Documente Academic

Documente Profesional

Documente Cultură

Cigar Holding Apparatus

Încărcat de

RakeshTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cigar Holding Apparatus

Încărcat de

RakeshDrepturi de autor:

Formate disponibile

3,483,872

United States Patent 0 "ice

Patented Dec. 16, 1969

vouring agent particularly a powdered sweetening agent

3,483,872

intimately admixed therein.

The ?avouring agent according to one embodiment of

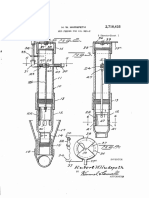

CIGAR HQLDER

Leo Conrad Laporte, Montreal, Quebec, Canada, assignor

to lmperiai Tobacco Company of Canada, Limited,

Montreal, Quebec, {Canada

No Drawing. Filed Apr. 4, 1966, Ser. No. 539,657

the present invention is a sweetening agent and thus is

most commonly used at the present time. However it will

be readily apparent that any type of ?avouring agent may

be used depending upon the taste desired in the smokers

mouth.

It has been found that the inclusion of the ?avouring

@Claims priority, application Canada, June 29, 1965,

934,634

Int. Cl. A24f 13/02, 11/00

US. Ci. 13112

1 Qiaim

10 agent in the resin has essentially no effect on the conven

ABSTRACT OF THE DISCLOSURE

A molded synthetic resin cigar holder having a sweeten

ing agent incorporated therein which is adapted to con

tinuously discharge into the mouth of the smoker. The

sweetening agent must be stable at the molding temper

ature of the resin.

The present invention relates to a cigar holder adapted

to continuously dispense a ?avouring particularly a Sweet

ening agent into the mouth of the smoker during the smok

ing of the cigar. In particular, the present invention relates

to such a cigar holder molded from a resin containing a .

?avouring particularly a sweetening agent therein.

In the manufacture of many types of cigars, it is com

mon practice to include at the end of the cigar intended

to be put in the mouth of the smoker a sweetening agent

so that the sweetening agent is continuously discharged

into the mouth during the smoking of the cigar. This pro

vides a sweet taste on the smokers tongue as he smokes

tional process by which the cigar holders are molded and,

as such, conventional techniques and machines may be

used for making the cigar holders. It is, however, essen

tial that the ?avouring agent is stable at the temperature

at which the resin is molded to form the cigar holder

and in this connection synthetic sweetening agents have

particular application. Of these synthetic sweetening

agents, saccharin, sodium saccharin and sodium and cal

cium cyclamate may be mentioned.

The amount of ?avouring agent present in the resin

molding powder and, as such, in the product cigar hold

er, is not critical and is purely subjective in that it de

pends upon the level of ?avour which the cigar manufac

turer desires to be present in the smokers mouth. How

ever, with the aforesaid synthetic sweenting agents, these

are particularly effective sweetening agents in that small

amounts produce a strong sweetening effect, amounts in

the range 1 to 25% by weight based on the weight of the

resin have been found to be generally suitable.

The resins from which the cigar holder may be made

are the conventional resins from which these cigar hold

ers have previously been made as the presence of the

the cigar and thus provides the cigar with a characteristic

?avouring agent has little effect upon the resin and the

taste. Typical sweetening agents used for this purpose are

method of molding as has been explained aforesaid. Typi

saccharin, sodium saccharin or sodium or calcium cycla 35 cal resins which may be mentioned in this respect include

mate and these are conveniently included in the adhesive

polyacetal, polyacrylic resins, polyallyl resins, amine res

e.g. gum tragacanth with which the free end of the binder

ins such as urea or melamine resins, casein resins, cel

and the wrapper are sealed in the manufacture of the

cigar.

However, it has now become common practice for ci

gar manufacturers to sell their cigars complete with the

cigar holder which are commonly known in the trade as

?exible tips. With these ?exible tips, the manufacturers

of cigars, which incorporate the sweetening agents there

lulosic resins, polyesters, polyole?nes, phenolic resins,

polyvinyl resins, polystyrene resins and coumarone indene

resins. Synthetic resins, in particular polyole?nes, such as

polyethylene and polypropylene, have been used with ad

zantage.

