Documente Academic

Documente Profesional

Documente Cultură

An Introduction To SCADA For Electrical Engineers Beginners

Încărcat de

Sibtain Ul Hassan0 evaluări0% au considerat acest document util (0 voturi)

35 vizualizări3 paginiAn Introduction to SCADA for Electrical Engineers Beginners

Titlu original

Electrical-Engineering-portal.com-An Introduction to SCADA for Electrical Engineers Beginners

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAn Introduction to SCADA for Electrical Engineers Beginners

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

35 vizualizări3 paginiAn Introduction To SCADA For Electrical Engineers Beginners

Încărcat de

Sibtain Ul HassanAn Introduction to SCADA for Electrical Engineers Beginners

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

e le ct rical-e ngine e ring-po rt al.

co m

http://electrical-engineering-po rtal.co m/an-intro ductio n-to -scada-fo r-electrical-engineers-beginners

An Introduction To SCADA For Electrical Engineers

Beginners

Bipul Raman

An Intro d uc tio n To SCADA (Sup e rvis o ry Co ntro l And Data Ac q uis itio n ) Fo r Be g inne rs // O n p ho to Mo nito r iFIX By

Se rviTe c no via Flic kR

Control and Supervision

It is impossible to keep control and supervision on all industrial activities manually. Some automated tool is

required which can control, supervise, collect data, analyses data and generate reports. A unique solution is

introduced to meet all this demand is SCADA system.

SCADA stands for supervisory control and data acquisition. It is an industrial control system where a

computer system monitoring and controlling a process.

Another term is there, Distributed Control System (DCS). Usually there is a conf usion between the

concept of these two.

A SCADA system usually ref ers to a system that coordinates, but does not control processes in real

time, but DCS do that. SCADA systems of ten have Distributed Control System (DCS) components.

Component s of SCADA

1. Human Machine Int erf ace (HMI)

It is an interf ace which presents process data to a human operator, and through this, the human operator

monitors and controls the process.

2. Supervisory (comput er) syst em

It gathers data on the process and sending commands (or control) to the process.

3. Remot e Terminal Unit s (RTUs)

It connect to sensors in the process, converting sensor signals to digital data and sending digital data to

the supervisory system.

4. Programmable Logic Cont roller (PLCs)

It is used as f ield devices because they are more economical, versatile, f lexible, and conf igurable than

special-purpose RT Us.

5. Communicat ion inf rast ruct ure

It provides connectivity to the supervisory system to the Remote Terminal Units.

SCADA Syst em Concept

T he term SCADA usually ref ers to centralized systems which monitor and control entire sites, or complexes

of systems spread out over large areas (anything between an industrial plant and a country).

Most control actions are perf ormed automatically by Remote Terminal Units (RTUs) or by programmable

logic controllers (PLCs).

Host control functions are usually restricted to basic overriding or supervisory level intervention. For

example, a PLC may control the f low of cooling water through part of an industrial process, but the

SCADA system may allow operators to change the set points f or the f low, and enable alarm conditions,

such as loss of f low and high temperature, to be displayed and recorded.

T he f eedback control loop passes through the RT U or PLC, while the SCADA system monitors the overall

perf ormance of the loop.

Advertisement

Advertisement

A s imp le SCADA s ys te m with s ing le c o mp ute r

SCADA/PLC Video Introduction/Example

Wast e Wat er Treat ment SCADA Syst em Raising your Plant IQ

Cant see this video? Click here to watch it on Youtube.

Int roducing st udent s t o Indust rial Programmable Cont rollers

Cant see this video? Click here to watch it on Youtube.

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- IEEE STD 979-2012, IEEE Guide For Substation Fire ProtectionDocument99 paginiIEEE STD 979-2012, IEEE Guide For Substation Fire ProtectionM Alim Ur Rahman100% (2)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- NYC Building Code Chapter 27 on Electrical Systems and Emergency Power RequirementsDocument3 paginiNYC Building Code Chapter 27 on Electrical Systems and Emergency Power RequirementsSibtain Ul HassanÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Designing Power GridsDocument19 paginiDesigning Power GridsSibtain Ul HassanÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- NYC Building Code Chapter 27 on Electrical Systems and Emergency Power RequirementsDocument3 paginiNYC Building Code Chapter 27 on Electrical Systems and Emergency Power RequirementsSibtain Ul HassanÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- ArrestersDocument4 paginiArrestersSibtain Ul HassanÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Unit # 06 - Procedures and Orderliness PDFDocument19 paginiUnit # 06 - Procedures and Orderliness PDFSibtain Ul HassanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Unit # 07 - Using The STOP System PDFDocument23 paginiUnit # 07 - Using The STOP System PDFSibtain Ul HassanÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Are you using the right CTs and PTs for your applicationDocument90 paginiAre you using the right CTs and PTs for your applicationEl Che CheÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Ami Spec DDS-98-2011Document17 paginiAmi Spec DDS-98-2011Sibtain Ul Hassan100% (1)

