Documente Academic

Documente Profesional

Documente Cultură

Cellular Glass

Încărcat de

Sergio PereiraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cellular Glass

Încărcat de

Sergio PereiraDrepturi de autor:

Formate disponibile

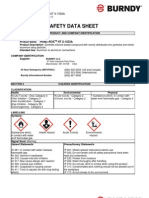

FOAMGLAS Insulation

Safety Data Sheet

SECTION 1 IDENTIFICATION

Product Name: FOAMGLAS insulation, FOAMGLAS ONE insulation, FOAMGLAS HLB insulation

Manufacturer/Supplier:

Pittsburgh Corning Corporation

800 Presque Isle Drive

Pittsburgh, PA 15239

Information Number: 724-327-6100

CHEMTREC:

800/424-9300

Generic Name:

Cellular glass insulation

Use:

Insulation of tanks, spheres, piping, roofs and equipment. For professional use

only.

Chemical Family:

Mixture

General

Comments:

General information and emergency information available 8:00 AM 5:00 PM

Monday through Friday.

CHEMTREC telephone number is to be used only in the event of chemical transportation emergencies

involving a spill, leak, fire, exposure, or accident involving chemicals. All non-emergency questions

should be directed to technical service.

SECTION 2 HAZARD(S) IDENTIFICATION

HAZARD CLASSIFICATION:

Potential Irritant

SIGNAL WORD:

WARNING

HAZARD STATEMENT:

Dust in contact with skin will cause irritation.

Direct contact of dust with eyes will cause eye

irritation.

HAZARDOUS

POLYMERIZATION:

Will Not Occur

ROUTES OF EXPOSURE:

Inhalation, Skin, Eyes and Ingestion.

IMMEDIATE EFFECTS:

INHALATION:

Inhalation of cell gas may produce headache, nausea, and difficult

breathing, dizziness. The sense of smell may be fatigued over time.

The odor and irritating effects do not offer dependable warning to

workers who may be exposed to gradually increasing amounts and

therefore become used to it.

SKIN CONTACT:

Irritation or abrasion from glass particles.

EYE CONTACT:

Contact can cause severe irritation, inflammation of the mucous

membrane, tearing, and sensitivity to light.

FOAMGLAS SDS 03132014.docx

March 13, 2014

FOAMGLAS Insulation

INGESTION:

Safety Data Sheet

May be harmful if ingested, although this is not a likely route of entry.

Ingestion can cause possible abrasion of mouth and throat from glass

particles.

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE:

ACUTE:

Preexisting skin and eye disorders may be aggravated by direct

contact to this product.

CHRONIC:

Prolonged or repeated overexposure to airborne glass dust can lead

to inflammation and scarring of lung tissue.

CARCINOGENICITY:

There are no components in this product that are listed as a

carcinogen by NTP, IARC, ACGIH or OSHA.

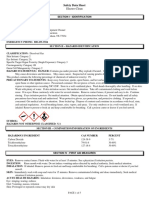

SECTION 3 - COMPOSITION/INFORMATION ON INGREDIENTS

Ingredient

App. % by Vol.

CAS #

Hydrogen Sulfide

< 0.1

7783-06-4

Carbon Monoxide

< 0.1

630-08-0

Carbon Dioxide

> 90

124-38-9

Varies

NA

Glass Dust

SECTION 4 FIRST AID MEASURES

GENERAL

ADVICE:

Obtain special instructions before use. Never give anything by mouth to an

unconscious person. If you feel unwell, seek medical advice (show the label if

possible)

INHALATION:

Move the exposed person to fresh air at once, apply artificial respiration if needed.

Call poison center, physician or emergency medical service giving CAS names and

numbers of gases. Encourage victim to cough, spit out, and blow nose to remove

dust. If breathing is difficult, GET MEDICAL ATTENTION.

SKIN CONTACT:

Wash thoroughly without pressure. If irritation persists or skin is broken, consult

physician.

EYE CONTACT:

Flush with potable water for 15 minutes, do not rub or apply pressure. Consult

physician or emergency medical service.

