Documente Academic

Documente Profesional

Documente Cultură

Daily

Încărcat de

ArchanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Daily

Încărcat de

ArchanDrepturi de autor:

Formate disponibile

CRADEL PHARMACEUTICALS PRIVATE LIMITED

STANDARD OPERATING PROCEDURE

QUALITY ASSURANCE

TITLE: DAILY INSPECTION

SOP No. : 1000XX

EFFECTIVE DATE. : DD/MM/YYYY

SUPERSEDES No. : NEW

ISSUE No. : 1000XX/0X

REVIEW DUE ON. : MM/YYYY

PAGE No. : Page 1 of 3

1.

Objective

To define the procedure for daily inspection to check the cGMP compliance.

2.

Scope

This procedure is applicable to Inspection on the GMP aspects of production activities at

Cradel Pharmaceuticals Pvt. Ltd., Kolkata.

3.

Responsibility

Executive QA

To prepare the cGMP noncompliance reports based on Daily inspection and submit the

report to concern Department.

To identify the cause and to recommend corrective action on inspected observation.

To follow-up and review the compliance of the Daily inspection findings on the given target

date.

4.

Accountability

Sr. Head-QA

5.5. Procedure

5.1 Inspection is conducted to determine whether the quality system requirements and regulatory

guidelines are effectively implemented, maintained and evaluated.

5.2 Inspection shall be conducted daily and followings activities must consider during inspection

(but not limited to) :

5.2.1 Compliance to SOPs.

5.2.2 Compliance to BPRs.

5.2.3 Status label.

5.2.4 Housekeeping record.

5.2.5 Compliance to GMP.

5.2.6 Daily Calibration record.

5.2.7 Temperature and Humidity.

5.2.8 Preventive maintenance etc.

5.3 The discrepancies / observations if any shall be entered on format No.: SPL/QA/019 by QA

and sent to concern department.

5.4 The concerned department and Q.A shall identify the root cause and fill the corrective action

accordingly.

Prepared By

Sign & Date

Name

Designation

Format No.: F100001/01/03

Checked By

Approved By

CRADEL PHARMACEUTICALS PRIVATE LIMITED

STANDARD OPERATING PROCEDURE

QUALITY ASSURANCE

TITLE: DAILY INSPECTION

SOP No. : 1000XX

EFFECTIVE DATE. : DD/MM/YYYY

SUPERSEDES No. : NEW

ISSUE No. : 1000XX/0X

REVIEW DUE ON. : MM/YYYY

PAGE No. : Page 2 of 3

5.5 The observation should be investigated and brought into the notice of head of QA.

5.6. All the observations to be evaluated and if required training to be imparted to the individual

or group.

6.

Records/Formats:

F1000XX/X/XX

7.

Daily Inspection Report

Annexure:

NA

8.

Reference:

Nil

9.

Abbreviations:

9.1. QA

Quality assurance

9.2. BPR

Batch Processing record

9.3. GMP

Good manufacturing Practice

10.

Revision History:

Revision No.

00

Effective Date

Revision History

Daily Inspection Report

Format No. F1000XX/X/XX

Area / Department: ________

Date: ________

Auditor/ inspector: ________

Prepared By

Sign & Date

Name

Designation

Format No.: F100001/01/03

Checked By

Approved By

CRADEL PHARMACEUTICALS PRIVATE LIMITED

STANDARD OPERATING PROCEDURE

QUALITY ASSURANCE

TITLE: DAILY INSPECTION

SOP No. : 1000XX

EFFECTIVE DATE. : DD/MM/YYYY

SUPERSEDES No. : NEW

Sr.

No.

Observation

ISSUE No. : 1000XX/0X

REVIEW DUE ON. : MM/YYYY

PAGE No. : Page 3 of 3

Root cause

Corrective

action

Target date

Follow up

Sign of auditor/Inspector

Sign of area in-charge

Sign of Head QA

Date

Date

Date

Root Cause code numbers: 1 Man 2 Machine 3 Material 4 Method

Prepared By

Sign & Date

Name

Designation

Format No.: F100001/01/03

Checked By

Approved By

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hotel Master Critical PathDocument14 paginiHotel Master Critical Pathtaola80% (25)

- Manpower Planning FormDocument1 paginăManpower Planning FormMohammad Abd Alrahim ShaarÎncă nu există evaluări

- Endowment vs. GrantDocument6 paginiEndowment vs. GrantamalekhÎncă nu există evaluări

- Corporate Governance and Role of Board of DirectorsDocument13 paginiCorporate Governance and Role of Board of DirectorsSanjayÎncă nu există evaluări

- Cash App - Activity 333Document2 paginiCash App - Activity 333ss dsÎncă nu există evaluări