- Unit # 05 - Tools and Equipment PDFDocument20 paginiUnit # 05 - Tools and Equipment PDFSibtain Ul HassanÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Unit # 04 - Reactions of People PDFDocument18 paginiUnit # 04 - Reactions of People PDFSibtain Ul HassanÎncă nu există evaluări

- Battery 2013 03Document8 paginiBattery 2013 03Sibtain Ul HassanÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Unit # 02 - Personal Protective Equipment PDFDocument22 paginiUnit # 02 - Personal Protective Equipment PDFSibtain Ul HassanÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Stop Series For SafetyDocument20 paginiStop Series For SafetySibtain Ul HassanÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Unit # 01 - Introduction The STOP System PDFDocument24 paginiUnit # 01 - Introduction The STOP System PDFSibtain Ul HassanÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- FFBL Plant LayoutDocument1 paginăFFBL Plant LayoutSibtain Ul HassanÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Con Edison Test Preparation GuidesDocument18 paginiCon Edison Test Preparation GuidesSibtain Ul Hassan94% (16)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- TestPrepGuide Sec3 PS 2016 PDFDocument19 paginiTestPrepGuide Sec3 PS 2016 PDFSibtain Ul Hassan100% (4)

- TestPrepGuide Sec4 NC 2016 PDFDocument22 paginiTestPrepGuide Sec4 NC 2016 PDFSibtain Ul Hassan80% (5)

- Pakistan National Transmission and Despatch CompanyDocument50 paginiPakistan National Transmission and Despatch CompanyUmer BhuttaÎncă nu există evaluări

- NYC Building Code Chapter 27 on Electrical Systems and Emergency Power RequirementsDocument3 paginiNYC Building Code Chapter 27 on Electrical Systems and Emergency Power RequirementsSibtain Ul HassanÎncă nu există evaluări

- TestPrepGuide Sec5 WE 2016 PDFDocument19 paginiTestPrepGuide Sec5 WE 2016 PDFSibtain Ul Hassan100% (3)

- 201 7-18 TOEFL iBT Test Registration Form: Do Not Complete This Form. Register Online atDocument5 pagini201 7-18 TOEFL iBT Test Registration Form: Do Not Complete This Form. Register Online atSibtain Ul HassanÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

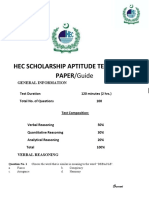

- HEC Scholarship Aptitude Test Sample Paper GuideDocument340 paginiHEC Scholarship Aptitude Test Sample Paper GuideMuhammad Faiz Ur Rehman0% (2)

- GAT Analytical ReasoningDocument272 paginiGAT Analytical ReasoningMuzaffar Iqbal90% (10)

- WAPDA Leave Rules 1982Document99 paginiWAPDA Leave Rules 1982Abdullah zeeshan50% (2)

- PLC Stepper Motor ControllerDocument12 paginiPLC Stepper Motor ControllerSibtain Ul Hassan100% (1)

- Water Level Sensing Using PLCDocument11 paginiWater Level Sensing Using PLCvinothnrvÎncă nu există evaluări

- Three Generations of SCADA System ArchitecturesDocument6 paginiThree Generations of SCADA System ArchitecturesSibtain Ul HassanÎncă nu există evaluări

- DZone ScyllaDB Database Systems Trend ReportDocument49 paginiDZone ScyllaDB Database Systems Trend ReportSidharth PallaiÎncă nu există evaluări

- Decision Trees Classification: Mustafa JarrarDocument46 paginiDecision Trees Classification: Mustafa Jarrarrferreira85Încă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Machine Learning Predicts DiabetesDocument18 paginiMachine Learning Predicts DiabetesMothish Kumar100% (1)

- Redp 5720Document60 paginiRedp 5720onlinenandaÎncă nu există evaluări

- Structuralism and SemioticsDocument2 paginiStructuralism and SemioticsAlejandra SánchezÎncă nu există evaluări

- Tanmayshankar CVDocument2 paginiTanmayshankar CVapi-255550165Încă nu există evaluări

