Documente Academic

Documente Profesional

Documente Cultură

Performance Analysis of IC Engines With Bio-Diesel Jatropha Methyl Ester (JME) Blends

Încărcat de

Dimaz Iyas ArmezyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Performance Analysis of IC Engines With Bio-Diesel Jatropha Methyl Ester (JME) Blends

Încărcat de

Dimaz Iyas ArmezyDrepturi de autor:

Formate disponibile

Vol. 4(5), pp.

90-93, May, 2013

DOI : 10.5897/JPTAF09.13

2013 Academic Journals

http://www.academicjournals.org/JPTAF

Journal of Petroleum Technology and

Alternatives Fuel

Full Length Research Paper

Performance analysis of IC engines with bio-diesel

jatropha methyl ester (JME) blends

Venkata Ramesh Mamilla1, M. V. Mallikarjun2 and G. Lakshmi Narayana Rao3

Department of Mechanical Engineering, QIS College of Engineering and Technology

Ongole, Andhra Pradesh, India.

Accepted 21 May, 2013

Petroleum products resources are limited and their consumption rate is increasing very fast with

technological development since the last two decades. The emissions from the usage of these

petroleum products pollute the environment considerably. Jatropha oil is one of the renewable energy

resources which are easily available in India. This study investigates the percentage substitution of

jatropha methyl ester blends to diesel as fuel for automobiles and other industrial purposes. The study

details the analysis of the performance and emission characteristics of the jatropha methyl esters and

its comparison with petroleum diesel. The tests were carried out on a 3.7 KW single cylinder, direct

injection and a water-cooled diesel engine. The fuels used were neat jatropha methyl ester, diesel and

different blends of the methyl ester with diesel. The experimental result shows that 20% of the blend

shows better performance with reduced pollution. The analysis shows that jatropha methyl ester

blended biodiesel is a good substitute for pure diesel.

Key words: Jatropha methyl ester, water-cooled diesel engine, performance, emission characteristics.

INTRODUCTION

Bio-diesel is a renewable fuel for diesel engines derived

from natural oils like vegetable oils. Bio-diesels can be

used as fuel at varying concentrations with petroleum

based diesel with little or no modification in existing diesel

engines (Sanjib and Anju, 2005; Heywood, 1998). It is

produced from raw vegetable oil by a chemical process,

which removes glycerol from the oil. Jatropa is a low cost

seeds with high oil content, small gestation period, which

grows on good and degraded soils, as well as areas with

low and high rainfall. The seeds are harvested in dry

season. Jatropha can yield up to 10 times the amount of

oil as other sources of biodiesel. It is a perennial crop,

lasting up to 50 years without replanting. In fact the

cake (portion of the seed left over after extracting the

oil) is full of nitrogen compounds making it an excellent

source of organic fertilizer. After 4 or 5 years of treatment

with this cake the soil of this originally non-agricultural

land will be suitable for planting food crops or trees for

reforestation.

The Jatropha plant bears fruit from the second year

after its plantation and the economic yield stabilizes from

the fourth or fifth year onwards. The plant may live for

more than 50 years with an average effective yielding

time of 50 years. The economic yield can be considered

as 0.75-2.0 kg/plant and 4.0 to 6.0 tons per ha, per year

depending on the agro-climatic zone and agricultural

practices. The cost of plantation has been estimated at

Rs.20, 000 a hectare inclusive of plant material,

maintenance for one year, training, overheads and the

like. A selling price of Jatropha seeds at Rs.12 a kilo

*Corresponding author. E-mail: maa_ram@yahoo.co.in, mvmsharma@yahoo.co.in, glnrao_68@yahoo.co.in.

Mamilla et al.

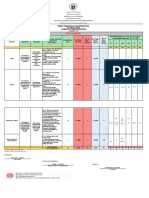

Table 1. Specifications of CI engine.