INGESTION:

An unlikely route of entry. Wash out mouth with water provided person is

conscious. Never give anything by mouth to an unconscious person. Call a

physician immediately

FOAMGLAS Industry

2 of 7

March 13, 2014

FOAMGLAS Insulation

Safety Data Sheet

SECTION 5 FIRE FIGHTING MEASURES

SUITABLE EXTINGUISHING MEDIA:

Fine Water Spray, CO2, Dry Chemical, Foam. If entering a

confined area, use self-contained breathing apparatus.

EXPLOSION DATA:

SENSITIVITY TO MECHANICAL IMPACT: NA

SENSITIVITY TO STATIC DISCHARGE: NA

UNUSUAL FIRE AND EXPLOSION

HAZARDS:

None. This product is not flammable.

HAZARDOUS COMBUSTION

PRODUCTS:

None known.

SPECIAL FIRE FIGHTING MEASURES:

May release small amounts of hydrogen sulfide and carbon

monoxide gas when involved in a fire. The small amounts

of hydrogen sulfide and carbon monoxide released are not

expected to contribute to the intensity of a fire. Wear selfcontained breathing apparatus and protective clothing.

SECTION 6 ACCIDENTAL RELEASE MEASURES

PRECAUTIONS FOR

PERSONNEL:

Do not get in eyes, on skin, or on clothing. Do not breathe dust. Avoid

generating dust

Wear personal protective equipment. Refer to recommendations in section 8.

Avoid contact with eyes, skin and clothing.

Wash thoroughly after handling and before eating or drinking.

ENVIRONMENTAL

PRECAUTIONS:

Ensure adequate ventilation. Use dustless methods. All in accordance with

local, state and federal government regulations.

PROCESS FOR

CLEANING:

Collect in sift proof containers. Avoid generation of dust.

REGULATORY

REQUIREMENTS:

Follow applicable OSHA regulations (29 CFR 1910.120).

SECTION 7 HANDLING AND STORAGE

HANDLING:

Avoid generation of dust. Wash hands before eating, drinking, smoking or using toilet.

Keep out of reach of children.

STORAGE:

If storing for long periods, protect product from weather.

FOAMGLAS Industry

3 of 7

March 13, 2014

FOAMGLAS Insulation

Safety Data Sheet

SECTION 8 EXPOSURE RESTRICTIONS AND PERSONAL PROTECTION

Ingredient

App. % by Vol.

Hydrogen Sulfide

<0.1

Carbon Monoxide

<0.1

Carbon Dioxide

>90

Varies

Glass Dust

EXPOSURE LIMITS

TLV

NIOSH

PEL

REL TWA

10 ppm

1 ppm

UN

TWA

50 ppm

25 ppm

UN

TWA

5000 ppm

5000 ppm

UN

TWA

15 mg/m3

5 mg/m3a

10 mg/m3

UN

a

( respirabl

e)

CAS #

7783-06-4

630-08-0

124-38-9

NA

EXPOSURE GUIDELINES:

When exposed to dust above recommended limits, wear a

suitable NIOSH-approved respirator with a protection factor

appropriate for the level of exposure. Seek guidance from a

qualified industrial hygienist or safety professional, prior to

respirator selection and use.

ENGINEERING CONTROLS:

When cutting, grinding, crushing, or drilling FOAMGLAS

insulation, provide general or local ventilation systems, as

needed, to maintain airborne dust concentrations below the

regulatory limits. Local vacuum collection is preferred since

it prevents release of contaminants into the work area by

controlling it at the source. Other technologies that may aid

in controlling airborne respirable dust include wet

suppression, ventilation, process enclosure, and enclosed

employee work stations.

.

PERSONAL PROTECTIVE EQUIPMENT:

EYE PROTECTION:

When cutting, grinding, crushing, or drilling FOAMGLAS

insulation, wear safety glasses with side shields or dust

goggles in dusty environments. Wear goggles for dust

protection while cutting or abrading in wind or overhead

work.

SKIN PROTECTION:

Wear rubber impregnated canvas gloves for abrasion

protection. Wear normal protective work clothing with long

sleeved shirt.

