/HR * 1ST

FROM UNIT#2

BOILER BLOWDOWN

SPRAY WATER

T/H

ITEM

{ ? } MC MA

300 M3/HR

MUTI MEDIA

/ACTIVED

CARBON

FILTER

270M3/HR*(3+1)S

PRETREATMENT

425M3/HR*2ST

320 M3/HR

RO REJECT

FOR EFFLUENCE

160 M3/HR

EFFLUENCE WATER

CLASS : SC

RAW MAKEUP WATER

REQ'D : 860 M3/HR

RAW

WATER

TANK

5,250 M3 *

TO UNIT#1 TO UNIT#2

BAG FILTER BAG FILTER

HEATING

HEATING

CONDENSATE WATER TABLE

T/H

ITEM

( ? ) MC MA

[R]

[P]

5.4

T/H

Mpa(G)

ITEM

[ ? ] MC DES. NO DES. NO DES.

DEMI. WATER

300 M3/HR TREATMENT SYSTEM

150M3/HR *(2+1)ST

FROM UNIT#1

BOILER BLOWDOWN

406 425

4.7

140 TG EXT. 5

(3)

CONDENSATE

POLISHER

BYPASS TANK

400M3*1

(4)

FROM COOLING

TOWER BLOWDOWN

245 270

MP STEAM HEADER

NO DES. NO DES.

4.6

1.6

[1]

DEMI.

WATER

TANK

3,500 M3 *2

[1-2]

TO UNIT#2 DFP

NO DES. NO DES.

HPS HEADER

GLAND

STEAM

13 T/H

[5]

STEAM TABLE

POLISHER

SYSTEM

100M3/HR*

2 ST

(2)

NO.1 LPH

TO SAMPLING

RACK COOLING

DESCRIPTION

(2)

DENI. TANK

50T/H

FROM PBR

CONDENSATED WATER

(7)

[2]

{A}

EXT. WATER

FROM UNIT #2 ID FAN

(3)

FROM #2 CONDENSOR

(5)

STORAGE

TANK

COOLING WATER

TO UNIT #2

CONDENOR &

AUX.

EQUIPMENTS

COOLING WATER

TO UNIT #1 AUX.

EQUIPMENTS

32.5

FROM MPS HEADER

Mpa(G)

769 M3/HR

[P]

TG EXT.2

T/H

ITEM

[ ? ] MC MA

ID FAN

FLOW:265T/H

DP:10.3KPa

Ca(OH)2

SLURRY

STORAGE

(2000KG/HR)

(0 TPH)

{6}

FLY

ASH SILO

630M3*1ST

(0KG/HR)

(@100% PETCOKE)

FLY ASH

Ca(OH)2

SLURRY

Ca(OH)2

(@100% COAL)

{5}

Gas Flow : 677,440kg/hr

Excess air : 20% for COAL

25% for PETCOKE

NOx <254mg/NM3

SOx <241mg/NM3

TSP

< 50mg/NM3

CO

<500mg/NM3

(6 T/HR)

INTERMITTEN

BFP

4590 M3/HR

CONDENS

Emission@8%O2

(B)

(----KG/HR)

HPH

COOLING TOWER

4000M3/HR*(3+1)CELLS

NO.1 LPH

NO.2 LPH

DEAERATOR

[K]

{4}

(64.8TPD)

60TON FOR

FIRST FILLING

[C]

COOLING TOWER

MAKEUP WATER

(C)

(24TPD)

SAND

[D]

{C}

SOOTBLOWER

BOTTOM ASH

(28.8TPD)

NOTE :

[E]

[J]

HPH

(252TPD)

[7]

TURBULAR GAS AIR HEATER

(408TPD)

LIMESTONE

SILO

640M3*1ST

[F]

[H]

(B1)

(0TPD)

LIMESTONE

SAND SILO

48M3*1ST

HP PROCESS

STEAM HEADER

MP PROCESS

STEAM HEADER

(0TPD)