- Incidental Vocabulary Acquisition ReferencesDocument4 paginiIncidental Vocabulary Acquisition ReferencesCarol TanaÎncă nu există evaluări

- جميع اسئلة الرؤياDocument13 paginiجميع اسئلة الرؤياamnaalbadrani7Încă nu există evaluări

- LMI Control ToolboxDocument356 paginiLMI Control Toolboxali_elec0% (1)

- A Review On Machine Learning TechniquesDocument5 paginiA Review On Machine Learning TechniquesEditor IJRITCCÎncă nu există evaluări

- Face Mask Detection in Real-Time Using MobileNetV2Document6 paginiFace Mask Detection in Real-Time Using MobileNetV2Ilman ZidniÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Evaluation of Liquefaction Potential Using Neural Networks (NNDocument25 paginiEvaluation of Liquefaction Potential Using Neural Networks (NNSuvadeep Dalal100% (1)

- Midterm Exam 1Document8 paginiMidterm Exam 1jagriti kumariÎncă nu există evaluări

- The Scope of Psycho Linguistics and The Significant of Psycho Linguistics For Language Teaching and LearningDocument2 paginiThe Scope of Psycho Linguistics and The Significant of Psycho Linguistics For Language Teaching and LearningFadel Tjipta88% (42)

- Crop Disease Detection Using CNNDocument5 paginiCrop Disease Detection Using CNNInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Suzuki Et Al IEEE ICCA 2000 x1Document6 paginiSuzuki Et Al IEEE ICCA 2000 x1Denis Constantin Ilie-AblachimÎncă nu există evaluări

- Modern Control Theory SolutionDocument43 paginiModern Control Theory Solutionengrmishtiaq71% (7)

- When Data Visualization Works - and When It Doesn'tDocument8 paginiWhen Data Visualization Works - and When It Doesn'tronald johannÎncă nu există evaluări

- Machine Learning-Based Approaches For Breast Cancer Detection in Microwave ImagingDocument2 paginiMachine Learning-Based Approaches For Breast Cancer Detection in Microwave ImagingPasan GunawardanaÎncă nu există evaluări

- MadhusudhanR ResumeDocument11 paginiMadhusudhanR ResumesriÎncă nu există evaluări

- Neutral Network Model Predictive ControlerDocument10 paginiNeutral Network Model Predictive ControlerNimai KowlessurÎncă nu există evaluări

- Unit 1 (ML)Document16 paginiUnit 1 (ML)BHAVIN THUMARÎncă nu există evaluări

- FoT Lesson Plan-Artificial IntelligenceDocument17 paginiFoT Lesson Plan-Artificial Intelligencejitendra rauthanÎncă nu există evaluări

- Introduction To Instrumentation and ControlDocument4 paginiIntroduction To Instrumentation and Controlsouvik5000Încă nu există evaluări

- Neural Networks & Fuzzy Control CourseDocument2 paginiNeural Networks & Fuzzy Control CourseSmruti RanjanÎncă nu există evaluări

- 6CS4 22 Machine Learning Lab ManualDocument46 pagini6CS4 22 Machine Learning Lab ManualPragati Bagul50% (2)

- Mastering Competencies in Family Therapy A Practical Approach To Theory and Clinical Case Documentation 2nd Edition Gehart Test BankDocument36 paginiMastering Competencies in Family Therapy A Practical Approach To Theory and Clinical Case Documentation 2nd Edition Gehart Test Banklloydburnsf0h2100% (20)

- Thesis On Content Based Image RetrievalDocument7 paginiThesis On Content Based Image Retrievalamberrodrigueznewhaven100% (2)

- Materi BIM (Pak Hafidz)Document44 paginiMateri BIM (Pak Hafidz)Syafrul MubaraqÎncă nu există evaluări

- Models of CommunicationDocument25 paginiModels of CommunicationGlenn Rhey S. OrillosÎncă nu există evaluări

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDe la EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeEvaluare: 5 din 5 stele5/5 (8)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4.5 din 5 stele4.5/5 (542)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsDe la EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsEvaluare: 4 din 5 stele4/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesDe la EverandThe Rare Metals War: the dark side of clean energy and digital technologiesEvaluare: 5 din 5 stele5/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingDe la EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingEvaluare: 4 din 5 stele4/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemDe la EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemÎncă nu există evaluări

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4 din 5 stele4/5 (331)

- Understanding Automotive Electronics: An Engineering PerspectiveDe la EverandUnderstanding Automotive Electronics: An Engineering PerspectiveEvaluare: 3.5 din 5 stele3.5/5 (16)