Documente Academic

Documente Profesional

Documente Cultură

Descripcion Falcon

Încărcat de

jlfyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Descripcion Falcon

Încărcat de

jlfyDrepturi de autor:

Formate disponibile

C1000-R3.

Installation, Operations, and Maintenance Manual

Introduction

1.1 Who is Sepro Mineral Systems?

SEPRO MINERAL SYSTEMS CORP. is a Canadian company operating internationally in the mining and

metals industries. Sepros core business for the last 25+ years has been manufacturing mineral processing

equipment including Falcon Centrifugal Gravity Concentrators for fine gold and mineral recovery, largescale ore scrubbers and agglomeration drums, smaller duty grinding mills, Sepro-Sizetec screens for coarse

particle separation and Sepro-Atalay screens for fine particle separation in addition to metallurgical testing

and process consulting. Basic services range from evaluative studies through equipment design, fabrication

and commissioning. Sepro is committed to providing state-of-the-art equipment and process solutions for

new and existing projects worldwide.

Thank you for purchasing your own Falcon Concentrator.

C1000 Continuous Concentrator

Sepro Mineral Systems Corp.

Page | 1-1

C1000-R3.1

Installation, Operations, and Maintenance Manual

1.2 The Continuous Concentrator

Recovering FINE metals and minerals from process streams has always been difficult. With the Falcon C

series, its design simplicity and 300 G-force, this has made the historically impossible process possible.

Designed to never stop, it continuously produces concentrate yielding weight recoveries as high as 40%.

The primary objective with this series is to maximize recovery and reduce weight to subsequent down

stream processes. This makes the units perfect for scavenging or pre-concentrating streams, as it uses no

elutriation water and produces concentrates that are de-slimed and de-watered (+70% solids by mass).

One moving part and top grade component materials such as 316 stainless steel, rubber, polyurethane,

tungsten carbide and ni-hard, mean that you can look forward to greater than 95% operational availability

as well as low operating costs.

The Falcon model C concentrator is normally utilized where separation of a relatively small amount of

fine heavy material (underflow) from a relatively large amount of lighter gangue is required.

The Falcon model C works for many minerals and metals:

Scavenging FINE gold and sulphides from leach or flotation tailings

Pre-concentrating before the leach to maximize leach performance

Scavenging FINE tantalum and tin from plant tailings

Removing ash and sulphides from coal

Scavenging FINE iron ore from LIMS tailings

Pre-concentrating of old gold and silver tailing dumps

Pre-concentrating and de-sliming heavy mineral deposits

Pre-concentration before flotation or leach rejecting light undesirables

1.2.1 How it Works

The feed stream particles are subjected to gravitational forces of up to 300 Gs and are segregated

according to effective specific gravity along the smooth spinning rotor wall. The heaviest layers are

continuously bled off at a controlled rate through a series of unique plane mass flow hoppers and patented

throttling nozzles.

The high Gs permit effective recovery of even very fine particles (below 10 microns). This unit requires

no feed interruptions or added process water. The adjustable fraction of heavy particles bled off are

effectively de-slimed and partially de-watered.

Feed capacity

Feed density

Feed particle size

Sepro Mineral Systems Corp.

4 sizes to 110 t/h solids

45% solids maximum

#20 (1mm) mesh maximum recommended

Page | 1-2

C1000-R3.1

Installation, Operations, and Maintenance Manual

1.3 Description

Frame:

All-welded construction, mild steel with epoxy paints to ensure long life of

the unit. The design and construction minimize normal operating vibrations.

Launders / Lid:

All-welded construction, mild steel with rubber linings and epoxy paint to

ensure long life of the unit.

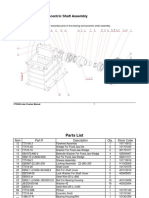

Rotating Assembly::

Machined shaft, rotor base, rotor bowl, and underflow discharge head. All

components contacting slurry are 316 stainless steel and/or rubber lined,

designed for easy replacement. This assembly is effectively the only moving

part.

Drive:

VFD, motor, belts and sprockets.

Control:

PLC, Operator Interface, and communications.

1.3.1 Process

Feed is screened at approximately 1 mm depending on the application, and is introduced as slurry through

a central vertical feed pipe, and then accelerated by an impeller. Rapid stratification according to specific

gravity occurs as the material is driven up the stratification zone, under the influence of an immense

gravity field. The size of the field is varied by changing the rate of revolution of the rotor with the variable

frequency drive.

