Documente Academic

Documente Profesional

Documente Cultură

Operations Management Operations Management: Chapter 6 - Managing Quality Chapter 6 - Managing Quality

Încărcat de

kennethllantosTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Operations Management Operations Management: Chapter 6 - Managing Quality Chapter 6 - Managing Quality

Încărcat de

kennethllantosDrepturi de autor:

Formate disponibile

9/20/2012

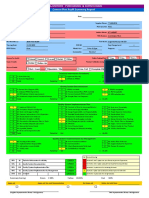

Operations

Management

Chapter 6

Managing Quality

PowerPoint presentation to accompany

Heizer/Render

Principles of Operations Management, 6e

Operations Management, 8e

2006

Prentice

Hall, Inc.Hall, Inc.

2006

Prentice

61

Outline

Global Company Profile: Arnold

Palmer Hospital

Quality And Strategy

Defining Quality

Implications of Quality

Malcolm Baldrige National Quality

Award

Cost of Quality (COQ)

2006 Prentice Hall, Inc.

62

9/20/2012

Outline Continued

Ethics and Quality Management

International Quality Standards

ISO 9000

ISO14000

2006 Prentice Hall, Inc.

63

Outline Continued

Total Quality Management

Continuous Improvement

Six Sigma

Employee Empowerment

Benchmarking

Just

Just--in

in--Time (JIT)

Taguchi Concepts

Knowledge of TQM Tools

2006 Prentice Hall, Inc.

64

9/20/2012

Outline Continued

Tools Of TQM

Check Sheets

Scatter Diagrams

Cause

Cause--and

and--Effect Diagram

Pareto Charts

Flow Charts

Histograms

Statistical Process Control (SPC)

2006 Prentice Hall, Inc.

65

Outline Continued

The Role Of Inspection

When and Where to Inspect

Source Inspection

Service Industry Inspection

Inspection of Attributes versus

Variables

TQM In Services

2006 Prentice Hall, Inc.

66

9/20/2012

Learning Objectives

When you complete this chapter, you

should be able to:

Identify or Define:

Quality

Malcolm Baldrige National Quality

Award

ISO International Quality Standards

Taguchi Concepts

2006 Prentice Hall, Inc.

67

Learning Objectives

When you complete this chapter, you

should be able to:

Explain:

Why quality is important

Total Quality Management (TQM)