- Manufacturing Accounts FormatDocument6 paginiManufacturing Accounts Formatkerwinm6894% (16)

- Summary OF FRIADocument5 paginiSummary OF FRIAMegan AglauaÎncă nu există evaluări

- 2.1. Apparatus: 2.1.1. DROPPERS 2.1.2. Comparative Table of Porosity of Sintered-Glass FiltersDocument1 pagină2.1. Apparatus: 2.1.1. DROPPERS 2.1.2. Comparative Table of Porosity of Sintered-Glass FiltersArchanÎncă nu există evaluări

- 1.4. MonographsDocument2 pagini1.4. MonographsArchanÎncă nu există evaluări

- 1.2. Other Provisions Applying To General Chapters and MonographsDocument2 pagini1.2. Other Provisions Applying To General Chapters and MonographsArchanÎncă nu există evaluări

- 1.1. General StatementsDocument1 pagină1.1. General StatementsArchanÎncă nu există evaluări

- Docs h06 FM 018Document2 paginiDocs h06 FM 018ArchanÎncă nu există evaluări

- HS 019 Control of RecordsDocument13 paginiHS 019 Control of RecordsgrantÎncă nu există evaluări

- Dabur India PPT MBADocument6 paginiDabur India PPT MBABabasab Patil (Karrisatte)Încă nu există evaluări

- Project Report GSTDocument57 paginiProject Report GSTVidhi RamchandaniÎncă nu există evaluări

- Ist 3 ChaptersDocument19 paginiIst 3 Chaptersrkpreethi100% (1)

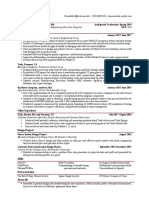

- Stacey Rosenfeld Resume 2018Document1 paginăStacey Rosenfeld Resume 2018api-333865833Încă nu există evaluări

- Accounting Standards Book Excercises CompilationDocument34 paginiAccounting Standards Book Excercises CompilationJay Ar OmbleroÎncă nu există evaluări

- The Strategic Position and Action EvaluationDocument3 paginiThe Strategic Position and Action EvaluationJoel Pérez GaliciaÎncă nu există evaluări

- Case AnalysisssDocument19 paginiCase AnalysisssNadine SalcedoÎncă nu există evaluări

- Asu 2019-09Document17 paginiAsu 2019-09janineÎncă nu există evaluări

- Key TermsDocument10 paginiKey Termscuteserese roseÎncă nu există evaluări

- Tariff Petition MEPCO PDFDocument170 paginiTariff Petition MEPCO PDFahmed khanÎncă nu există evaluări

- DMAS Financial Statement 31 Mar 2022Document82 paginiDMAS Financial Statement 31 Mar 2022Fendy HendrawanÎncă nu există evaluări

- Tara-Vel Travel and Tours: Organizational ChartDocument4 paginiTara-Vel Travel and Tours: Organizational ChartArnel IgnacioÎncă nu există evaluări

- Chapter 2 The Risk of FraudDocument49 paginiChapter 2 The Risk of FraudcessbrightÎncă nu există evaluări

- Struktur Organisasi GZ Kuta-BaliDocument1 paginăStruktur Organisasi GZ Kuta-BalioxiÎncă nu există evaluări

- Operation ManagementDocument35 paginiOperation ManagementJayvee Joble BigataÎncă nu există evaluări

- Employment Law For BusinessDocument18 paginiEmployment Law For Businesssocimedia300Încă nu există evaluări

- Management Accounting Level 3/series 2 2008 (Code 3024)Document14 paginiManagement Accounting Level 3/series 2 2008 (Code 3024)Hein Linn Kyaw67% (3)

- Supply Chain Management 5th Edition Chopra Solutions ManualDocument3 paginiSupply Chain Management 5th Edition Chopra Solutions Manualdammar.jealousgvg6100% (18)

- DigitalAutoCustomerJourney Bachelorthesis NatalieBacherDocument168 paginiDigitalAutoCustomerJourney Bachelorthesis NatalieBacherDiegoÎncă nu există evaluări

- 05-BI Framework and ComponentsDocument22 pagini05-BI Framework and ComponentsSiddharth SinghÎncă nu există evaluări

- BWU Notice 2024 Pass Out Batch Hero FinCorp Limited MBADocument4 paginiBWU Notice 2024 Pass Out Batch Hero FinCorp Limited MBAAditya Prakash ChaudharyÎncă nu există evaluări

- BAB 1 - Analisis Perilaku BiayaDocument31 paginiBAB 1 - Analisis Perilaku BiayaKartika Wulandari IIÎncă nu există evaluări