FUEL

FEEDER

[G]

{B}

(720TPD)

PETCOKEL

[A]

[B]

STACK

CRUSHER &

CONVEYOR

200TPH*(1+

(A1)

COAL

: Total enclosure water

air cooled

Power factor

: 0.85 lagging

Frequency

: 60Hz

Rated capacity : 35,000KW/41,177KVA

Terminal voltage : 13800V

TURBINE

{3}

TOTAL FUEL INPUT

: 140106 KCAL/HR

Type

SILICA <130ppm

FUEL DAILY

SILO

425M3*2ST

{D}

-- M3/HR

TO DESUPERHEATER

DIESEL OIL

TANK

250M3*1ST

FURANCE

[8]

ECONOMIZER

{2}

CYCLONE

{E}

SILICA <1ppm

TO UNIT#2

{1}

BACKPASS

[9]

Generator and auxiliaries

GENERATOR

177 M3/HR

OVERALL BOILER EFFICIENCY : 90%

HEATING SURFACE

Furnace EPRS

: 899m 2

Superheater(Backpass) : 2,288m 2

Economizer

: 3,032m 2

Superheater panel

: 284m 2

STEAN DRUM

Inside diameter

: 66"

Material

: SA-299 or SA-516 Gr.70

Construction type : Fusion welded

: BR-MBD-001

: ----- C ----: Apr.13, 2011

Mpa(G)

ITEM

(?)

FLOW

PRESSURE

TEMP

T/H

Kpa(G)

FURNACE OUTLET

150

22.7

50

P.A FAN OUTLET

840/856

CYCLONE OUTLET

A1

150

--

227

GAS HEATER-PA SIDE

-2.5

278/276

ECO OUTLET

71

19.1

50

S.A FAN OUTLET

257/260

-3.3

140/128

GAH OUTLET

B1

71

--

227

GAS HEATER-SA SIDE

257/265

-5.9

78

DeSOx & BAG FILTER SYS.

10

51.6

99

F.A BLOWER OUTLET

257/265

4.4

78

ID. FAN OUTLET

FLOW

PRESSURE

T/H

Kpa(G)

164 200 BFP EXTRACTION

257/260

840/856

8.6

164 200 FOR TG EXT.1 TO HPS

257/260

-2

6.7

8.6

164 200 FOR TG EXT.2 TP MPS

257/260

6.7

8.6

164 200 FOR SCV TO HPS

6.7

8.6

164 200 FOR SCV TO MPS

NO DES. NO DES.

AIR TABLE

FLUE GAS TABLE (COAL/PETCOKE)

ITEM

{?}

DESCRIPTION

TEMP

DESCRIPTION

DESCRIPTION

NOTE :

1. THE DATA @ MCR IS BASED ON

GUARANTY CASE ( A5-1-1 ) IN

TECHINCAL PROPOSAL.

2. A5-1-1 CONDITION :

EXTRACTION STEAM TO PROCESS:

2.1 - 50TPH@47.5barA & 406C

2.2 - 27.5TPH@14.5barA & 245C

POWER GENERATION:

2.3 - 35 MWe

S-ar putea să vă placă și

- Calculation of Heat and Mass BalanceDocument16 paginiCalculation of Heat and Mass BalanceHEMANTÎncă nu există evaluări

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 paginiDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraÎncă nu există evaluări

- PSV Sizing Tool API Based Calc Sheets PDFDocument11 paginiPSV Sizing Tool API Based Calc Sheets PDFLucas Farias0% (1)

- Utility, Instrument Air, Nitrogen Demand Calculation for Alur Siwah CPPDocument4 paginiUtility, Instrument Air, Nitrogen Demand Calculation for Alur Siwah CPPParthi DatchinamoorthyÎncă nu există evaluări

- Calculate Vent Sizing for Storage TanksDocument5 paginiCalculate Vent Sizing for Storage TanksSteve WanÎncă nu există evaluări