RESPIRATORY

PROTECTION:

FOAMGLAS Industry

Use nuisance dust mask when cutting or abrading with

adequate ventilation. Seek guidance from a qualified

industrial hygienist or safety professional, prior to dust

mask/respirator selection and use. (Supplied air or selfcontained breathing apparatus in poorly ventilated areas is

required when cutting or crushing of FOAMGLAS insulation

causes PEL of hydrogen sulfide and carbon monoxide gases

to be exceeded.

4 of 7

March 13, 2014

FOAMGLAS Insulation

Safety Data Sheet

ENVIRONMENTAL EXPOSURE

CONTROL:

Use local exhaust when cutting. Use mechanical ventilation

when crushing large volumes.

WORK/HYGIENIC PRACTICES:

Avoid contact with eyes and skin. Wash thoroughly after

handling and before eating or drinking.

SPECIAL PRECAUTIONS:

Respirable dust particles may be generated by crushing,

cutting, grinding or drilling FOAMGLAS insulation. Follow

protective controls listed in the Exposure Guidelines above

when handling these products.

SECTION 9 PHYSICAL PROPERTIES

Odor Threshold:

pH

Black cellular

solid

no odor unless

cut or crushed,

rotten egg odor

when cells are

crushed or cut

0.002 ppm

NA

Melting Point/Freezing Point: C (F)

732 (1350)

Boiling Point: C (F)

Solubility in Water:

Partition Coefficient: n-octanol/water:

Viscosity

VOC: g/l (lbs./gal)

NA

Insoluble

NA

NA

0.0 (0.0)

Appearance:

Odor:

Flash Point : C (F) TCC

NA

Ignition Temperature: C (F)

NA

Evaporation Rate (BuAC=1)

Flammability:

Flammable Limits:

LEL

UEL

Vapor Pressure: (MM Hg): pH:

Vapor Density: (Air = 1)

Specific Gravity: (H20 = 1):

Evaporation Rate: (BuAC=1)

Percent Volatile By Volume: (%)

NA

Non-Flammable

NA

NA

NA

NA

0.11 0.22

NA

NA

SECTION 10 STABILITY AND REACTIVITY

REACTIVITY:

Hazardous reactions will not occur under normal

conditions.

STABILITY:

Stable

POSSIBILITY OF HAZARDOUS

REACTIONS:

Hazardous reaction will not occur

CONDITIONS TO AVOID:

NA

MATERIALS TO AVOID:

NA

DECOMPOSITION PRODUCTS:

None

FOAMGLAS Industry

5 of 7

March 13, 2014

FOAMGLAS Insulation

Safety Data Sheet

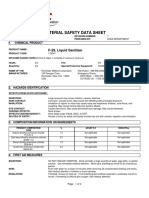

SECTION 11 TOXICOLOGICAL INFORMATION

CAS #

INGREDIENT

DERMAL LD50

7783-06-4

Hydrogen Sulfide

NE

630-08-0

Carbon Monoxide

NE

124-38-9

NA

Carbon Dioxide

Glass Dust

NE

NE

CAS #

INGREDIENT

7783-06-4

630-08-0

124-38-9

NA

Hydrogen Sulfide

Carbon Monoxide

Carbon Dioxide

Glass Dust

CARCINOGENICITY

ACGIH

IARC

NE

NE

NE

NE

NE

NE

NE

NE

INHALATION LD50

444 ppm-rat

634 ppm-mus

1807 ppm-rat

2444 ppm-mus

NE

NE

ORAL LD50

TERATOGENICITY

MUTAGENICITY

NE

NE

NE

NE

NE

NE

NE

NE

NE

NE

NE

NE

SECTION 12 ECOLOGICAL INFORMATION

BIODEGRADATION: NA

BIOACCUMULATION: NA

AQUATIC TOXICITY: NA

OTHER INFORMATION: None

SECTION 13 DISPOSAL CONSIDERATIONS

DISPOSAL METHOD:

Dispose of waste material in accordance with all local, regional, national,

provincial, territorial and international regulations.