Once in the retention zone, the concentrated heavy fraction is withdrawn continuously through a series of

plane mass flow hoppers distributed evenly around the perimeter of the rotor.

The flow of heavy fraction or underflow is controlled by the Falcons patented throttling nozzles. This

heavy solid fraction is deposited in an annular launder, which is provided with two opposing discharge

points. Water can be added in the launder to dilute this stream which is normally >70% solids.

The lighter solid fraction or overflow and most of the associated process water flow upward and are

discharged into an outer launder and ultimately conducted away from the machine.

Sepro Mineral Systems Corp.

Page | 1-3

C1000-R3.1

Installation, Operations, and Maintenance Manual

1.3.2 Figure 1.3.1

Process Schematic

SLURRY FEED

RUBBER LINED LID

FEED PIPE

LIGHTS

LIGHTS

HIGH

HEAVIES

RETENTION

STRATIFICATION

HEAVIES

IMPELLER

LAUNDERS

THROTTLING NOZZLES (30)

COMPRESSED AIR SUPPLY

(Introduced at Rotating Union)

All this is done through the Automation Package or AutoPac, strongly recommended on all production

units. The AutoPac includes a programmable variable frequency drive (VFD), PLC control, dynamic

braking, a pneumatic proportional valve (PPV), vibration switch and solenoids.

These are control various operating parameters including acceleration ramp, centrifugal field, deceleration

ramp, throttling nozzle pressure (heavy fraction discharge), automatic rinsing, and others. An external

operator interface with a 4-line display screen enables the user to program many of these operating

parameters without opening the enclosure.

Sepro Mineral Systems Corp.

Page | 1-4

S-ar putea să vă placă și

- GekkoDocument6 paginiGekkojlfyÎncă nu există evaluări

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDocument3 pagini2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyÎncă nu există evaluări

- GekkoDocument6 paginiGekkojlfyÎncă nu există evaluări

- Seguridad y TransporteDocument6 paginiSeguridad y TransportejlfyÎncă nu există evaluări

- Digital PresureDocument11 paginiDigital PresurejlfyÎncă nu există evaluări

- Selenoid eDocument9 paginiSelenoid ejlfyÎncă nu există evaluări

- Filtro de AireDocument7 paginiFiltro de AirejlfyÎncă nu există evaluări

- Jaw Part3Document6 paginiJaw Part3jlfy100% (1)

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocument4 pagini5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyÎncă nu există evaluări

- Falcon c1000Document9 paginiFalcon c1000jlfyÎncă nu există evaluări

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDocument6 paginiRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyÎncă nu există evaluări

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument8 paginiC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyÎncă nu există evaluări

- Jaw Part2Document6 paginiJaw Part2jlfyÎncă nu există evaluări

- Jaw Part1Document7 paginiJaw Part1jlfy0% (1)

- PitmanDocument7 paginiPitmanjlfyÎncă nu există evaluări

- Appendix A - Torque Specs Torque Charts: Standard Bolt Torque Metric Bolt TorqueDocument6 paginiAppendix A - Torque Specs Torque Charts: Standard Bolt Torque Metric Bolt TorquejlfyÎncă nu există evaluări

- Operation & Maintenance Manual Maintenance Checks: This Page Intentionally Left BlankDocument6 paginiOperation & Maintenance Manual Maintenance Checks: This Page Intentionally Left BlankjlfyÎncă nu există evaluări

- Operation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw CrushersDocument4 paginiOperation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw CrushersjlfyÎncă nu există evaluări

- Chancadora TrioDocument123 paginiChancadora Triojlfy100% (1)

- Operation & Maintenance Manual What Is Lockout & Tagout?: This Page Intentionally Left BlankDocument6 paginiOperation & Maintenance Manual What Is Lockout & Tagout?: This Page Intentionally Left BlankjlfyÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Graphs of Quadratic EquationsDocument10 paginiGraphs of Quadratic EquationsROSLINA BINTI ABDUL RASHID MoeÎncă nu există evaluări

- Civil GeomechanicsAndStructuresDocument64 paginiCivil GeomechanicsAndStructuresJOE G PHILIP CEÎncă nu există evaluări