- Spreadsheet Heat Loss from a PipeDocument1 paginăSpreadsheet Heat Loss from a PipeJogender DhayalÎncă nu există evaluări

- Steam Boiler Spec.Document17 paginiSteam Boiler Spec.bandithaguru6338100% (1)

- Acids and Bases NotesDocument17 paginiAcids and Bases NotesNap DoÎncă nu există evaluări

- 100 People Who Changed History and The WorldDocument400 pagini100 People Who Changed History and The WorldManjunath.RÎncă nu există evaluări

- CSEC-Chemistry-p2 May-June 2012 PDFDocument20 paginiCSEC-Chemistry-p2 May-June 2012 PDFdela250% (4)

- XSize Pump CALCDocument7 paginiXSize Pump CALCsegunoyesÎncă nu există evaluări

- Gas Pressure Drop Calculation Using SCFM: Pipe ValvesDocument3 paginiGas Pressure Drop Calculation Using SCFM: Pipe ValvesDavid Muñoz CastroÎncă nu există evaluări

- Oracle Coherence Admin GuideDocument156 paginiOracle Coherence Admin Guidegisharoy100% (1)

- HP Dosing - AgecDocument12 paginiHP Dosing - AgecShameer MajeedÎncă nu există evaluări

- API 12j SizingDocument1 paginăAPI 12j SizingAdewunmi OlufemiÎncă nu există evaluări

- Pipes. Maxi 1Document1 paginăPipes. Maxi 1Nasrul AdliÎncă nu există evaluări

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 paginăCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaÎncă nu există evaluări

- Spec ReferenceDocument40 paginiSpec ReferencesohaibÎncă nu există evaluări

- Network of Global Corporate Control. Swiss Federal Institute of Technology in ZurichDocument36 paginiNetwork of Global Corporate Control. Swiss Federal Institute of Technology in Zurichvirtualminded100% (2)

- Optimize CO2 Removal from Natural Gas StreamDocument12 paginiOptimize CO2 Removal from Natural Gas StreamMuhammad Sheraz GorayaÎncă nu există evaluări

- Heat Loss Insulated PipeDocument3 paginiHeat Loss Insulated PipeKatie BensonÎncă nu există evaluări

- QAP - LT Panel PDFDocument8 paginiQAP - LT Panel PDFAkshay Ajay100% (2)

- TG Temperature GaugeDocument2 paginiTG Temperature GaugeAr RahmanÎncă nu există evaluări

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 paginiControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986Încă nu există evaluări

- Calculation of reactor parameters for steam reforming of natural gasDocument2 paginiCalculation of reactor parameters for steam reforming of natural gasMeidinaSekarNadistiÎncă nu există evaluări

- Plate Heat ExchangersDocument4 paginiPlate Heat Exchangersamini_mohiÎncă nu există evaluări

- Nitric Acid Plant DetailsDocument21 paginiNitric Acid Plant DetailsBon BonÎncă nu există evaluări

- PFD Dme PlantDocument1 paginăPFD Dme PlantSyamsul Rizal Abd ShukorÎncă nu există evaluări

- Datasheet For Pressure Gauge - Process DataDocument8 paginiDatasheet For Pressure Gauge - Process DataLai HuynhÎncă nu există evaluări

- GBE Version 3: API: New API SpecificationDocument44 paginiGBE Version 3: API: New API SpecificationAdi BauÎncă nu există evaluări

- HP Separator Performance AnalysisDocument5 paginiHP Separator Performance Analysisfirman adiyantoÎncă nu există evaluări

- Tank Pressure During Pump OutDocument1 paginăTank Pressure During Pump OutRexx MexxÎncă nu există evaluări

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pagini7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPÎncă nu există evaluări

- Debating Deponency: Its Past, Present, and Future in New Testament Greek StudiesDocument32 paginiDebating Deponency: Its Past, Present, and Future in New Testament Greek StudiesSeth BrownÎncă nu există evaluări