BP Vs BTE

3.7kW (5 H.P)

1500 rpm

80 mm

110 mm

20 mm

16.5:1

BTE in %

Max. BP

Speed

Bore

Stroke

Orifice diameter

Compression ratio

91

40

35

30

25

20

15

10

5

0

-0.3

diesel

20%JTME

40%JTME

60%JTME

80%JTME

JTME

0.7

1.7

2.7

3.7

BP in kW

gram would be an economically attractive proposition for

farmers. India has vast stretches of degraded land,

mostly in areas with adverse agro climatic conditions,

where species of Jatropha can be grown easily. The use

of 11 million hectare of wasteland for Jatropha cultivation

can lead to generation of a minimum of 12 million jobs.

India with its huge waste/non fertile lands, has taken a

well-noted lead in Jatropha cultivation, and commercial

production is what the industries have to focus on for

sustainable development.

Properties of Jatropha:

Specific gravity: 0.87 to 0.9

Kinematic viscosity at room temperature (m2/sec):

0.14*10-4

Dynamic viscosity (N-sec/m2): 12.5*10-3

Cetane number: 46 to 70

Flash point C: 150

Fire point C: 158

Calorific value (kj/kg): 40105

Pour point C : -15 to 13

EXPERIMENTAL PROCEDURE

Description

The engine used, is a four stroke vertical single cylinder diesel

engine. The Mechanical brake drum is fined to the engine flywheel

and mounted on a frame and its features mounted on antivibrations. The panel board is provided with 3 way cock digital

temperature indicator with selector switch, digital RPM indicator and

U-tube manometer (Table 1).

Figure 1. Comparison of brake thermal Efficiency for

JTME/diesel blends.

The readings noted are:

(1) Spring balance reading in kg-f (S).

(2) Time taken for 10cc fuel consumption in seconds (t).

(3) Manometer reading (hw).

Experimental results

On comparing bio diesel with diesel, the following was

obtained:

(1) BTE slightly decreases

(2) SFC slightly increases

(3) HC reduces

(4) CO reduces

(5) NOx increases

(6) CO2 increases

PERFORMANCE ANALYSIS

Performance properties are slightly lesser for biodiesel

compared to diesel. Accordingly, they improve injection

process and ensure better atomization of the fuel in the

combustion chamber (Heywood, 1998). Biodiesel can be

blended in any ratio for better performance and the

increased lubricity makes for a better running of vehicles.

Results of the experiments in the form of brake power,

brake thermal efficiency, specific fuel consumption for

different load conditions for various blends of jatropha

methyl esters are compared with the petroleum diesel in

the form of graphs.

Procedure

(1) The fuel level and lubrication oil levels were checked and a

three way cock is opened to allow the flow of fuel into the engine.

(2)The cooling water is supplied to the engine cooling water jacket

and to the brake drum.

(3)The electrical power is supplied to the panel instrumentation.

(4)The engine is de-compressed by a decompression lever

provided on the top of the engine head.

(5)The engine is unloaded by removing the weights from the hanger

and started by cranking.

(6)The experiment is repeated for different loads and

(7)The above steps 6 and 7 are repeated for different blends of fuels

Brake thermal efficiency

From Figure 1, it is observed that the brake thermal

efficiency is low at low values of BP and increases with

increase of BP for all blends of fuel (Raheman and

Phadatare, 2004). For a blend of 20% the brake thermal

efficiency is high at low BP values when compared with

other blends of fuel and is very close to diesel at high

values of BP. Hence at the blend of 20% of methyl ester

the performance of the engine is good.

92

J. Pet. Technol. Altern. Fuels

BP Vs CO

BP Vs SFC

0.12

0.5

diesel

20%JTME

40%JTME

60%JTME

80%JTME

JTME

0.4

0.3

0.2

0.1

0

-0.3

0.7

1.7

2.7

0.1

0.06

0.04

0.02

3.7

BP in KW

Figure 2. Comparison of Specific Fuel Consumption for

JTME/diesel blends.

diesel

20%JTME

40%JTME

60%JTME

80%JTME

JTME

0.08

COin %

SFC(kg/kW-hr)

0.6

0

-0.3

0.7

1.7

2.7

3.7

BP in KW

Figure 3. Comparison of CO for JTME/diesel blends.