Seven tools of TQM

Quality robust products

Deming, Juran, Feigenbaum, and

Crosbys ideas

2006 Prentice Hall, Inc.

68

9/20/2012

Managing Quality Provides a

Competitive Advantage

Arnold Palmer Hospital

Deliver over 10,000 babies annually

Virtually every type of quality tool is

employed

Continuous improvement

Employee empowerment

Benchmarking

Just

Just--in

in--time

Quality tools

2006 Prentice Hall, Inc.

69

Quality and Strategy

Managing quality supports

differentiation, low cost, and

response strategies

Quality helps firms increase sales

and reduce costs

Building a quality organization is a

demanding task

2006 Prentice Hall, Inc.

6 10

9/20/2012

Ways Quality Improves

Productivity

Sales Gains

Improved response

Higher Prices

Improved

Quality

Improved reputation

Reduced Costs

Increased productivity

Increased

Profits

Lower rework and scrap costs

Lower warranty costs

Figure 6.1

2006 Prentice Hall, Inc.

6 11

The Flow of Activities

Organizational Practices

Leadership, Mission statement, Effective operating

procedures, Staff support, Training

Yields: What is important and what is to be accomplished

Quality Principles

Customer focus, Continuous improvement, Benchmarking,

Just-in-time, Tools of TQM

Yields: How to do what is important and to be

accomplished

Employee Fulfillment

Empowerment, Organizational commitment

Yields: Employee attitudes that can accomplish

what is important

Figure 6.2

2006 Prentice Hall, Inc.

Customer Satisfaction

Winning orders, Repeat customers

Yields: An effective organization with

a competitive advantage

6 12

9/20/2012

Defining Quality

The totality of features and

characteristics of a product or

service that bears on its ability to

satisfy stated or implied needs

American Society for Quality

2006 Prentice Hall, Inc.

6 13

Different Views

User

User--based better performance,

more features

Manufacturing

Manufacturing--based

conformance to standards,

making it right the first time

Product

Product--based specific and

measurable attributes of the

product

2006 Prentice Hall, Inc.

6 14

9/20/2012

Implications of Quality

1. Company reputation

Perception of new products

Employment practices

Supplier relations

2. Product liability

Reduce risk

3. Global implications

Improved ability to compete

2006 Prentice Hall, Inc.

6 15

Key Dimensions of Quality

Performance

Durability

Features

Serviceability

Reliability

Aesthetics

Conformance

Perceived quality

Value

2006 Prentice Hall, Inc.

6 16

9/20/2012

Malcom Baldrige National

Quality Award

Established in 1988 by the U.S.

government

Designed to promote TQM practices

Recent winners

The Bama Companies, Kenneth W.

Monfort College of Business,

Caterpillar Financial Services, Baptist

Hospital, Clarke American Checks,

Los Alamos National Bank

2006 Prentice Hall, Inc.

6 17

Baldrige Criteria

Applicants are evaluated on:

Categories

Leadership

Strategic Planning

Customer & Market Focus

Information & Analysis

Human Resource Focus

Process Management

Organizational Results

2006 Prentice Hall, Inc.

Points

120

85

85

90

85

85

450

6 18

9/20/2012

Takumi

A Japanese character

that symbolizes a

broader dimension

than quality, a deeper

process than

education, and a more

perfect method than

persistence

2006 Prentice Hall, Inc.

6 19

Costs of Quality

Prevention costs - reducing the

potential for defects

Appraisal costs - evaluating

products, parts, and services

Internal failure - producing defective

parts or service before delivery

External costs - defects discovered

after delivery

2006 Prentice Hall, Inc.

6 20

10

9/20/2012

Costs of Quality

Total

Cost

Total Cost

External Failure

Internal Failure

Prevention

Appraisal

Quality Improvement

2006 Prentice Hall, Inc.

6 21

International Quality

Standards

Industrial Standard Z8101Z8101-1981 (Japan)

Specification for TQM

ISO 9000 series (Europe/EC)

Common quality standards for products

sold in Europe (even if made in U.S.)

2000 update places greater emphasis on

leadership and customer satisfaction

ISO 14000 series (Europe/EC)

2006 Prentice Hall, Inc.

6 22

11

9/20/2012

ISO 14000

Environmental Standard

Core Elements:

Environmental management

Auditing

Performance evaluation

Labeling

Life

Life--cycle assessment

2006 Prentice Hall, Inc.

6 23

Leaders in Quality

W. Edwards Deming

14 Points for

Management

Joseph M. Juran

Top management

commitment,

fitness for use

Armand Feigenbaum

Total Quality

Control

Philip B. Crosby

Quality is Free

2006 Prentice Hall, Inc.

6 24

12

9/20/2012

Ethics and Quality

Management

Operations managers must

deliver healthy, safe, quality

products and services

Poor quality risks injuries,

lawsuits, recalls, and regulation

Organizations are judged by

how they respond to problems

2006 Prentice Hall, Inc.

6 25

TQM

Encompasses entire organization,

from supplier to customer

Stresses a commitment by

management to have a continuing,

companywide drive toward

excellence in all aspects of products

and services that are important to the

customer

2006 Prentice Hall, Inc.

6 26

13

9/20/2012

Demings Fourteen Points

1. Create consistency of purpose

2. Lead to promote change

3. Build quality into the product; stop

depending on inspection

4. Build long term relationships based on

performance, not price

5. Continuously improve product, quality,

and service

6. Start training

7. Emphasize leadership

Table 6.1

2006 Prentice Hall, Inc.

6 27

Demings Fourteen Points

8.