- CNC Lathe Machining CatiaDocument82 paginiCNC Lathe Machining CatiamasoudÎncă nu există evaluări

- 11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFDocument328 pagini11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFTheresaÎncă nu există evaluări

- Radiation ProcessesDocument20 paginiRadiation ProcessesAnmol MalgotraÎncă nu există evaluări

- Trial MRSM SPM 2014 Physics K2 No SkemaDocument37 paginiTrial MRSM SPM 2014 Physics K2 No SkemajeglilaÎncă nu există evaluări

- Manual CTI Technical Manual PDFDocument39 paginiManual CTI Technical Manual PDFaricomen43% (7)

- 3 Die CuttingDocument41 pagini3 Die CuttingNarendrareddy RamireddyÎncă nu există evaluări

- Water Stagnant of Solar ModulesDocument6 paginiWater Stagnant of Solar ModulesNITIN MISHRAÎncă nu există evaluări

- NgspicemanualDocument517 paginiNgspicemanualronakmehta31Încă nu există evaluări

- Notes Engineering SurveyDocument73 paginiNotes Engineering Surveyxai_hafeezÎncă nu există evaluări

- Semiconductor Memories Semiconductor Memories Semiconductor Memories Semiconductor MemoriesDocument37 paginiSemiconductor Memories Semiconductor Memories Semiconductor Memories Semiconductor MemoriesPriyank DevpuraÎncă nu există evaluări

- A Detailed Lesson Plan in Science 10Document9 paginiA Detailed Lesson Plan in Science 10Maricae NathanielÎncă nu există evaluări

- Characterizing Metallic Microstructure Cu-Based AlloysDocument51 paginiCharacterizing Metallic Microstructure Cu-Based AlloysjuegyiÎncă nu există evaluări

- Cromax 4140 PDFDocument2 paginiCromax 4140 PDFDidik PrihantoroÎncă nu există evaluări

- Worksheet em WavesDocument2 paginiWorksheet em WavesYug GandhiÎncă nu există evaluări

- Carbon-Carbon Composites A Summary of Recent Developments and ApplicationsDocument5 paginiCarbon-Carbon Composites A Summary of Recent Developments and Applicationsdroessaert_stijn100% (1)

- Surface PlateDocument3 paginiSurface PlateSaket OraonÎncă nu există evaluări

- Kaleay Hagos 2018Document34 paginiKaleay Hagos 2018ghouti ghoutiÎncă nu există evaluări

- Time Varying Fields and Maxwell's EquationsDocument14 paginiTime Varying Fields and Maxwell's EquationsDevender MaddyÎncă nu există evaluări

- An Alternative Method For The Removal of Surfactants From WaterDocument7 paginiAn Alternative Method For The Removal of Surfactants From WatervahidÎncă nu există evaluări

- Treatment of Anchorage of Main Bars in Reinforced Concrete by Codes of Practice - A Critical Review (Part One: Straight Bar Anchorages)Document19 paginiTreatment of Anchorage of Main Bars in Reinforced Concrete by Codes of Practice - A Critical Review (Part One: Straight Bar Anchorages)Govind GauravÎncă nu există evaluări

- ANSI/AIHA Ventilation Standards - " A Consensus ApproachDocument132 paginiANSI/AIHA Ventilation Standards - " A Consensus ApproachSamiYousifÎncă nu există evaluări

- Course File & Lab (2) .File ListDocument3 paginiCourse File & Lab (2) .File ListRAMESHÎncă nu există evaluări

- Potential Difference WorksheetDocument2 paginiPotential Difference WorksheetDigCity DiggÎncă nu există evaluări

- Differential Equations: Learning ObjectivesDocument17 paginiDifferential Equations: Learning ObjectiveskalyanÎncă nu există evaluări

- PLSC 0013Document7 paginiPLSC 0013balaji100% (1)

- Acido AceticoDocument13 paginiAcido Aceticoting_tatÎncă nu există evaluări

- Cross Taping - A Practical Guide 12Document2 paginiCross Taping - A Practical Guide 12jfjjfjfjjfjfÎncă nu există evaluări

- Presented By:: ASQ Section 0700 ASQ Section 0701Document35 paginiPresented By:: ASQ Section 0700 ASQ Section 0701fennyÎncă nu există evaluări