BP vs NOx

Specific fuel consumption

1000

900

800

NOx in PPM

From the Figure 2, it is observed that the methyl ester

shows higher SFC compared to diesel as calorific value

is less (Suresh et al., 2008). It was observed that 20%

blend is having comparable closer values with diesel.

However SFC was higher for all the other blends. The

SFC decreases with the increasing loads and it is inversly

praportional to the thermal efficiency of the engine.

700

diesel

600

20%JTME

40%JTME

500

60%JTME

80%JTME

400

JTME

300

200

100

0

-0.3

0.7

Emission characteristics are improved for biodiesel

compared to conventional diesel except oxides of

nitrogen, which is slightly higher than diesel. Biodiesel

runs in any conventional unmodified diesel engine and

yields approximately equal performance as petroleum

diesel (Vivek, 2004; Srivastava and Madhumita, 2008).

Basically the engine just runs like normal except for the

odour. Trasesterified vegetable oils have lower viscosities

than the parent oils (Mehar et al., 2004). Accordingly,

they improve injection process and ensure better

atomization of the fuel in the combustion chamber. Biodiesel can be blended in any ratio for reduced emissions

and the increased lubricity makes for a better running of

the vehicle (Sharma and Singh, 2008). Results of the

experiments in the form of carbon monoxide (CO),

Nitrogen oxides (NOx) and Smoke density for different

load conditions for various blends of jatropha methyl

esters is compared with the petroleum diesel in the form

of graphs.

CO emission

The comparison of various levels of carbon monoxide

(CO) emissions with break power for diesel, with different

blends of jatropha methyl esters are shown in Figure 3.

From the figure, it was observed that CO decreases with

1.7

2.7

3.7

BP in kw

EMISSION ANALYSIS

Figure 4. Comparison of nitrogen oxides for JTME/diesel

blends.

increasing load for all the blends of Jatropha methyl

esters. If percentage of blends of Jatropha methyl esters

increases, CO reduces (Magin et al., 2008). The

concentration of CO decreases with the increase in

percentage of Jatropha Methyl Esters (JTME) in the fuel.

This may be attributed to the presence of O2 in JTME,

which provides sufficient oxygen for the conversion of

carbon monoxide (CO) to carbon dioxide (CO2). It can be

observed that blending 20% JTME with diesel results in a

slight reduction in CO emissions when compared to that

of only diesel.

NOx emission

From Figure 4, it was observed that NOx increases with

increasing load for all the blends of jatropha methyl

esters. If percentage of blends of jatropha methyl esters

increases, NOx increases. It can be seen that NOx

emissions increase with increase in percentage of JTME

in the diesel-JTME fuel blend. The NOx increase for

JTME may be associated with the oxygen content of the

JTME, since the fuel oxygen may augment in supplying

additional oxygen for NOx formation. Moreover, the

Mamilla et al.

BP Vs Smoke density

REFERENCES

Smoke density

density (mg/m

)

smoke

(mg/m3)

160

140

diesel

20%JTME

40%JTME

60%JTME

80%JTME

JTME

120

100

80

60

40

20

0

-0.3

0.7

1.7

2.7

93

3.7

BP in kW

Figure 5. Comparison of smoke density for JTME/diesel

blends.

higher value of peak cylinder temperature for JTME when

compared to diesel may be another reason that might

explain the increase in NOX formation (Sagar and

Rajendra, 2010).

Smoke density

The comparison of smoke density for diesel, neat JTME

and blends are shown in Figure 5. From the figure, it was

observed that smoke density increases with increasing

load for all the blends of jatropha methyl esters. If

percentage of blends of jatropha methyl esters increases,

smoke density decreases. Because of increasing the

load, the fuel entering into the cylinder increases in that

proper oxygen is not allowed because the smoke density

is high for the diesel.