9.

10.

11.

12.

13.

14.

Drive out fear

Break down barriers between

departments

Stop haranguing workers

Support, help, improve

Remove barriers to pride in work

Institute a vigorous program of

education and selfself-improvement

Put everybody in the company to work

on the transformation

Table 6.1

2006 Prentice Hall, Inc.

6 28

14

9/20/2012

Seven Concepts of TQM

Continuous improvement

Six Sigma

Employee empowerment

Benchmarking

Just

Just--in

in--time (JIT)

Taguchi concepts

Knowledge of TQM tools

2006 Prentice Hall, Inc.

6 29

Continuous Improvement

Represents continual

improvement of all processes

Involves all operations and work

centers including suppliers and

customers

People, Equipment, Materials,

Procedures

2006 Prentice Hall, Inc.

6 30

15

9/20/2012

Shewharts PDCA Model

1.Plan

4. Act

Identify the

Implement improvement

and make

the plan

a plan

3. Check

Is the plan

working?

2. Do

Test the

plan

Figure 6.3

2006 Prentice Hall, Inc.

6 31

Six Sigma

Originally developed by Motorola,

Six Sigma refers to an extremely

high measure of process capability

A Six Sigma capable process will

return no more than 3.4 defects per

million operations (DPMO)

Highly structured approach to

process improvement

2006 Prentice Hall, Inc.

6 32

16

9/20/2012

Six Sigma

1. Define critical outputs

and identify gaps for

improvement

DMAIC Approach

2. Measure the work and

collect process data

3. Analyze the data

4. Improve the process

5. Control the new process to

make sure new performance

is maintained

2006 Prentice Hall, Inc.

6 33

Six Sigma Implementation

Emphasize DPMO as a standard metric

Provide extensive training

Focus on corporate sponsor support

(Champions)

Create qualified process improvement

experts (Black Belts, Green Belts, etc.)

Set stretch objectives

This cannot be accomplished without a major

commitment from top level management

2006 Prentice Hall, Inc.

6 34

17

9/20/2012

Employee Empowerment

Getting employees involved in product

and process improvements

85% of quality problems are due to process

and material

Techniques

Build communication networks that include

employees

Develop open, supportive supervisors

Move responsibility to employees

Build a highhigh-morale organization

Create formal team structures

2006 Prentice Hall, Inc.

6 35

Quality Circles

Group of employees who meet

regularly to solve problems

Trained in planning, problem

solving, and statistical methods

Often led by a facilitator

Very effective when done

properly

2006 Prentice Hall, Inc.

6 36

18

9/20/2012

Benchmarking

Selecting best practices to use as a

standard for performance

Determine what to

benchmark

Form a benchmark team

Identify benchmarking partners

Collect and analyze benchmarking

information

Take action to match or exceed the

benchmark

2006 Prentice Hall, Inc.

6 37

Best Practices for Resolving

Customer Complaints

Make it easy for clients to complain

Respond quickly to complaints

Resolve complaints on first contact

Use computers to manage

complaints

Recruit the best for customer

service jobs

2006 Prentice Hall, Inc.

6 38

19

9/20/2012

Just--in

Just

in--Time (JIT)

Relationship to quality:

JIT cuts the cost of quality

JIT improves quality

Better quality means less

inventory and better, easiereasier-to

to-employ JIT system

2006 Prentice Hall, Inc.

6 39

Just--in

Just

in--Time (JIT)

Pull system of production scheduling

including supply management

Production only when signaled

Allows reduced inventory levels

Inventory costs money and hides process

and material problems

Encourages improved process and

product quality

2006 Prentice Hall, Inc.

6 40

20

9/20/2012

Just--In

Just

In--Time (JIT) Example

Work in process

inventory level

(hides problems)