SECTION 14 TRANSPORT INFORMATION

SPECIAL SHIPPING INFORMATION:

DOT SHIPPING CLASS:

TDG

IATA

FOAMGLAS Industry

Not regulated

Not regulated.

Not regulated.

Not regulated

6 of 7

March 13, 2014

FOAMGLAS Insulation

Safety Data Sheet

SECTION 15 REGULATORY INFORMATION

US Regulatory Information

OSHA 29 CFR 1910-1200

TSCA

Irritant

All components of this product are listed on TSCA

Inventory

SARA Title III:

SARA SECTION 302:

SARA SECTION 304:

SARA (311,312) HAZARD CLASS:

SARA (313) CHEMICALS:

CERCLA:

RCRA:

CPSC CLASSIFICATION:

None

NA

None

None

NA

Refer to section 13

NA

HMIS:

FLAMMABILITY:

REACTIVITY:

HEALTH:

NFPA:

FLAMMABILITY:

REACTIVITY:

HEALTH:

WHMIS CLASSIFICATION:

D2B

CALIFORNIA PROPOSITION 65:

A. This product contains a chemical known to the State of CA to cause birth defects or other

reproductive harm.

B. This product contains a chemical known to the State of CA to cause cancer.

C. This product contains a chemical known to the State of CA to cause cancer and birth defects or

other reproductive harm.

SECTION 16 OTHER INFORMATION

Prepared in accordance with 29 CFR 1910.1200

This Product has been classified in accordance with the hazard criteria of the Controlled Products

NA = not applicable

NEGL = Negligible

NE = not established

PROP. = Proprietary

UN = unavailable

CL = Ceiling Limit

THE DATA INCLUDED HEREIN ARE PRESENTED IN ACCORDANCE WITH THE VARIOUS ENVIRONMENT, HEALTH AND SAFETY REGULATIONS. IT IS THE RESPONSIBILITY

OF A RECIPIENT OF THIS DATA TO REMAIN CURRENTLY INFORMED ON CHEMICAL HAZARD INFORMATION, TO DESIGN AND UPDATE ITS INFORMED ON CHEMICAL

HAZARD INFORMATION, TO DESIGN AND UPDATE ITS OWN PROGRAM AND TO COMPLY WITH ALL NATIONAL, FEDERAL, STATE AND LOCAL LAWS AND REGULATIONS

APPLICABLE TO SAFETY, OCCUPATIONAL HEALTH, RIGHT-TO-KNOW AND ENVIRONMENTAL PROTECTION.

WHILE THE INFORMATION AND RECOMMENDATIONS SET FORTH HEREIN ARE BELIEVED TO BE ACCURATE, PITTSBURGH CORNING MAKES NO WARRANTY WITH

RESPECT THERETO, AND DISCLAIMS ALL LIABILITY FROM RELIANCE THEREON.

FOAMGLAS is a registered trademark of Pittsburgh Corning.

FOAMGLAS Industry

7 of 7

March 13, 2014

S-ar putea să vă placă și

- CertainTeed Fiberglass Insulation MSDSDocument10 paginiCertainTeed Fiberglass Insulation MSDSbsiofncÎncă nu există evaluări

- Used Oil MsdsDocument7 paginiUsed Oil Msdspequenita34Încă nu există evaluări

- Elkon Products - Silica Fume MSDS, April 2013Document11 paginiElkon Products - Silica Fume MSDS, April 2013Sigit PurwandiÎncă nu există evaluări

- Dr. P. Clean MSDSDocument6 paginiDr. P. Clean MSDSjayand_netÎncă nu există evaluări

- Rockwool Pipe MSDSDocument5 paginiRockwool Pipe MSDSJullius CarballoÎncă nu există evaluări

- Msds Formalin - 2Document4 paginiMsds Formalin - 2somara natalisÎncă nu există evaluări

- Sigma Paints 21-06Document6 paginiSigma Paints 21-06Asela BollegalaÎncă nu există evaluări

- modified starch MSDSDocument5 paginimodified starch MSDSdewi.mizobataÎncă nu există evaluări