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 paginiEIND 3184 15 Liquid Flash Vessel SizingzamijakaÎncă nu există evaluări

- Plant Cost EstimateDocument29 paginiPlant Cost EstimateKevin J. MillsÎncă nu există evaluări

- Heat Exchanger Calculation Version 2Document2 paginiHeat Exchanger Calculation Version 2huangjlÎncă nu există evaluări

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 paginiProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381Încă nu există evaluări

- Tank Vent Calculation SpreadsheetDocument3 paginiTank Vent Calculation SpreadsheetJack SonÎncă nu există evaluări

- Line Sizing Design Basis - General Specification PDFDocument11 paginiLine Sizing Design Basis - General Specification PDFSaiKumarÎncă nu există evaluări

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 paginiGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Amec SpecDocument32 paginiAmec Specshinojbaby4148Încă nu există evaluări

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 paginăCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiÎncă nu există evaluări

- Design of A Vapor-Liquid SeparatorDocument2 paginiDesign of A Vapor-Liquid SeparatorpowerveeÎncă nu există evaluări

- Cal. Dew PointDocument1 paginăCal. Dew PointJuan Pablo ApazaÎncă nu există evaluări

- Earth and Life Science Test ReviewDocument3 paginiEarth and Life Science Test Reviewmerlyn m romerov100% (1)

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualDocument6 paginiBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingÎncă nu există evaluări

- Radiation and Convection Heat TransferDocument5 paginiRadiation and Convection Heat TransfergsdaundhÎncă nu există evaluări

- Sarco Sizing SoftwareDocument4.922 paginiSarco Sizing SoftwarePetarPetrovic100% (1)

- Steam CalculationDocument27 paginiSteam CalculationRAVI KUMAR CarpenterÎncă nu există evaluări

- Self-Coached Climber - The Guide To Movem - Dan M (1) HagueDocument376 paginiSelf-Coached Climber - The Guide To Movem - Dan M (1) HagueBill Frisch100% (1)

- Vent Line Pressure Drop CalculationDocument4 paginiVent Line Pressure Drop CalculationRubensBoerngenÎncă nu există evaluări

- Steam Pipe Sizing VGDocument39 paginiSteam Pipe Sizing VGSolooloo Kebede NemomsaÎncă nu există evaluări

- Cálculo de Eficiencia de Un HornoDocument29 paginiCálculo de Eficiencia de Un HornoFranklin Santiago Suclla PodestaÎncă nu există evaluări

- Emergency Scrubber DesignDocument36 paginiEmergency Scrubber DesignSurajit das0% (1)

- Kalyani Steels Ltd. Media Consumption ListDocument14 paginiKalyani Steels Ltd. Media Consumption Listmadhusri002Încă nu există evaluări

- Use of Nitrogen Purge in Flare and Vent SystemsDocument2 paginiUse of Nitrogen Purge in Flare and Vent Systemsandistwn99Încă nu există evaluări

- Centrifugal Pumps: Process Calculation / Data SheetDocument3 paginiCentrifugal Pumps: Process Calculation / Data SheetMurali MuthuÎncă nu există evaluări

- Proc Eng P&I DDocument60 paginiProc Eng P&I DGiang T LeÎncă nu există evaluări

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 paginiN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridÎncă nu există evaluări

- P103e Gas Scrubbing PlantsDocument12 paginiP103e Gas Scrubbing PlantsAswad Ali100% (1)

- Desuperheater Boiler Feed Water RequirementDocument2 paginiDesuperheater Boiler Feed Water RequirementmayurjannuÎncă nu există evaluări

- Spreadsheet-Based Process Group SoftwareDocument10 paginiSpreadsheet-Based Process Group SoftwareHendy ArmantoÎncă nu există evaluări

- Chemical Plant Utility - Nitrogen System DesignDocument10 paginiChemical Plant Utility - Nitrogen System DesignIJRASETPublicationsÎncă nu există evaluări