Unreliable

Vendors

Scrap

Capacity

Imbalances

2006 Prentice Hall, Inc.

6 41

Just--In

Just

In--Time (JIT) Example

Reducing inventory reveals

problems so they can be solved

Unreliable

Vendors

2006 Prentice Hall, Inc.

Scrap

Capacity

Imbalances

6 42

21

9/20/2012

Taguchi Concepts

Experimental design methods to

improve product and process design

Identify key component and process

variables affecting product variation

Taguchi Concepts

Quality robustness

Quality loss function

Target

Target--oriented quality

2006 Prentice Hall, Inc.

6 43

Quality Robustness

Ability to produce products

uniformly in adverse manufacturing

and environmental conditions

Remove the effects of adverse

conditions

Small variations in materials and

process do not destroy product

quality

2006 Prentice Hall, Inc.

6 44

22

9/20/2012

Quality Loss Function

Shows that costs increase as the

product moves away from what

the customer wants

Costs include customer

dissatisfaction, warranty and

service, internal scrap and repair,

and costs to society

Traditional conformance

specifications are too simplistic

2006 Prentice Hall, Inc.

6 45

Quality Loss Function

L = D2C

High loss

Unacceptable

Loss (to

producing

organization,

customer,

and society)

Poor

Good

Best

Low loss

where

L = loss to society

D = distance from

target value

C = cost of deviation

Target-oriented quality

Targetyields more product in

the best category

Target-oriented quality

Targetbrings product toward

the target value

Frequency

Conformance-oriented

Conformancequality keeps products

within 3 standard

deviations

Lower

2006 Prentice Hall, Inc.

Target

Upper

Specification

Figure 6.4

6 46

23

9/20/2012

Tools of TQM

Tools for Generating Ideas

Check sheets

Scatter diagrams

Cause and effect diagrams

Tools to Organize the Data

Pareto charts

Flow charts

Tools for Identifying Problems

Histogram

Statistical process control chart

2006 Prentice Hall, Inc.

6 47

Seven Tools for TQM

(a) Check Sheet: An organized method of

recording data

Defect

A

B

C

1

///

//

/

2

/

/

//

3

/

Hour

4

5

/

/

/

6

/

7

///

//

//

8

/

///

////

Figure 6.5

2006 Prentice Hall, Inc.

6 48

24

9/20/2012

Seven Tools for TQM

Productivity

(b) Scatter Diagram: A graph of the value

of one variable vs. another variable

Absenteeism

Figure 6.5

2006 Prentice Hall, Inc.

6 49

Seven Tools for TQM

(c) Cause and Effect Diagram: A tool that

identifies process elements (causes) that

might effect an outcome

Cause

Materials

Methods

Effect

Manpower

Machinery

Figure 6.5

2006 Prentice Hall, Inc.

6 50

25

9/20/2012

Seven Tools for TQM

Percent

Frequency

(d) Pareto Charts: A graph to identify and plot

problems or defects in descending order of

frequency

E

Figure 6.5

2006 Prentice Hall, Inc.

6 51

Seven Tools for TQM

(e) Flow Charts (Process Diagrams): A chart

that describes the steps in a process

Figure 6.5

2006 Prentice Hall, Inc.

6 52

26

9/20/2012

Seven Tools for TQM

(f) Histogram: A distribution showing the

frequency of occurrence of a variable

Frequency

Distribution

Repair time (minutes)

Figure 6.5

2006 Prentice Hall, Inc.

6 53

Seven Tools for TQM

(g) Statistical Process Control Chart: A chart with

time on the horizontal axis to plot values of a

statistic

Upper control limit

Target value

Lower control limit

Time

Figure 6.5

2006 Prentice Hall, Inc.

6 54

27

9/20/2012

Inadequate

supply of

magazines

Machinery

Deicing

equipment

not available

Material

& blankets

on--board

on

Insufficient

clean pillows

Cause--and

Cause

and--Effect Diagrams

Mechanical delay

on plane

Inadequate special

Broken luggage

meals onon-board

carousel

Dissatisfied

Airline

Customer

Understaffed

Overbooking policies

crew

Poorly trained

attendants

policies

bags

Mistagged

Methods

Poor checkcheck-in

Understaffed

Bumping policies

ticket counters

Manpower

Figure 6.6

2006 Prentice Hall, Inc.

6 55

Pareto Charts

Data for October

Frequency (number)

60

54

72

50

40

Number of

occurrences

30

20

12

10

Minibar

4%

Misc.