- PENETROXTM A OXIDE INHIBITING COMPOUND Safety Data SheetDocument10 paginiPENETROXTM A OXIDE INHIBITING COMPOUND Safety Data SheetyesrtyÎncă nu există evaluări

- MSDS SolarguardDocument5 paginiMSDS SolarguardKeyleen LinaresÎncă nu există evaluări

- Safety Data Sheet: Spotcheck SKC-S - AerosolDocument6 paginiSafety Data Sheet: Spotcheck SKC-S - AerosolChandrasekhar SonarÎncă nu există evaluări

- DMDS MSDSDocument11 paginiDMDS MSDSamirhosseine00Încă nu există evaluări

- 3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDSDocument7 pagini3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDSRick OshayÎncă nu există evaluări

- 3D Trasar® 3DT120 PDFDocument10 pagini3D Trasar® 3DT120 PDFwjawichÎncă nu există evaluări

- Material Safety Data Sheet: Section 1 Identification of The Substance/Preparation and of The Company/UndertakingDocument5 paginiMaterial Safety Data Sheet: Section 1 Identification of The Substance/Preparation and of The Company/UndertakingAnonymous gUySMcpSqÎncă nu există evaluări

- MSDS of AB GlueDocument10 paginiMSDS of AB GlueThanhnam PhanÎncă nu există evaluări

- Weld-On 3 MsdsDocument2 paginiWeld-On 3 MsdsSergio SanchezÎncă nu există evaluări

- SDS Cellosize QP 15000 H ISS150320 EnglishDocument7 paginiSDS Cellosize QP 15000 H ISS150320 EnglishJulie Umbarila GutierrezÎncă nu există evaluări

- Material Safety Data Sheet: Coupling GreaseDocument6 paginiMaterial Safety Data Sheet: Coupling GreaserefeiÎncă nu există evaluări

- 1250 White Sds PDFDocument4 pagini1250 White Sds PDFkwerwaÎncă nu există evaluări

- 1240 EnglishDocument8 pagini1240 EnglishNikos StamopoulosÎncă nu există evaluări

- EverGreen MSDS 05.12Document5 paginiEverGreen MSDS 05.12AuburnMfgÎncă nu există evaluări

- MSDS AlumDocument5 paginiMSDS Alumdhinda clariestaÎncă nu există evaluări

- MSDS - Anionic Polyacrylamide - "Snow": Section 1: Name & Hazard SummaryDocument5 paginiMSDS - Anionic Polyacrylamide - "Snow": Section 1: Name & Hazard SummaryNashruÎncă nu există evaluări

- 492 MSDSDocument5 pagini492 MSDSsrinivignaÎncă nu există evaluări

- Safety Data Sheet: Exxonmobil Lubricants & Specialties Europe, A Division of Exxonmobil Petroleum & Chemical, Bvba (Empc)Document8 paginiSafety Data Sheet: Exxonmobil Lubricants & Specialties Europe, A Division of Exxonmobil Petroleum & Chemical, Bvba (Empc)Ali YasinÎncă nu există evaluări

- Penetrox HT x-1552 A (GHS)Document10 paginiPenetrox HT x-1552 A (GHS)yesrtyÎncă nu există evaluări

- ABRO Spray Paint PDFDocument6 paginiABRO Spray Paint PDFAnonymous QQZcso63% (8)

- Material Safety Data Sheet: Product: Woodkeeper Wood StainerDocument6 paginiMaterial Safety Data Sheet: Product: Woodkeeper Wood StainerPuneeth RajÎncă nu există evaluări

- Safety Data Sheet: Penetrox A-13 Oxide Inhibiting Compound Product NameDocument8 paginiSafety Data Sheet: Penetrox A-13 Oxide Inhibiting Compound Product NameTAEWARAT RAKRUANGÎncă nu există evaluări

- Electro-Clean SDS Safety SummaryDocument5 paginiElectro-Clean SDS Safety Summaryaldrin de guzmanÎncă nu există evaluări

- Knauf Insulation GMBH Material Safety Data Sheet: Section I - Chemical Product and Company IdentificationDocument4 paginiKnauf Insulation GMBH Material Safety Data Sheet: Section I - Chemical Product and Company IdentificationAvicena AlbiruniÎncă nu există evaluări