- HRSG SpecificationsDocument2 paginiHRSG SpecificationsBv RaoÎncă nu există evaluări

- 20120507091359 (1)Document6 pagini20120507091359 (1)Noman Abu-FarhaÎncă nu există evaluări

- Chapter 24: Energy Conservation Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument18 paginiChapter 24: Energy Conservation Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallRafael ReyesÎncă nu există evaluări

- PSV data sheets for existing refinery steam boilerDocument1 paginăPSV data sheets for existing refinery steam boilermaurya888Încă nu există evaluări

- Roots blower data sheetDocument1 paginăRoots blower data sheetPhượng NguyễnÎncă nu există evaluări

- Antoine Equation Curve FittingDocument2 paginiAntoine Equation Curve FittingJM Flores De SilvaÎncă nu există evaluări

- OptQuest User ManualDocument190 paginiOptQuest User ManualYamal E Askoul TÎncă nu există evaluări

- Remote Sensing: Comparison of The Selected State-Of-The-Art 3D Indoor Scanning and Point Cloud Generation MethodsDocument26 paginiRemote Sensing: Comparison of The Selected State-Of-The-Art 3D Indoor Scanning and Point Cloud Generation MethodsVICTOR PEREZÎncă nu există evaluări

- PMR v39 I3 117 126Document10 paginiPMR v39 I3 117 126rezaeibehrouzÎncă nu există evaluări

- Preparation of Gases in LaboratoryDocument7 paginiPreparation of Gases in LaboratoryChu Wai Seng50% (2)

- Forrester Roi StudyDocument30 paginiForrester Roi StudymcgettsÎncă nu există evaluări

- 1-Newton Second Law-ForMATDocument5 pagini1-Newton Second Law-ForMATVAIBHAV KUMARÎncă nu există evaluări

- Maintenance Recommendations: Operation and Maintenance ManualDocument10 paginiMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SÎncă nu există evaluări

- Problem #1: Session #19: Homework SolutionsDocument4 paginiProblem #1: Session #19: Homework SolutionsMD Abu RaselÎncă nu există evaluări

- Effect of Bond Administration On Construction Project DeliveryDocument7 paginiEffect of Bond Administration On Construction Project DeliveryOlefile Mark MolokoÎncă nu există evaluări

- Kidney AnatomyDocument55 paginiKidney AnatomyMohammad zreadÎncă nu există evaluări

- GSM Modem XM1510S-B00-103 ManualDocument19 paginiGSM Modem XM1510S-B00-103 ManualPaul MaposaÎncă nu există evaluări

- Sensitive Albuminuria Analysis Using Dye-Binding Based Test StripsDocument24 paginiSensitive Albuminuria Analysis Using Dye-Binding Based Test StripsВалерия БедоеваÎncă nu există evaluări

- B. Solving Quadratic EquationsDocument23 paginiB. Solving Quadratic EquationsHasnain -GamerÎncă nu există evaluări

- 478 - Phs 242 NotesDocument61 pagini478 - Phs 242 NotesSovan ChakrabortyÎncă nu există evaluări

- Differential Analysis of Fluid FlowDocument42 paginiDifferential Analysis of Fluid FlowAmr Faisal RaghebÎncă nu există evaluări

- NTSE 2015 Stage I Official Result Karnataka PDFDocument10 paginiNTSE 2015 Stage I Official Result Karnataka PDFAnnu NaikÎncă nu există evaluări

- Bio Inorganic ChemistryDocument2 paginiBio Inorganic ChemistryMeghna KumarÎncă nu există evaluări

- Chapter 13: The Electronic Spectra of ComplexesDocument42 paginiChapter 13: The Electronic Spectra of ComplexesAmalia AnggreiniÎncă nu există evaluări

- Financial Accounting IIDocument16 paginiFinancial Accounting IIMiguel BuenoÎncă nu există evaluări

- Lighting SchemesDocument7 paginiLighting SchemesSharath CherryÎncă nu există evaluări