Conclusion

The experiment was done by blending biodiesel

(jatropha) in different volumes with diesel. The engine

performance indicating parameters like brake power,

indicated power, indicated thermal efficiency, brake

thermal efficiency, mechanical efficiency, etc., have been

observed for various blends at different loads.

From the experiments conducted, it is concluded that

biodiesel and its blends as a fuel for diesel engine have

better emission characteristics compared with diesel as

follows:

(1) CO emissions are less compared with diesel

(2) NOx emissions for biodiesel and blended fuel are

slightly higher than that of diesel

(3) From this analysis it can be concluded that 20%

JTME gives better performance with reduced pollution.

Heywood JB (1998). ''Internal combustion Engines Fundamentals",

Mcgraw Hill, New York pp. 491-558.

Magin L, Octavio A, Rodriguez-Fernandez J (2008). Effect of biodiesel

fuels on diesel engine emissions. J. Progress Energy Combustion

Sci. 34:198-223.

Mehar LC, Naik SN, Das LM (2004). Methanolysis of Pongamia pinnata

(karanja) oil for Production of biodiesel. J. Sci. Indust. Res. 63:913918.

Raheman H, Phadatare AG (2004). Diesel engine emissions and

performance from blends of karanja methyl ester and diesel. J.

Biomass Bioenergy. 27:393-397.

Sagar PK, Rajendra HS (2010). Experimental Investigations on the use

of preheated neat karanja oil as fuel in a compression ignition engine.

World Acad. Sci. Eng. Technol. 72:540-544.

Sanjib KK, Anju C (2005). Preparation of biodiesel from crude oil

pongamia pinnata. J. Bioresource Technol. 96:1425-1429.

Sharma YC, Singh B (2008). Development of biodiesel from karanja , a

tree found in rural India. J. Fuel. 1740-1742:87.

Srivastava PK, Madhumita V (2008). Methyl Ester of karanja oil as an

alternate renewable source energy. J. Fuel 87:1673-1677.

Suresh KK, Velraj R, Ganesan R (2008). Performance and exhaust

emission characteristics of a CI engine fueled with pongamia pinnata

methyl ester (PPME) and its blends with diesel. J. Renewable Energy

33:2294-2302.

Vivek GAK (2004). Biodiesel production from karanja oil. J. Sci. Indust.

Res. 63:39-47.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Effects of PH Conditions That Simulate Acid Precipitation On The Growth of Brassica RapaDocument8 paginiEffects of PH Conditions That Simulate Acid Precipitation On The Growth of Brassica RapaDimaz Iyas ArmezyÎncă nu există evaluări

- ScienceDocument1 paginăScienceDimaz Iyas ArmezyÎncă nu există evaluări

- Qualitative Analysis For Fe, Ba, Ni, PB, and AgDocument2 paginiQualitative Analysis For Fe, Ba, Ni, PB, and AgDimaz Iyas ArmezyÎncă nu există evaluări

- Recommendation From The Scientific Committee On Occupational Exposure Limits: Lead ChromateDocument7 paginiRecommendation From The Scientific Committee On Occupational Exposure Limits: Lead ChromateDimaz Iyas ArmezyÎncă nu există evaluări

- Nitriding and NitrocarburisingDocument3 paginiNitriding and NitrocarburisingDimaz Iyas ArmezyÎncă nu există evaluări

- Flame HardeningDocument2 paginiFlame HardeningDimaz Iyas ArmezyÎncă nu există evaluări

- TrellisDocument1 paginăTrellisCayenne LightenÎncă nu există evaluări

- Invoices For UEG IstanbulDocument7 paginiInvoices For UEG IstanbulIesaw IesawÎncă nu există evaluări

- LKG Math Question Paper: 1. Count and Write The Number in The BoxDocument6 paginiLKG Math Question Paper: 1. Count and Write The Number in The BoxKunal Naidu60% (5)

- Avid Final ProjectDocument2 paginiAvid Final Projectapi-286463817Încă nu există evaluări