- FOAMGLAS® Insulation SDSDocument7 paginiFOAMGLAS® Insulation SDSAyman JadÎncă nu există evaluări

- MSDS PC1003R Gc9atDocument7 paginiMSDS PC1003R Gc9atNguyễn Hồng NamÎncă nu există evaluări

- Aculon NanoProof 5.0X SDSDocument9 paginiAculon NanoProof 5.0X SDSAlan TanÎncă nu există evaluări

- Molykote 1000 Paste MSDSDocument9 paginiMolykote 1000 Paste MSDSNikola Polimenov100% (1)

- Ely Supramor4 Black MPI SprayDocument5 paginiEly Supramor4 Black MPI SprayFaiz FalehÎncă nu există evaluări

- Identification of Product and Company: Safety Data Sheet INK 70000-00034Document5 paginiIdentification of Product and Company: Safety Data Sheet INK 70000-00034Hector GaracheÎncă nu există evaluări

- Material Safety Data Sheet: F-29, Liquid SanitizerDocument4 paginiMaterial Safety Data Sheet: F-29, Liquid SanitizerNiraÎncă nu există evaluări

- Product and Company Identification: Safety Data SheetDocument6 paginiProduct and Company Identification: Safety Data SheetGabo TellezÎncă nu există evaluări

- Material Safety Data Sheet Furan Resin Section I - Product & Company IdentificationDocument4 paginiMaterial Safety Data Sheet Furan Resin Section I - Product & Company IdentificationSHAIK ASIMUDDINÎncă nu există evaluări

- MSDS for Elastomeric SealantDocument7 paginiMSDS for Elastomeric SealantNIKKA MANAHANÎncă nu există evaluări

- MSDS Sodium NitriteDocument5 paginiMSDS Sodium NitritemarcÎncă nu există evaluări

- Alfamar MsdsDocument6 paginiAlfamar Msdsvangeliskyriakos8998Încă nu există evaluări

- Coal Cure SDSDocument9 paginiCoal Cure SDSIvan OsipovÎncă nu există evaluări

- Material Safety Data Sheet: 1. Company and Product IdentificationDocument8 paginiMaterial Safety Data Sheet: 1. Company and Product IdentificationYan MoraesÎncă nu există evaluări

- Safety Data Sheet - Petroleum CokeDocument7 paginiSafety Data Sheet - Petroleum CokeStephen BoyleÎncă nu există evaluări

- Cetus de 100 UsDocument6 paginiCetus de 100 UsAustin UdofiaÎncă nu există evaluări

- Urea4600 Msds - 2Document7 paginiUrea4600 Msds - 2sahilchemÎncă nu există evaluări

- TYRIN-200Document10 paginiTYRIN-200Nicol AlejandraÎncă nu există evaluări

- Safety Data Sheet: TECTYL 506 RAL 5008Document6 paginiSafety Data Sheet: TECTYL 506 RAL 5008sureshÎncă nu există evaluări

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 paginiMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1Încă nu există evaluări

- Gilsonite MSDSDocument6 paginiGilsonite MSDSPT. SURYAGITA NUSARAYAÎncă nu există evaluări

- Chevron Sri Grease MsdsDocument9 paginiChevron Sri Grease MsdsRonald AranhaÎncă nu există evaluări

- Sigma Thinner 91 - 92Document7 paginiSigma Thinner 91 - 92mevansmetreelÎncă nu există evaluări

- Coke Msds (Opal)Document6 paginiCoke Msds (Opal)Viral PatelÎncă nu există evaluări

- Sds For 60 Powder 20191231 - ENDocument7 paginiSds For 60 Powder 20191231 - ENCarrie WuÎncă nu există evaluări

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesDe la EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesÎncă nu există evaluări

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEDe la EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEÎncă nu există evaluări

- Unidentified Remains Provide CluesDocument15 paginiUnidentified Remains Provide CluestrisnaÎncă nu există evaluări