What I claim as my invention is:

1. A cigar holder adapted to continuously discharge

in, have to ?nd alternative means for Continuously dis 45 a ?avouring agent into the mouth of the smoker, said

charging sweetening agent into the smokers mouth from

holder being molded at least in part from a particulate

the cigar as the smokers mouth does not come into direct

polyole?n resin molding material in which the said ?a

contact with the cigar.

vorant is incorporated, the said ?avorant being a synthetic

It has now been found that when a ?avouring particu

sweetening agent which is normally stable at the tempera

larly a sweetening agent is intimately admixed with the

ture at which the holder is molded.

resin molding powder from which the cigar holders are

formed, a cigar holder is obtained on molding which sat

is?es the above requirements in that on being held in the

References Cited

mouth, ?avouring agent is continuously and constantly

UNITED STATES PATENTS

discharged.

According to the present invention, therefore, there is

provided a cigar holder adapted to continuously discharge

a ?avouring agent particularly a sweetening agent into the

mouth of the smoker, said holder having at least that por

tion normally held in the mouth molded from a resin (30

containing a ?avouring agent, said agent being stable at

the molding temperature of the resin.

While it is only necessary for that part of the cigar

holder normally held in the mouth during smoking to

have the ?avouring agent therein, it is most convenient

and commercially practicable particularly where one piece

holders, e.g. ?exible tips are being molded, that the whole

of the holder is molded from the resin containing the

?avouring agent.

The present invention also includes the molding poW-

der from which the aforesaid cigar holders are produced

which comprises a resin powder having a powdered ?a

1,671,182

5/1928

2,309,729

2/1943

Gordon.

2,782,180

2/1957

Weidman ______ __ 264-122 X

1/1963

Marx et a1. _____ __ 264-122 X

3,072,593

2,956,569

1,987,354

3,120,670

3,137,303

2,114

Eberlein et al _______ __ 131-12

10/1960 Adams.

1/1935

2/1964

6/1964

Albert 2 ___________ __ 131187

Amoded _________ __ 128359

Shaw ____________ __ 131-187

FOREIGN PATENTS

1861 Great Britain.

MELVIN D. REIN, Primary Examiner

U .3. Cl. X.R.

99-140, 141; 13 1-172, 230

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Process For Surface Sizing PaperDocument7 paginiProcess For Surface Sizing PaperRakeshÎncă nu există evaluări

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterDocument3 paginiLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshÎncă nu există evaluări

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 paginiSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshÎncă nu există evaluări

- Hybrid Topcoat Formulations For PaperDocument11 paginiHybrid Topcoat Formulations For PaperRakeshÎncă nu există evaluări

- Vernier DesignDocument9 paginiVernier DesignRakeshÎncă nu există evaluări

- F PenDocument3 paginiF PenRakeshÎncă nu există evaluări

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 paginiErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshÎncă nu există evaluări

- Interconnected Solar CellsDocument13 paginiInterconnected Solar CellsRakeshÎncă nu există evaluări

- Load BalancingDocument16 paginiLoad BalancingRakeshÎncă nu există evaluări

- Multipurpous KeyDocument12 paginiMultipurpous KeyRakeshÎncă nu există evaluări

- Electro Magnetic MotorDocument9 paginiElectro Magnetic MotorRakeshÎncă nu există evaluări

- Sri LankaDocument2 paginiSri LankaRakeshÎncă nu există evaluări

- Sri Lanka BuddhismDocument2 paginiSri Lanka BuddhismRakeshÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Potential Prospect 1.7Document6 paginiPotential Prospect 1.7Joshua M. GenoviaÎncă nu există evaluări

- Exercise 6Document2 paginiExercise 6Satyajeet PawarÎncă nu există evaluări

- Water Quantity Estimation PDFDocument3 paginiWater Quantity Estimation PDFOladunni AfolabiÎncă nu există evaluări

- Governance, Business Ethics, Risk Management and Internal ControlDocument4 paginiGovernance, Business Ethics, Risk Management and Internal ControlJosua PagcaliwaganÎncă nu există evaluări

- EarthWear Clothier MaterialsDocument1 paginăEarthWear Clothier MaterialsZhining LimÎncă nu există evaluări

- JIDMR SCOPUS Ke 4 Anwar MallongiDocument4 paginiJIDMR SCOPUS Ke 4 Anwar Mallongiadhe yuniarÎncă nu există evaluări