- Bài Tập Từ Loại Ta10Document52 paginiBài Tập Từ Loại Ta10Trinh TrầnÎncă nu există evaluări

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Document6 paginiRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoÎncă nu există evaluări

- Financial Accounting 1: Chapter 5 Cash and Short Term InvestmentDocument31 paginiFinancial Accounting 1: Chapter 5 Cash and Short Term InvestmentCabdiraxmaan GeeldoonÎncă nu există evaluări

- 1996 OKI LCD Driver Controller DatabookDocument232 pagini1996 OKI LCD Driver Controller Databookpiptendo100% (1)

- III.A.1. University of Hawaii at Manoa Cancer Center Report and Business PlanDocument35 paginiIII.A.1. University of Hawaii at Manoa Cancer Center Report and Business Planurindo mars29Încă nu există evaluări

- Will Smith BiographyDocument11 paginiWill Smith Biographyjhonatan100% (1)

- Catálogo MK 2011/2013Document243 paginiCatálogo MK 2011/2013Grupo PriluxÎncă nu există evaluări

- Packet Unit 3 - Atomic Structure-Answers ChemistryDocument11 paginiPacket Unit 3 - Atomic Structure-Answers ChemistryMario J. KafatiÎncă nu există evaluări

- Rare Malignant Glomus Tumor of The Esophagus With PulmonaryDocument6 paginiRare Malignant Glomus Tumor of The Esophagus With PulmonaryRobrigo RexÎncă nu există evaluări

- Protection in Distributed GenerationDocument24 paginiProtection in Distributed Generationbal krishna dubeyÎncă nu există evaluări

- Hetal Patel: Team Leader - SalesDocument2 paginiHetal Patel: Team Leader - SalesPrashant kumarÎncă nu există evaluări

- Adverbs of Manner and DegreeDocument1 paginăAdverbs of Manner and Degreeslavica_volkan100% (1)

- Better Photography - April 2018 PDFDocument100 paginiBetter Photography - April 2018 PDFPeter100% (1)

- Le Chatelier's Principle Virtual LabDocument8 paginiLe Chatelier's Principle Virtual Lab2018dgscmtÎncă nu există evaluări

- The Piano Lesson Companion Book: Level 1Document17 paginiThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelÎncă nu există evaluări

- Manual Samsung Galaxy S Duos GT-S7562Document151 paginiManual Samsung Galaxy S Duos GT-S7562montesjjÎncă nu există evaluări

- GTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerDocument1 paginăGTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerThanuja DilshanÎncă nu există evaluări

- Addition Color by Code: Yellow 1, 2, Blue 3, 4, Pink 5, 6 Peach 7, 8 Light Green 9, 10, Black 11Document1 paginăAddition Color by Code: Yellow 1, 2, Blue 3, 4, Pink 5, 6 Peach 7, 8 Light Green 9, 10, Black 11Noor NadhirahÎncă nu există evaluări

- Tree PruningDocument15 paginiTree Pruningrita44Încă nu există evaluări

- Docsity Detailed Lesson Plan 5Document4 paginiDocsity Detailed Lesson Plan 5Sydie MoredoÎncă nu există evaluări

- The International Poker RulesDocument2 paginiThe International Poker RulesOutontheBubbleÎncă nu există evaluări

- Bigbazaar PDFDocument14 paginiBigbazaar PDFazhagu sundaramÎncă nu există evaluări

- Asim Kumar Manna - Business Mathematics and Statistics (2018, McGraw-Hill Education)Document624 paginiAsim Kumar Manna - Business Mathematics and Statistics (2018, McGraw-Hill Education)rerr50% (2)

- Tetra IntroductionDocument65 paginiTetra Introductionuniversidaddistrital100% (2)

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesDocument1 paginăLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDÎncă nu există evaluări

- Hydrogeological Survey and Eia Tor - Karuri BoreholeDocument3 paginiHydrogeological Survey and Eia Tor - Karuri BoreholeMutonga Kitheko100% (1)