3%

0

Room svc

72%

Check-in Pool hours

Check16%

5%

Cumulative percent

100

93

88

70

Causes and percent

2006 Prentice Hall, Inc.

6 56

28

9/20/2012

Flow Charts

Packing and shipping process

Packing

station

Sealing

Weighing

Labeling

Quick freeze

storage

(60 Mins)

Storage

(4 to 6 hrs)

Shipping

dock

2006 Prentice Hall, Inc.

6 57

Statistical Process Control

(SPC)

Uses statistics and control charts to

tell when to take corrective action

Drives process improvement

Four key steps

Measure the process

When a change is indicated, find the

assignable cause

Eliminate or incorporate the cause

Restart the revised process

2006 Prentice Hall, Inc.

6 58

29

9/20/2012

An SPC Chart

Plots the percent of free throws missed

20%

Upper control limit

10%

Coachs target value

0%

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

Lower control limit

Game number

Figure 6.7

2006 Prentice Hall, Inc.

6 59

Inspection

Involves examining items to see if

an item is good or defective

Detect a defective product

Does not correct deficiencies in

process or product

It is expensive

Issues

When to inspect

Where in process to inspect

2006 Prentice Hall, Inc.

6 60

30

9/20/2012

When and Where to Inspect

1. At the suppliers plant while the supplier

is producing

2. At your facility upon receipt of goods from

the supplier

3. Before costly or irreversible processes

4. During the stepstep-by

by--step production

processes

5. When production or service is complete

6. Before delivery from your facility

7. At the point of customer contact

2006 Prentice Hall, Inc.

6 61

Inspection

Many problems

Worker fatigue

Measurement error

Process variability

Cannot inspect quality into a

product

Robust design, empowered

employees, and sound processes

are better solutions

2006 Prentice Hall, Inc.

6 62

31

9/20/2012

Source Inspection

Also known as source control

The next step in the process is

your customer

Ensure perfect product to your

customer

Poka-yoke is the concept of foolproof devices

or techniques designed to pass only

acceptable product

2006 Prentice Hall, Inc.

6 63

Service Industry Inspection

Organization

What is

Inspected

Jones Law Office Receptionist

performance

Standard

Is phone answered by the

second ring

Billing

Accurate, timely, and

correct format

Attorney

Promptness in returning

calls

Table 6.4

2006 Prentice Hall, Inc.

6 64

32

9/20/2012

Service Industry Inspection

Organization

Hard Rock Hotel

What is

Inspected

Standard

Reception

desk

Use customers name

Doorman

Greet guest in less than 30

seconds

Room

All lights working, spotless

bathroom

Minibar

Restocked and charges

accurately posted to bill

Table 6.4

2006 Prentice Hall, Inc.

6 65

Service Industry Inspection

Organization

Arnold Palmer

Hospital

What is

Inspected

Standard

Billing

Accurate, timely, and

correct format

Pharmacy

Prescription accuracy,

inventory accuracy

Lab

Audit for lablab-test accuracy

Nurses

Charts immediately

updated

Admissions

Data entered correctly and

completely

Table 6.4

2006 Prentice Hall, Inc.

6 66

33

9/20/2012

Service Industry Inspection

Organization

Hard Rock Cafe

What is

Inspected

Standard

Busboy

Serves water and bread

within 1 minute

Busboy

Clears all entre items and

crumbs prior to dessert

Waiter

Knows and suggest

specials and desserts

Table 6.4

2006 Prentice Hall, Inc.

6 67

Service Industry Inspection

Organization

Nordstroms

Department

Store

What is

Inspected

Standard

Display areas Attractive, wellwell-organized,

stocked, good lighting

Stockrooms

Rotation of goods,

organized, clean

Salesclerks

Neat, courteous, very

knowledgeable

Table 6.4

2006 Prentice Hall, Inc.

6 68

34

9/20/2012

TQM In Services

Service quality is more difficult to

measure than the quality of goods

Service quality perceptions depend

on

Intangible differences between

products

Intangible expectations customers

have of those products

2006 Prentice Hall, Inc.

6 69

Service Quality

The Operations Manager must

recognize:

1. The tangible component of

services is important

2. The service process is important

3. The service is judged against the

customers expectations

4. Exceptions will occur

2006 Prentice Hall, Inc.

6 70

35

9/20/2012

Service

Specs

at UPS

2006 Prentice Hall, Inc.

6 71

Determinants of Service

Quality

Reliability

Credibility

Responsiveness

Security

Competence

Understanding/

knowing the

customer

Access

Courtesy

Communication

2006 Prentice Hall, Inc.

Tangibles

6 72

36

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Contributing To Business Success and ROI - Vincent LeungDocument25 paginiContributing To Business Success and ROI - Vincent LeungkennethllantosÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Part 5.1 The Changing Environment of Management PDFDocument19 paginiPart 5.1 The Changing Environment of Management PDFkennethllantosÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Contributing To Business Success and ROI - Vincent LeungDocument25 paginiContributing To Business Success and ROI - Vincent LeungkennethllantosÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Part 5.3 - Managements Social and Ethical Responsibilities PDFDocument24 paginiPart 5.3 - Managements Social and Ethical Responsibilities PDFkennethllantosÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Part 4 Leading Directing PDFDocument44 paginiPart 4 Leading Directing PDFAlex N. Mabalot100% (1)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Part 5 - Controlling PDFDocument22 paginiPart 5 - Controlling PDFkennethllantosÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Part 3 - Organizing and Staffing PDFDocument43 paginiPart 3 - Organizing and Staffing PDFkennethllantosÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Part 2 - Planning Decision MakingDocument51 paginiPart 2 - Planning Decision MakingkennethllantosÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- PedicabDocument9 paginiPedicabkennethllantosÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- 1 Intro To Engineering Management PDFDocument48 pagini1 Intro To Engineering Management PDFkennethllantosÎncă nu există evaluări

- Socialism," Because It Tried To Bring Forth A Government Involved in "Social" Interests Which WasDocument2 paginiSocialism," Because It Tried To Bring Forth A Government Involved in "Social" Interests Which WaskennethllantosÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Define Literature. Explain It.: Anecdote Is A Short and Amusing or Interesting Story About A Real Incident or PersonDocument2 paginiDefine Literature. Explain It.: Anecdote Is A Short and Amusing or Interesting Story About A Real Incident or PersonkennethllantosÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- IDENTIFYING A RESEARCH PROBLEM Summary'Document14 paginiIDENTIFYING A RESEARCH PROBLEM Summary'NammaÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Frequency of Calibration PDFDocument3 paginiFrequency of Calibration PDFApoloTrevinoÎncă nu există evaluări

- Human ErrorDocument167 paginiHuman ErrorRoy ShahzadÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Lamont, Michèle. 2012. Toward A Comparative Sociology of Valuation and Evaluation. Annual Review of Sociology 38, No. 1: 201-221.Document31 paginiLamont, Michèle. 2012. Toward A Comparative Sociology of Valuation and Evaluation. Annual Review of Sociology 38, No. 1: 201-221.Juan Cruz AndradaÎncă nu există evaluări

- BS en 12517-RT Acceptance of Welds PDFDocument11 paginiBS en 12517-RT Acceptance of Welds PDFlinhcdt3Încă nu există evaluări