- VSR 411 QB AnaesthesiaDocument7 paginiVSR 411 QB Anaesthesiavishnu dathÎncă nu există evaluări

- WWW - Devicemanuals.eu: GardenaDocument6 paginiWWW - Devicemanuals.eu: GardenapotoculÎncă nu există evaluări

- Naming Alcohols, Aldehydes. EtcDocument1 paginăNaming Alcohols, Aldehydes. Etcim_mikezÎncă nu există evaluări

- Akin To PityDocument356 paginiAkin To PityPaul StewartÎncă nu există evaluări

- Book Report British Airways Flight 5390Document7 paginiBook Report British Airways Flight 5390KaruÎncă nu există evaluări

- Music Recognition, Music Listening, and Word.7Document5 paginiMusic Recognition, Music Listening, and Word.7JIMENEZ PRADO NATALIA ANDREAÎncă nu există evaluări

- Industrial Attachment ReportDocument34 paginiIndustrial Attachment ReportOtsile Charisma Otsile Saq100% (1)

- Eim s2000 Series Brochure PDFDocument16 paginiEim s2000 Series Brochure PDFHumbertoOtaloraÎncă nu există evaluări

- Scenario of Shale Gas Exploration in IndiaDocument24 paginiScenario of Shale Gas Exploration in IndiaManish TiwariÎncă nu există evaluări

- Annual Sustainability Report 2022-23 FinalDocument93 paginiAnnual Sustainability Report 2022-23 FinalLakshay JajuÎncă nu există evaluări

- Assignment 2 ME 326Document10 paginiAssignment 2 ME 326divided.symphonyÎncă nu există evaluări

- GCU 0103 Computer PlatformsDocument5 paginiGCU 0103 Computer PlatformsArani NavaratnarajahÎncă nu există evaluări

- Muet Topic 10 City Life Suggested Answer and IdiomsDocument3 paginiMuet Topic 10 City Life Suggested Answer and IdiomsMUHAMAD FAHMI BIN SHAMSUDDIN MoeÎncă nu există evaluări

- Topic: Going To and Coming From Place of WorkDocument2 paginiTopic: Going To and Coming From Place of WorkSherry Jane GaspayÎncă nu există evaluări

- Wax Depilation ManualDocument17 paginiWax Depilation ManualAmit Sharma100% (1)

- Listes de Produits GAURAPADDocument1 paginăListes de Produits GAURAPADBertrand KouamÎncă nu există evaluări

- Schengen Certificate ExampleDocument2 paginiSchengen Certificate ExampleGabriel Republi CanoÎncă nu există evaluări

- Uji Stabilitas Tablet Floating Ranitidin HCL: Pengaruhnya Terhadap Sifat Fisik Dan Profil Disolusi Dalam Medium SGF Tanpa PepsinDocument16 paginiUji Stabilitas Tablet Floating Ranitidin HCL: Pengaruhnya Terhadap Sifat Fisik Dan Profil Disolusi Dalam Medium SGF Tanpa PepsinZeaa MaysÎncă nu există evaluări

- Question Bank Chemistry (B.Tech.) : Solid StateDocument10 paginiQuestion Bank Chemistry (B.Tech.) : Solid StatenraiinÎncă nu există evaluări

- Operator's Manual: SE Series Slab ScissorsDocument52 paginiOperator's Manual: SE Series Slab ScissorsthuanÎncă nu există evaluări

- ANNEX I of Machinery Directive 2006 - 42 - EC - Summary - Machinery Directive 2006 - 42 - CE - Functional Safety & ATEX Directive 2014 - 34 - EUDocument6 paginiANNEX I of Machinery Directive 2006 - 42 - EC - Summary - Machinery Directive 2006 - 42 - CE - Functional Safety & ATEX Directive 2014 - 34 - EUAnandababuÎncă nu există evaluări

- Complete Denture TechniquesDocument6 paginiComplete Denture TechniquesJohn Hyunuk ChoÎncă nu există evaluări

- An Agriculture Testament Albert HowardDocument297 paginiAn Agriculture Testament Albert Howardjagadeeshsunkad100% (1)

- Tenses Các NămDocument4 paginiTenses Các NămAnh MinhÎncă nu există evaluări