- Unit 2Document1 paginăUnit 2Чыонг ТанÎncă nu există evaluări

- 2017 VF Product Safety ManualDocument78 pagini2017 VF Product Safety Manualdesly raini mutiara dewiÎncă nu există evaluări

- Risala - Ibn Fadlan's Account of The RusDocument28 paginiRisala - Ibn Fadlan's Account of The RusErika Campos-CorrentinÎncă nu există evaluări

- 087176Document1.420 pagini087176AdvocateÎncă nu există evaluări

- Executive SummaryDocument2 paginiExecutive SummarySohel SiddiquiÎncă nu există evaluări

- Komatsu Hydraulic Excavator Pc210lc 11 Hydraulic Electric Circuit DiagramsDocument22 paginiKomatsu Hydraulic Excavator Pc210lc 11 Hydraulic Electric Circuit Diagramsbrianwong090198pni100% (12)

- IXCHEL ManuscriptDocument30 paginiIXCHEL ManuscriptcherylannmillsÎncă nu există evaluări

- The Age of Industrialization PDFDocument5 paginiThe Age of Industrialization PDFSivasankar50% (2)

- Splice BookDocument30 paginiSplice BooklmantuanoÎncă nu există evaluări

- Curso de Inglés para Ingeniería IndustrialDocument110 paginiCurso de Inglés para Ingeniería Industrialygnacio rodriguez rosarioÎncă nu există evaluări

- English: Quarter 1 - Module 3Document9 paginiEnglish: Quarter 1 - Module 3Maribel A. BustilloÎncă nu există evaluări

- Relative Clauses Exercise 1Document3 paginiRelative Clauses Exercise 1Léo KostasÎncă nu există evaluări

- Jawani Ka NashaDocument1.775 paginiJawani Ka Nashatarrriq54% (13)

- FLOW OF WORK IN A BUYING HOUSE Week 2Document5 paginiFLOW OF WORK IN A BUYING HOUSE Week 2aman rajÎncă nu există evaluări

- Fundamentals of Nursing Bed Bath & PositioningDocument3 paginiFundamentals of Nursing Bed Bath & PositioningRowena SamsonÎncă nu există evaluări

- Examples of Dirty Talk With A High Class Hooker GirlfriendDocument1 paginăExamples of Dirty Talk With A High Class Hooker GirlfriendNanda Singh100% (1)

- Alexander, Lloyd - Westmark 2 - The KestrelDocument374 paginiAlexander, Lloyd - Westmark 2 - The KestrelDragosPinoÎncă nu există evaluări

- AbacáDocument3 paginiAbacáapi-3830277Încă nu există evaluări

- The Boat by Alistair MacLeod PDFDocument25 paginiThe Boat by Alistair MacLeod PDFramzyjunior2004Încă nu există evaluări

- Bandaging GNMDocument46 paginiBandaging GNMjoslinjohn100% (2)

- User'S Manual: Questions?Document36 paginiUser'S Manual: Questions?dianÎncă nu există evaluări

- The Universe Is On The FloorDocument92 paginiThe Universe Is On The FloorDan Nothingness DeMarseÎncă nu există evaluări

- Honeywell Spectra High Tenacity Super Line LRDocument2 paginiHoneywell Spectra High Tenacity Super Line LRMd Abu ShohagÎncă nu există evaluări

- Balloon Price List LeafletDocument2 paginiBalloon Price List LeafletHolly-Jane WoontonÎncă nu există evaluări

- The History of Fashion Journalism (PDFDrive)Document318 paginiThe History of Fashion Journalism (PDFDrive)蛍小百合100% (6)

- Aibileen and Skeeter's JourneyDocument61 paginiAibileen and Skeeter's Journeygaryart111Încă nu există evaluări

- Hard Hat Safety TipsDocument2 paginiHard Hat Safety TipsWelma JohnsonÎncă nu există evaluări

- Long Hair LoveDocument5 paginiLong Hair LoveManjunath UBÎncă nu există evaluări

- Walters A Meredith-Cloud WalkingDocument77 paginiWalters A Meredith-Cloud Walkingkitty240790% (1)