- SSPC-QP 9 Application of Architectual Paints CoatingsDocument8 paginiSSPC-QP 9 Application of Architectual Paints CoatingsRinush SinagaÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- GEHRIMED 2015E Compliance Certificate-10082018Document1 paginăGEHRIMED 2015E Compliance Certificate-10082018Host MomÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Sap Senior Application Consultant Hitachi Zosen Inova AgDocument17 paginiSap Senior Application Consultant Hitachi Zosen Inova AgRamiro SanchezÎncă nu există evaluări

- Educational Taxonomies With Examples, Example Questions and Example Activities Cognitive, Psychomotor, and AffectiveDocument9 paginiEducational Taxonomies With Examples, Example Questions and Example Activities Cognitive, Psychomotor, and AffectiveJesús Eduardo Carbonó Niebles100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Group 2 Program EvaluationDocument26 paginiGroup 2 Program EvaluationKayse MorrisÎncă nu există evaluări

- PCPA Report-Large Roof Lamp With LEDDocument3 paginiPCPA Report-Large Roof Lamp With LEDawdhut kulkarniÎncă nu există evaluări

- Informational Training MethodsDocument6 paginiInformational Training MethodskmnowinskaÎncă nu există evaluări

- TCS EnQuode 2018 SyllabusDocument10 paginiTCS EnQuode 2018 SyllabusVivekÎncă nu există evaluări

- 5 - Corporate Governance, Unit - II, Lectures-10 - 15Document37 pagini5 - Corporate Governance, Unit - II, Lectures-10 - 15PRAKHAR GUPTAÎncă nu există evaluări

- Gender Checklist EducationDocument24 paginiGender Checklist EducationLorna Sibala ManilaÎncă nu există evaluări

- booksAT Poptropica EnglishTESTBOOKLE6.PDF 3Document68 paginibooksAT Poptropica EnglishTESTBOOKLE6.PDF 3Antonio Manuel Mora Lopez100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Evaluation of Regional Flood Frequency Analysis With A Region of in Uence ApproachDocument10 paginiEvaluation of Regional Flood Frequency Analysis With A Region of in Uence ApproachRupesh MishraÎncă nu există evaluări

- The College of Business Faculty Performance Evaluation SystemDocument21 paginiThe College of Business Faculty Performance Evaluation SystemTycon Joy DumayahonÎncă nu există evaluări

- Unit Plan For ClaymationDocument4 paginiUnit Plan For Claymationapi-377084958Încă nu există evaluări

- Chapter 7 EVALUATION OF ALTERNATIVES AND STRATEGIC CHOICEDocument44 paginiChapter 7 EVALUATION OF ALTERNATIVES AND STRATEGIC CHOICEAisha Khan100% (1)

- Executive Summary: Performance Management SystemDocument85 paginiExecutive Summary: Performance Management SystemJanhavi MahajanÎncă nu există evaluări

- Strategy 4 TH UnitDocument21 paginiStrategy 4 TH UnitElango VSÎncă nu există evaluări

- ..Pgcqae - Assignment 1-2023 - Precious M. Dithuri - Eoa 812.. 2023Document18 pagini..Pgcqae - Assignment 1-2023 - Precious M. Dithuri - Eoa 812.. 2023Precious DithuriÎncă nu există evaluări

- Conducting An ABC AnalysisDocument8 paginiConducting An ABC AnalysisMark K. Williams100% (2)

- Training Evaluation: 6 Edition Raymond A. NoeDocument42 paginiTraining Evaluation: 6 Edition Raymond A. NoeMhd ZainÎncă nu există evaluări

- Cultural CompetenceDocument15 paginiCultural CompetenceSobiii BooksÎncă nu există evaluări

- MMPI-3 Update Dec-2019Document2 paginiMMPI-3 Update Dec-2019esteban alvarezÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Health Promotion SettingsDocument51 paginiHealth Promotion SettingsjudemcÎncă nu există evaluări

- Head TeacherDocument7 paginiHead Teacheremilyaranas100% (2)

- Organizational Behavior: Instructor's Manual To AccompanyDocument25 paginiOrganizational Behavior: Instructor's Manual To AccompanyAgnes Lyn100% (4)